Page 1

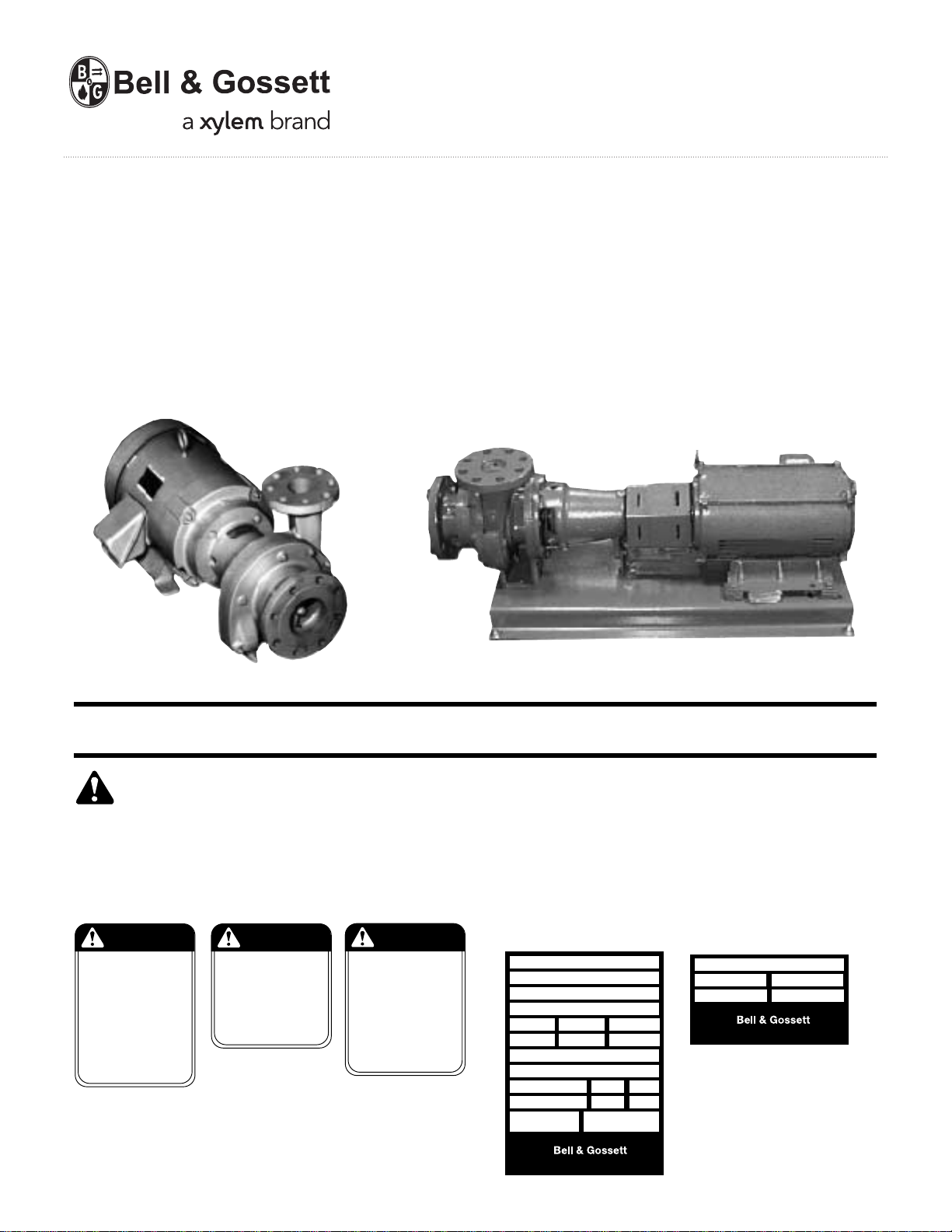

Domestic® Pump

2’ NPSH Horizontal Pumps

INSTRUCTION MANUAL

DN0141

REVISION D

Series HB17,™ HB35,™ DB,™ DB-F

™

SERIES DB

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SERIES DBF

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on

the unit safety instruction decals to draw attention to safety

related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN A SAFETY HAZARD.

WARNING

ROTATING COMPONENTS

DISCONNECT AND LOCK OUT

POWER BEFORE SERVICING.

DO NOT OPERATE WITHOUT

ALL GUARDS IN PLACE.

CONSULT INSTALLATION

AND SERVICE INSTRUCTION

SHEET BEFORE OPERATING

OR SERVICING.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY

OR DEATH.

P70642

WARNING

EYEBOLTS OR LIFTING

LUGS IF PROVIDED ARE

FOR LIFTING ONLY THE

COMPONENTS TO WHICH

THEY ARE ATTACHED.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY

OR DEATH.

P70643

CAUTION

DO NOT RUN PUMP DRY,

SEAL DAMAGE MAY OCCUR.

INSPECT PUMP SEAL

REGULARLY FOR LEAKS,

REPLACE AS REQUIRED.

FOR LUBRICATION

REQUIREMENTS, CONSULT

SERVICE INSTRUCTIONS.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY OR

PROPERTY DAMAGE.

P70644

If the decals as noted below are missing or are illegible contact

your local B&G representative for a replacement.

1. Electrical connections to be made by qualified Electrician in

accordance with all National, State and Local codes.

2. Motor must have properly sized starter with properly sized

heaters to provide overload and undervoltage protection.

3. If pump, motor or piping are operating at extremely high or

low temperatures, guarding or insulation is required.

4. Operating personnel should be trained in the operation of

pumps and associated systems (condensate, boiler feed, etc.).

TM

SERIES

MODEL

SERIAL

GPM PSI PUMP

CFM IN HG. PUMP

DWGS

POWER V. PH. HZ60

CONTROL V. PH. 1 HZ60

TOTAL LARGEST MOTOR

F.L. AMP F.L. AMP

DN0016

TM

Morton Grove, Illinois 60053

DOMESTIC® PUMPS

SERIES

SERIAL

DN0024

TM

GPM

PSI

Morton Grove, Illinois 60053

®

Page 2

DESCRIPTION

FOUNDATION BOLT

PIPE SLEEVE

WASHER

BUILT-UP

CONCRETE FOUNDATION

These horizontal end suction pumps feature a flow inducing

propeller and one or two impellers in series. These pumps

are supplied with or without mounting base (except for the

DB-F which requires a mounting base). All pumps are constructed with mechanical seals intended for high temperature

operations.

All models are bronze fitted with replaceable bronze wear rings.

APPLICATION

The 2' NPSHR rating of these pumps makes them uniquely

suited to pumping hot water. With 2 feet of static suction head,

the pumps will pump boiling water. Typical applications are on

condensate return and boiler feed systems.

These pumps are also well suited for general pumping service

of benign liquids.

WARNING: EXPLOSIBLE

Maximum suction pressure is 35 psi unless otherwise

specified by manufacturer. Do not exceed this pressure.

Failure to follow these instructions could result in serious

injury or death.

PRELIMINARY INSPECTION

Assure that there is no shipping damage.

Assure that nameplate ratings agree with job specifications and

actual conditions.

LOCATION

The best pump location for sound and vibration absorption

is on a concrete floor with sub soil underneath. If the pump

location is overhead, special precautions should be undertaken to reduce possible sound transmission, consult a sound

specialist.

If the pump is not installed on a closed system, it should be

placed as near as possible to the source of the liquid supply,

and located to permit installation with the fewest number of

bends or elbows in the suction pipe.

The installation must be evaluated to determine that the Net

Positive Suction Head Available (NPSHA) meets or exceeds the

Net Positive Suction Head Required (NPSHR) as stated by the

pump performance curve.

INSTALLATION

This pump is built to provide years of service if installed properly and attached to a suitable foundation. A base of concrete

weighing 21/2 times the weight of the pump is recommended.

(Check the shipping ticket for pump weight.)

If possible, tie the concrete pad in with the finished floor. Retain

access to pump mounting screws of DB-F pumps.

CAUTION: NOT A CHEMICAL PUMP

Inject boiler feed compounds from chemical feed tank

into boiler feed piping – never into pump suction. Failure to

follow these instructions could result in injury or property

damage.

PUMP LOCATION

Locate the pump so there is sufficient room for inspection,

maintenance and service. If the use of a hoist or tackle is

needed, allow ample head room.

WARNING: Eyebolts or lifting lugs if provided are for

lifting only the components to which they are

attached. If lifting of the entire pump is required, do so with

slings placed under the pump assembly as shown. Failure

to follow these instructions could result in injury or death.

To facilitate easy servicing, some type of expansion fitting

should be utilized. The female portion should be inserted into a

suitable hole in the floor so that its top surface is flush with the

floor surface. Thus, when the hold-down bolts are removed,

the motor can be removed by sliding it back from the pump.

(See below.)

2

Page 3

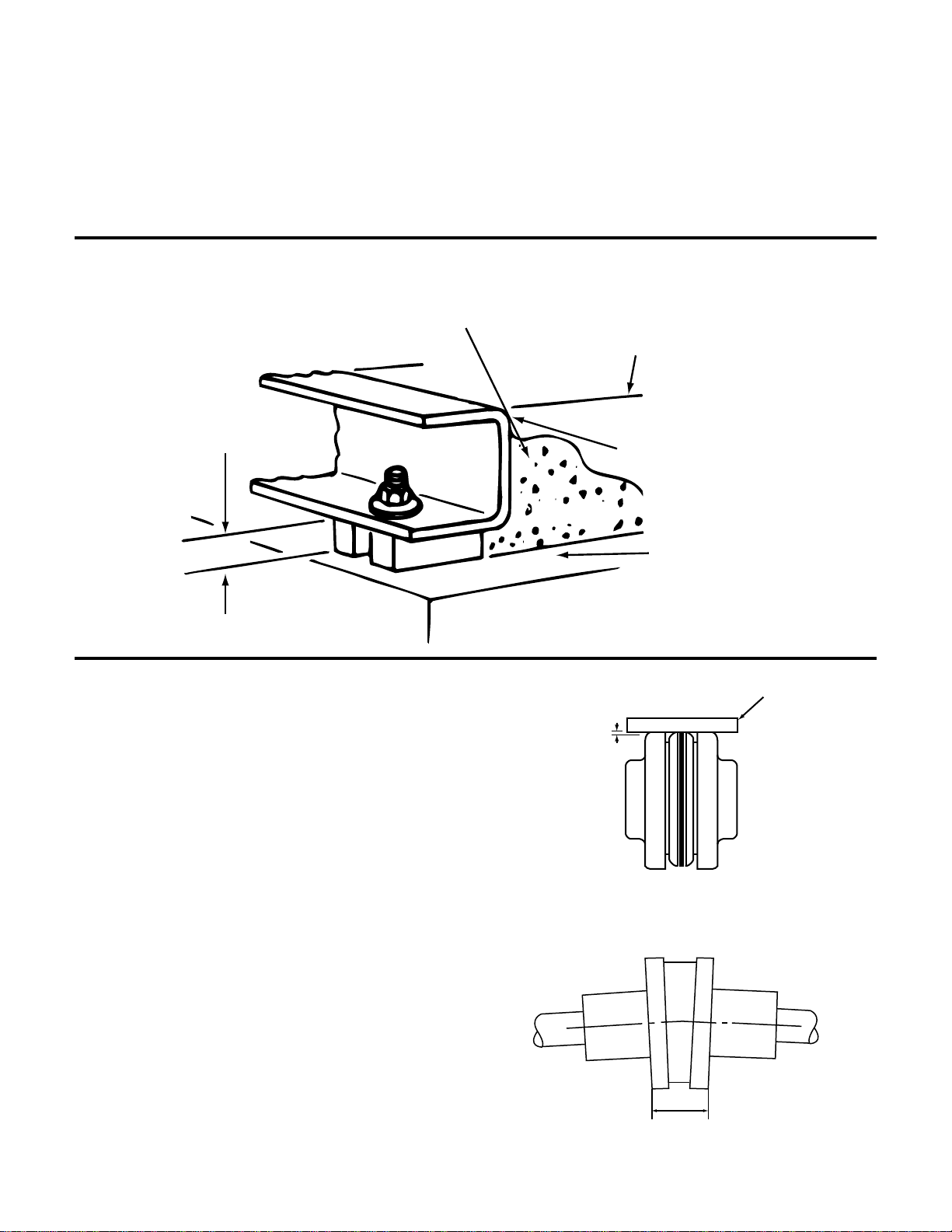

LEVELING

NOTE:

TO KEEP SHIMS IN PLACE

ALLOW NON-SHRINKING

GROUT TO FLOW AROUND

HOLD DOWN LUGS

ALLOW 1" FOR SHIMS.

PLACE ON BOTH SIDES

OF ANCHOR BOLTS

APPROX.

1" GAP

GROUT ONLY TO

TOP OF BASE RAIL

PUMP BASE RAIL

CONCRETE FOUNDATION

GROUT

PUMP BASE

STRAIGHT EDGE

.015 MAX

DISTANCES ACROSS

COUPLER FLANGES

SHOULD BE EQUAL

(CHECK 4 PLACES)

Place the pump on its concrete foundation supporting it with

steel wedges or shims totaling 1" in thickness. These wedges

or shims should be put on both sides of each anchor-bolt to

provide a means of leveling the base. (See below.)

IT IS VERY IMPORTANT THAT THE PUMP-BASE BE SET

LEVEL TO AVOID ANY MECHANICAL DIFFICULTIES WITH

THE MOTOR OR PUMP. THIS PUMP WAS PROPERLY

ALIGNED (IF FURNISHED WITH A MOTOR) AT THE FACTORY.

LEVELING OF PUMP BASE

ON CONCRETE FOUNDATION

HOWEVER, SINCE ALL PUMP BASES ARE FLEXIBLE THEY

MAY SPRING AND TWIST DURING SHIPMENT. DON’T PIPE

THE PUMP UNTIL IT IS REALIGNED. AFTER PIPING IS

COMPLETED AND AFTER THE PUMP IS GROUTED IN AND

BOLTED-DOWN, ALIGN IT AGAIN. IT MAY BE NECESSARY

TO RE-ADJUST THE ALIGNMENT FROM TIME TO TIME

WHILE THE UNIT AND FOUNDATION ARE NEW.

FLEXIBLE COUPLING ALIGNMENT

(SERIES DB-F PUMPS ONLY)

Check parallel alignment by placing a straight edge across the

two coupling flanges and measuring the maximum offset at

various points around the periphery of the coupling. DO NOT

rotate the coupling. If the maximum offset exceeds the .015,

realign the coupling.

Check angular alignment with a micrometer or caliper. Measure

from the outside of one flange to the outside of the other at

intervals around the periphery of the coupling. DO NOT rotate

the coupling. The difference between the maximum and minimum must not exceed .056".

If a correction is necessary, be sure to recheck the parallel

alignment.

(Note: For maximum life, keep misalignment values as near to

zero as possible.)

If the coupling employs the two-piece sleeve with the wire ring,

force the ring into its groove in the center of the sleeve. It

may be necessary to pry the ring into position with a blunt

screwdriver.

All alignment should be done by moving or shimming the motor

only. Adjustments in one direction may alter alignment in

another. Therefore, check alignment in all directions after a correction is made.

If couplings are to operate at speeds higher than 1800 RPM,

greater accuracy of shaft alignment will be required. A dial indicator should then be used.

CHECK PARALLEL ALIGNMENT

ANGULAR ALIGNMENT CHECK

3

Page 4

GROUTING

After the pump has been leveled, securely bolted to the floor,

and properly aligned, a good grade of non-shrinking grout

ELECTRICAL WIRING & CONTROLS

Connect power wiring per NEC. Recheck nameplate vs. specifications and conditions. All single phase motors have internal

thermal protection.

WARNING: HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

should be poured inside the pump base. To hold wedges or

shims in place, allow the grout to flow around them.

Three phase motors must use starters with properly sized overload relays. Overload relays furnished are designed for manual

reset.

ROTATION

Pump rotation is clockwise when viewed from back of the

motor. An arrow is also located on the motor bracket or motor

to show the direction of rotation.

PIPING

Always install a section of straight pipe between the suction

side of the pump and first elbow. This reduces turbulence of

the suction by straightening out the flow of liquid before it

enters the pump. The length should be equal to five times the

diameter of the pipe. A Bell & Gossett suction diffuser can be

used if there is not adequate room for a straight suction line.

Be sure to eliminate any pipe-strain on the pump. Support the

suction and discharge pipes independently by use of pipe

hangers near the pump. Line up the vertical and horizontal

piping so that the bolt-holes in the pump flanges match the

bolt-holes in the pipe flanges. DO NOT ATTEMPT TO SPRING

THE SUCTION OR DISCHARGE LINES INTO POSITION.

Bearing wear will result if suction or discharge lines are forced

into position. The code for Pressure Piping (A.S.A.B. 31.1) lists

many types of supports available for various applications.

PUTTING THE UNIT INTO SERVICE

1. Assure that the unit is piped in accordance with instructions.

WARNING: EXPLOSIBLE

Maximum suction pressure is 35 psi unless otherwise

specified by manufacturer. Do not exceed this pressure.

Failure to follow these instructions could result in serious

injury or death.

2. Validate that the connected system is ready to operate.

3. Connect electrical supply per National Electrical Code.

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

4. Install drain plugs.

5. Prime pump and bleed air from system. Avoid freezing

conditions after pump has been primed.

6. Check for proper rotation of all three phase motors.

Rotation must be clockwise looking down on the motor as

indicated by directional arrow on pump casting. If pump

runs backwards, interchange two wires (3 phase only).

4

As a rule, ordinary wire or band hangers are not adequate to

maintain alignment. It is very important to provide a strong,

rigid support for the suction and discharge lines.

Where considerable temperature changes are anticipated,

fittings for absorbing expansion should be installed in the system in such a way as to avoid strain on the pump.

A check valve and an isolation/throttling valve should be

installed at the discharge of the pump.

NOTES:

1. When installing the pump, suction and discharge gauge

ports should be installed in the pipeline.

2. The pipeline should have isolation valves around the pump

and have a drain valve in the suction pipe.

3. When installing the suction and discharge connections to a

threaded pump housing the use of PTFE tape sealer or a

high quality thread sealant is recommended.

CAUTION: DO NOT REVERSE

Reverse operation can cause extensive damage to

pumps. Jog the motor to test for direction of rotation. Failure

to follow these instructions could result in serious injury or

property damage.

7. Throttle plug cock in discharge line until pressure at pump

(while pump is discharging) approaches pump rated pressure. Secure adjustment.

CAUTION: DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks. Replace as required.

Failure to follow these instructions could result in injury or

property damage.

8. Bleed all air from the volute. Where appropriate, use an

air bleed line to a tank ahead of the pump or to the pump

suction.

9. If possible, observe operation thru several cycles.

Page 5

OPERATION AND MAINTENANCE

Retaining

Ring

1.062

Operators must be familiar with all sections of this manual to

understand the operation of the unit.

Hot water, steam and electricity can be hazardous.

SAFETY INSTRUCTIONS

SEE COVER OF THIS MANUAL

WARNING: EXPLOSIBLE

Maximum suction pressure is 35 psi unless otherwise

specified by manufacturer. Do not exceed this pressure.

Failure to follow these instructions could result in serious

injury or death.

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

Check motor nameplate for any lubrication requirements.

NOTICE/AUTO RESTART

Single phase motors will restart automatically after thermal

overload protector trips.

Overload thermal relays in starters must be reset manually.

LUBRICATION

While pump is running regrease pump bearing with #2

lithium base petroleum grease about every 2500 hours of operation or every 6 months whichever occurs first.

Lubricate motor per motor manufacturer’s instructions.

GENERAL INSTRUCTIONS

1. Keep this pump and motor properly lubricated.

2. When there is a danger of freezing, drain the pump.

3. Inspect pump regularly for leaky seals or gaskets and

loose or damaged components. Replace or repair as

required.

SEAL REVISION

As of June 1997, DB and DB-F pumps use a Type 2 seal. This

seal is interchangeable with pumps that pre-date this cut-off

date. Regardless of date of manufacture of the pump, when

installing the Type 2 seal, the retaining ring is oriented with the

large OD facing the seal. (See illustration.)

CAUTION: SUBSEQUENT DAMAGE

A unit showing symptoms of possible problems (overflow, noise, leaks, vibrations, continual operation, etc.) must

be corrected immediately. Failure to follow this instruction

may result in full liability for subsequent injury or property

damage.

Specific maintenance and service instructions follow.

PUMP SERVICE INSTRUCTIONS FOR SERIES DB AND DB-F PUMP ENDS

1. Close pump isolation valve or system return line valve.

Operate pump momentarily to discharge as much water as

possible. Close pump discharge valve.

CAUTION: HOT SURFACES

Surfaces may be hot when system is in operation. Do

not tough exposed components, let unit cool before servicing. Failure to follow these instructions could result in serious injury or death.

2. Shut-off and lock out power.

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

4. Carefully remove pump drain plug and air relief tube. Wait

for complete drainage.

5. Loosen both the discharge connection and the suction

housing to pump volute fasteners. Assure that pressure is

relieved per caution note.

CAUTION: PRESSURIZED SYSTEM

Operating system may contain very hot water under

pressure. Close inlet and open drains before servicing.

When servicing, loosen screws and move components to

assure pressure is relieved before removing screws. Keep

drains open during servicing. Failure to follow these instructions could result in injury or property damage.

3. Make sure unit is cool enough that pump can be handled

safely. Open drain to remove remaining liquid.

5

Page 6

PUMP SERVICE INSTRUCTIONS FOR SERIES DB AND DB-F PUMP ENDS cont.’d

SEAL COLLAR

2ND STAGE VOLUTE

MECHANICAL

SEAL COLLAR

MECHANICAL SEAL

2ND STAGE IMPELLER

DIAPHRAM

W/ WEAR RING

PIN

SHAFT EXTENSION

WASHER

SET SCREW

FIRST STAGE VOLUTE

FIRST STAGE

IMPELLER

SUCTION

HOUSING

PIN

PROPELLER

DIFFUSER

15

16

6. Remove discharge connection and suction connection.

Unbolt motor and or pump from base. Place assembly on

workbench.

7. Remove suction housing and then axial flow impeller,

shaft, and straightening vanes in the following manner:

Remove axial flow impeller set screws. Remove the axial

flow impeller, remove the straightening vanes, and

unscrew the shaft extension.

8. Remove cap screws holding pump volute and motor

bracket together. Remove volute by lifting straight away

from motor and bracket assembly.

9. Remove first centrifugal impeller by inserting two pry bars

between motor bracket and impeller on opposite sides of

impeller, being careful to pry equally, and ONLY WHERE

THE SHROUD OR THE IMPELLER IS SUPPORTED BY A

VANE. Lift off the diaphragm plate and wearing rings as an

assembly. Remove second centrifugal impeller, using a

puller. The machined groove on the impeller hub is for this

purpose.

10. To install new seal proceed as follows:

(1) Thoroughly clean recess in head. Moisten or soap the

“rubber” portion of seal. Press rubber and ceramic into

recess firmly by hand making certain both parts bottom

evenly. If seat cannot be bottomed with fingers place

the cardboard shipping disc on seat and force into

place with flat tool. Wipe clean with soft clean cloth to

remove dirt or excess soap.

(2) Carefully place head into position on motor shaft with-

out displacing ceramic seat, and secure bracket to

motor with cap screws.

(3) Place motor vertically with pump end up. Do not

attempt reassembly of pump with the shaft horizontal.

(4) The “carbon” of the rotating part of the seal should not

be loose. If it is, hold in place with grease. Using a

clean, lint-free cloth, wipe mating surfaces, perfectly

clean. Soap the shaft and push seal onto shaft so that

it touches the carbide seat.

(5) Replace seal collar as close as possible to original

position, and tighten the set screw.

11. Replace second impeller on shaft, being careful to bottom

it on shaft shoulder. Replace diaphragm plate with its

wearing rings, and replace first impeller. Reassemble

pump volute to bracket.

12. Reassemble propeller. Tighten thoroughly.

13. Reassemble straightening vanes, being careful to locate

properly on pin. Reassemble axial flow impeller and

tighten the set screws holding it to the propeller stem.

Reassemble suction housing using new gasket.

14. Reposition the pump in place, and bolt down. Reconnect

discharge and suction.

15. Reconnect air relief tubing and motor wiring.

NOTE: See page 4 for additional DB-F instructions

(Coupler Alignment).

CAUTION: DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks. Replace as required.

Failure to follow these instructions could result in injury or

property damage.

16. Close drain and slowly open inlet gate valves.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Do not plug overflow. Pipe

vent opening to atmosphere. Do not restrict. Open valves

slowly. Failure to follow these instructions could result in

serious injury or death.

17. Three phase motors should be started momentarily to

check rotation. If pump runs backward, interchange any

two motor leads. (Any electrical service should be performed by a qualified electrician).

CAUTION: DO NOT REVERSE

Reverse operation can cause extensive damage to

pumps. Jog the motor to test for direction of rotation. Failure

to follow these instructions could result in serious injury or

property damage.

18. Observe operation thru several cycles.

2DPB03

SERIES DB CROSS SECTION

PUMP SERVICE INSTRUCTIONS FOR SERIES HB17 AND HB35 PUMPS

1. Close pump isolation valve or system return line valve.

not tough exposed components, let unit cool before servicing. Failure to follow these instructions could result in serious injury or death.

6

Operate pump momentarily to discharge as much water as

possible. Close pump discharge valve.

CAUTION: HOT SURFACES

Surfaces may be hot when system is in operation. Do

2. Shut-off and lock out power.

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

3. Make sure unit is cool enough that pump can be handled

safely. Open drain to remove remaining liquid.

Page 7

PUMP SERVICE INSTRUCTIONS FOR SERIES HB17 AND HB35 PUMPS cont.’d

MECHANICAL

SEAL

M & R

BRACKET

VOLUTE W/

WEAR RING

IMPELLER

PROPELLER STEM

PIN

WASHER

SET SCREW

PROPELLER CAP

SET SCREW

PROPELLER

SUCTION HOUSING

DIFFUSER

ROTATED FOR CLARITY

DISCHARGE FLANGE

LOCKING CAPSCREW

PROPELLER SUCTION

CASTING

PROPELLER CAP

PROPELLER

DIFFUSER

SHAFT EXTENSION

4. Carefully remove pump drain plug and air relief tube. Wait

for complete drainage.

5. Loosen both the discharge connection and the suction

housing to pump volute fasteners. Assure that pressure is

relieved per caution note.

CAUTION: PRESSURIZED SYSTEM

Operating system may contain very hot water under

pressure. Close inlet and open drains before servicing.

When servicing, loosen screws and move components to

assure pressure is relieved before removing screws. Keep

drains open during servicing. Failure to follow these instructions could result in injury or property damage.

6. Complete the removal of the above hardware. Remove

pump/motor assembly and place on work bench.

7a. Remove the suction housing capscrews and separate the

pump/motor assembly from the suction housing. Note, the

diffuser should separate from the suction housing to allow

the pump/motor assembly to be removed.

7b. Remove propeller, propeller stem and diffuser from the

assembly as follows: Keyed Motor Shafts (5HP and larger).

Remove propeller set screws. Remove propeller, remove

diffuser, and unscrew the propeller stem.

8. Remove capscrews holding motor bracket and pump

volute together. Remove motor and bracket assembly

from volute by lifting straight away from volute.

9. To remove impeller from the motor shaft proceed as

follows: Keyed Shafts. Remove impeller with gear puller or

other means which will not damage impeller or bend motor

shaft.

10. Remove rotating part of seal from shaft, being careful not

to break carbon face.

11. Remove capscrews holding motor bracket to motor and

remove bracket.

12. Remove stationary part of seal assembly, being careful not

to chip or break ceramic seal.

13. To install seal proceed as follows:

(1) Clean recess in bracket thoroughly. Coat recess and

“rubber” portion of seat with soap solution. Press seat

into recess firmly by hand making certain both parts

bottom evenly. If seat cannot be bottomed with fingers

place cardboard shipping disc on ceramic and force

into place with flat tool.

(2) Carefully place bracket into position on motor shaft

without displacing ceramic seat and secure bracket to

motor with capscrews.

(3) Place motor vertically with pump end up. Do

not attempt assembly of seal and impeller with shaft

horizontal.

(4) The “carbon” of rotating part of seal should not be loose.

14. Place impeller on shaft. Make sure impeller is seated.

15. Reassemble volute to bracket.

If it is, hold in place with grease. Using clean, lint free

cloth, wipe mating surfaces perfectly clean. Soap shaft

and push seal onto shaft so that carbon will contact

ceramic seal. If spacer is required, use grease to cause

spacer to adhere to bottom of seal after seal has been

put on shaft. Be sure spacer is on larger diameter of shaft

so that it will not catch between shoulder and impeller.

SERIES HB17 CROSS SECTION

SERIES HB-35 CROSS SECTION

16. Install stem over drive pin in impeller eye. Tighten lock nut.

17. Set stem to .004 TIR.

18. Install diffuser.

19. Install propeller and tighten set screws.

19a.Install propeller cap and tighten set screws.

20. Using new gasket and noting alignment pin, install assembly on suction housing.

21. Install suction housing and discharge fasteners and tighten.

22. Reconnect pump bleed line and motor wiring.

CAUTION: DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks. Replace as required.

Failure to follow these instructions could result in injury or

property damage.

23. Close drain and slowly open inlet valves.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Do not plug overflow. Pipe

vent opening to atmosphere. Do not restrict. Open valves

slowly. Failure to follow these instructions could result in

serious injury or death.

24. Jog to check motor rotation.

CAUTION: DO NOT REVERSE

Reverse operation can cause extensive damage to

pumps. Jog the motor to test for direction of rotation. Failure

to follow these instructions could result in serious injury or

property damage.

25. Observe operation thru several cycles.

7

Page 8

DOMESTIC® PUMPS

Bell & Gossett

Morton Grove, Illinois 60053

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. DN0141D November 2012

Loading...

Loading...