Page 1

INSTRUCTION MANUAL

HS-232

REVISION C

Hoffman Specialty

®

Series I

In-line Float and Thermostatic

Steam Traps

CAUTION

WARNING

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of steam systems in accordance with all applicable codes

and ordinances.

WARNING

!

®

• To prevent serious burns, wear heat resistant gloves when opening and closing steam

valves, or handling hot equipment.

• To prevent serious burns, the internal pressure of the trap must be 0 psi (0 bar) before

servicing.

• To prevent serious personal injury from steam pipe blow down, connect a temporary

pipe between the steam pipe opening and a drain, or stand at least 100 ft. (30m) from

the front of the pipe opening.

• To prevent property damage, personal injury, or death, cap off the gate valves if they

are not connected to a drain and when they are not in use for test or pressure relief.

Failure to follow this warning could cause property damage, personal injury or death.

IMPORTANT: To prevent system damage from water

hammer or sudden shock, open supply valves slowly.

If you are uncertain about the product’s adaptability for

your application, please call the factory or authorized

representative before using the product.

The trap seat rating (stamped on the nameplate) must

be equal to or greater than the maximum pressure differential across the trap.

Page 2

2

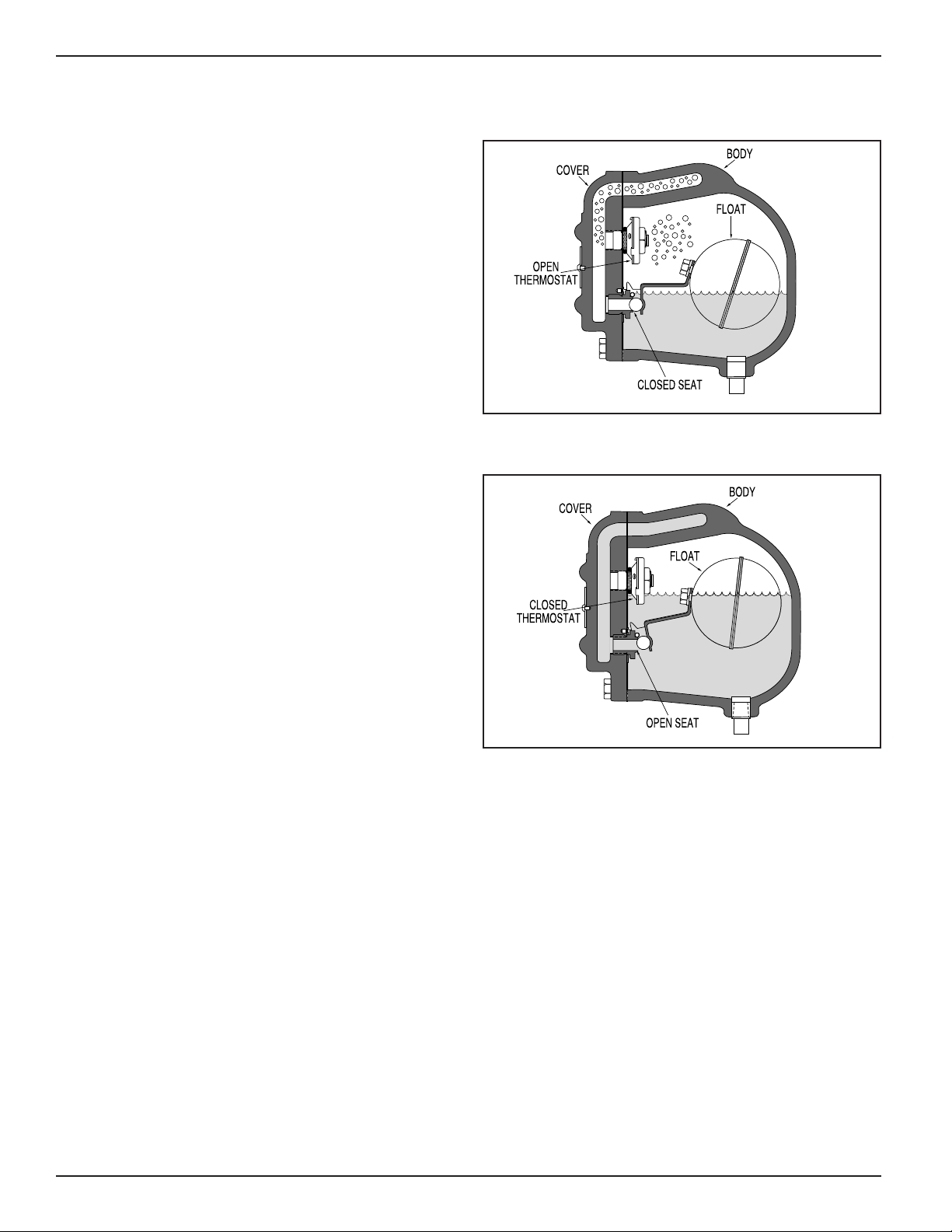

The balanced pressure thermostatic element is

open to vent air from the steam space into the

return line.

The balanced pressure thermostatic element

is closed to prevent the loss of steam into the

return line.

The float will modulate to provide continuous

drainage of condensate.

OPERATION

START-UP

NORMAL OPERATION

Page 3

3

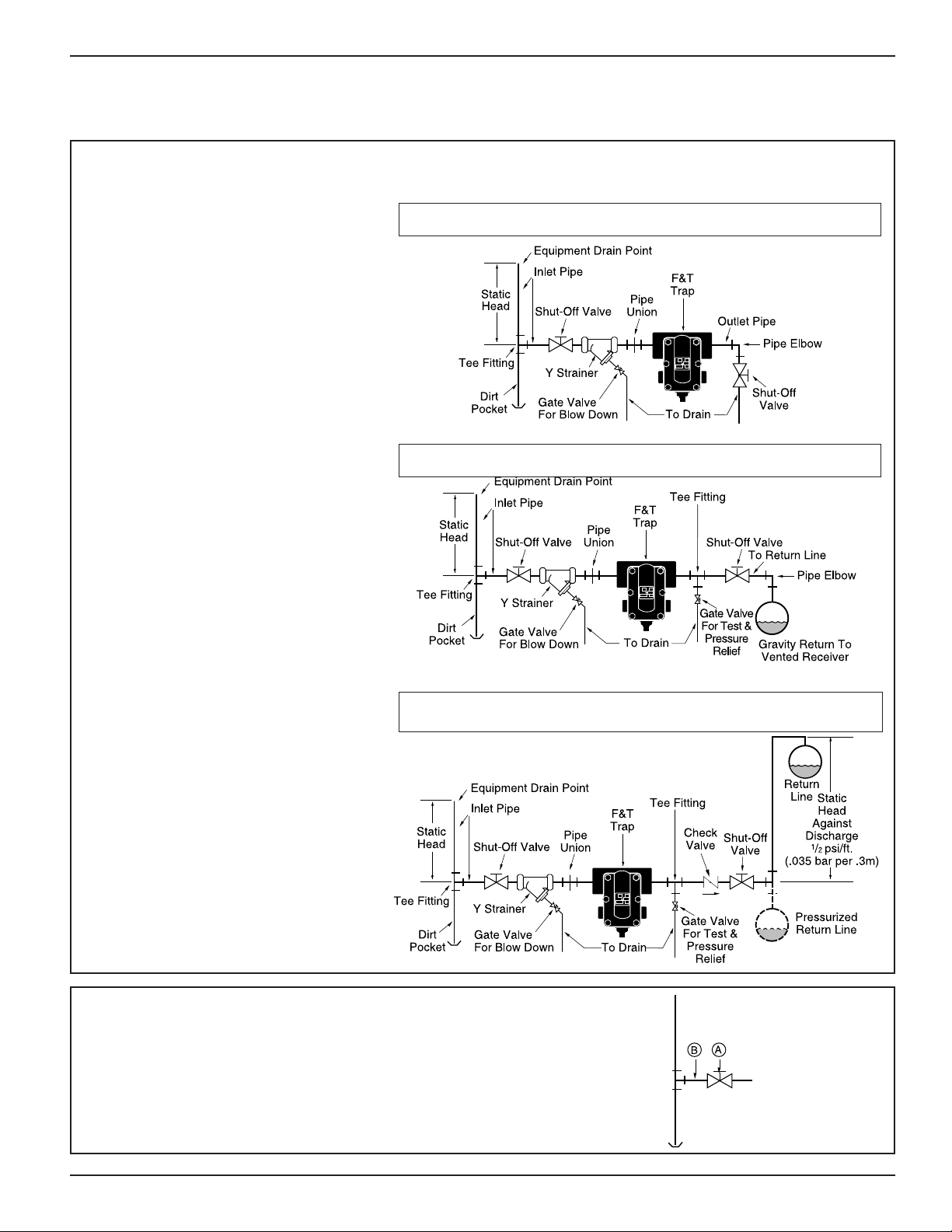

INSTALLATION –

Series I In-line Float and Thermostatic Steam Traps

TYPICAL PIPING DIAGRAMS

Trap Draining to Open Drain

Trap Draining to Gravity Return Line

Trap Draining to Overhead Return Line

or Pressurized Return Line

1. Determine where to install the trap,

based on the following requirements:

a. The trap must be located as close

as possible and below the equipment

to be drained.

b. The trap must be in a straight run

of horizontal pipe and pitched to

allow condensate to flow into the

trap inlet and away from the

trap outlet. Refer to the Typical

Piping Diagrams at the right.

c. Plenty of space around the trap is

needed for servicing, which may

include removal of the body or cover.

2. Install a shut-off valve (A) on the inlet pipe (B).

Page 4

3. Install a Y Strainer (C) on

the inlet pipe (B).

6. Close the gate valve (D). If it is not connected

to a drain, install a cap (E) on the outlet pipe (F).

Note: Remove the cap (E) when the gate valve

(D) is used for test or pressure relief. Recap when

the test or pressure relief is complete.

5a. Cap off the outlet pipe (X).

b. Slowly turn steam on with full pressure for

(5) five minutes to blowdown the inlet pipe (B).

c. Turn off steam and allow pipe to cool.

d. Remove cap from the outlet pipe (X).

To prevent serious personal injury

from steam pipe blow down, connect

a temporary pipe between the steam

pipe opening and a drain, or stand

at least 100 ft. (30m) from the front

of the pipe opening.

Failure to follow this warning

could cause property damage,

personal injury, or death.

!

WARNING

To prevent serious burns, the internal

pressure of the trap must be 0 psi (0

bar) before servicing.

Failure to follow this caution will cause

personal injury.

!

CAUTION

4. Install a gate valve for blow down (D) by con-

necting it to the Y Strainer drain tapping (C).

To prevent property damage, personal injury, or death, cap off the gate valve if it is

not connected to a drain and when it is not in use for test or pressure relief.

Failure to follow this warning could cause property damage, personal injury, or death.

!

WARNING

4

Page 5

5

7. Install a pipe union (G) on the inlet pipe (B).

G

B

8. Position the F&T trap so that the inlet pipe (B)

will connect with the “IN” tapping on the body (H),

and the “DOWN” arrow (J) is pointing down.

J

H

B

IN

9. Install the F&T trap (K) on the inlet pipe (B)

as positioned in Step 8.

K

B

10. Install a tee fitting (L) on the return line (M)

near the trap outlet (N).

N

L

M

Q

P

For Applications with a Return Line

11a. Install a gate valve (P) on the outlet pipe (Q)

for test or pressure relief.

b. Close the gate valve (P).

Page 6

12. If the gate valve (P) is not connected to a

drain, install a cap (R) on the outlet pipe (Q).

Note: Remove the cap (R) when the gate

valve (P) is used for test or pressure relief.

Recap when the test or pressure relief is

complete.

Q

P

R

13. Install a check valve (S) on the return line (M).

M

S

14. Install a shut-off valve (T) on the return line (M).

M

T

For Applications with a Gravity Return, Pressurized Return or

Return Line Above the Trap Discharge

For All Series Applications

To prevent property damage, personal injury, or death, cap off the gate valve if it is

not connected to a drain, and when it is not in use for test or pressure relief.

Failure to follow this warning could cause property damage, personal injury, or death.

!

WARNING

6

Page 7

7

15. Depending on your application, complete one

of the following steps:

a. Connect the return line (M) to a drain (U)

OR

b. Add a gravity return line (V)

OR

c. Add a pressurized return (W) or a return line

above the trap discharge (X).

M

U

V

X

W

INSTALLATION COMPLETE

MAINTENANCE

When checked regularly and properly maintained, the

Series I Float and Thermostatic Traps will provide optimum performance and long life.

SCHEDULE:

• Initially, every 2-3 days after start-up until

system is clean.

• Every 6 months thereafter.

PROCEDURE:

• To prevent serious burns, the internal pressure of the trap must be 0 psi (0 bar)

before servicing.

• To prevent serious personal injury from steam pipe blow down, connect a temporary

pipe between the steam pipe opening and a drain, or stand at least 100 ft. (30m) from

the front of the pipe opening.

Failure to follow this caution will cause personal injury.

!

CAUTION

1.Inspect joints for leaks. Stop all leaks by tightening

bolts and replacing gaskets, if necessary.

2.Clean strainers by opening the blow down valve and

allowing full steam pressure to flow out for (2) two

minutes. Then, close the valve.

3.Test traps by following the “Troubleshooting”

procedure.

Page 8

TROUBLESHOOTING

We recommend trap replacement when parts no

longer operate properly. A new trap or a complete

cover assembly is more economical than repairing or

replacing individual parts, and it will provide greater

Problem:

1. Improper Heating

a. Cause: The float assembly is not opening or

functioning properly. This could be

caused by a leak in the float.

Test: Use a thermometer to test inlet tem-

perature. A cold trap is an indication

the trap failed closed.

Solution: Disassemble the trap. Shake the float,

listening for water, and inspect for leaks.

Replace any worn or defective parts.

b. Cause: The steam pressure is higher than

the trap’s seat rating pressure which

prevents the trap from opening.

Test: Check the seat pressure rating on the

In-line F&T trap nameplate with the

available steam pressure to the

equipment being drained.

Solution: Install a new Hoffman Specialty Bear

®

Tra p

with the proper pressure range.

Note: The trap must be selected for

the maximum differential pressure that

will be encountered. A high pressure

seat may be used at lower differential

pressures, but the capacity rating will

be less than an identical size trap with

a low pressure rated seat.

reliability. If you choose to repair the trap, order

Hoffman Specialty replacement parts and follow the

Repair Procedure provided.

Problem:

2. Energy Wasted

a. Cause: A worn pin and seat, or dirt deposited

on the seat prevents tight closure.

Test: Using a stethoscope, listen for a low

pitch whistle sound. A low pitch whistle sound indicates the trap is open

and blowing live steam.

Solution: Disassemble the trap and inspect for

dirt or worn parts. Clean if dirty, or

replace if worn.

b. Cause: The thermostatic element failed open

and is blowing live steam.

Test: Using a stethoscope, listen for a low

pitch whistle sound. A low pitch whistle sound indicates the trap is open

and blowing live steam.

Solution: Disassemble the trap and replace the

thermostatic element

c. Cause: Full capacity drainage is prevented

by worn linkage.

Test: Disassemble the trap and inspect for

worn parts.

Solution: Install a new Hoffman Specialty In-

line F&T Bear Trap

®

.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. HS-232C October 2012 Part No. 510987

Loading...

Loading...