Page 1

• Application

• Selection

• Installation

• Piping Diagrams

Hoffman Specialty®

Steam Traps

ENGINEERING DATA MANUAL

HS-203C

Page 2

Contents

3

Introduction

Steam Trap Functional Requirements 4

Operation, Advantages, Disadvantages

and Primary Applications 5

Chapter 1

Selection Guide Chart 10

4-Step Method for Sizing 11

Helpful Hints, Formulas and Conversion Factors 12

Properties of Saturated Steam 13

Steam Flow in Pipes 15

Condensation in Pipes 15

Chapter 2

Flash Steam Explanation and Calculation 16

Operating Pressure Limits 17

Installation and Calculating Differential Pressure 18

Drip Traps for Distribution Pipes 20

Chapter 3

Selecting Traps for Heat Exchangers 24

Lock-out Traps for Start-up Loads 27

Draining Condensate to Overhead Returns 28

Draining Submerged Coils 29

Jacketed Kettles 30

Cylinder Dryers 31

Unit Heaters 31

Steam Radiators 32

Typical Piping for Steam Heating 33

Trapping Steam Tracer Lines 39

Chapter 4

4-Step Method for Sizing Steam Lines 40

4-Step Method for Sizing Return Lines 42

Chapter 5

Testing Steam Traps 43

Chapter 6

Definition of Heating Terms 46

Page 3

Steam Trap

Functional

Requirements

Selecting the

proper type of

steam trap is an

important element

in steam systems.

There are many types of steam traps each

having its unique characteristics and system

benefits. Hoffman Specialty offers thermostatic, thermodisc, float and thermostatic, and

bucket traps which are the most commonly

used types. Deciding which type of trap to use

is sometimes confusing and, in many cases,

more than one type can be used. The following is intended to point out system conditions

that may be encountered and the characteristics of each type of trap.

Within steam systems, important considerations must be taken into account. These considerations include venting of air during

start-up; variations of system pressures and

condensing loads; operating pressure and

system load; continuous or intermittent operation of system; usage of dry or wet return

lines; and overall probability of water hammer.

Air Venting

At start-up all steam piping, coils, drums, tracer

lines, or steam spaces contain air. This air

must be vented before steam can enter.

Usually the steam trap must be capable of

venting the air during this start-up period. A

steam heating system will cycle many times

during a day. Fast venting of air is necessary

to obtain fast distribution of steam for good

heat balance. A steam line used in process

may only be shut down once a year for repair

and venting of air may not be a major concern.

Modulating Loads

When a modulating steam regulator is used,

such as on a heat exchanger, to maintain a

constant temperature over a wide range of

flow rates and varying inlet temperatures, the

condensate load and differential pressure

across the trap will change. When the condensate load varies, the steam trap must be

capable of handling a wide range of conditions at constantly changing differential pressures across the trap.

Differential Pressure Across Trap

When a trap drains into a dry gravity return

line, the pressure at the trap discharge is normally at O psig. When a trap drains into a wet

return line or if the trap must lift condensate

to an overhead return line, there will normally

be a positive pressure at the trap discharge.

To assure condensate drainage, there must

be a positive differential pressure across the

trap under all load conditions.

Water Hammer

When a trap drains high temperature condensate into a wet return, flashing may occur.

When the high temperature condensate at

saturation temperature discharges into a

lower pressure area, this flashing causes

steam pockets to occur in the piping, and

when the latent heat in the steam pocket is

released, the pocket implodes causing water

hammer. Floats and bellows can be damaged

by water hammer conditions.

When traps drain into wet return lines, a

check valve should be installed after the trap

to prevent backflow. The check valve also

reduces shock forces transmitted to the trap

due to water hammer. Where possible, wet

returns should be avoided.

Application

The design of the equipment being drained is

an important element in the selection of the

trap. Some equipment will permit the condensate to back up. When this occurs the steam

and condensate will mix and create water

hammer ahead of the trap. A shell and tube

heat exchanger has tube supports in the

shell. If condensate backs up in the heat

exchanger shell, steam flowing around the

tube supports mixes into the condensate and

causes steam pockets to occur in the condensate. When these steam pockets give up their

latent heat, they implode and water hammer

occurs, the water hammer often damages the

heat exchanger tube bundle. The trap selection for these types of conditions must completely drain condensate at saturation

temperature under all load conditions.

Steam mains should be trapped to remove all

condensate at saturation temperature. When

condensate backs up in a steam main, steam

flow through the condensate can cause water

hammer. This is most likely to occur at expansion loops and near elbows in the steam

main.

Applications such as tracer lines or vertical

unit heaters do not mix steam and condensate. In a tracer line, as the steam condenses, it flows to the end of the tracer line. Back

up of condensate ahead of the trap does not

cause water hammer. Steam does not pass

through condensate.

Vertical unit heaters normally have a steam

manifold across the top. As the steam condenses in the vertical tubes, it drains into a

bottom condensate manifold. Because steam

does not pass through the condensate, water

hammer should not occur.

4

Introduction

Page 4

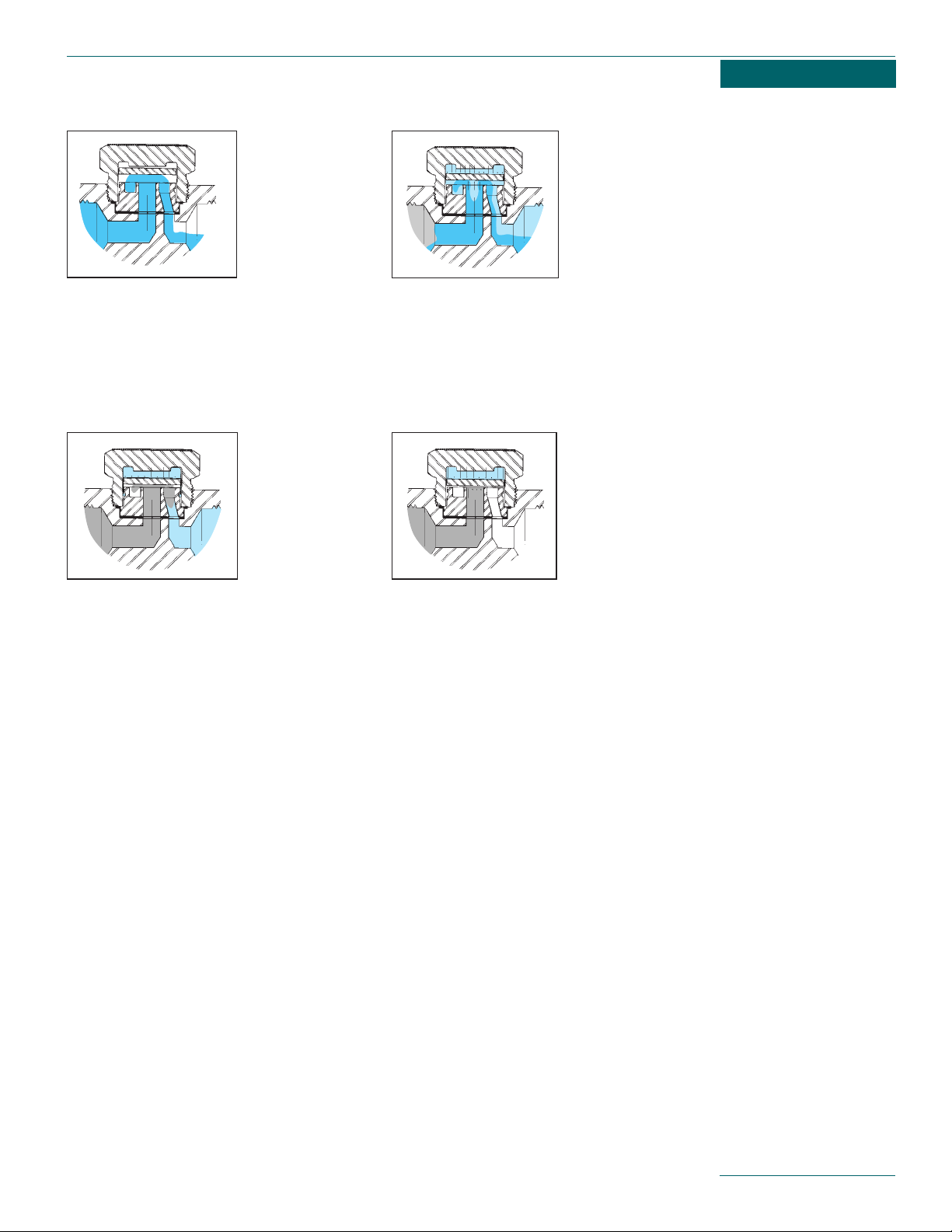

FLOAT & THERMOSTATIC TRAP

The condensate port is normally closed during

no load. As condensate enters the float chamber, the seat opens to provide drainage equal

to the condensing rate.

Primary Applications

Heating main drip traps.

Shell & tube heat exchangers.

Tank heaters with modulating temperature

regulators.

Unit heaters requiring fast venting.

Steam humidifiers.

Air blast heating coils.

Air pre-heat coils.

Modulating loads.

Fast heating start-up applications.

TRAP OPERATION

A review of the trap operating principle will

show how various types of traps meet the different system characteristics.

Float & Thermostatic Traps

Advantages

Completely drains condensate at saturation temperature.

Modulates to handle light or heavy loads,

continuous discharge equal to condensing

load.

Large ports handle high capacities.

Separate thermostatic vent allows fast

venting of air during start-up.

Modulating ports provide long life.

Cast iron bodies.

Disadvantages

Float or bellows may be damaged by water

hammer.

Primary failure mode is closed.

Does not withstand freezing temperatures.

Pressure limit of 175 psig.

FLOAT & THERMOSTATIC TRAP

During start-up the thermostatic vent is open

to allow free passage of air.

The thermostatic vent will close at near saturation temperature. The balanced design will

allow venting of noncondensables that collect

in the float chamber, when operating at

design pressure.

Operation,

Advantages,

Disadvantages,

and Primary

Applications

5

Page 5

Bucket Traps

Advantages

Completely drains condensate at saturation

temperature.

Open bucket will tolerate moderate

water hammer.

Available in pressures up to 250 psig.

Normal failure mode is open.

Cast iron bodies.

Disadvantages

Marginal air handling during start-up.

Cycles fully open or closed.

May lose prime during light loads and blow

live steam.

Requires manual priming to provide

water seal.

Does not withstand freezing temperatures.

Primary Applications

Process main drip traps.

Where condensate is lifted or drains into wet

return line.

Drum type roller dryers.

Steam separators.

Siphon type or tilting kettles.

6

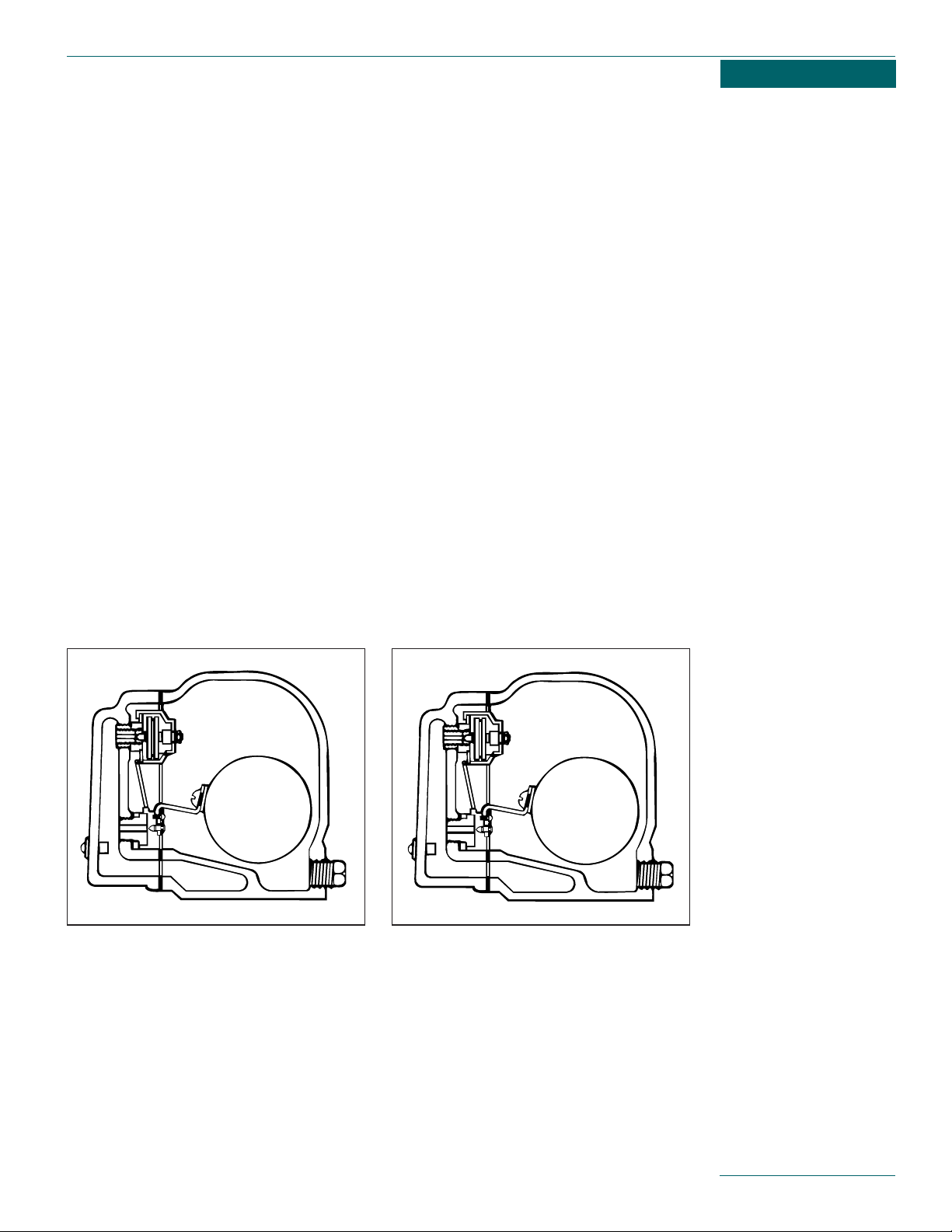

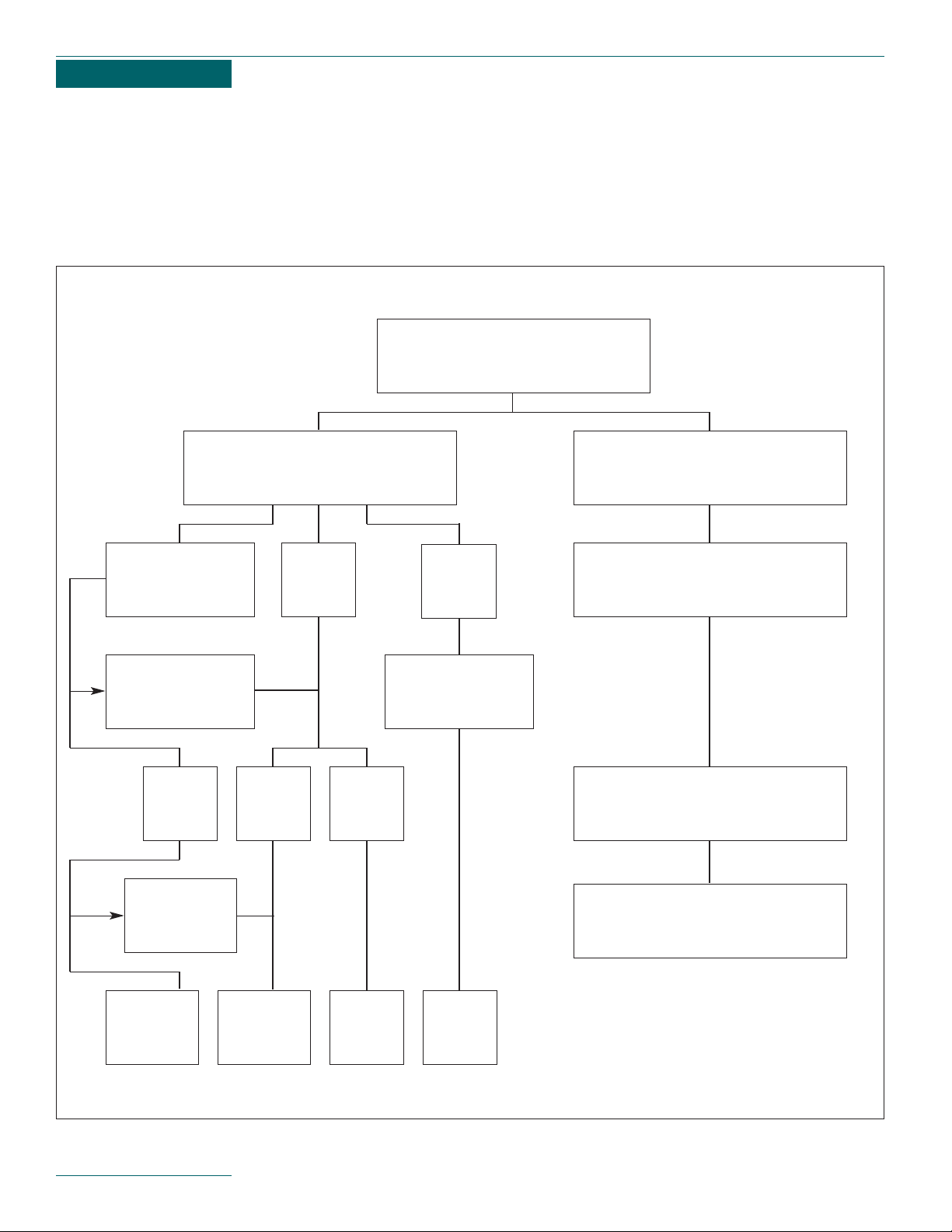

BUCKET TRAP

The trap body must be manually primed at initial start-up. Under operation the body will

remain full of condensate.

During start-up, air is vented through the

bleed hole in the top of the bucket into the

return line.

Condensate entering the trap will flow around

the bucket and drain through the open seat.

BUCKET TRAP

As steam flows into the trap it collects in the

top of the bucket. The buoyancy of the steam

raises the bucket and closes the seat.

BUCKET TRAP WITH OPTIONAL

THERMAL VENT.

An optional thermal vent installed in the bucket allows faster air venting during start-up.

COVER

A

V

INLET

BUCKET

STEAM BUBBLES

THROUGH WATER

OUTLET

BODY

COVER

A

V

INLET

BUCKET

OUTLET

BODY

COVER

A

V

INLET

BUCKET

STEAM BUBBLES

THROUGH WATER

OUTLET

BODY

Page 6

Applications

Radiators, convectors, unit heaters.

Cooking kettles.

Sterilizers.

Heating coils.

Tracer lines.

Evaporators.

NOTE: A solid fill expansion element (see

Hoffman Specialty 17K) thermostatic trap

should be used where water hammer (cavitation) may occur.

Thermostatic Bellows Type Trap

Advantages

Sub-cools condensate usually 10° to 30°F.

Normally open at start-up to provide fast

air venting.

Follows steam saturation curve to operate

over wide range of conditions.

Brass bodies.

Self draining.

Energy efficient.

Compact size and inexpensive.

Fast response to changing conditions.

Fail open models.

Disadvantages

Water hammer can damage bellows.

Superheat can damage bellows if it

exceeds trap temperature rating.

Pressure limit of 125 psig.

Cooling leg required in some applications.

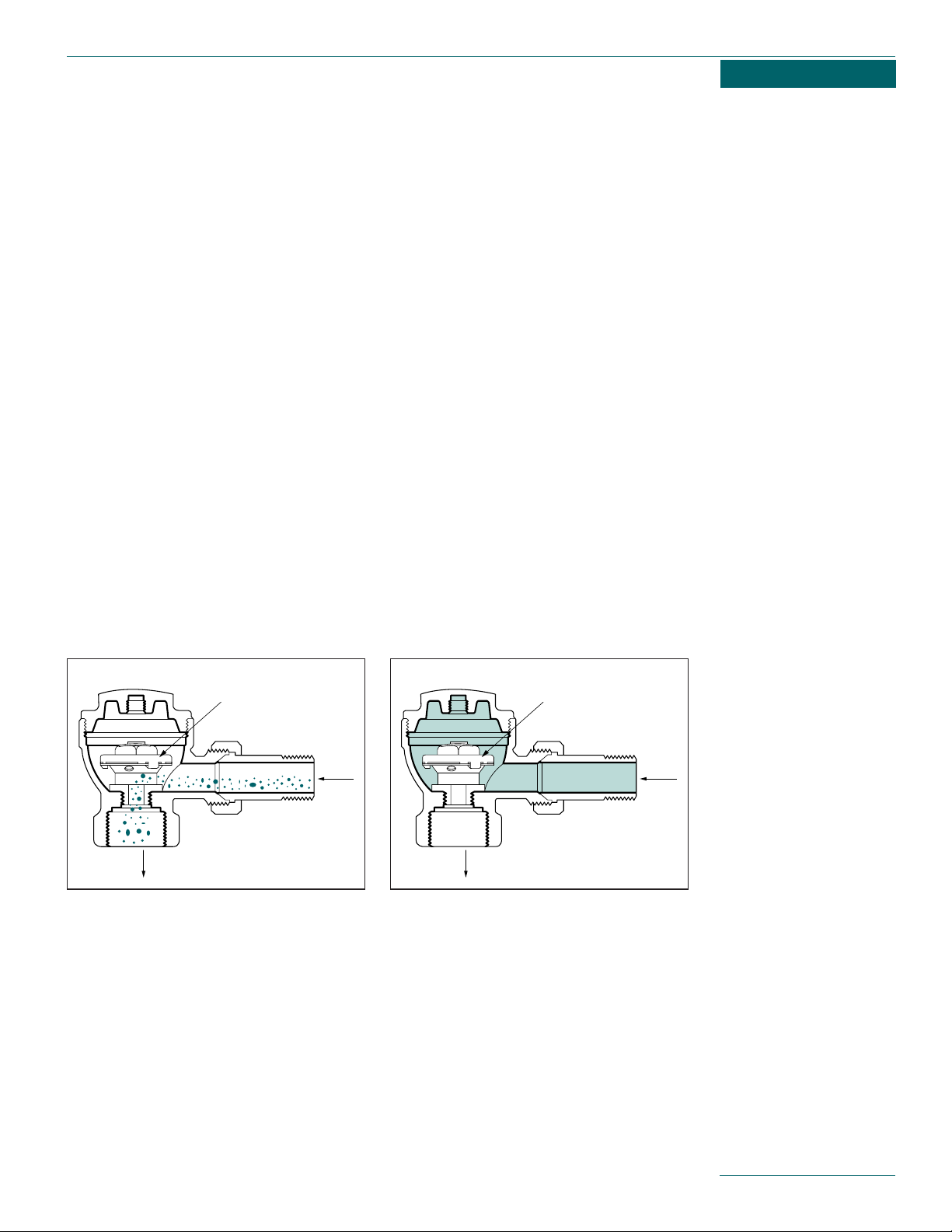

THERMOSTATIC TRAP

Thermostatic traps are normally open. This

allows fast venting of air during start-up.

THERMOSTATIC TRAP

Cold condensate during start-up drains

through the trap. As temperatures reach 10°

to 30° F of saturation, the trap closes.

During operation, thermostatic traps find an

equilibrium point to drain condensate approximately 10° to 30°F below saturation at a continuous flow.

7

INLET

OUTLET

INTERNAL

FLEXIBLE DIAPHRAGM

INLET

OUTLET

INTERNAL

FLEXIBLE DIAPHRAGM

Page 7

Disc Traps

Advantages

Completely drains condensate at saturation temperature.

May be installed vertically, to drain trap

body when steam is off, to prevent freezing.

Compact size.

Easily serviced in line, replaceable seat

and disc (some models).

All stainless steel.

Will tolerate water hammer and superheat.

Disadvantages

Noise.

Sensitive to dirt, prevents tight closing

of disc.

Available in sizes up to 1” only.

Applications

Steam tracer lines where maximum temperature is required.

Outdoor applications including drips on

steam mains.

Drying tables.

Tire mold press and vulcanizing equipment

Dry kilns.

Pressing machines.

Rugged applications (superheat & water

hammer).

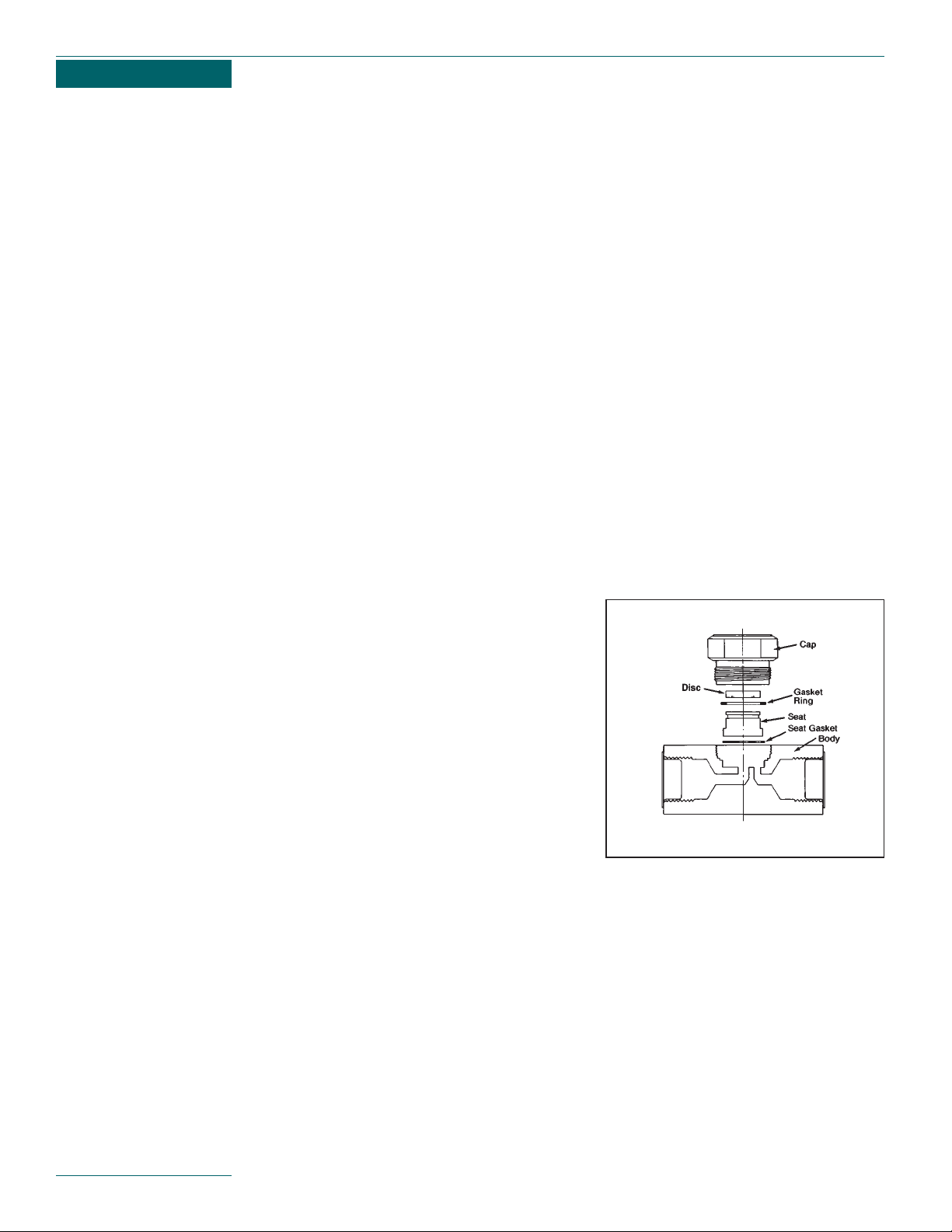

Description

Thermodisc steam traps provide dependable

performance for applications with light to

moderate condensate loads. Thermodisc

traps are excellent for high pressure drip

and steam tracing applications.

Because the disc is the only moving part,

the traps are rugged and resistant to damage. However, if the seat and disc require

servicing they may be easily replaced without removing the trap body from the piping.

8

Page 8

Orifice Traps

Advantages

No moving parts to wear.

Disadvantages

Does not close against steam.

Small hole easily plugs due to dirt.

Backs up condensate on heavy loads and

during start-up.

Does not respond to modulating loads.

Does not vent air when handling conden-

sate—causes slow system start-up and

may cause water hammer.

Not easily recognized as trap during

energy survey.

Built-in small screen plugs easily.

Discharges condensate at saturation

temperature with some live steam, often

causes excessive condensate temperatures and cavitation at condensate pumps.

Waste energy.

Sizing critical.

Applications

Should be limited to constant load

continuous operation.

Start-Up

The disc is pushed off the seat by the inlet

pressure and is held open by the impact force

of the condensate hitting the disc.

Operating

As the condensate nears saturation temperature, greater amounts of flash steam will

appear. Some of the flash steam escapes to

the area above the disc, causing the pressure

above the disc to increase, pushing the disc

closer to the seat.

Closing

When all the condensate is discharged, flash

steam enters the seat-disc chamber at high

velocity. This high velocity causes a sudden

pressure drop at the lower side of the disc

and it snaps closed against the seat.

Closed

At the instant the disc snaps closed on the

seat, the pressure above the disc is approximately equal to the upstream line pressure.

The disc is held closed because the pressurized area above the disc is much larger than

the inlet area. The pressure above the disc

decreases either by steam condensation or by

non-condensables being removed via the

micro-bleed on the disc. When the pressure is

low enough, the disc is pushed off the seat

and the process is repeated.

9

Disc Trap Operation

Page 9

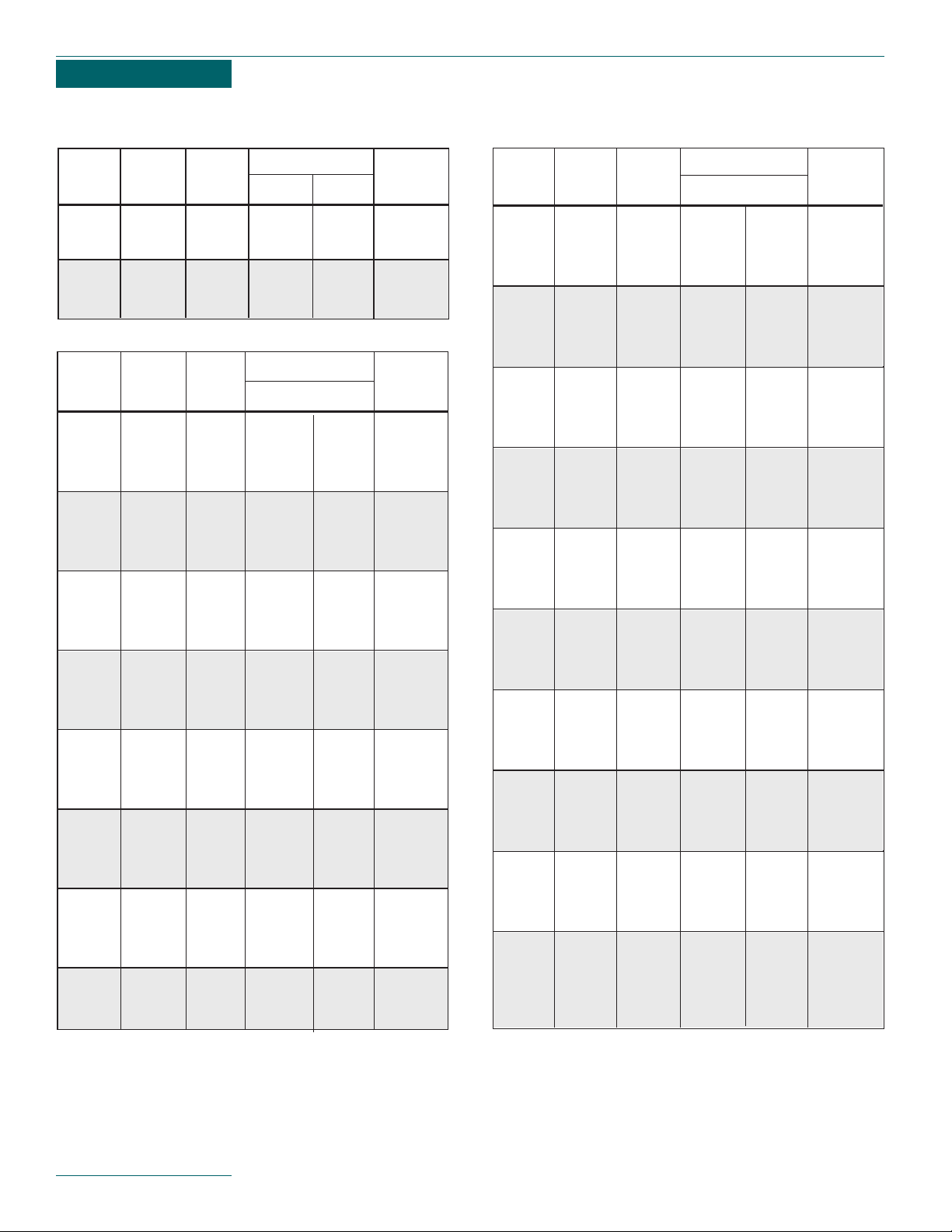

Selection

Guide Chart

The proper type of steam trap selected is an

important consideration in steam systems.

There are many types of steam traps. Each

has unique characteristics and system benefits. Hoffman Specialty offers thermostatic,

float and thermostatic, bucket

and disc traps. This line chart points out system conditions that may be encountered and

suggests a trap that may best handle the

requirement. Several types of traps may be

used for a specific application. The line chart

should be used only as a guide.

10

Chapter 1

Condensate must be completely

removed at saturation condition

to prevent water hammer

Type of Steam Trap Required

Based on System Conditions

Modulating load,

wide range of

condensate load

Water hammer

due to

wet returns or lifts

Float and

thermostatic

Bucket trap

with thermal

vent

Bucket

trap

Disc

trap

Constant

load

Outdoor

location

Super heat or

water hammer

Fast air

venting

required

Air vent

rate not

important

Fast air

venting

required

Condensate may be sub-cooled

ahead of trap to improve

operating efficiency of system

Varying pressure and load where fast

response is required

Pressure

up to 125 psig

Thermostatic bellows type trap

Pressure

over 175 psig

Page 10

Step 1:

Collect All Required Information.

A. Determine maximum condensate load in

Lbs./Hr. (Pounds per Hour). See “Helpful

Hints—Approximating Condensate Loads”

on page 12.

B. Inlet pressure at steam trap. It could be

different than supply pressure at boiler.

Heat exchanger applications with modulating control valves are good examples.

C. Back-pressure at steam trap. Pressure

against outlet can be due to static pressure in return line or due to lifting to

overhead return.

D. Determine Pressure Differential.

Inlet pressure (B) - Back-pressure (C)

= Differential Pressure.

Step 2:

Select Proper Type ot Trap.

A. Other Things to Consider.

1. Condensate Flow—Fluctuate?

1. Continuous?

2. Large Amount of Air?

3. Pressure—Constant? Fluctuate?

B. Application.

1. Main.

2. Drip Leg.

3. Process Heat Exchanger.

4. Other.

C. Critical Process.

1. Fail Cold.

2. Fail Hot.

Step 3:

Apply Safety Factor.

A. SFA Recommended.

1. Float & Thermostatic Trap 1.5 to 2.5.

2. Bucket Trap 2 to 4.

3. Thermostatic 2 to 4.

4. Disc Traps 1 to 1.2.

See specific applications.

B. The SFA Will Depend On Degree of

Accuracy at Step 1.

1. Estimated Flow.

2. Estimated Pressure—Inlet.

3. Estimated Pressure—Back.

Step 4:

Select Correct Trap Size.

A. Use manufacturer’s capacity table to size

trap. Capacity tables should be based on

hot condensate (some specified temperature below saturation) rather than cold

water rating. Hoffman Specialty published

actual test data, unless stated, is 10°F.

below saturation.

B. The trap seat rating must always be

higher than the maximum inlet pressure

specified.

C. When inlet to equipment is controlled by a

modulating control valve, the trap size

should be selected with a pressure rating

greater than the maximum inlet pressure

at the trap. The capacity should be

checked at the minimum differential pressure to assure complete condensate

removal under all possible conditions.

4 Step Method

for Sizing

11

Page 11

3. Steam heats a solid or slurry indirectly

through a metallic wall.

—Clothing press, cylinder driers, platen

—press.

Lbs./hr. condensate =

970 x (W

1-W2) + W1 x (T2-T1)

L x T

When:

W

1

= Initial weight of product

W

2

= Final weight of product

T

1

= Initial temp.

T

2

= Final temp.

L = Latent heat in Btu/lb.

T = Time required for drying (hours).

Note: 970 is the latent heat of vaporization

at atmospheric pressure. It is included

because the drying process requires that

all moisture in the product be evaporated.

4. Steam heats a solid through direct

contact.

—Sterilizer, autoclave

Lbs./hr. condensate =

W = Weight of material being

heated in Ibs.

S

h

= Specific heat of material

being heated.

T

1

= Initial temp.

T

2

= Final temp.

L = Latent heat Btu/lb.

T = Time to reach final temp. (hours)

Conversion Factors

One Boiler Horsepower = 140 sq. ft. EDR or

33,475 Btu/hr. or 34.5 Ibs./hr. steam at 212° F.

1,000 sq. ft. EDR yields .5 gpm condensate.

To convert sq. ft. EDR to Ibs. of condensate—

divide sq. ft. by 4.

.25 Ibs./hr. condensate = 1 sq. ft. EDR.

One sq. ft. EDR (Steam) = 240 Btu/hr. with

215°F. steam filling radiator and 70°F. air

surrounding radiator.

To convert Btu/hr. to Ibs./hr.—

divide Btu/hr. by 960.

One psi = 2.307 feet water column (cold).

One psi = 2.41 feet water column (hot).

One psi = 2.036 inches mercury.

One inch mercury = 13.6 inches water column.

Size condensate receivers for 1 min. net

storage capacity based on return rate.

Size condensate pumps at 2 to 3 times

condensate return rate.

W x S

h x (T2-T1)

L x T

Helpful Hints,

Formulas and

Conversion

Factors

Helpful Hints

Approximating Condensate Loads

Heating Water with Steam

lbs./hr. Condensate =

GPM

x Temperature Rise °F.

Heating Fuel Oil with Steam

lbs./hr. Condensate =

GPM

x Temperature Rise °F.

Heating Air with Steam Coils

lbs./hr. Condensate =

CFM

x Temperature Rise °F.

SHEMA Ratings

Thermostatic traps and F & T traps for low

pressures may be rated in accordance with

the Steam Heating Equipment Manufacturers

Association (SHEMA). SHEMA ratings have a

built-in safety factor.

Formulas

1. Steam heats a liquid indirectly through

a metallic wall.

—Cooking coils, storage tanks, jacketed

—kettles, stills.

Lbs./hr. condensate =

Q

l x 500 x Sg x Sh x (T2-T1)

L

When:

Q

l

= Quantity of liquid being

heated in gal/min

S

g

= Specific gravity

S

h

= Specific heat

L = Latent heat in Btu/lb

500 = Constant for converting

gallons per minute to

pounds per hour.

T

2

= Final temperature

T

1

= Initial temperature

2. Steam heats air or a gas indirectly

through a metallic wall.

—Plain or finned heating coils,

—unit space heaters.

Lbs./hr. condensate =

Q

g x D x Sh x (T2-T1) x 60

L

When:

Q

g

= Quantity of air or gas in ft3/min.

D = Density in Ib/ft

3

Sh= Specific heat of gas being heated.

T

1

= Initial temp.

T

2

= Final temp.

L = Latent heat in Btu/lb

60 = Minutes in hour

12

2

4

900

Page 12

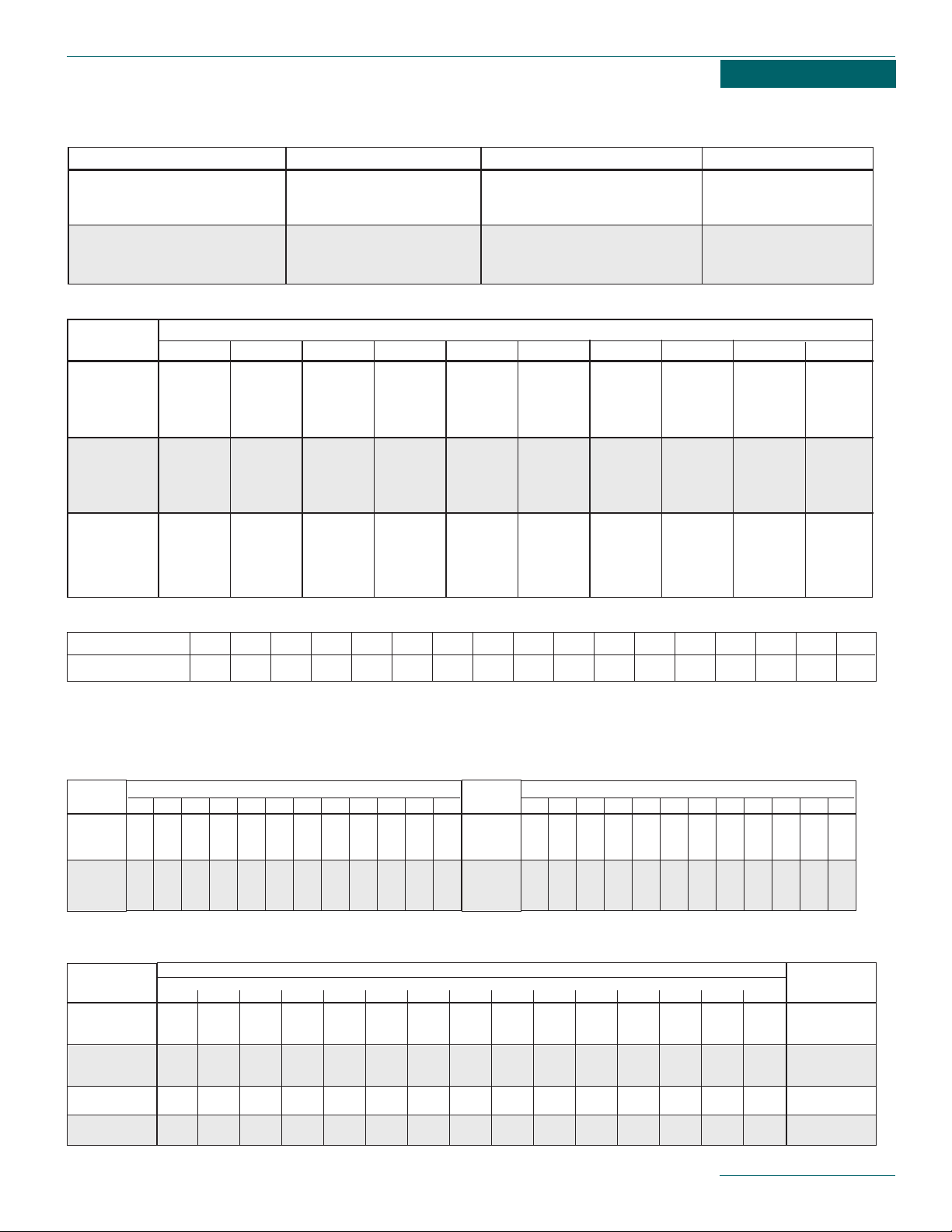

The Properties of Saturated Steam table

provides the relationship of temperature and

pressure. The table also provides Btu heat

values of steam and condensate at various

pressures and shows the specific volume of

steam at various pressures.

Saturated Steam:

Pure steam at the temperature corresponding

to the boiling point of water.

Pressure psig:

Gauge pressure expressed as Ibs./sq. in. The

pressure above that of atmosphere. It is pressure indicated on an ordinary pressure gauge.

Sensible Heat:

Heat which only increases the temperature of

objects as opposed to latent heat. In the saturation tables it is the Btu remaining in the

condensate at saturation temperature.

Latent Heat:

The amount of heat expressed in Btu required

to change 1 Ib. of water at saturation temperature into 1 Ib. of steam. This same amount

of heat must be given off to condense 1 Ib. of

steam back into 1 Ib. of water. The heat value

is different for every pressure temperature

combination shown.

Total Heat:

The sum of the sensible heat in the condensate and the latent heat. It is the total heat

above water at 32° F.

Specific Volume Cu. Ft. Per Lb.:

The volume of 1 Ib. of steam at the corresponding pressure.

See Properties of Saturated Steam table on

the following page.

Properties of

Saturated

Steam

13

Page 13

14

Properties of Saturated Steam

Specfic

Heat Content

Latent

Vacuum Saturated Volume

Btu per Ib.

Heat of

Inches of Temp Cu. ft. Saturated Saturated Vaporization

Mercury °F. per Ib. Liquid Vapor Btu per Ib.

29 79 657.0 47 1094 1047

27 115 231.9 83 1110 1027

25 134 143.0 102 1118 1017

20 161 74.8 129 1130 1001

15 179 51.2 147 1137 990

10 192 39.1 160 1142 982

5 203 31.8 171 1147 976

1 210 27.7 178 1150 971

BELOW ATMOSPHERIC PRESSURE

ABOVE ATMOSPHERIC PRESSURE (Cont.)

ABOVE ATMOSPHERIC PRESSURE

Specfic

Heat Content

Latent

Pressure Saturated Volume

Btu per Ib.

Heat of

PSI Temp Cu. ft. Saturated Saturated Vaporization

(Gauge) °F. per Ib. Liquid Vapor Btu per Ib.

0 212 26.8 180 1150 970

1 215 24.3 183 1151 967

2 218 23.0 186 1153 965

3 222 21.8 190 1154 963

4 224 20.7 193 1155 961

5 227 19.8 195 1156 959

6 230 18.9 198 1157 958

7 232 18.1 200 1158 956

8 235 17.4 203 1158 955

9 237 16.7 205 1159 953

10 239 16.1 208 1160 952

11 242 15.6 210 1161 950

12 244 15.0 212 1161 949

13 246 14.5 214 1162 947

14 248 14.0 216 1163 946

15 250 13.6 218 1164 945

16 252 13.2 220 1164 943

17 254 12.8 222 1165 942

18 255 12.5 224 1165 941

19 257 12.1 226 1166 940

20 259 11.1 227 1166 939

25 267 10.4 236 1169 933

30 274 9.4 243 1171 926

35 281 8.5 250 1173 923

40 287 7.74 256 1175 919

45 292 7.14 262 1177 914

50 298 6.62 267 1178 911

55 302 6.17 272 1179 907

60 307 5.79 277 1181 903

65 312 5.45 282 1182 900

70 316 5.14 286 1183 897

75 320 4.87 290 1184 893

80 324 4.64 294 1185 890

85 327 4.42 298 1186 888

90 331 4.24 301 1189 887

95 334 4.03 305 1190 884

100 338 3.88 308 1190 882

105 341 3.72 312 1189 877

110 343 3.62 314 1191 877

115 347 3.44 318 1191 872

120 350 3.34 321 1193 872

125 353 3.21 324 1193 867

130 355 3.12 327 1194 867

135 358 3.02 329 1194 864

140 361 2.92 332 1195 862

145 363 2.84 335 1196 860

Specfic

Heat Content

Latent

Pressure Saturated Volume

Btu per Ib.

Heat of

PSI Temp Cu. ft. Saturated Saturated Vaporization

(Gauge) °F. per Ib. Liquid Vapor Btu per Ib.

150 366 2.75 337 1196 858

155 368 2.67 340 1196 854

160 370 2.60 342 1196 854

165 373 2.53 345 1197 852

170 375 2.47 347 1197 850

175 378 2.40 350 1198 848

180 380 2.34 352 1198 846

185 382 2.29 355 1199 844

190 384 2.23 357 1199 842

195 386 2.18 359 1199 840

200 388 2.14 361 1199 838

210 392 2.05 365 1200 835

220 396 1.96 369 1200 831

230 399 1.88 373 1201 828

240 403 1.81 377 1201 824

250 406 1.75 380 1201 821

260 410 1.68 384 1201 817

270 413 1.63 387 1202 814

280 416 1.57 391 1202 811

290 419 1.52 394 1202 807

300 421 1.47 397 1202 805

325 429 1.37 405 1202 797

350 436 1.27 412 1202 790

375 442 1.19 419 1202 782

400 448 1.09 426 1202 774

425 454 1.06 432 1202 770

450 459 .972 438 1202 761

475 465 .948 444 1202 757

500 469 .873 449 1201 748

525 475 .850 455 1201 746

550 480 .820 461 1200 740

575 485 .784 466 1200 734

600 490 .733 472 1199 727

625 493 .721 476 1198 723

650 498 .692 481 1197 718

675 502 .645 485 1197 712

700 505 .642 490 1195 703

750 513 .598 498 1195 697

800 520 .555 514 1194 680

850 527 .521 523 1193 670

900 534 .489 532 1192 661

950 540 .462 540 1191 651

1000 548 .435 547 1189 642

1050 553 .413 550 1187 637

1100 558 .390 564 1185 621

1150 563 .372 572 1183 612

1200 567 .353 579 1182 603

1300 579 .322 593 1176 583

1400 588 .295 606 1172 565

1500 597 .271 619 1167 548

1570 604 .2548 624 1162 538

1670 613 .2354 636 1155 519

1770 621 .2179 648 1149 501

1870 628 .2021 660 1142 482

1970 636 .1878 672 1135 463

2170 649 .1625 695 1119 424

2370 662 .1407 718 1101 383

2570 674 .1213 743 1080 337

2770 685 .1035 770 1055 285

2970 695 .0858 801 1020 219

3170 705 .0580 872 934 62

Page 14

Steam Flow in Pipes

15

REASONABLE VELOCITIES for fluid flow through pipes

Pipe Size, Inches

1

⁄2

3

⁄4 111⁄4 11⁄2 221⁄2 331⁄2 441⁄2 5678910

Capacity Factor 2.0 3.5 5.5 10.0 13.5 22.5 31.5 48.5 65.0 84.0 105. 131.5 190. 255. 329. 430. 539.

COMPARATIVE CAPACITIES of different sizes of pipe

STEAM PRESSURE PSI (Gauge)

Pounds Condensed Per Hour, Per Lineal Foot of Pipe

12468102030405075100125150200

.11 .13 .14 .14 .15 .15 .16 .18 .20 .22 .26 .29 .32 .35 .40

.15 .15 .16 .16 .17 .18 .20 .23 .25 .27 .31 .35 .39 .42 .49

.21 .21 .22 .23 .23 .24 .28 .33 .36 .39 .45 .50 .55 .60 .69

.24 .25 .26 .27 .27 .29 .33 .38 .42 .46 .54 .61 .68 .74 .81

.30 .31 .32 .33 .34 .36 .41 .46 .51 .55 .65 .73 .81 .88 .97

.38 .39 .40 .41 .43 .44 .50 .56 .61 .66 .77 .86 .94 1.03 1.19

.46 .47 .48 .49 .51 .53 .61 .68 .76 .83 1.04 1.11 1.23 1.33 1.50

.55 .56 .59 .60 .62 .64 .74 .83 .91 1.00 1.24 1.32 1.46 1.59 1.81

.34 .35 .36 .37 .39 .41 .47 .53 .59 .65 .73 .81 .90 1.00 1.15

CONDENSATION RATES at 70°F. (for bare steel pipe with natural movement of air)

Pipe

Size

(Inches)

3

⁄4

1

1

1

⁄2

2

2

1

⁄2

3

4

5

Per Sq. Ft.

Heat. Surface

Sq. Ft. of

Surface =

to 1 Lineal

Ft. of Pipe

.275

.345

.497

.622

.752

.917

1.179

1.459

EXAMPLE: To get size of pipe to serve a

1

⁄2" and 3⁄4" pipe, add factors: 1⁄2" factor (2) + 3⁄4" factor (3.5) = 5.5 (1" factor).

Condensation in Pipes

Fluid Pressure PSI (Gauge) Service Velocities—FPM

SATURATED STEAM 0-15 Heating Mains 4000-6000

SATURATED STEAM 50-up Miscellaneous 6000-8000

SUPERHEATED STEAM 200-up Turbine and Boiler Leads 10000-15000

WATER 25-40 City Service 120-300

WATER 50-150 General Service 300-600

WATER 150 Boiler Feed 600

Pipe Size

PRESSURE PSI (GAUGE)

(Inches) 5 10 15 30 50 75 100 125 200 250

1

⁄2 30 40 45 60 90 120 150 180 270 330

3

⁄4 55 70 80 110 160 220 280 340 510 620

1 90 110 125 180 270 390 460 560 840 1020

11⁄4 160 200 225 325 480 650 820 990 1490 1830

11⁄2 220 270 300 450 650 900 1100 1300 2060 2550

2 370 455 520 750 1100 1500 1900 2300 3450 4200

2

1

⁄2 525 650 750 1050 1600 2175 2750 3300 4950 6050

3 800 950 1350 1600 2500 3350 4250 5150 7700 9450

31⁄2 1100 1350 1550 2200 3300 4550 5700 6900 10200 12700

4 1450 1800 2000 2900 4300 5850 7400 8900 13450 16400

5 2300 2800 3200 4600 6900 9300 11700 14100 21200 26000

6 3200 3900 4500 6400 9800 13200 16800 20300 30800 36900

8 5700 7000 8000 11400 17200 23300 29300 35400 53100 65200

10 9300 11400 13000 18900 28200 38000 48100 58100 87100 106500

12 13500 16600 18900 27000 40800 55300 69700 84200 126500 154700

SATURATED STEAM (lbs/hr) at 6000 ft/min (velocity) in iron or steel pipe

DIAMETER OF PIPE IN INCHES

3

⁄4 111⁄2 221⁄2 345681012

233445678111315

233445679111415

3344556710121417

3344557911131518

33455581012151821

34556791113162024

CONDENSATION (lbs/hr) per 100 ft. pipe with 2-in. thick 85% magnesia insulation

Pressure

PSI

(Gauge)

1

3

5

10

20

30

DIAMETER OF PIPE IN INCHES

3

⁄4 111⁄2 221⁄2 345681012

445679111316192428

4567810131518222732

5578912151820253137

5678913161922283541

66891014172124313845

67891115192428354451

Pressure

PSI

(Gauge)

50

70

100

125

150

200

Condensation in 3" and larger pipe are corrected for heat loss due to friction. Velocity taken at 8000 ft./min. Based on standard formulas.

Page 15

Flash Steam

Explanation

and

Calculation

Flash Steam

When hot condensate above the saturation

temperature under pressure, is released to

atmospheric pressure, the excess heat is

given off by reevaporation or what is commonly referred to as flash steam.

Flash steam is important because it contains

heat which can often be utilized for economy.

It is necessary to know how it is formed and

how much will be formed under given conditions.

The Btu values given in the Properties of

Saturated Steam tables provide the necessary data for calculating energy loss due to

flash steam.

Float and thermostatic traps, bucket traps,

and disc traps discharge condensate at

approximately saturation temperature.

Thermostatic traps discharge condensate 10°

to 30°F. below the saturation temperature.

Flash Steam Heat Loss Calculation

The form provided to the right will allow you to

easily calculate the flash steam loss and

associated energy cost.

Lines A, B, C, D, and E are based on the actual operating conditions. It may be necessary

to estimate the average conditions when

loads fluctuate.

Lines F, G, H and I can be filled in using the

values from the Properties of Saturated

Steam table.

The calculation for flash loss may now be

made with the annual loss determined.

The calculation of energy cost may now be

made to determine the flash loss and

required heating of make-up water to replace

the flash loss.

The amount of make-up water and water cost

can also be determined using this form.

How to Calculate Your Own Flash Steam

and Energy Loss

List Operating Conditions:

A. ____Initial Saturation Pressure.

B. ____Reduced Pressure.

C. ____System Load in Lbs. Per Hr..

D. ____Cost of Steam Per 1,000 Lbs.

E. ____Make-up Water Temperature ° F.

From Properties of Saturated Steam Table:

F. ____Btu/Lb. in Condensate at Initial

F. ____Pressure.

G. ____Btu/Lb. in Condensate at Reduced

G. ____Pressure.

H. ____Btu/Lb. Latent Heat in Steam at

H. ____Reduced Pressure.

I._____Btu/Lb. in Make-up Water.

Calculation of Flash Steam Loss

F – G

x 100 = % flash loss

______ x 100 = ______% of flash loss

C x % flash loss = lbs. per hr. loss

To obtain annual loss multiply Ibs. per hr.

Ioss x hr. per day x days per year process

operates = Ib. of flash steam annually.

Calculation of Energy Loss:

This calculation must take into consideration

that, not only are we reducing the temperature of the returns, but that the condensate

removed in the form of flash steam must be

replaced with cooler make-up water.

% of returns x system load Ibs./hr. x (F - G)

= Btu/hr. condensate cooling.

% of flash loss x system load Ibs./hr. x (F - I)

= Btu/hr. make-up water loss.

Btu condensate cooling + make-up loss

= Btu/hr. Ioss.

Btu/hr. Ioss x hr. per day x days per year

= annual Btu loss.

Btu annual loss ÷ H = equivalent Ib./yr. Ioss.

Lb./hr. Ioss ÷ 1,000 x D

= annual cost of flash steam loss.

Lb./Year Flash Loss ÷ 8.33

= Gallons per year make-up water.

16

H

Page 16

Steam Trap Operating Pressure Selection

A given size float and thermostatic trap or

bucket trap is offered with various orifice

sizes which determine the maximum pressure

rating. A Hoffman Specialty F & T trap for

example is offered with seats rated 15 psi,

30 psi, 75 psi, 125 psi and 175 psi. A low

pressure seat and pin has a larger orifice size

which provides a higher condensate rating

than a high pressure seat.

When actual operating pressure is higher than

the seat rating, the differential pressure

across the seat will prevent the trap from

opening. Thus, the trap must be selected for

the maximum differential pressure that will be

encountered. The trap capacity tables show

capacities at lower pressures to allow selection at various operating points.

A high pressure seat may be used at lower

differential pressures, however, the capacity

rating will be less than the same size trap

with a low pressure rated seat.

Operating

Pressure

Limits

17

Excessive Steam Pressure

Forces Trap Closed

ATMOSPHERIC

PRESSURE

WEIGHT OF

BUCKET

STEAM

PRESSURE

Page 17

Installation

and

Calculating

Differential

Pressure

Trap Installation

Steam traps should be installed in an accessible location at least 15 inches below the

condensate outlet of equipment or steam

mains being drained. A 15 inch static head at

the trap will provide approximately

1

⁄2 psi differ-

ential across the trap when it drains into a

vented gravity return system. During start-up,

before a positive steam pressure is achieved,

the static head is the only differential pressure across the trap. When the steam equipment is controlled by a temperature regulator,

the steam pressure will be reduced as the

valve modulates toward the closed position.

When the pressure drops to O psi, the static

head is the only differential pressure across

the trap. The differential pressure across the

trap can be increased by lowering the trap below the steam equipment.

A 2.4 ft. static head

will provide 1 psig. A greater differential pressure will reduce the size of the trap required.

Piping Details

A dirt pocket should be provided ahead of the

steam trap to collect scale and dirt. A shut-off

valve should be provided ahead of the trap to

permit service.

Strainers should be provided ahead of the

steam trap to prevent dirt from entering the

trap. Dirt entering the trap can deposit on the

seat and prevent tight closing. A blow-off valve

on the strainer will permit strainer screen

cleaning. Unions or flanges should be provided to allow removal of the trap for testing,

repair or replacement.

A test and relief valve installed after the trap

permits visual indication of the trap operation,

and assures that internal pressures are

relieved prior to servicing.

A shut-off valve in the trap outlet to the return

line isolates the trap from the return line for

service.

18

Trap Installation

Trap draining to open drain

Trap Installation

Trap draining to gravity return line

EQUIPMENT DRAIN POINT

STATIC

HEAD

SHUT-OFF VALVE

“Y”

STRAINER

DIRT

POCKET

TO DRAIN

TRAP

PRESSURE

TO RETURN LINE

TEST &

RELIEF

GRAVITY RETURN TO

VENTED RECEIVER

EQUIPMENT DRAIN POINT

STATIC

HEAD

SHUT-OFF VALVE

STRAINER

DIRT

POCKET

“Y”

TO DRAIN

TRAP

Page 18

The use of bypass piping around steam traps

is not recommended. Bypass valves, if

opened, may cause pressurization of condensate receivers and cause a safety hazard.

Where stand-by protection is desired the use

of a stand-by trap in parallel to the normal

trap is recommended.

Where the trap drains into a pressurized

return line or to an overhead return, a check

valve should be installed after the trap to prevent backflow through the trap when the

steam is off. The check valve also helps protect the trap from cavitation (water hammer)

that may occur when traps discharge high

temperature condensate into wet return lines.

Water hammer occurs when high temperature

condensate under pressure ahead of the trap

discharges into a lower pressure return line.

The high temperature condensate flashes,

causing steam pockets to form. When these

steam pockets give up their heat they implode

and cause water hammer.

Differential Pressure

The differential pressure across the trap will

be the sum of the minimum operating pressure, plus the positive static head at the trap

inlet minus any back-pressure in the return

line minus static head in the discharge piping.

Trap capacities should be calculated at the

minimum differential pressure to assure complete condensate drainage.

Lifts in the return piping should be avoided

wherever possible. High temperature condensate discharging from the trap may flash at

the lower return line pressure. The flashing

into a wet return line will cause steam pockets. As these steam pockets lose their latent

heat they implode, causing water hammer.

Water hammer can damage traps, pipe and

fittings.

Lifts in the discharge piping after a trap will

cause back-pressure. A 2.4 ft. Iift is equal to

a 1 psig pressure. This is especially important

on low pressure operation or where a modulating control valve is used to control the flow

of steam. Reduced flow will cause pressure

drops. A positive differential must be assured

under all possible conditions to assure complete condensate drainage.

19

Trap Installation

Trap draining to overhead return line or pressurized return line

Differential Pressure = P

1

minus P

2

P1(Inlet) P2(Outlet)

TRAP

EQUIPMENT DRAIN POINT

RETURN

STATIC

HEAD

SHUT-OFF

DIRT

POCKET

VALVE

“Y”

STRAINER

TO DRAIN

TRAP

CHECK

VALVE

TEST &

PRESSURE

RELIEF

SHUT-OFF

VALVE

LINE

STATIC

HEAD

AGAINST

DISCHARGE

1

/2 PSI/FT.

PRESSURIZED

RETURN LINE

Page 19

Drip Traps for

Distribution

Pipes

Drip Traps for Steam Distribution Piping

The steam distribution piping, often referred

to as steam mains, provides the link between

the boiler and the steam utilizing equipment.

The steam piping must be kept free of air and

condensate. This requirement is met with the

use of steam traps installed in the piping. The

traps used for draining the steam mains are

commonly referred to as drip traps. If the

steam mains are not adequately trapped the

results are often water hammer in the piping.

Water hammer is caused by slugs of condensate traveling at high speed in the steam

pipes, which can damage valves and piping.

Drip traps are installed in the steam mains at

all risers, ahead of all reducing valves, ahead

of all regulators, at the end of mains, throughout the piping at intervals at least every 500

feet, at expansion joints and at all steam

separators.

The size and type of drip traps used will

depend on the method used in heating the

steam mains to final pressure and temperature. The two methods commonly used are

automatic start-up and supervised start-up.

In systems using automatic start-up the

steam boiler is used to bring the mains up

to final pressure and temperature without

supervision. The drip traps must handle the

full condensing load during start-up of the

system.

In systems using supervised start-up the operator opens manual valves in the steam piping

before steam is admitted to the system.

When the system reaches normal pressure

and temperature, the manual valves are

closed. The drip traps for supervised start-up

are sized only for the running load.

The sizing of drip traps will depend on the

type of start-up used. During the initial startup of automatic startup systems, a large

amount of condensing occurs, bringing the

steam piping from ambient temperature up to

the final steam temperature.

When supervised start-up is used the drip trap

is sized only to handle the heat loss through

the steam piping.

20

Page 20

Calculation of the running load is figured

using the following formula:

Ibs./hr. running load heat loss =

L x U x ∆T x E

S x H

L = Length of steam line.

U = Heat transfer from curve in Figure 1.

T = Temperature difference between steam

temperature and minimum ambient in

degrees F.

E = 1- Efficiency of insulation (for 80% effi-

cient insulation use 1.80 = .2).

S = Linear feet of pipe to provide 1 sq. ft.

surface area.

H = Latent heat of steam in Btu/lb. (see

Properties of Saturated Steam Table).

Calculation for warm-up load at start-up:

Warm-up load Ib./hr. =

W x(T

1- T2)x.114 L

W = Weight of pipe (see table below for

weight per ft.).

T

1 = Steam temperature at saturation.

T

2 = Initial pipe temperature at ambient.

L = Latent heat of steam at final

operating pressure.

.114= Specific heat of steel or wrought

iron pipe.

21

S VALUE FT. OF PIPE PER

SQ. FT. OF SURFACE AREA

Pipe Size S Value

1" 2.904

1

1

⁄4" 2.301

1

1

⁄2" 2.010

2" 1.608

3" 1.091

4" 0.848

5" 0.686

6" 0.576

8" 0.442

10" 0.355

12" 0.299

14" 0.272

16" 0.238

18" 0.212

20" 0.191

24" 0.159

W VALUES

WEIGHT OF WELDED SEAMLESS STEEL PIPE

Schedule 40 Schedule 80

Nominal Wt. Lbs. Wt. Lbs.

Pipe Size Per Linear Ft. Per Linear Ft.

1

⁄2" .85 1.09

3

⁄4" 1.13 1.47

1" 1.68 2.17

1

1

⁄4" 2.27 3.0

1

1

⁄2" 2.72 3.63

2" 3.65 5.02

2

1

⁄2" 5.79 7.66

3" 7.58 10.25

4" 10.79 14.98

6" 18.97 28.57

8" 28.55 43.39

Page 21

Example: Assume a steam supply header to

feed tracer lines is 11/4” pipe size operating

at 30 psig and is 800 ft. Iong, insulated 75%

effect, minimum ambient at start-up is 10°F.

Calculate running load and warm-up load.

Step 1

Running load Ib./hr. =

L x U x ∆T x E

S x H

= 800 x 2.7 x (274 -10) x .25

2.301 x 926

= 66.9 Ib./hr.

Step 2

Calculate warm-up load:

C =

W x(T

1- T2) x.114

L

= (2.27 x 800) x (274 -10) x .114

926

= 59 Ibs. of steam

A warm-up time must be selected to compute

Ibs./hr. Assuming a warm-up of 15 minutes,

we must multiply 59 Ibs. x 4 = 236 Ibs./hr.

Thus, the trap must be sized for 236 Ibs./hr.

for a 15 minute start-up period, plus a safety

factor.

Step 3

We will size the trap for the large value (running load vs. warm-up load), which in almost

all instances will be the warm-up load.

Traps should be sized with a safety factor to

handle start-up and abnormal loads. Normal

practice is to size the trap at three times the

running load or two times the warm-up load.

The final sizing for our example would be to

size the trap for 236 x 2 = 472 Ibs./hr. condensate based on the differential pressure

between the header supply pressure and

return line pressure. Assuming a gravity return

line, this would be 30 psi.

Step 4

Select the trap.

Based on the previous description of traps, if

the trap from a steam header is not subject

to freezing conditions, the normal selection

would be an F & T or Bucket Trap.

If the trap is located in an area subject to

freezing, to assure complete condensate

drainage during shut-down, we should use

either a Thermostatic or Thermodisc Trap.

Based on the calculated condensate rate plus

the applied safety factor, we would go directly

to the trap manufacturer’s catalog and select

the trap.

The drip trap should be installed in a drip connection that is at least equal to the size of

the steam main for pipe size up to 4 inches.

Above 4 inch size the drip connection should

be at least 4 inches minimum or 1/2 the size

of the steam main, whichever is larger. The

height of the drip connections should be the

larger of 5 inches or 1

1

⁄2 times the diameter of

the pipe.

The static head will provide the differential

pressure across the trap during automatic

start-up until the steam pressure is above 0

psig. A 15 inch static head will provide 1/2

psi differential assuming the trap drains into a

gravity return line. A 2.4 ft. static head will

provide 1 psi differential pressure.

22

Installation at end of steam main drip trap

STATIC

HEAD

SHUT-OFF

VALVE

“Y” STRAINER

TRAP

SHUT-OFF

VALVE

Page 22

Trapping Ahead of Steam

Regulators

When steam pressure or temperature regulator valves are installed in a steam line, condensate may back up ahead of the valve

when it is off. When the valve opens with condensate backed up on the inlet side, the condensate will cause water hammer.

Where the branch connection to a control

valve is less than 10 ft., the branch line may

pitch toward the steam main to allow condensate to flow back into main.

When the branch line is over 10 ft., pitch the

branch line toward the control valve and

install a steam trap. The steam trap should

be as close to the control valve as possible.

23

Installation of drip trap ahead of riser or expansion joint

Installation of drip trap in long run of steam piping or ahead of control valves

STATIC

HEAD

SHUT-OFF

VALVE

“Y” STRAINER

TRAP

SHUT-OFF

VALVE

STATIC

HEAD

SHUT-OFF

VALVE

“Y” STRAINER

TRAP

SHUT-OFF

VALVE

10' OR LESS

PITCH TOWARD STEAM

MAIN 1/2" PER FOOT

STEAM

MAIN

OVER 10'

PITCH TOWARD

STEAM MAIN

1/2" PER FOOT

STEAM

MAIN

TRAP

Page 23

Selecting

Steam Traps

for Heat

Exchangers

Steam heating devices using a modulating

temperature regulator must operate over a

wide range of conditions. As the temperature

regulator controls the flow of steam, condesation causes a change in pressure. Thus, the

steam trap must be capable of handling a

wide range of capacities at varying pressures.

Selection of the trap for these conditions is

more involved than it would be for drip traps

or steam equipment operating at constant

pressure.

A heat exchanger is sized to heat a maximum

expected flow rate through the tubes, over the

maximum expected temperature rise with a

predetermined maximum steam operating

pressure.

When the tube side flow rate is reduced, or

the incoming fluid being heated requires less

of a temperature rise, the steam control valve

partially closes, reducing the flow of steam to

maintain a constant set temperature of the

fluid being heated. The condensing of the

steam under reduced load conditions results

in a lower steam pressure in the shell of the

heat exchanger.

During very low load conditions the condensing of the steam can create an induced vacuum in the shell of the heat exchanger. This

condition requires that a vacuum breaker be

installed to allow air to enter and relieve the

induced vacuum. Without a vacuum breaker,

the induced vacuum would cause a negative

pressure differential across the trap and the

condensate would not be drained from the

heat exchanger shell.

Complete condensate drainage under all varying pressure and condensing loads is essential to prevent tube damage due to water

hammer. The steam flow in the heat exchanger shell must pass around the tube support

sheets. If condensate builds up in the heat

exchanger shell, it will condense rapidly as

steam is mixed with it, causing water hammer. The water hammer is often evident by

indentations in the tubes and collapsed

tubes.

Thus, it becomes evident that the design condensing rate at design pressure is not the

only load the trap must handle. The condensing load of a heat exchanger designed for 15

psi may in fact be in excess of 90% at 0 psig.

When the heat exchanger is selected, a fouling factor is added to assure adequate tube

area as scale builds up on the tube walls.

Before this scale develops, the heat exchanger is in fact oversized which results in a lower

steam operating pressure.

A steam trap must then be selected to handle

the full condensing load with the heat

exchanger operating at 0 psig. The heat

exchanger may operate at a slight vacuum

due to the condensing of steam. A vacuum

breaker is required on a heat exchanger to

prevent induced vacuum. The differential

required to open the vacuum breaker is usually less than 0.25 psi.

Recommended practice is to install the trap

as far below the heat exchanger as possible.

The minimum distance should be 15 inches.

A 15 inch static head will develop approximately 0.5 psig at the trap inlet, less the differential required to open the vacuum

breaker. Assuming 0.25 psi to open the vacuum breaker, a properly sized trap must be

capable of draining the full rated condensing

load with 0.25 psi differential across the trap,

draining into an atmospheric gravity return

line. A static head of 2.4 feet will provide 1

psig. The differential required to open the vacuum breaker must be subtracted from the

static pressure to determine the differential

across the trap.

Selecting the type of trap becomes the next

step. Traps that operate in response to temperature should be avoided for heat exchanger operation. This eliminates thermostatic

traps from our selection. As described above,

the trap must be capable of responding to

varying condensing rates at various differential pressures. The two types of traps that can

meet these requirements are Float and

Thermostatic Traps and Bucket Traps. The

Float and Thermostatic Trap has the ability to

24

Chapter 3

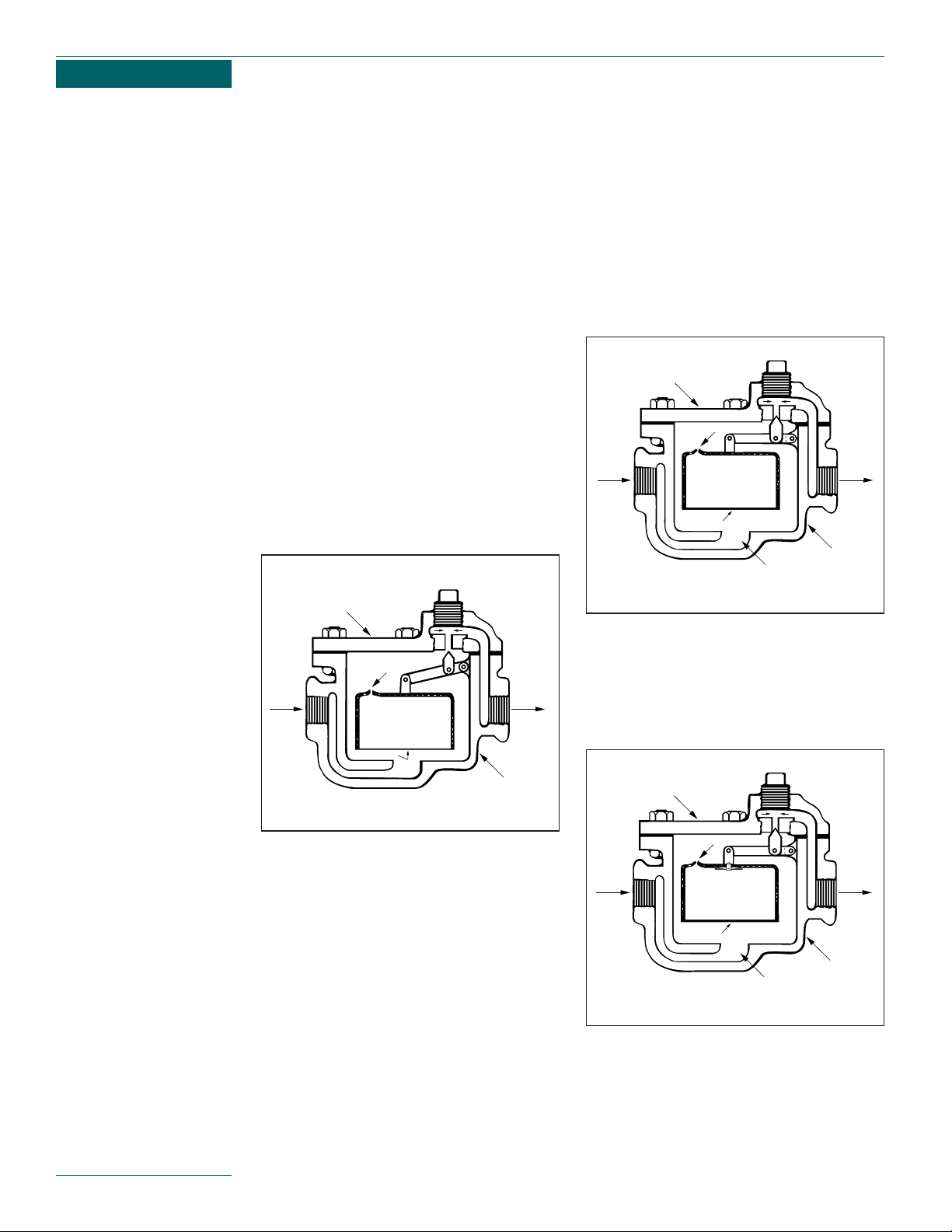

Steam to Fluid Heat Exchanger

HEATED FLUID

OUT

FLUID TO BE

HEATED IN

VACUUM BREAKER

HEAT EXCHANGER

SHELL

TEMPERATURE

REGULATOR

STEAM LINE

TUBE SUPPORTS

HEAT EXCHANGER

TUBE BUNDLE

F&T TRAP

Page 24

modulate over a wide range of conditions, providing a drainage rate equal to the system

load. The Float and Thermostatic Trap also

has a separate thermostatic vent to provide

quick passage of air during start-up or during

a change of condition. The bucket trap will

completely drain the condensate but operates

in cycles between full open and close. The

bucket trap has a slower air venting rate

unless fitted with a separate thermostatic element. Return line sizing can be minimized

using the Float and Thermostatic Trap due to

its modulating feature which provides a continual flow equal to the condensing rate.

General practice in sizing traps is to allow a

safety factor in the selection. During start-up

when the heat exchanger shell is cold, the

steam piping is cold and the fluid to be heated may be at less than design temperature.

All these conditions will cause a higher steam

condensing rate. Float and Thermostatic Trap

safety factors are normally 1.5 to 2.5 times

rated load. Bucket Trap safety factors are normally 2 to 4 times rated load .

Guidelines for selecting traps for heat

exchangers using modulating steam temperature regulators are as follows:

—Select capacity based on maximum condensing load at minimum differential pressure

that can occur. The heat exchanger manufacturer can provide this information.

—No lifts should be installed in the return line

piping. The trap must drain into an atmospheric gravity return line.

—Install a vacuum breaker to prevent induced

vacuum in the heat exchanger from causing a

reverse in differential pressure across the

trap.

—Install the trap as far below the heat

exchanger as possible to develop a static

pressure to the trap inlet. The minimum

should be 15 inches.

—Select a trap that provides complete

drainage of condensate. Avoid use of temperature controlled traps.

—Allow an adequate safety factor for start-up

conditions.

25

Typical Heat Exchanger Installation

Float & Thermostatic Traps assure complete condensate drainage

at saturation temperature. They also modulate to handle varying

condensate loads associated with temperature regulators. The

thermostatic element provides rapid air venting during start-up.

PRESSURE

GAUGE

Y STRAINER

FLOAT AND

THERMOSTATIC

GATE

VALVE

CONDENSATE

RETURN

TRAP

THERMOSTATIC

FLOAT AND

TRAP

Y STRAINER

Y STRAINER

GATE

VALVE

BREAKER

VACUUM

GATE

VALVE

GLOBE

VALVE

TEMPERATURE

REGULATING VALVE

HEAT EXCHANGER

15" MINUMUM

RECOMMENDED

GATE

VALVE

PRESSURE

GAUGE

CONNECTION TO

HEAT EXCHANGER

HOT

WATER

THERMOMETER

COLD

WATER

CONDENSATE

RETURN

Page 25

Condensate Coolers

When heat exchangers are selected for operation above 2 psig, consideration should be

given to the addition of a condensate cooler.

The justification will vary depending on the

size of the heat exchanger and the actual

time the unit is in operation.

With a condensate cooler, the discharge from

the trap on the primary heat exchanger is

piped through a water-to-water heat exchanger.

This lowers the condensate temperature and

recovers wasted heat. A second trap is then

installed on the discharge of the condensate

cooler to maintain saturation pressure and

prevent flashing and water hammer in the

condensate cooler.

The water-to-water heat exchanger design differs from steam heat exchangers. The waterto-water heat exchanger has internal baffles

to direct the water flow across the tubes to

improve heat transfer. The water-to-water heat

exchangers are externally distinguishable

because the top and bottom shell openings

are both the same size. The steam-to-water

heat exchangers have a large opening in the

top for the steam inlet and a smaller bottom

outlet for the condensate drainage.

When a modulating steam regulator is used

on the steam-to-water heat exchanger, the

vacuum breaker will allow air to enter to prevent an induced vacuum from holding up condensate. The F & T Trap must be installed 15

inches below the heat exchanger to provide

condensate drainage when the internal pressure drops to O psig. A separate Thermostatic

Trap should be provided to allow the air to be

vented when the pressure increases above O

psig. This trap bypasses the condensate cooler to allow free passage of the air into the

gravity return line.

The fluid in the condensate cooler on the tube

side, may be the same fluid that is to be heated in the steam heat exchanger when the initial temperature is sufficiently low. When the

initial temperature of the fluid is too high to

cool the condensate below 212°F, other fluids

may be heated. Heating domestic hot water

or pre-heating boiler make-up water are two

possibilities.

26

Piping Detail of Condensate Cooler

When fluid being heated is too hot to cool condensate below 212°F., other heating

requirements may be circulated through the condensate cooler.

TEMPERATURE

REGULATOR

STEAM LINE

HEAT EXCHANGER

THERMOSTATIC

TRAP

F&T TRAP

HEAT EXCHANGER

CONDENSATE COOLER

TO RETURN

LINE

Page 26

Lock-out Traps For Draining Condensate

Under Low Pressure.

In the discussion of trap operation, we pointed out that if the differential pressure across

the trap seat exceeds the trap pressure rating, the trap will fail closed. This occurs when

the differential force across the seat and pin

exceeds the drop-away force created by the

weight of the float or bucket and linkage.

Under certain conditions we can use a trap

with a low differential pressure in a high pressure application to drain condensate during

start-up or operation at reduced pressure.

Low pressure F & T or Bucket Traps may be

used for lock-out applications.

Lock-out Trap Used to Drain

Underground Steam Main.

One application of a lock-out trap is to drain

condensate from underground steam lines

during start-up. The low pressure trap connected to an open drain or sump drains condensate during start-up. When the steam line

pressure exceeds the trap rating it will close

and remain closed. The differential pressure

will then allow the condensate to flow through

the high pressure drip trap and be recovered

through the return line.

This method may also be used where a modulating temperature regulator may reduce pressure ahead of the trap. When the regulator

reduces the flow of steam, the pressure in

the steam space drops due to the condensing

rate in relation to steam flow. The low pressure trap connected to a sump or drain will

then operate when the pressure drops approximately to the rated pressure of the trap.

Lock-Out

Traps for

Start-Up

Loads

27

Lock-out trap used to drain underground steam main

POWER

PLANT

UNDERGROUND WET

RETURN LINE

UNDERGROUND

STEAM LINE

LOCKOUT

TRAP TO DRAIN

HIGH PRESSURE

DRIP TRAP

Page 27

Draining

Condensate to

Overhead

Returns

Draining Condensate to Overhead

Returns or into Pressurized Return Lines

When a positive pressure is assured across

the steam trap, 1 psi will raise condensate

2 feet. When a positive pressure is not

assured, such as the case when using a

steam control valve, provision must be made

to drain condensate at reduced pressure

loads and during initial start-up. The use of a

second trap installed at a higher elevation

and connected to a drain may be used as

shown below. The normal trap is connected to

the overhead return line with a check valve to

prevent backflow. The second trap may be a

low pressure trap. When condensate backs

up 4 inches it will drain into the second trap

which will drain condensate into a floor drain

or sump.

When a trap drains into an overhead return

line or pressurized return line, water hammer

may occur due to high temperature condensate flashing as it drains through the trap into

a lower pressure. The check valve after the

trap protects it from the forces created by

water hammer. It also prevents backflow

through the trap when the steam is off.

28

Draining condensate to overhead return lines

TEMPERATURE

REGULATOR

OVERHEAD RETURN

STEAM LINE

TRAP

MAX. LIFT

2 FOOT

PER PSI

DRIP

TRAP

4" MIN.

TRAP

Page 28

Submerged Pipe Coils

Submerged pipe coils are sometimes gravity

drained, with the trap installed below the coil.

Figure 2 shows such an installation. Use a

safety factor of 2 for trap sizing.

When it is not practical to install the trap

below the tank level, a lift fitting or water seal

must be provided to bring the condensate to

the trap level over the heated tank. Figure 3

shows a water seal arrangement. Note that

the trap is installed below the siphon looped

over the top of the tank. Condensate collects

in the water seal and is elevated to the

siphon loop by the differential pressure. A

safety factor of 3 should be used.

Large diameter coils may require yet another

type of installation. Where the coil diameter is

larger than the trap inlet size, the installation

shown in Figure 4 should be used. A smaller

tube is placed inside the large tube and

insures that steam will not enter the trap until

all of the condensate has been drained from

the coil. The lift fitting tube is usually sized

one pipe size smaller than the trap inlet, but

never less than 1/2” pipe size.

The coils in Figures 2,3 and 4 are of the continuous type. Coils are often multi-circuited. A

safety factor of 4 is needed where this is the

case because of the higher warm-up load.

Embossed plate coils are piped in the same

fashion as ordinary pipe coils. Where the coil

is of the continuous type and gravity drained,

the safety factor is 2 to 1. Siphon drained

coils require a 3 to 1 safety factor. Multiple

header plate coils should have a safety factor

of 3 to 1 if they are gravity drained and 4 to 1

if siphon drained. Figure 5 illustrates these

coil types.

Draining

Submerged

Coils

29

Continuous coils–gravity drained

Figure 2

Continuous coils–siphon drained

Figure 3

Large diameter continuous coil

siphon drained

Figure 4

Typical embossed plate coil installations

Figure 5

Continuous coil–gravity drained Continuous coil–siphon drained

Multiple header coil

siphon drained

Multiple header coil

gravity drained

STEAM

TANK

STRAINER

STEAM

TANK

PLATE COIL

STEAM

TRAP

TANK

STRAINER

PLATE COIL

TANKTANK

TRAP

TRAP

PLATE COIL

SWING CHECK VALVE

PLATE COIL

TRAP

STRAINER

TRAP

SWING CHECK VALVE

TRAP

TANK TANK

TRAP

Page 29

Jacketed

Kettles

Jacketed Kettles

Kettles are often of the tilting type. These

require the use of a siphon drain. Siphon

drains may either be internal or external. The

Fig. 6 shows both types.

As shown in the illustration, external siphons

are surrounded by ambient air, while the internal siphon is surrounded by steam.

Flash steam tends to form in siphons and the

trap must be able to operate properly with a

certain amount of it present in the condensate. Figure 7 illustrates how this takes

place, and how a steam main is drained.

First, condensate drains into the water seal.

Steam in the siphon above the water seal

condenses, dropping the pressure.

Condensate rises in the siphon as this takes

place. The siphon may form and break several

times before it is established and condensate

enters the trap.

A check valve must be used to hold the

siphon while it is forming. This should be

installed after the strainer as shown. Once

the siphon is established, the drop in static

pressure as the elevation decreases causes

some of the hot condensate to “flash off.”

The presence of steam in the condensate

decreases its density and actually assists the

flow. An external type siphon loses some heat

by radiation to the ambient air and the condensate within it tends to cool. As a result,

the amount of flash steam is less than in an

internal siphon, which absorbs heat from the

steam surrounding it.

Air Handling Capability

The excellent air handling capability of

Thermostatic Traps makes them suitable for

trapping applications where quick air removal

is required. For example, batch processes

resulting in on-off operation of steam heating

equipment are prone to air problems. The

steam space becomes filled with air in

between heating cycles. Unless this air is

quickly removed with the condensate, slow

heating of the batch results. Thermostatic

Traps must be fitted with a cooling leg, when

used for this purpose, to minimize back up of

condensate into the equipment.

Figure 8 shows a steam kettle serviced by a

Thermostatic Trap. A cooling leg with a minimum length of 5 ft. is provided to insure

enough cooling of the condensate to open the

trap.

Notice the check valve provided at the trap

outlet. This prevents back drainage of the

condensate in the vertical line. A check valve

should always be provided at the trap outlet

where vertical lifts exists.

The safety factor for steam kettles is usually

3 times rated capacity. Siphon type kettles

may use either F & T or Bucket Traps.

Stationary kettles may use Thermostatic

Traps.

30

External and internal jacketed kettles

Figure 6

Principle of condensate line siphon

Figure 7

Steam kettle showing cooling leg

Figure 8

Stationary type

jacketed kettle with

internal siphon

Tilting type

jacketed kettle with

external siphon

STRAINER

CHECK VALVE

STRAINER

CHECK VALVE

TRAP

TRAP

STRAINER

STATIC PRESSURE

DROPS AND FLASH

STEAM FORMS

MAXIMUM STATIC

PRESSURE

SIPHON

WATER SEAL

CHECK VALVE

STEAM MAIN

TRAP

OVERHEAD

RETURN MAIN

THERMOSTATIC

TRAP

COOLING LEG

5 FT. MINIMUM

STRAINER

CHECK VALVE

Page 30

Cylinder Dryers

Cylinder dryers are widely used in the processing industry. Since they are usually rotating in

nature, siphon drainage of the condensate is

involved. Figure 9 shows a typical arrangement. Condensate is drained from the bottom

of the rotating cylinder by a typical siphon

arrangement.

Because of their large volume and surface

area, traps for this type of application should

be sized with a substantial safety factor. This

is required to eliminate the air and handle the

large warm-up load. It is not uncommon to

use safety factors of between 5 and 8 for

cylinder dryers.

Unit Heaters

Unit heaters may be selected to operate over

a wide range of pressures. Operation may

have maintained steam pressure in coils with

a thermostat to control the fan or steam control may be on-off as heat load is required.

Small low pressure unit heaters up to 15 psi

often use Thermostatic Traps. Large unit

heaters or those operating at higher pressure

may use F & T as first choice and Bucket

Traps as second choice.

When the ambient air may be below freezing

or when outside make-up air is used, a vacuum breaker is required to prevent an induced

vacuum from occurring when the steam is

turned off. Induced vacuum causes a reverse

differential pressure across the trap and

holds up condensate in the coils. This is the

major cause of coil freezeup. The trap must

also be able to drain by gravity to assure complete condensate removal.

The recommended safety factor for sizing

traps for unit heaters is 3 times rated

capacity. Low pressure traps may be sized

using SHEMA rating without any additional

safety factor.

Cylinder

Dryers, Unit

Heaters

31

Siphon drained cylinder dryer Figure 9

Unit heater

STRAINER

SWING CHECK VALVE

TRAP

VACUUM

BREAKER

UNIT HEATER

UNIT HEATER

TRAP

GRAVITY

RETURN

LINE

Page 31

Steam

Radiators

Radiators

Radiators normally use Thermostatic Traps to

drain condensate. The Thermostatic Trap is a

pressure balanced device that will open usually 10° to 30° F. below saturation temperature.

A Thermostatic Trap on a low pressure 3 psi

system will open at approximately 190° to

200°F. A 10° to 30° F. drop in condensate

temperature normally occurs in the return piping in a low pressure heating system. This

controls the return condensate at about

160°F. and simplifies the selection of condensate return units.

Low pressure Thermostatic Traps are normally

rated in sq. ft. E.D.R. heating load and have a

SHEMA rating which allows the proper safety

factor.

Thermostatic Traps are inexpensive in relation

to other types of traps. This makes them

attractive for heating systems where many

large numbers of traps are required.

Trap Damage from Water Hammer

When automatic temperature controlled supply valves are used, water hammer may occur

when the valve closes. This occurs due to the

condensing of steam in the radiator causing

an induced vacuum. The induced vacuum may

pull in flash steam from the return line. As

this steam enters the condensate in the bottom of the radiator, steam pockets form and

implode as they lose their heat. The forces of

water hammer (cavitation), can quickly

destroy bellows or diaphragm type radiator

traps. A solid fill Hoffman Specialty 17K is

designed to withstand this service.

Water hammer may also occur during start-up

when lifts are present in the discharge piping

after the trap.

32

SUPPLY MAIN

RETURN MAIN

SUPPLY VALVE

TRAP

SUPPLY VALVE

TRAP

RETURN MAIN

SUPPLY MAIN

Page 32

33

Typical Piping

for Steam

Heating

The piping and radiator connections shown in this section are

diagrammatic and illustrate the proper method of making piping

connections. They are not dimensional and cannot be scaled for

pipe size or product size.

DRY RETURN

SUPPLY MAIN

SUPPLY

VALVE

TRAP

DRY RETURN

TRAP

REDUCING TEE

SUPPLY MAIN

FULL SIZE OF

TAPPING

SUPPLY VALVE WITH CHAINPULL

SUPPLY MAIN

NO-PRESSURE WET RETURN

REDUCING ELL

NOT LESS THAN 24

"

WATERLINE OF BOILER

SUPPLY VALVE WITH CHAINPULL

TRAP

FULL SIZE

OF TAPPING

DRY RETURN MAIN

MINIMUM COOLING LEG 5'-0" LONG

SUPPLY VALVE

DOWN FEED RISERS

TRAP

Two pipe steam systems radiator connections

Dripping heel of

downfeed riser

into dry return

Connections to ceiling radiators with return bled into wet return

Connections to ceiling radiator located above supply & return

Connections to radiator wall panel

SUPPLY MAIN

RETURN MAIN

SUPPLY VALVE

TRAP

Radiator connections

taken from up or

downfeed risers

Page 33

34

Low pressure closed gravity system

High pressure system

Unit heater connections for two pipe gravity

or vacuum system

Unit heater connections for two pipe gravity or

vacuum system with supply branch dripped

through trap

Vacuum or low pressure open

gravity system

Piping connections for unit heaters (steam)

GRAVITY OR VACUUM DRY RETURN MAIN

GRAVITY OR VACUUM DRY RETURN MAIN

SUPPLY LINE

UNIT HEATER

SEDIMENT POCKET

UNIT HEATER

VENT VALVE

AT LEAST 12" RETURN

CHECK VALVE

SUPPLY LINE

UNIT HEATER

SEDIMENT POCKET

UNIT HEATER

VENT VALVE

STRAINER

BUCKET TRAP

SUPPLY LINE

UNIT HEATER

SEDIMENT

POCKET

STRAINER

GATE VALVE

SUPPLY MAIN

UNIT HEATER

SAME SIZE AS TRAP

FULL SIZE

OF

TAPPING

GRAVITY VACUUM DRY RETURN MAIN

MINIMUM COOLING LEG 5'-0" LONG

TRAP

SUPPLY MAIN

GATE VALVE

UNIT HEATER

TRAP

MINIMUM COOLING LEG 5'-0" LONG

FULL SIZE

OF

TAPPING

GRAVITY VACUUM DRY RETURN MAIN

SAME SIZE AS TRAP

TRAP

Page 34

35

Connections to header coils

having more than 8 pipes

Connections to header coils

of not over 8 pipes

Connections for upfeed risers

Method of reducing size of main

Dripping end of supply main into dry return

Dripping drop riser or end of main

into dry return

Two pipe steam systems

convector connections

Two pipe–

steam trap installations

Exposed pipe coils–

two pipe steam

TRAP

DRY RETURN

SUPPLY MAIN

RETURN RISER

HORIZONTAL BRANCH

45° ELBOWS

SUPPLY RISER

PIPES

BRANCH

ECCENTRIC REDUCER

DRY RETURN MAIN

SUPPLY MAIN

MINIMUM COOLING LEG 5'0" LONG

SAME SIZE AS TRAP

DROP RISER OR

END OF MAIN

MINIMUM COOLING LEG 5'0" LONG