Page 1

Domestic® Pump

WARNING

Vacuum Heating Units

INSTRUCTION MANUAL

DN0134

REVISION D

Series VLR

™

SERIES VLR UNITS

1,000 – 20,000 SQ. FT. EDR

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on

the unit safety instruction decals to draw attention to safety

related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN A SAFETY HAZARD.

DO NOT PRESSURIZE TANK.

ISOLATE TANK DURING LEAK TEST.

DO NOT RESTRICT VENT.

DO NOT PLUG OVERFLOW.

OPEN INLET VALVES SLOWLY.

EXPLOSIBLE

(2) All Units

DN0483 (Small) - DN0484 (Large)

DO NOT USE AS A FLASH TANK.

FAILURE TO FOLLOW

INSTRUCTIONS COULD RESULT

IN SERIOUS INJURY OR DEATH.

EXPLOSIBLE

DURING LEAK TEST

DN0485 (Small)

DN0486 (Large)

If the decals as noted below are missing or are illegible contact

your local B&G representative for a replacement.

1. Electrical connections to be made by qualified Electrician in

accordance with all National, State and Local codes.

2. Motor must have properly sized starter with properly sized

heaters to provide overload and undervoltage protection.

3. If pump, motor or piping are operating at extremely high or

low temperatures, guarding or insulation is required.

4. Operating personnel should be trained in the operation of

vacuum/condensate return units.

TM

WARNING

ISOLATE TANK

(2) All Units

SERIES HV

MODEL

SERIAL

GPM PSI PUMP

CFM IN HG. PUMP

DWGS

POWER V. PH. HZ 60

CONTROL V. PH. 1 HZ 60

TOTAL LARGEST MOTOR

F.L. AMP F.L. AMP

DN0016

DN0116 Units with Panel

TM

Morton Grove, Illinois 60053

CAUTION

DO NOT RUN PUMP DRY,

SEAL DAMAGE MAY OCCUR.

INSPECT PUMP SEAL

REGULARLY FOR LEAKS,

REPLACE AS REQUIRED.

FOR LUBRICATION

REQUIREMENTS, CONSULT

SERVICE INSTRUCTIONS.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY OR

PROPERTY DAMAGE.

P70644 All Units

P70644

Page 2

2

DESCRIPTION AND INSTALLATION

The Series VLR vacuum heating units are designed to serve the

dual purpose of pumping accumulated condensate back to the

boiler feed tank and maintaining vacuum in the condensate

system. This vacuum will draw air out of the system on start-up

and facilitate the flow of steam thru the heating system.

One pump/vacuum producer/discharge valve assembly

controls both the condensate discharge and the production of

vacuum. Two pump (duplex) units have a second assembly for

backup and to provide extra capacity to handle peak loads.

Various electrical controls are offered to meet system requirements. These controls are normally supplied as part of the

assembled unit and a wiring diagram is furnished with the unit.

Refer to this electrical diagram as required.

The units respond to both changing condensate levels and

system vacuum requirements. The Series VLR units feature a

low inlet height and therefore have a second float (in lower

compartment). As condensate accumulates in the lower compartment, this float starts the pump and siphons the condensate to the upper chamber.

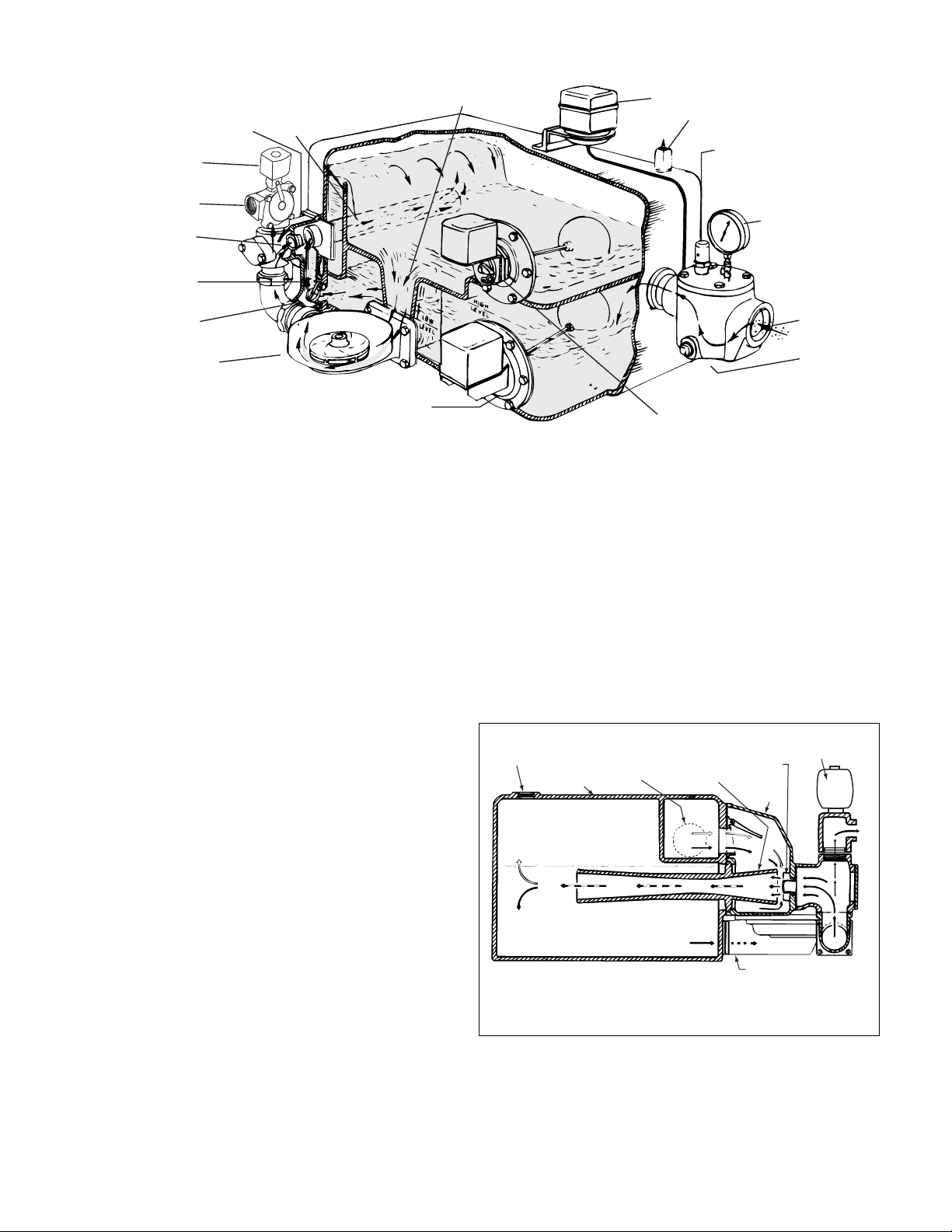

In operation the centrifugal pump circulates condensate from

the upper compartment thru the multi-jet nozzle creating multiple jets of water entering the venturi. These jets entrain air and

gasses creating a smooth steady vacuum in the lift manifold

and in the condensate system. The air and gasses are separated in the upper compartment and vented to atmosphere.

See Figure 1.

Low system vacuum or high water in the upper compartment

or high water in the lower compartment will start the pump to

create vacuum and transfer water to the upper tank. High water

level in the upper compartment will also cause the discharge

valve to open.

When the vacuum and float switches have been satisfied and

the pump stops, the check valve in the lift manifold closes, preventing the return of air and water to the system.

The solenoid operated discharge valve is opened in response

to the condensate level float switch in the upper compartment.

Controlled opening of the discharge valve holds sufficient back

pressure in the nozzle body that the vacuum producer continues to function even when discharging condensate (simultaneous ratings).

NOZZLE BODY

MULTI-JET NOZZLE

VENTURI

PUMP SUCTION

SOLENOID OPERATED

DISCHARGE VALVE

DISCHARGE

LIFT MANIFOLD

CHECK VALVE

CENTRIFUGAL PUMP

LOWER COMPARTMENT FLOAT SWITCH

UPPER COMPARTMENT FLOAT SWITCH

STRAINER

LOW INLET

VACUUM GAUGE

VACUUM BREAKER

VACUUM SWITCH

AIR VENT

OPERATION IS SIMPLE, EFFECTIVE AND RELIABLE

FIG. 1 CUT-AWAY VIEW OF SINGLE SERIES VLR SINGLE UNIT: TYPICAL OF ALL SINGLE AND DUPLEX MODELS

FIG. 2 SERIES VLR VACUUM PRODUCER

AIR VENT

RECEIVER

INLET

MULTI-JET NOZZLES

VENTURI

NOZZLE

BODY

CENTRIFUGAL PUMP

DSK-1328

SOLENOID

DISCHARGE

VALVE

Page 3

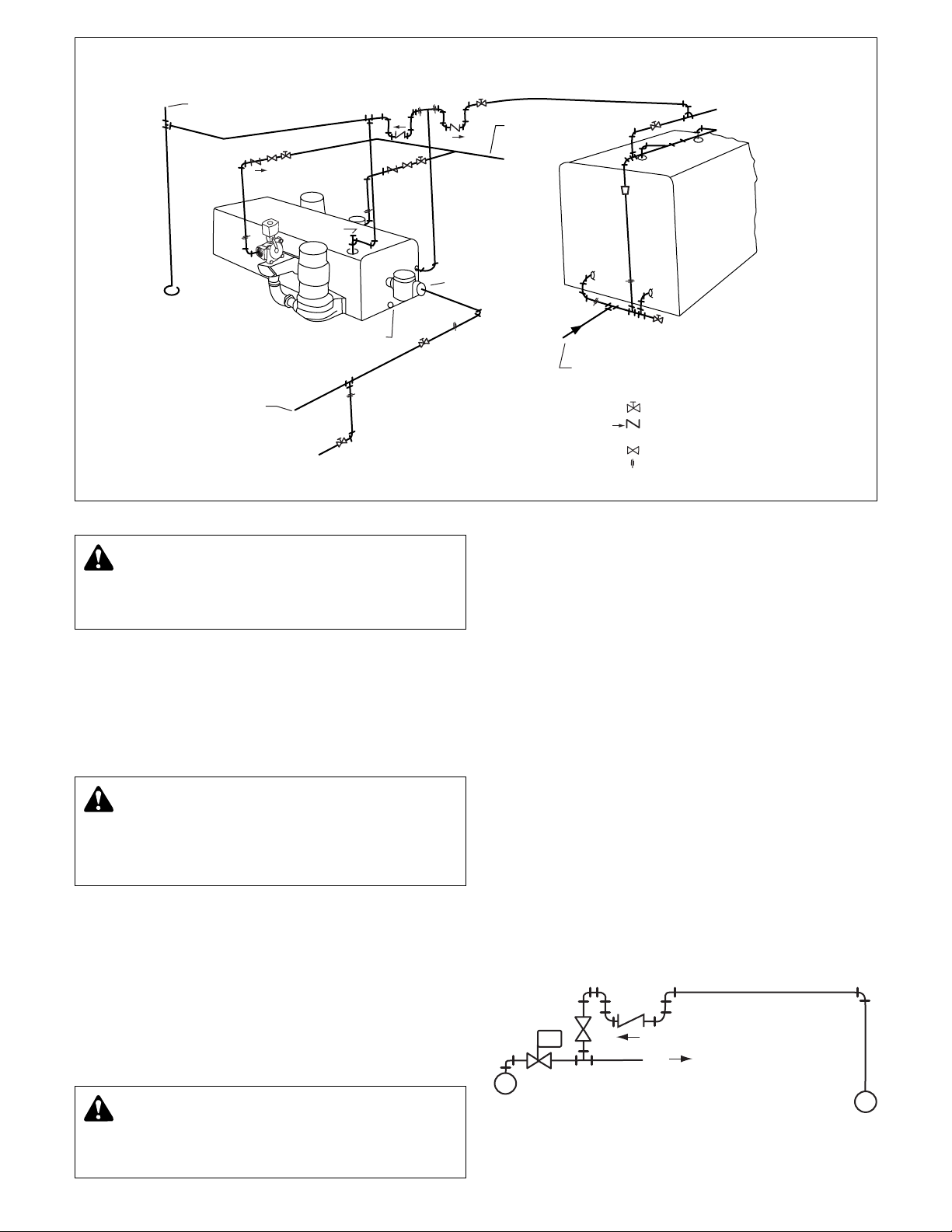

TO BOILER

FEED

SYSTEM

REDUCER

STRAINER

SERIES VLR DUPLEX

PIPING DIAGRAM

DRAIN

DRAIN

DRAIN

DV

PRIMING

OPENING

EQUALIZING LINE —

3

/4"

BOILER

FROM BOILER

FEED SYSTEM

— GATE VALVE

— DISCHARGE VALVE

DV

— STEAM OR PLUG COCK

— UNION

— CHECK VALVE

OPEN VENT ABOVE

BOILER WATER LINE

RETURN FROM

HEATING SYSTEM

Receivers are non-code cast iron.

PRELIMINARY INSPECTION

Assure that there is no shipping damage.

Assure that nameplate ratings agree with job specifications and

actual conditions.

HANDLING

Use care in installing unit.

LOCATION

Place unit for easy access to all parts. Allow adequate space

for servicing. Check ambient conditions.

NOTICE/TEMPERATURE LIMITS

Motors are designed to operate in 104°F max. ambient.

Insulate or ventilate as required.

PIPING (General)

Pipe the unit per the Elementary Piping Diagram. Locate and

support piping so as to not load the discharge valve.

PIPING (Vent)

Install a vent pipe to atmosphere. Pipe to be size of vent port

on unit. Do not restrict or reduce vent opening or exceed 20

inch vertical height unless an overflow connection is provided.

PRIMING PORT

Provide a priming port as shown on piping diagram.

FLOAT SWITCHES

Floats are locked in place to prevent damage during shipment.

Remove shipping locks. Check factory settings. Floats are

adjustable for various levels of operation.

See page 7 for detailed instructions.

EQUALIZING LINE

An equalizing line must be installed with all Series VLR units.

This line must be installed to prevent formation of a vacuum on

the radiation side of the system when steam stops flowing in

the mains. This vacuum may be higher than return line vacuum,

which would prevent condensate from flowing back to pump.

To correct this in an unzoned system, install equalizer line as

shown in the piping diagram. To correct this in a zoned system,

install equalizer line for each zoned section or install a vacuum

breaker on supply line on radiation side of each zone control

valve.

3

CAUTION: UNIT LIFTING EYE

Use unit lifting eyes only to lift unit as shipped from

factory. Unit must be empty and disconnected from pipes,

anchors and other restraints. Use proper rigging procedures. Failure to follow these instructions could result in

injury or property damage.

CAUTION: NOT A CHEMICAL PUMP

Inject boiler feed compounds from chemical feed tank

into boiler feed piping – never into condensate tank. Failure

to follow these instructions could result in injury or property

damage.

EQUALIZING CONNECTIONS FOR ZONED SYSTEMS

ZONE CONTROL

VALVE

STEAM MAIN

M

TO ZONE

RETURN MAIN

FIG. 3.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during leak

test. Do not plug overflow. Do not restrict vent opening to

atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.

FIG. 4

Page 4

4

PIPING (Returns)

Gravity return lines from system must be properly pitched down

to unit inlet. Returns must also be trapped to prevent steam

entry into the unit. An inlet basket strainer is recommended.

Install gate valve in return line for testing pump shut off vacuum,

closing off hot returns when cleaning strainer, etc. Do not install

check valve in return line. Avoid elbow or tee located closer

to strainer inlet than 10 times inlet diameter. If unavoidable

relocate vacuum switches to top of nearest “dry” point on

return main unless a portion of return is below pump inlet. If

returns are lower than pump inlet an accumulation tank is recommended. Accumulator tank may not be necessary if low

length of return is not lower than 24" below pump inlet or

longer than 30'. See TYPICAL PIPING-LOW RETURNS. High

pressure steam traps should empty into uninsulated flash tank

where condensate will cool before entering unit.

DISCHARGE LINE

Install union, check valve, steam cock and gate valve at unit in

each discharge line. Steam cock to be adjusted to cause pump

to operate at specified pressure. If discharge line is more than

100' long, install pipe 1 or 2 sizes larger than discharge valve

tapping.

ELECTRICAL WIRING & CONTROLS

Connect power wiring per the National Electric Code. Recheck

nameplate vs specifications and conditions. All single phase

motors have internal thermal protection.

Three phase motors must use starters with properly sized overload relays. Overload relays furnished are designed for manual

reset.

WARNING: HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

PUTTING THE UNIT INTO SERVICE

1. Assure that the unit is piped in accordance with instruc-

tions.

2. Isolate tank before performing any system leak test. Do not

pressurize the tank as part of the leak test. Failure to do this

can result in serious injury or death.

3. Check floats for free operation.

4. Check power leads in accordance with wiring diagram

enclosed in control cabinet (when furnished).

5. Units are shipped with receiver and pump drain plugs

removed. Drain plugs are removed and replaced with

thread protection. Locate drain plugs that are shipped

loose with the unit. Identify openings that the plugs were

removed from. Remove thread protectors and install drain

plugs.

6. Fill receiver (upper compartment on Series VLR) half full of

water to prime pump(s) and prevent possible damage to

pump seals. Avoid freezing conditions after unit receiver

has been filled.

7. Check for proper rotation of all three phase motors.

Rotation must be clockwise looking down on the motor as

indicated by directional arrow on pump casting. If pump

runs backwards, interchange two wires (3 phase only).

8. Throttle plug cock in discharge line until pressure at pump

(while pump is discharging) approaches pump rated pressure. Tighten plug nut to secure adjustment.

9. Remove start-up label (below) from panel (if applicable)

after complying with instructions.

10. If possible, observe operation thru several cycles using

Selector or Vacuum Switch settings as noted below.

The vacuum switches are adjusted and tested at the factory for

proper operation. The vacuum switch on a single unit and the

lead switch of a duplex unit is set to close at 3" Hg vacuum and

open at 8". The lag switch of a duplex unit is set to close at

2" and open at 8".

These settings are suitable for all normal installations including

those having an accumulator tank or lift fitting. If settings must

be readjusted refer to manufacturer’s instructions.

POSITION WHEN USED OPERATION

“Vacuum and Float” or “FL-Vac’’ Normal position

Pumps operate on either low

vacuum or high condensate

“Float Only” or “Float”

Sometimes used for night and week-end service. Pump starts and stops on

This setting is not recommended for use with lift fitting. condensate level change

“Continuous” or “Hand”

Testing and for unusually high

Continuous

lift conditions in return lines.

“Off” (Duplex Units only) Adjust controls, inspect pump Prevent operation of motor

SELECTOR OR VACUUM SWITCH SETTINGS

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could result

in serious injury or death.

CAUTION: DO NOT REVERSE

Reverse operation can cause extensive damage to

pumps. Jog the motor to test for direction of rotation. Failure

to follow these instructions could result in injury or property

damage.

CAUTION: DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks. Replace as required.

Failure to follow these instructions could result in injury or

property damage.

ELECTRICIAN/INSTALLER/OPERATOR

REMOVE AND DESTROY THIS TAG AFTER —

1. ASSURING THAT ALL PUMPS ROTATE CLOCKWISE PER ARROWS CAST

ON VOLUTES. (JOG PUMP MOMENTARILY TO TEST – INTERCHANGE

ANY TWO MOTOR POWER WIRES TO REVERSE 3PH MOTORS.)

2. ASSURING THAT SHIPPING LOCKS HAVE BEEN REMOVED FROM ALL

FLOAT SWITCHES.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during leak

test. Do not plug overflow. Do not restrict vent opening to

atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.

Page 5

5

SPECIAL PIPING ARRANGEMENTS FOR LOW RETURNS

(IF LIFT EXCEEDS 5 FEET, A MECHANICAL LIFT IS RECOMMENDED)

Page 6

6

OPERATION AND MAINTENANCE

Operators must be familiar with all sections of this manual to

understand the operation of the unit.

Hot water, steam and electricity can be hazardous.

LUBRICATION

The only pump bearing requiring lubrication is the ball bearing

in the motor support just below the flexible coupling. It has a

reservoir, which is filled with moisture resistant high temperature grease.

Remove pipe plug in motor support and add approximately 3

ounces of Shell Alvania RL 2 grease (or equivalent) from once

a year (normal) to twice a year for extremely hot conditions. Do

not use ordinary grease.

NOTICE/AUTO RESTART

Single phase motors will restart automatically after thermal

overload protector trips.

Overload thermal relays in starters must be reset manually.

A properly installed unit should function unattended for long

periods of time. Periodic checks to assure proper operation are

highly recommended. Refer to trouble shooting section when

necessary.

A variety of control options are available and are furnished in

accordance with user specifications. Refer to wiring diagrams

(when furnished) to determine control switch settings.

The inlet strainer (when furnished) is intended to protect the

pump and system. Periodic cleaning should be included in the

maintenance schedule. Check frequently in new systems.

GAGE GLASS MAINTENANCE (Vented Systems)

Clean gage glass as required using commercial glass cleaner.

Dilute muratic acid may be used if required (observe handling

precautions). Never clean gage glass with wire brushes,

scrapers or harsh abrasives.

Do not reuse gage glass or packing or seals.

Immediately replace glass which is broken, cracked, chipped,

scratched or otherwise damaged. Inspect periodically with a

bright concentrated light. Anything which glistens and catches

the fingernail or any star-shaped or crescent-shaped mark

which glistens is cause for replacement. Any gage glass which

appears cloudy or roughened and will not respond to cleaning

procedures should be replaced.

When replacing gage glass, use new packings specified for this

use. Install glass with sufficient end clearance for expansion

(keep glass to metal clearance at each end) and tighten nuts

just enough to avoid leakage (do not over tighten).

Condensate enters the screen from the bottom and flows

outward from the inside. Foreign matter intercepted by the

screen may drop into the large dirt pocket in the lower portion

of the strainer body; however, grease, oil, gasket material and

other foreign substances present in all heating systems are

likely to stick and clog the strainer screen. For this reason it

may be necessary to clean the strainer several times a week

during the first few months of operation.

To clean strainer proceed as follows: (1) open disconnect

switch(es), (2) close return line gate valve, (3) remove drain

plug, (4) remove cap screws, cover and screen, (5) clean screen

thoroughly, (6) flush strainer body and dirt pocket, (7) inspect

gasket, (8) reassemble.

While the pump is shut down inspect and clean the multi-jet

nozzles as follows: (1) drain receiver below nozzle level by

removing drain plug, (2) remove discharge manifold cover plate

and multi-jet nozzle, (3) clean nozzle, (4) inspect gasket and

reassemble, (5) reprime pump to half way level in gauge glass,

(6) close switches, (7) open return line gate valve slowly.

INLET BASKET STRAINER MAINTENANCE

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

CAUTION: SUBSEQUENT DAMAGE

A unit showing symptoms of possible problems (over-

flow, noise, leaks, vibrations, continual operation, etc.) must

be corrected immediately. Failure to follow these instructions

may result in full liability for subsequent injury or property

damage.

SAFETY INSTRUCTIONS

SEE COVER OF THIS MANUAL

VACUUM GAUGE TAPPING

VACUUM BREAKER TAPPING

CAPSCREWS

COVER

GASKET

SCREEN

STRAINER BODY

DRAIN PLUG

(ON REAR OF STRAINER)

THERMOMETER (ON FRONT OF STRAINER)

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during leak

test. Do not plug overflow. Do not restrict vent opening to

atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.

FIG. 11

Page 7

7

CONTROLS ARE PRESET AT THE FACTORY BUT

MAY VARY DUE TO HANDLING DURING SHIPMENT.

PROPER ADJUSTMENT OF CONTROLS

ASSURES BEST PERFORMANCE

1. Close the inlet gate valve and operate the pump on CON-

TINUOUS to remove as much water as possible from the

receiver. Open disconnect switch(es).

2. Adjust cut-off point of lower compartment float switch so

that switch opens just before float touches bottom of

receiver. Both switches of duplex units should open at

same low level. (See switch manufacturer’s instructions for

procedure).

3a.(One float switch in lower compartment.) Remove strainer

cover and fill lower compartment thru strainer. Close inlet

valve and remove drain plug from strainer. When water

stops flowing from drain opening adjust cut-in point of

lower float switch by depressing float arm slightly and setting adjusting strip so that switch turns on when float arm is

released.

3b.(Two float switches in lower compartment.) Adjust cut-in

point of second switch so that operating range ia approximately 2 divisions narrower than range for switch adjusted

in 3a.

4. Adjust cut-off point of upper compartment float switch so

that switch opens when there is about

1

/4" water in gauge

glass. Check as follows: (1) close discharge gate valve (2) fill

top compartment until upper float switch closes (3) close

inlet valve (4) set selector switch on FLOAT ONLY (5) open

discharge gate valve. When float switch opens and pump

stops, level should be

1

/4" in guauge glass.

5. Adjust the cut-in point of upper compartment switch by setting it for minimum level change.

FLOAT SWITCH ADJUSTMENT PROCEDURES

HIGH LEVEL

FLOAT SWITCH-ON

WATER LEVEL

GAUGE

INLET

1

/4

"

HIGH LEVEL

FLOAT SWITCH -ON

LOW LEVEL

FLOAT SWITCH -OFF

VENTURI

LOW LEVEL

FLOAT SWITCH-OFF

PUMP SERVICE INSTRUCTIONS FOR VACUUM PRODUCING CENTRIFUGAL PUMPS

Close coupled centrifugal pumps are designed for years of

trouble free service. Units have mechanical shaft seals and are

vertically mounted to put the motor above floor dirt and water.

1. Drain hurling chamber.

2. Shut-off and lock out power.

3. Make sure unit is cool enough that pump can be handled

safely. Open drain to remove remaining liquid.

4. Carefully remove pump drain plug and bleed line. Wait for

complete drainage.

5. Loosen the motor bracket to pump volute capscrews.

Assure that the pressure is relieved per caution note.

6. Complete the removal of the above hardware. Remove

pump/motor assembly and place on work bench.

7. Remove self locking stainless steel capscrews and stainless steel washer (or self locking brass cap nut and washer)

that secure the impeller in place.

8. To remove impeller from motor shaft proceed as follows:

(1) Keyed Shafts. Remove impeller with gear puller or other

means which will not damage impeller or bend motor

shaft.

(2) Threaded Shafts. Hold end of motor shaft opposite

pump with large screwdriver or other suitable tool and

back impeller off with a rectangular bar or other flat tool

inserted between the vanes of the impeller.

9. Remove rotating part of seal from shaft, being careful not

break carbon face.

10. Remove capscrews holding motor bracket to motor and

remove bracket.

11. Remove stationary part of seal assembly, being careful not

to chip or break ceramic seal.

12. To install seal proceed as follows:

(1) Clean recess in bracket thoroughly. Coat recess and

“rubber” portion of seat with soap solution. Press seat

into recess firmly by hand making certain both parts

bottom evenly. If seal cannot be bottomed with fingers

place cardboard shipping disc on ceramic and force into

place with tool.

(2) Carefully place bracket in position on motor shaft

without displacing ceramic seat and secure bracket to

motor with capscrews.

CAUTION: PRESSURIZED SYSTEM

Operating system may contain very hot water. Close

inlet and open drains before servicing. When servicing,

loosen screws and move components to assure pressure is

relieved before

removing screws. Keep drains open during

servicing. Failure to follow these instructions could result in

injury or death.

CAUTION: HOT SURFACE

Surfaces are hot when system is in operation. Do not

touch hot receiver, let unit cool before servicing. Failure to

follow these instructions could result in serious injury or

death.

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting

servicing unit. Failure to follow these instructions could

result in serious injury or death.

FIG. 12

Page 8

(3) Place motor vertically with pump end up. Do not attempt

assembly of seal and impeller with shaft horizontal.

(4) The “carbon” of rotating part of seal should not be loose.

If it is, hold in place with grease. Using clean, lint free

cloth, wipe mating surfaces perfectly clean. Soap shaft

and push seal onto shaft so that carbon will contact

ceramic seal. If spacer is required, use grease to cause

spacer to adhere to bottom of seal after seal has been

put on shaft. Be sure spacer is on larger diameter of

shaft so that will not catch between shoulder and

impeller.

13. Replace impeller on shaft. Replace stainless steel washer

and secure impeller with capscrew or cap nut.

14. Place new gasket on pump volute and reassemble motor

and pump subassembly on pump volute.

15. Reconnect pump bleed line and motor wiring.

16. Close drain and slowly open inlet valves. See warning.

17. Jog to check motor rotation. See caution.

18. Observe operation thru several cycles.

8

CAUTION: DO NOT REVERSE

Reverse operation can cause extensive damage to

pumps. Jog the motor to test for direction of rotation. Failure

to follow these instructions could result in serious injury or

death.

CAUTION: DO NOT RUN DRY.

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks Replace as required.

Failure to follow these instructions could result in serious

injury or death.

TROUBLESHOOTING SERIES VLR UNITS

ALL UNITS ARE THOROUGHLY TESTED AT THE FACTORY BEFORE SHIPMENT AND SHOULD OPERATE SATISFACTORILY

WITHOUT FURTHER ADJUSTMENT IF PROPERLY INSTALLED AND IF NOT DAMAGED BY ROUGH HANDLING IN TRANSIT.

IF SYSTEM OR UNIT PERFORMANCE IS NOT SATISFACTORY, REFER TO THE FOLLOWING CHECK LIST.

PUMP WILL NOT START

1. The power supply has been interrupted, disconnect switch

is open or selector switches improperly positioned.

2.Insufficient condensate accumulated to actuate float

switch.

3. Vacuum is not low enough to actuate vacuum switch.

4. Incorrect voltage for motor. Check voltage and wiring with

motor characteristics.

5. Incorrect starter coil for power supply.

6. The overload relays in the starter have tripped out and must

be reset. Ambient temperature may be too high.

7. Check float switch, vacuum switch or other control for

proper operation.

8. Wiring to control panel is incorrect or connections are loose.

PUMP DOES NOT RETURN ALL CONDENSATE TO

BOILER FEED SYSTEM (UNIT FLOODS)

1. Pump is running backward looking down on motor.

Rotation of 3 phase motors may be corrected by interchanging any two of the three wires. Pump should run

clockwise.

2. Steam traps are blowing through causing condensate to

return at excessive temperatures. If 160°F is exceeded the

capacity of the pump may be reduced below its rating.

Traps should be repaired or replaced.

3. The total pressure at the pump discharge is greater than the

pressure for which the pump was designed. Check the total

pressure which includes the boiler pressure, the friction

head and the static head.

4. A valve in the discharge line between pump and boiler is

closed or throttled too tightly. Check valve is installed

backwards.

5. Condensate is held up in system periodically by induced

vacuum in boiler or radiation then released in a flood when

the pump starts. Install equalizer line.

6. The strainer is dirty thus retarding flow. Refer to instructions

for cleaning.

7. The impeller eye is clogged with debris. Clean.

8. The solenoid discharge valve is not opening. This may be

caused by loss of power to the solenoid discharge valve or

upper chamber float switch failure.

9. Systems with accumulator tanks should have equalizer

line run from accumulator tank to steam header NOT

from accumulator tank to pump receiver NOR from pump

receiver to steam header. Install vacuum breaker on

accumulator tank, NOT on pump.

10. Pump is too small for the system.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during leak

test. Do not plug overflow. Do not restrict vent opening to

atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.

VIEW OF

THREADED

IMPELLER

WATER

SLINGER

MECHANICAL

SEAL

MOTOR BRACKET

WEAR RING

VOLUTE

IMPELLER

2DPF03

Page 9

9

VACUUM PUMP RUNS CONTINUOUSLY OR FAILS TO

PRODUCE SUFFICIENT VACUUM*

1. Selector switch is set on “continuous” or “hand”.

2. The temperature of the condensate is too high. Normal

operating condensate temperature should not exceed

160°F for rated capacities. Correct the cause for high

temperature condensate.

3. There are excessive leaks in the system piping preventing

the pump from producing sufficient vacuum to satisfy the

vacuum switch setting. To confirm this, make sure pump is

primed, close inlet valve, close equalizing line valve, plug

other check valve on this line, replace vacuum breaker with

plug and observe shut-off vacuum while pump is running.

4. The vacuum or float switch electrical contacts remain in

closed position. Adjust controls.

5. The nozzle, strainer, or impeller passageways are clogged

with foreign matter. Refer to instructions for cleaning.

6. A vacuum breaker is set too low. It should not admit air at a

vacuum within the range of the vacuum switch setting.

7. The pump has lost its “hurling” water. There should never

be less water than shown on float adjustment sketch. Loss

of “hurling” water may be caused by:

(1) Solenoid discharge valve lleaks due to dirt or worn seat.

(2) Solenoid discharge valve stuck in “open” position.

(3) Check valve in nozzle body is leaking.

8. Check valve in equalizer line or air vent line from receiver or

accumulator tank leaks, or is installed backwards.

9. One nozzle body check valve, Figure 2, page 2, on duplex

pump remains open, permitting air to recirculate.

10. Pump is too small for the system.

11. Lower float switch does not turn off. Float rests on receiver

bottom and should be raised.

PUMP STARTS AND STOPS IN RAPID SUCCESSION

1. A check valve in return line. Remove.

2. A partially closed inlet valve. Valve should be a gate valve

rather than globe.

3. A lift in return line at or near the pump. Low return lines will

fill with condensate between pump operations. The inertia

of the collected water may be quite great, and before the

vacuum suddenly produced by starting of the pump can set

the water in motion, the vacuum at the pump may reach the

cut-off point of the vacuum switch, thus stopping the

pump. The vacuum quickly recedes as the condensate

moves into the receiver and the pump “trips in” on vacuum

control again, thus repeating this “hunting action”.

There are two ways to correct this difficulty:

(1) If the vacuum sensing line can be relocated away from

the vacuum switch(es), connect this sensing line into the

nearest “dry” point in the return main so that the operation of the unit may be governed by the vacuum in the

system.

(2) If the nearest “dry” point on the return main is more than

2 ft. above the vacuum switch, relocate and reconnect

the switches to sense the vacuum at this point. If a

separate selector switch for “FL-Vac,” “Float,” “Hand”

operation is not already furnished with the unit, one

must be provided for each vacuum switch for installation

in control panel.

4. Elbow in return line too close to unit inlet. Correct as

described in item 3, or if there is no lift in the return line at

or near the pump, extend the

3

/4" equalizing line to top of

“dry” point on return main.

5. Equalizer line is improperly connected.

6. Strainer clogged with dirt. Clean strainer.

PUMP MAKES NOISE

1. The pump is working against a lower pressure than

designed for. While pump is discharging, adjust square

headed steam cock in discharge line until pressure at pump

approaches pump rated pressure. Secure adjustment of

steam cock by tightening lock nut.

2.Excessive condensate temperature. Correct system

conditions.

3. Magnetic hum or bearing noise in motor. Consult motor

manufacturer’s authorized service station nearest pump

location.

4. Starter chatters. Trouble is caused by low line voltage, poor

connections, defective starter coil, or burned contacts.

5. Pump is running backward.

6. Water hammer when discharge valve closes:

(1) Adjust steam cock to reduce discharge velocity or

(2) Install surge chamber on boiler side of discharge check

valve or

(3) Install additional check valve near boiler or

(4) Install discharge piping 1 or 2 sizes larger.

THE SYSTEM IS NOISY

1. Banging in the steam mains is usually caused by

“imploding” in condensate lying in low points in lines. These

pockets can be eliminated by “dripping” low points,

properly supporting the pipe, or by increasing the pitch of

the lines.

2. Improper dripping of the steam mains and risers. Where

there is a rise in the steam main, or where it branches off

into a riser, a drip trap must be installed to the drain line.

3. The piping is too small to drain properly.

4. A defective trap is holding condensate in radiation.

5. A priming boiler is permitting a carry-over of water with the

steam. A priming boiler is caused by:

(1) Oil or other foreign matter. Clean boiler thoroughly.

(2) A reduction of the steam liberating area due to too high

water level in the boiler. Reduce water line.

(3) Overloading. Reduce firing rate.

(4) Undersized steam outlet area, resulting in velocities in

excess of 15 to 25 ft. per second.

*Product life and product efficiency are greatly affected by system maintenance. A

tight (leak-free) system with properly functioning traps is essential for efficient

operation.

Page 10

TM

DEALER SERVICE

If trouble occurs that cannot be rectified, contact your local

B&G representative. He will need the following information in

order to give you assistance.

1. Complete nameplate data of pump and motor.

SEE RATING NAMEPLATE at right.

2. Vacuum readings.

3. Ampere draw of the motor.

4. A sketch of system piping.

SERIES HV

TM

MODEL

SERIAL

GPM PSI PUMP

CFM IN HG. PUMP

DWGS

POWER V. PH. HZ 60

CONTROL V. PH. 1 HZ 60

TOTAL LARGEST MOTOR

F.L. AMP F.L. AMP

DN0016

Morton Grove, Illinois 60053

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. DN0134D November 2012

Loading...

Loading...