Page 1

INSTRUCTION MANUAL

DN0412

REVISION C

Hoffman Specialty

®

Vented Boiler Feed Units

Series HCM,™ HSM

HCM Boiler Feed Units

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on

the unit safety instruction decals to draw attention to safety

related instructions. When used, the safety alert symbol

means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD.

CAUTION

DO NOT RUN PUMP DRY,

SEAL DAMAGE MAY OCCUR.

INSPECT PUMP SEAL

REGULARLY FOR LEAKS,

REPLACE AS REQUIRED.

FOR LUBRICATION

REQUIREMENTS, CONSULT

SERVICE INSTRUCTIONS.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY OR

PROPERTY DAMAGE.

P70644 ALL UNITS

P70644

EXPLOSIBLE

(2) All Units

DN0483 (Small) - DN0484 (Large)

WARNING

DO NOT PRESSURIZE TANK.

ISOLATE TANK DURING LEAK TEST.

DO NOT RESTRICT VENT.

DO NOT PLUG OVERFLOW.

OPEN INLET VALVES SLOWLY.

DO NOT USE AS A FLASH TANK.

FAILURE TO FOLLOW

INSTRUCTIONS COULD RESULT

IN SERIOUS INJURY OR DEATH.

If the decals as noted below are missing or are illegible contact your local B&G representative for a replacement.

1. Electrical connections to be made by qualified Electrician in

accordance with all National, State and Local codes.

2. Motor must have properly sized starter with properly sized

heaters to provide overload and undervoltage protection.

3. If pump, motor or piping are operating at extremely high or

low temperatures, guarding or insulation is required.

4. Operating personnel should be trained in the operation of

boiler feed units.

WARNING

EXPLOSIBLE

ISOLATE TANK

DURING LEAK TEST

(2) All Units

DN0485 (Small)

DN0486 (Large)

TM

SERIES

MODEL

SERIAL

GPM PSI PUMP

CFM IN HG. PUMP

DWGS

POWER V. PH. HZ60

CONTROL V. PH. 1 HZ60

TOTAL LARGEST MOTOR

F.L. AMP F.L. AMP

DN0016

TM

Morton Grove, Illinois 60053

SERIES

MODEL

SERIAL

GPM PSI PUMP

POWER V. PH. HZ60

CONTROL V. PH. 1 HZ60

TOTAL LARGEST MOTOR

F.L. AMP F.L. AMP

DN0019

UNITS LESS PANEL

TM

TM

Morton Grove, Illinois 60053

DN0019

DN0016

UNITS WITH PANEL

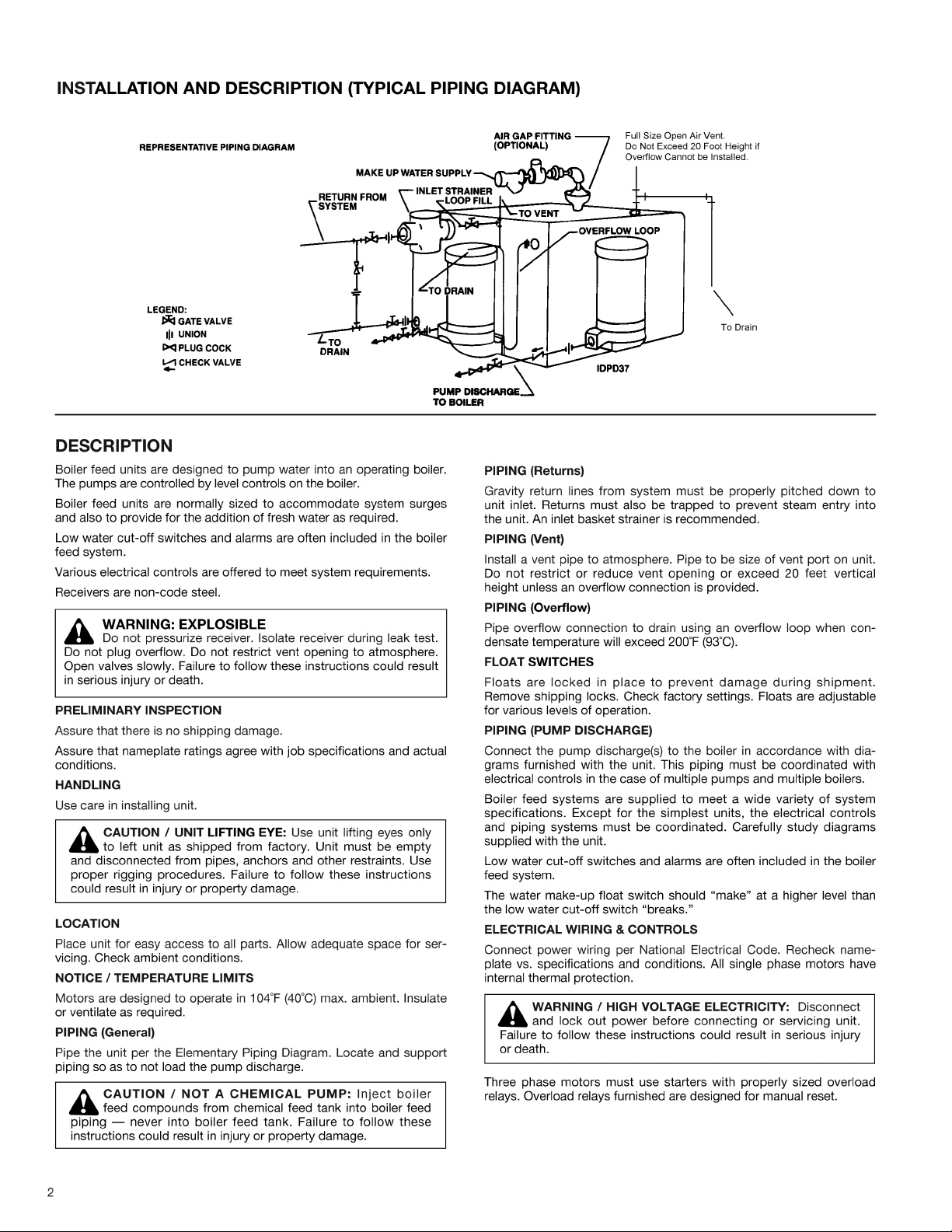

Page 2

Page 3

3

PUTTING THE UNIT INTO SERVICE

1. Assure that the unit is piped in accordance with instructions on

page 2.

2. Isolate tank before performing any system leak test. Do not pressurize the tank as part of the leak test. Failure to do this can result

in serious injury or death.

3. Check floats and alternators for free operation.

4. Check power leads in accordance with wiring diagram enclosed in

control cabinet (when furnished).

5. Install drain plugs.

6. Fill receiver half full of water to prime pump(s) and prevent possible damage to pump seals. Avoid freezing conditions after unit

receiver has been filled.

7. Check for proper rotation of all three phase motors. Rotation must

be clockwise looking down on the motor as indicated by directional arrow on pump casting. If pump runs backwards, interchange two wires (3 phase only).

8. Throttle plug cock in discharge line until pressure at pump (while

pump is discharging) approaches pump rated pressure. Tighten

plug nut to secure adjustment.

9. Connect the water make-up assembly to city water. Use piping at

least as large as the valve piping provided. Provide a manual fill

valve if not included on the unit.

10. Boiler Level Controls — Assure that the controls on and related to

the boiler match the control systems provided on the unit (see the

wiring diagram furnished) (applicable when electrical control panel

is furnished).

11. Check that the pump discharge pressure exceeds the maximum

operating pressure of the boiler.

12. Manually move the make-up water float indicator and assure that

the make-up solenoid admits water.

13. Manually move the low water cut-off float switch indicator to

check for pump shut-off.

14. Remove start-up label (below) from panel (if applicable) after complying with instructions.

15. If possible, observe operation thru several cycles.

OPERATION AND MAINTENANCE

Operators must be familiar with all sections of this manual to under-

stand the operation of the unit.

Hot water, steam and electricity can be hazardous.

Check motor nameplate for any lubrication requirements. Pumps

require no lubrication.

NOTICE / AUTO RESTART

Single phase motors will restart automatically after thermal overload

protector trips.

Overload thermal relays in starters must be reset manually.

A properly installed unit should function unattended for long periods

of time. Periodic checks to assure proper operation are highly recommended. Refer to trouble shooting section when necessary.

A variety of control options are available and are furnished in accordance with user specifications. Refer to wiring diagrams (when furnished) to determine control switch settings.

The inlet strainer (when furnished) is intended to protect the pump and

system. Periodic cleaning should be included in the maintenance

schedule. Check frequently in new systems.

WARNING / HIGH VOLTAGE: Disconnect and lock out

power before connecting or servicing unit. Failure to follow

these instructions could result in serious injury or death.

WARNING / MAINTAIN BOILER SAFETY FEATURES:

When connecting the boiler feed unit to the boiler, assure

that all boiler safety controls (burner cutoff, etc.) are and remain

operational. With certain control arrangements, dedicated boiler

controllers are required for the boiler feed pumps. Failure to follow these instructions could result in serious injury, death or

extensive property damage.

CAUTION: DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks. Replace as required.

Failure to follow these instructions could result in injury or property damage.

CAUTION / DO NOT REVERSE: Reverse operation can

cause extensive damage to pumps. Jog the motor to test

from direction of rotation. Failure to follow these instructions

could result in injury or property damage.

WARNING / HIGH VOLTAGE: Disconnect and lock

out power before connecting or servicing unit. Failure to

follow these instructions could result in serious injury or death.

WARNING / EXPLOSIBLE: The installed boiler feed

unit becomes an integral part of the boiler system. Boiler

operation and maintenance requires specific skills and training

and may require licensing or certification. The boiler feed unit

must be operated and maintained so as not to jeopardize the

boiler operation. Failure to follow these instructions could result

in serious injury, death or extensive property damage.

SAFETY INSTRUCTIONS

SEE COVER OF THIS MANUAL.

CAUTION / SUBSEQUENT DAMAGE: A unit showing

symptoms of possible problems (overflow, noise, leaks,

vibrations, continual operation, etc.) must be corrected immediately. Failure to follow this instruction may result in full liability for

subsequent injury or property damage.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during leak test.

Do not plug overflow. Do not restrict vent opening to atmosphere.

Open valves slowly. Failure to follow these instructions could result

in serious injury or death.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during leak test.

Do not plug overflow. Do not restrict vent opening to atmosphere.

Open valves slowly. Failure to follow these instructions could result

in serious injury or death.

ELECTRICIAN/INSTALLER/OPERATOR

REMOVE AND DESTROY THIS TAG AFTER —

1. ASSURING THAT ALL PUMPS ROTATE CLOCKWISE PER ARROWS CAST ON VOLUTES. (JOG

PUMP MOMENTARILY TO TEST – INTERCHANGE ANY TWO MOTOR POWER WIRES TO

REVERSE 3PH MOTORS.)

2. ASSURING THAT SHIPPING LOCKS HAVE BEEN REMOVED FROM ALL FLOAT SWITCHES.

Page 4

4

TROUBLE SHOOTING PROCEDURES

All units are thoroughly tested at the factory before shipment. They

should operate satisfactorily without further adjustment if properly

installed and provided they have not been damaged by rough handling

in transit. If system or unit performance is not satisfactory, refer to the

following check list.

Pump Will Not Start

1. The power supply has been interrupted, disconnect switch is open

or selector switch is improperly positioned.

2. Incorrect voltage for motor. Check voltage and wiring with motor

characteristics.

3. Incorrect starter coil for power supply.

4. The overload relays and the starter have tripped out and must be

reset. Ambient temperature may be too high.

5. Check pump controls or other controls for proper operation.

6. Wiring to control cabinet is incorrect or connections are loose.

7. The basket strainer is dirty thus restricting flow into the receiver.

Clean periodically.

8. Boiler is full or boiler control switch is defective.

9. The low water cut-off float switch is open due to low water, incorrect adjustment or failure.

Pumps Runs Continuously

1. Pump is running backward. Rotation of three phase motors may be

corrected by interchanging any two of the three wires. Rotation

should be clockwise looking down on motor.

2. Steam traps are blowing through causing condensate to return at

excessive temperatures. This may reduce the capacity of pump

below its rating. Traps should be repaired or replaced.

3. Pump discharge pressure is less than operating pressure of the

boiler.

4. The total required pressure at the pump discharge is greater than

the pressure for which the pump was designed. Check the total

pressure which includes atmospheric pressure, the friction head

and the static head.

5. A valve in the discharge line is closed or throttled too tightly. Check

valve is installed backwards.

6. The impeller eye is clogged.

7. Pump is too small for system.

Boiler Feed Pump is Noisy

1. The pump is working against a lower pressure than designed for.

While pump is discharging, adjust plug cock in discharge line until

pressure at pump approaches pump rated pressure.

2. Excessive condensate temperature. Correct system conditions. However, this applies to certain units only; others are designed to handle

boiling water.

3. Magnetic hum or bearing noise in motor. Consult motor manufacturer's authorized serviced station nearest unit location.

4. Starter chatters. Trouble is caused by low line voltage, poor connections, defective starter coil, or burned contacts.

5. Pump is running backward.

The System is Noisy

1. Banging in the steam mains is usually caused by steam “imploding”

in condensate lying in low points in lines. These problems can be

eliminated by dripping low points, properly supporting the pipe, or

by increasing the pitch of the lines.

2. Improper dripping of the steam mains and risers; where there is a

rise in the steam main, or where it branches off into a riser, a drip

trap must be installed in the drain line.

3. The piping is too small to drain properly.

4. A defective steam trap is holding condensate in steam supply line.

5. Defective check valve permits steam, to vent thru pump into the

boiler feed tank.

6. A priming boiler is discharging water with the steam. Consult boiler

manufacturer.

Excessive Water Overflow From Unit

1. Receiver sized too small to accommodate system surges.

2. Water make-up valve open or float set too high.

3. Water make-up valve leaks.

Morton Grove, Illinois 60053

TM

SERIES HCM

MODEL

SERIAL

GPM PSI PUMP

CFM IN HG. PUMP

DWGS

POWER V. PH. HZ 60

CONTROL V. PH. 1 HZ 60

TOTAL LARGEST MOTOR

F.L. AMP F.L. AMP

DN0016

DEALER SERVICING

If trouble occurs that cannot be rectified, contact your local B&G rep-

resentative. He will need the following information in order to give you

assistance.

1. Complete nameplate data of pump and motor. SEE RATING

NAMEPLATE.

2. Suction and discharge pipe pressure gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pump hook-up and piping.

5. Provide complete information on boiler control switches and any

motorized or solenoid valves in the boiler feed piping.

HOFFMAN SPECIALTY

®

Page 5

5

These close coupled vertical centrifugal pumps are equipped with

mechanical seals. If system has not been properly cleaned prior to

installation of pump, foreign matter such as dirt, pipe scale, core sand,

etc. may clog the impeller and damage the seal. A strainer is recommended in return line to pump.

Pump must not be operated dry. Seals

may be damaged if operated without water present.

1. Close inlet line gate valve and operate pump momentarily to

remove as much liquid as possible from pump. Close discharge

line gate valve.

2. Shut-off and lock-out power.

3. Disconnect wiring to motor.

4. Make sure unit is cool enough that pump can be handled safely.

Open receiver drain to remove remaining liquid.

5. Loosen the motor to pump volute fasteners. Assure that pressure

is relieved per caution note.

6. Remove four capscrews (7) holding pump case to motor and lift

motor and impeller out of pump case.

7. Remove pump/motor assembly and place on work bench.

8. Hold top end of motor shaft with large screwdriver via screwdriver

slot in shaft and back off impeller (counter clockwise) with a rectangular bar or other flat tool inserted between the vanesof the

impeller.

9. Remove the rotating part of the mechanical seal from the end of

the shaft.

10. Remove seal holder (2) with stationary ceramic part of mechanical

seal and cup rubber from the end of the shaft.

11. Remove stationary ceramic part of mechanical seal and cup rubber from recess in seal holder.

12. To install new seal, proceed as follows: Clean recess in seal

holder thoroughly. Orient motor so that conduit opening on motor

is to the left when looking at the motor shaft. Replace seal holder

on the face of the motor maintaining concentricity with motor

face. Place new ceramic part of seal in the cup rubber over motor

shaft and press firmly into recess of seal holder by hand, making

certain both parts bottom evenly. If assembly cannot be bottomed

with fingers place a wooden or cardboard tube over shaft onto

ceramic and push into place. Using a clean, lint-free cloth, wipe

the mating surfaces of the seal clean of any foreign matter.

Moisten the carbon section of the rotating part of the seal and

place onto shaft to seat against the ceramic. Place seal spring

onto shaft.

13. Hold motor shaft as described in #8 and replace the impeller on

the shaft (clockwise rotation) making sure it is tight.

14. Orient motor for pump reassembly with conduit opening to the

left. When mounting the pump case, discharge should be 90˚ to

the right of the conduit opening on motor. Use care to insure tight

gasket fit to prevent water leakage.

15. Replace four capscrews (7). Tighten down capscrews evenly to

avoid damage.

16. Reconnect pump bleed line (where applicable) and motor wiring.

17. Close drain and slowly open inlet valves. See warning.

18. Jog to check motor rotation. See caution.

19. Observe operation thru several cycles.

PUMP SERVICE INSTRUCTIONS FOR 609PF CENTRIFUGAL PUMPS

WARNING / HIGH VOLTAGE: Disconnect and lock out

power before connecting or servicing unit. Failure to follow

these instructions could result in serious injury or death.

CAUTION / HOT SURFACES: Surfaces are hot when

system is in operation. Do not touch hot receiver, let unit

cool before servicing. Failure to follow these instructions could

result in injury or property damage.

CAUTION / PRESSURIZED SYSTEM: Operating system

may contain very hot water under pressure. Close inlet and

open drains before servicing. When servicing, loosen screws and

move components to assure pressure is relieved before remov-

ing screws. Keep drains open during servicing. Failure to follow

these instructions could result in injury or property damage.

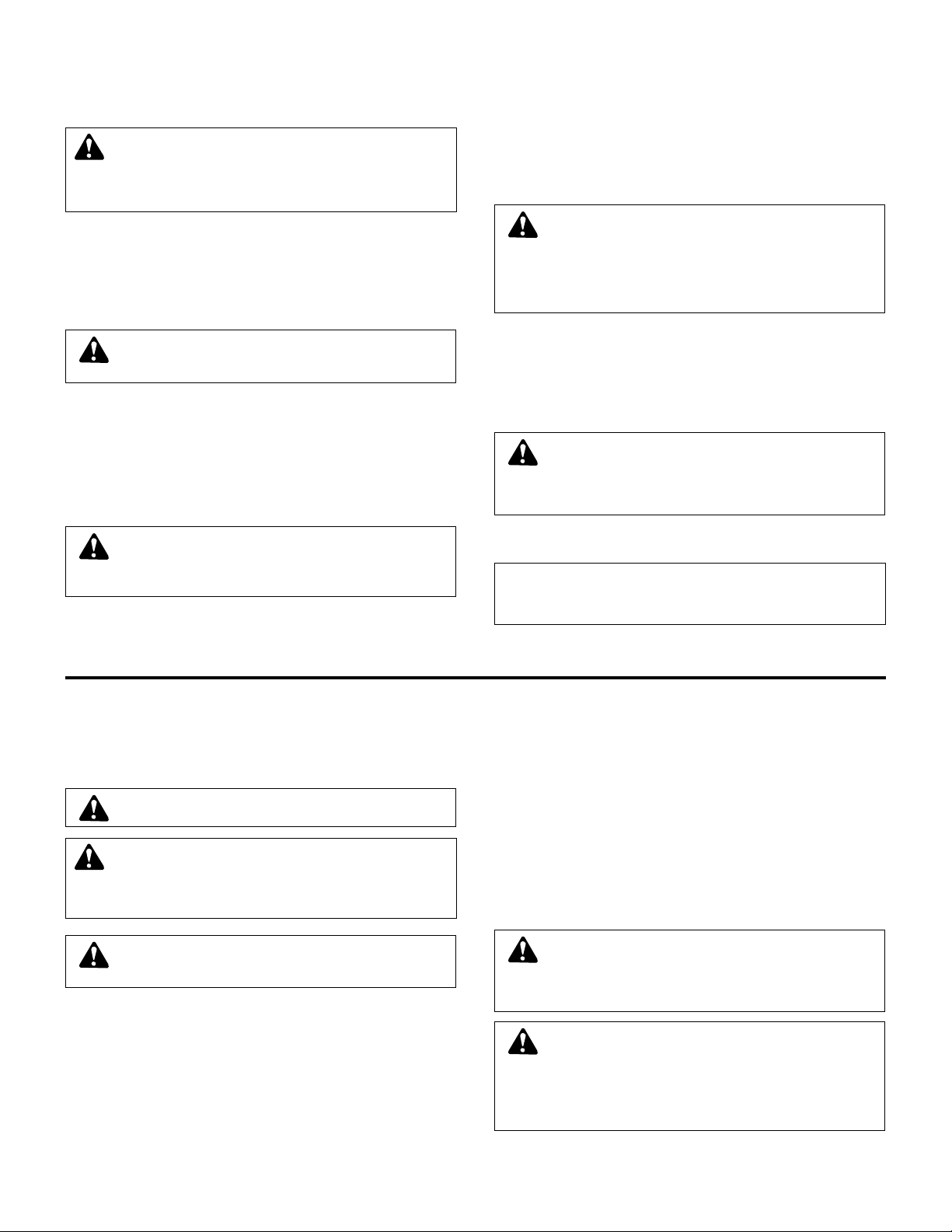

1. Motor

2. Seal Holder

3. Seal

4. Impeller

5. Gasket

6. Case

7. Capscrew

(motor to

volute)

8. Wear Ring

9. Pipe Plug

10. Slinger

1

10

7

3

4

8

6

9

5

2

CAUTION: DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks. Replace as required. Failure

to follow these instructions could result in injury or property

damage.

CAUTION / DO NOT REVERSE: Reverse operation can

cause extensive damage to pumps. Jog the motor to test

for direction of rotation. Failure to follow these instructions could

result in injury or property damage.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during leak test.

Do not plug overflow. Do not restrict vent opening to atmosphere.

Open valves slowly. Failure to follow these instructions could result

in serious injury or death.

Page 6

Close coupled centrifugal pumps are designed for years of trouble

free service. Units have mechanical shaft seals.

1. Close inlet gate valve and operate pump momentarily to remove

as much liquid as possible from pump. Close discharge line gate

valve.

2. Shut-off and lock out power.

3. Make sure unit is cool enough that pump can be handled safely.

Open drain to remove remaining liquid.

4. Carefully remove pump drain plug and bleed line. Wait for complete drainage.

5. Loosen the motor bracket to pump volute capscrews. Assure that

the pressure is relieved per caution note.

6. Complete the removal of the hardware. Remove pump/motor

assembly and place on work bench.

7. Remove self locking stainless steel capscrews and stainless steel

washer (or self locking brass cap nut and washer) that secure the

impeller in place.

8. To remove impeller from motor shaft proceed as follows:

(1) Keyed Shafts. Remove impeller with gear puller or other

means which will not damage impeller or bend motor shaft.

(2) Threaded Shafts. Hold end of motor shaft opposite pump with

large screwdriver or other suitable tool and back impeller off

with a rectangular bar or other flat tool inserted between the

vanes of the impeller.

9. Remove rotating part of seal from shaft, being careful not break

carbon face.

10. Remove capscrews holding motor bracket to motor and remove

bracket.

11. Remove stationary part of seal assembly, being careful not to chip

or break ceramic seal.

12. To install seal proceed as follows:

(1) Clean recess in bracket thoroughly. Coat recess and “rubber”

portion of seat with soap solution. Press seat into recess firmly

by hand making certain both parts bottom evenly. If seal cannot be bottomed with fingers place cardboard shipping disc

on ceramic and force into place with flat tool.

(2) Carefully place bracket in position on motor shaft without

displacing ceramic seat and secure bracket to motor with

capscrews.

(3) Place motor vertically with pump end up. Do not attempt

assembly of seal and impeller with shaft horizontal.

(4) The “carbon” of rotating part of seal should not be loose. If it

is, hold in place with grease, Using clean, lint free cloth, wipe

mating surfaces perfectly clean. Soap shaft and push seal

onto shaft so that carbon will contact ceramic seal. If spacer is

required, use grease to cause spacer to adhere to bottom of

seal after seal has been put on shaft, Be sure spacer is on

larger diameter of shaft so that will not catch between shoulder and impeller.

13. Replace impeller on shaft. Replace stainless steel washer and

secure impeller with capscrew or cap nut.

14. Place new gasket on pump volute and reassemble motor and

pump subassembly on pump volute.

15. Reconnect pump bleed line and motor wiring.

16. Close drain and slowly open inlet valves. See warning.

17. Jog to check motor rotation. See caution.

18. Observe operation thru several cycles.

6

PUMP SERVICE INSTRUCTIONS FOR CENTRIFUGAL PUMPS (EXCEPT ‘B’ OR 609)

Vertical mounting puts motor above floor direct and water

CAUTION: PRESSURIZED SYSTEM

Operating system may contain very hot water. Close inlet

and open drains before servicing. When servicing,

loosen screws

and move components to assure pressure is relieved before

removing screws. Keep drains open during servicing. Failure to fol-

low these instructions could result in injury or death.

CAUTION: HOT SURFACE

Surfaces are hot when system is in operation. Do not touch

hot receiver, let unit cool before servicing. Failure to follow these

instructions could result in serious injury or death.

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting servicing

unit. Failure to follow these instructions could result in serious

injury or death.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during leak test.

Do not plug overflow. Do not restrict vent opening to atmosphere.

Open valves slowly. Failure to follow these instructions could result

in serious injury or death.

CAUTION: DO NOT REVERSE

Reverse operation can cause extensive damage to pumps.

Jog the motor to test for direction of rotation. Failure to follow

these instructions could result in injury or property damage.

CAUTION: DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks. Replace as required. Failure

to follow these instructions could result in injury or property

damage.

VOLUTE

IMPELLER

THREADED

IMPELLER

WATER

SLINGER

MECHANICAL

SEAL

MOTOR BRACKET

WEAR RING

VIEW OF

2DPF03

Page 7

7

NOTES:

Page 8

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,700 people unied in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efciently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.bellgossett.com

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. DN0412C April 2013

Loading...

Loading...