Page 1

INSTRUCTION MANUAL

G97035G

Readout Valve

RV-125A

(G97030)*

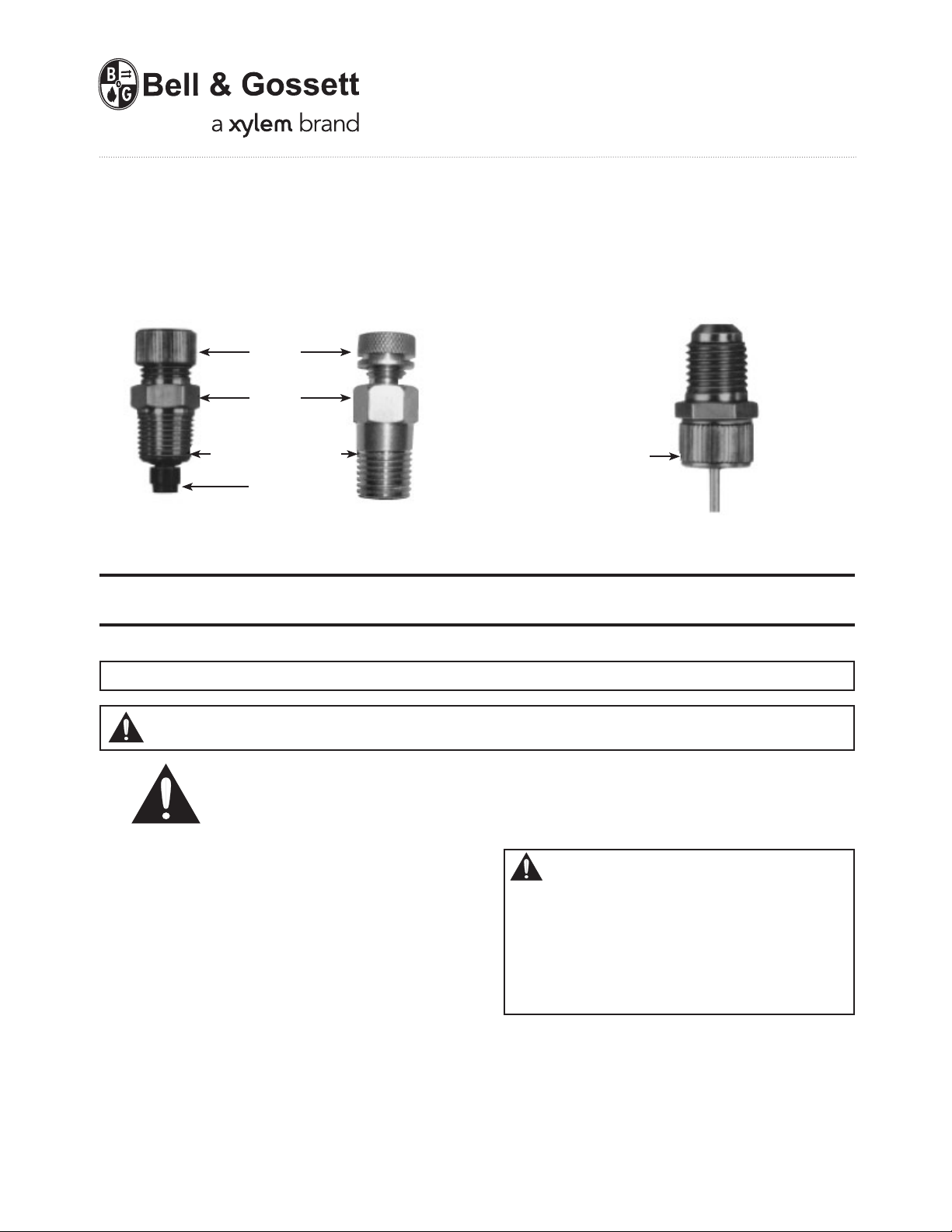

PROTECTIVE

CAP

BODY

1/8" NPT 1/4" NPT

CHECK

VALVE

*SET OF TWO *SET OF TWO

V58050PK*

*SET OF TEN

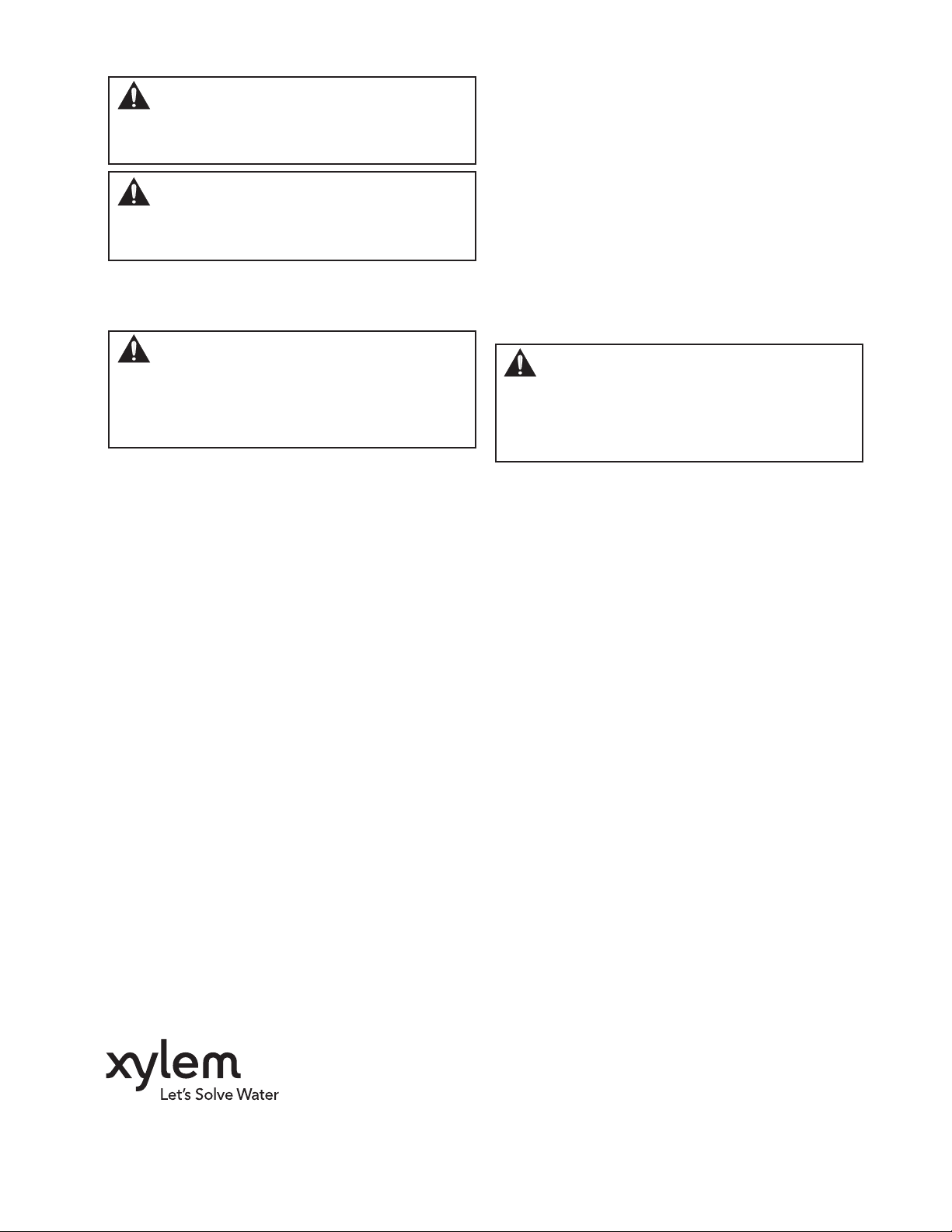

Readout Probe

RP-250B

(G97032)*

FERRULE

NUT

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

NOTE: This product is not intended for use in potable water applications.

WARNING: California Proposition 65 Warning! This product contains chemicals known to the State of California to

cause cancer and birth defects or other reproductive harm.

OPERATIONAL LIMITS

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual to draw attention to safety related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD.

DESCRIPTION

The Readout Valve is equipped with an integral EPDM rubber check valve designed to minimize system fluid loss when used with a RP250B Readout Probe to monitor pumps, heat exchangers, valves, etc., handling hot or cold water.

CONNECTION SIZE

Readout Valve: 1/8" NPT and 1/4" NPT

Readout Probe: 7/16" – 20 UNF-2A THD Meter Connection

Working Pressure 300 PSIG

Temperature 250°F

INSTALLATION INSTRUCTIONS

WARNING: Hot fluids and/or flu-

id under pressure. Isolate the prod-

uct in which the readout valve is to be installed with shut off valves, or drain the system. Make sure that all drainage from the system has stopped and that the system temperature has cooled to 100° F or less. Vent off any pressure prior to installation. Failure to follow these instructions could result in serious personal injury or death

and property damage.

1. Apply pipe joint compound to NPT end of readout valve body and install into NPT opening.

2. Tighten cap on top of the readout valve.

3. Repressurize the system.

Page 2

OPERATING INSTRUCTIONS

WARNING: Potential for escape of hot fluids. Use

only B&G companion readout probes to obtain

accurate and safe readout from the readout valve. Failure to follow these instructions could result in serious

personal injury or death and property damage.

WARNING: Hot fluids may escape. When moni-

toring system flow, care must be exercised to

avoid skin or eye contact with liquids that may escape.

Failure to follow these instructions could result in serious personal injury or death and property damage.

1. Connect readout probes to pressure or differential pressure meter with the male thread connection. Make sure

the connection is tight.

WARNING: Hot fluids under pressure. Before

inserting readout probe, slowly loosen the protective cap to vent off any pressure accumulation. The

protective cap must be replaced when readout probe

is removed. Failure to follow these instructions could

result in serious personal injury or death and property

damage.

2. Insert the full length of the probe into each readout

valve and tighten the ferrule nut. It is not uncommon

for a small amount of system fluid to escape during the

insertion.

3. Read pressures according to instructions supplied with

the pressure measuring device.

4. If the measuring device is not to be left permanently

connected to the readout valves, remove the readout

probes from the readout valve and reinstall protective

caps. If left in place, periodically inspect the probes for

leakage and replace if necessary.

SERVICE INSTRUCTIONS

After use, inspect probe for blockage by visual or other

means. Periodically inspect for damage and replace if

necessary.

WARNING: Leakage, corrosion or indications of

damage are signs of an impending serious failure

of the readout valve or readout probe. Periodically

inspect the readout valve or readout probe for signs of

leakage or corrosion. Replace if noted. Failure to follow

these instructions could result in serious personal injury

or death and property damage.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. G97035G April 2012

Loading...

Loading...