Page 1

INSTRUCTION MANUAL

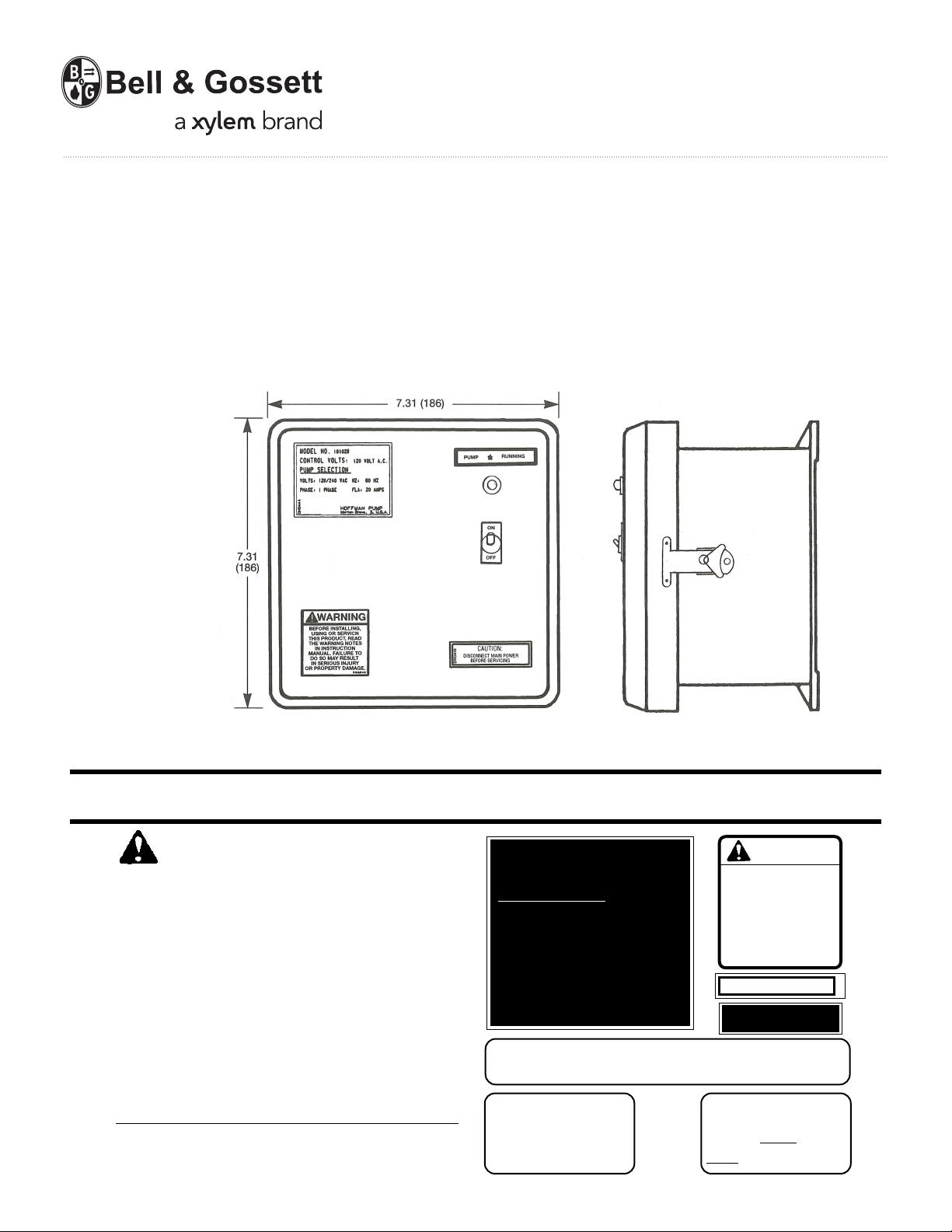

63/4

(171)

NEMA 4 ENCLOSURE

6x6x4.03

(152x152x110)

Dimensions in Inches (mm)

4 (102)

5

/

16 (8) Mounting Hole

(4 Places)

DN0178

REVISION B

Hoffman Specialty

®

Single Phase Simplex

Control Panel

B&G

Dimensions in Inches (mm)

INSTALLER:

PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on

the unit safety instruction decals to draw attention to safety

related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THE INSTRUCTIONS MAY RESULT IN

A SAFETY HAZARD.

If the decals as noted to the right are missing or are illegible contact your local Hoffman Pump representative for a

replacement.

1. Electrical connections to be made by a qualified Electrician

in accordance with National, State or Local codes.

2. Motor must be sized in accordance with contactor rating

and have internal overload and undervoltage protection.

MODEL NO. 161029

CONTROL VOLTS: 120 VOLT A.C.

PUMP SELECTION

VOLTS: 120/240 VAC HZ: 60 HZ

PHASE: 1 PHASE FLA: 20 AMPS

Bell & Gossett

M Illinois 60053orton Grove,

DN0444

USE COPPER WIRE ONLY

6 0°C INSULATION R ATING F OR A MPACITIES LESS T H A N 1 0 0 A

S80379

7 5°C INSULATION RATI NG FO R AMPACITIES GR EA TER T H A N 1 0 0 A

DNO442

WARNING

BEFORE INSTALLING,

USING OR SERVICING

THIS PRODUCT, READ

THE WARNING NOTES

AND INSTRUCTIONS

IN INSTRUCTION

MANUAL. FAILURE TO

DO SO MAY RESULT

IN SERIOUS INJURY

OR PROPERTY DAMAGE.

PUMP ✽ RUNNING

CAUTION:

DISCONNECT MAIN POWER

DN0445

BEFORE SERVICING

DNO443

CAUTION

G R D

US E TYPE FUSE

AMP

V56846

DN0430

Page 2

DESCRIPTION

The Hoffman Single Phase Simplex Electrical Control

Panel is designed to provide a reliable means of controlling

one 120 volt or 230 volt (3 wire) single phase pump installation that does not exceed a FLA of 20 amps

.

OPERATION AND MAINTENANCE

Operators must be familiar with all sections of this manual

to understand the operation of the unit.

Hot Water, steam and electricity can be hazardous.

PRELIMINARY INSPECTION

Assure that there is no shipping damage.

Assure that the nameplate ratings agree with the job spec-

ifications and actual conditions.

Assure all connections are secure and made per NEC

requirements.

HANDLING

Use care in installing unit.

LOCATION

Place unit for easy access.

Allow adequate space for servicing. Check ambient

conditions.

Notice: Insulation temperature limits. Ventilate as required.

ELECTRICAL WIRING AND CONTROLS

Connect power wiring per NEC. Recheck nameplate vs.

specifications and conditions.

WARNING: HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

PUTTING THE UNIT INTO SERVICE

Assure that the main power has been disconnected.

SAFETY INSTRUCTIONS

See Cover of this Manual.

WARNING: HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

NOTICE / AUTO RESTART

Single phase motors will restart automatically after thermal

overload protector trips.

A properly installed unit should function unattended for

long periods of time. Periodic checks to assure proper

operation are highly recommended. Refer to trouble shooting section when necessary.

Refer to wiring diagrams to determine control switch

settings.

CAUTION: SUBSEQUENT DAMAGE

A unit showing symptoms of possible problems must

be corrected immediately. Failure to follow these instruc-

tions could result in full liability for subsequent injury or

property damage.

UNIT WIRING

WARNING: HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

WARNING: HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

Wire unit per National Electrical Code. See representative

wiring diagrams.

Observe operation of unit through several cycles.

Select the required configuration for the control panel to fit

the application. CAUTION: Verify that the incoming voltage

and the motor voltage correspond to the configuration of

the panel. Rewire jumper terminals if necessary.

Disconnect all power.

Identify incoming power and motor voltage configuration

from the Selection Chart below.

SELECTION CHART

Incoming Motor Connect Power Connect Pump Motor Jumper Connect Float Control

Voltage Voltage to Terminals to Terminals Terminals to Terminals

230/1/60 230/1/60 N, L2, L1 T1, T2 — L1, 2

115/1/60 115/1/60 L2, L1 T1, T2 N, L2 L1, 2

2

Page 3

ELEMENTARY DIAGRAM

SINGLE PHASE SIMPLEX CONTROL PANEL

WIRING / CONNECTIONS

WARNING: HIGH VOLTAGE ELECTRICITY

Panel remains fully energized at all times, unless

incoming power is disconnected. Disconnect and lock out

power before connecting or servicing unit. Failure to follow

these instructions could result in serious injury or death.

Wire incoming power to the terminals identified in the

Selection Chart on page 2.

Connect electrical ground wire to ground lug.

Wire the float switch.

Wire pump motor to the terminals identified in the

Selection Chart. Connect all necessary ground wires to the

ground lug. Connect ground lug to a good earth ground.

Check pump motor before installation for proper rotation.

Re-wire motor is necessary. Re-connect incoming power.

TYPICAL SEQUENCE OF OPERATION

1. When the float control “makes,” incoming electrical power

is supplied to the pump “ON-OFF” selector switch.

2. With the selector switch in the “ON” position the contactor

coil and the “Pump Run” pilot light will be energized.

3. When the contactor coil is energized, electrical power is

fed to the pump motor.

3

Page 4

TROUBLE SHOOTING

SYMPTOM PROBLEM SOLUTION

Pump will not start Incoming power not connected. Connect incoming Power.

Float control not “Made”. Operate system to “Make” Float Control.

Pump “ON-OFF” Switch not ON. Turn ON switch.

Fuse Blown. Replace fuse per label in enclosure.

Pump runs but light doesn’t light Blown pilot light. Replace pilot light.

DEALER SERVICING

If trouble occurs that cannot be rectified, contact your local

B&G representative. He will need the following information

in order to give you assistance.

1. Complete nameplate data of panel.

2. Voltage, phase, and FLA of motor.

3. Actual ampere draw of motor.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. DN0178B July 2013

Loading...

Loading...