Page 1

INSTRUCTION MANUAL

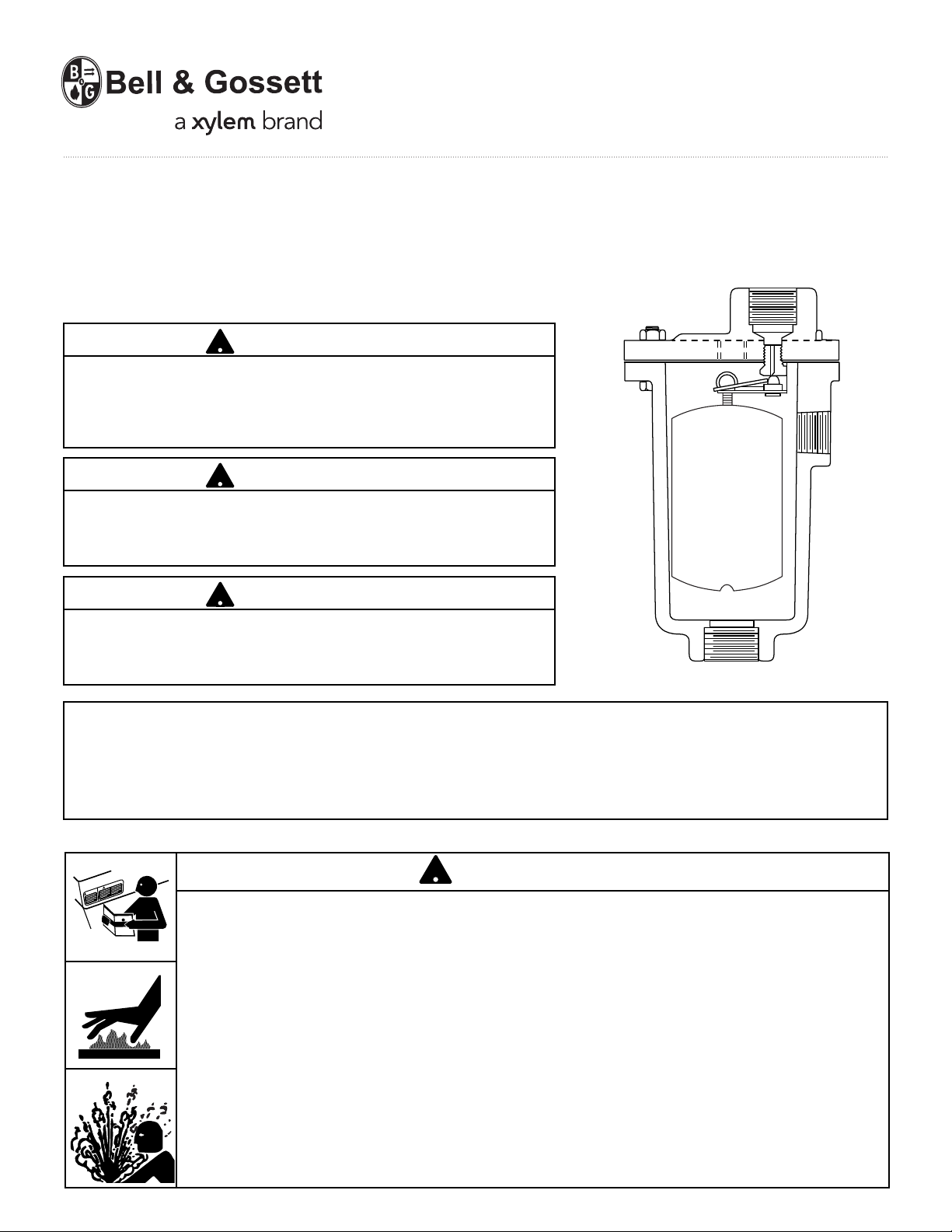

Model 792

High Pressure Water Vent Valve

!

!

!

HS-112

REVISION D

Hoffman Specialty

®

Model 792

High Pressure Water Vent Valve

CAUTION

Excessive use of pipe joint compound when installing air vent will foul

the vent’s operating mechanism allowing water to escape. Pipe joint

compound must be conservatively applied to male threads only. Failure

to follow this instruction can result in personal injury from hot water

and/or property damage.

CAUTION

The use of PTFE impregnated pipe compound and PTFE tape on pipe

threads provide lubricity which can lead to overtightening and breakage.

Do not overtighten. Failure to follow this instruction can result in

personal injury from hot water and/or property damage.

CAUTION

When the vent discharges air or if foreign material from the system

fouls the vent’s operating mechanism, it is possible for water to also be

discharged. Vent must be piped to a drain. Failure to follow this instruction can result in personal injury from hot water and/or property damage.

IMPORTANT: To prevent system damage from water

hammer or sudden shock, open supply valves slowly.

If you are uncertain about the product’s adaptability for

your application, please call the factory or authorized

representative before using the product.

CAUTION

WARNING

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of systems in accordance with all applicable codes

and ordinances.

• To prevent serious burns, wear heat resistant gloves when opening and closing supply

valves, or handling hot equipment.

• To prevent serious burns, the internal pressure of the system must be 0 psi (0 bar) before

servicing.

Failure to follow these cautions will cause personal injury.

!

The vent pressure rating must be equal or greater than

the maximum system pressure.

The vent discharge must be connected to a drain or fluid

recovery unit to prevent damage to the equipment or

structures in the event of leakage.

CAUTION

Page 2

INSTALLATION

!

!

!

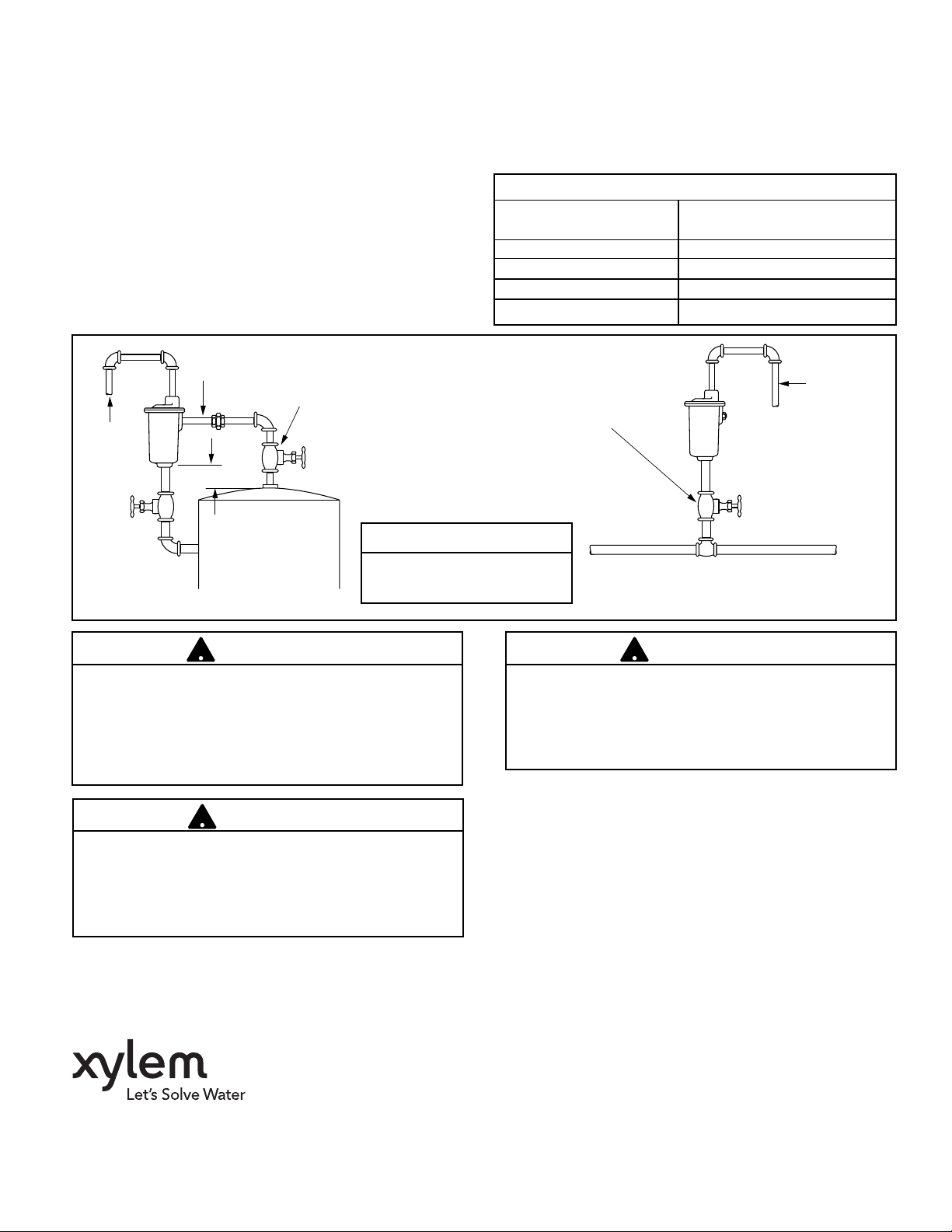

An equalizing line is recommended for continuous

operation applications as with water storage tanks.

See Figure 1.

The Hoffman No. 792 Water Vent should always

be installed with a safety drain from the discharge

port to a suitable waste. At high rates of discharge

at pressure, a fine mist will be discharged with the

air. If dirt lodges between valve pin and seat, the

valve will not close properly and water will be

discharged at system pressure until problem is

corrected.

1/2’’ EQUALIZING LINE WHERE

LARGE AMOUNTS OF AIR

1/2’’ SAFETY

DRAIN

MUST BE VENTED

1’’ MINIMUM

INSTALL SHUTOFF VALVES

IN VERTICAL PIPE ONLY

Temperature and Pressure Limits

Maximum Temperature: 300˚F (149˚C)

Maximum Operating Pressure: 250 psig (17.3 bar)

Maximum Hydrostatic Pressure: 350 psig (24.2 bar)

Model 792 Capacity

Water Pressure Air Discharge to Atmosphere

psig (bar) CFM (M3/min.)

100 (6.9) 10 (.28)

150 (10.3) 15 (.42)

200 (13.8) 20 (.57)

250 (17.3) 25 (.70)

1/2’’ SAFETY

DRAIN

INSTALL SHUTOFF VALVES

IN VERTICAL PIPE ONLY

STORAGE TANK

Note: Leave shut-off valves open

for proper installation. Close only

to service unit.

FIGURE 1

WARNING

The air vent will discharge air and possibly some liquid

during its normal functioning. Avoid eye, face or skin

contact with top area of air vent. We recommend the vent

connection be piped to a drain to prevent accidental contact with discharging fluids. Failure to follow this instruction can result in serious personal injury and/or property

damage.

WARNING

Corrosion or leakage are indications that the air vent may

be about to cause serious damage from leakage or rupture. It should be periodically inspected and if noted, air

vent must be replaced or serviced. Failure to follow this

instruction can result in serious personal injury and/or

property damage.

NOTE

HIGH POINT OF SYSTEM

FIGURE 2

WARNING

System fluid under pressure and/or at high temperatures

can be very hazardous. Before servicing, reduce system

pressure to zero or isolate the air vent from the system.

Allow system to cool below 100˚F. Failure to follow this

instruction can result in serious personal injury and/or

property damage.

Model 792

High Pressure Water

Vent Valve (complete unit) . . . . . . . . . . . . 401494

Service Parts Available

Cover Gasket Part No.. . . . . . . . . . . . . . . . . 601273

Internal Parts Kit Part No. . . . . . . . . . . . . . . 600204

(includes cover gasket, pin, seat, lever arm, yoke,

cotter pin and integral connecting hardware)

Float . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600247

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. HS-112D February 2013 Part No. 512725

Loading...

Loading...