Page 1

Domestic® Pump

250˚F Condensate Units

INSTRUCTION MANUAL

DN0130

REVISION D

Series SA™ and SA-P

™

SERIES SA-P

SERIES SA

™

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

WARNING

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on

the unit safety instruction decals to draw attention to safety

related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN A SAFETY HAZARD.

If the decals are missing or are illegible contact your local B&G

representative for a replacement.

1. Electrical connections to be made by a qualified Electrician

in accordance with all National, State and Local codes.

2. Motor must have properly sized starter with properly sized

heaters to provide overload and undervoltage protection.

3. If pump, motor or piping are operating at extremely high or

low temperatures, guarding or insulation is required.

4. Operating personnel should be trained in the operation of

condensate return units.

Ê

Ê

Ê

Ê

Ê

EXPLOSIBLE

DO NOT EXCEED PRESSURE

RATING OF THE UNIT.

DO NOT ALTER OR DEFEAT

PRESSURE RELIEF V

OPEN VALVES SLOWLY.

MAXIMUM PRESSURE 15 PSI.

FAILURE TO FOLLOW

INSTR

UCTIONS COULD

RESUL

T IN INJURY OR

PROPER

TY DAMAGE.

DN0124 ALL UNITS

Ê

Ê

Ê

Ê

Ê

Ê

Ê

Ê

Ê

SERIES

Ê

MODEL

Ê

SERIAL

GPM PSI PUMP

CFM IN HG. PUMP

Ê

DWGS

Ê

Ê

POWER V. PH. HZ60

CONTROL V. PH. 1 HZ60

TOTAL LARGEST MOTOR

F.L. AMP F.L. AMP

Morton Grove, Illinois 60053

DN0016

DN0016 UNITS PANEL

™

DOMESTIC® PUMPS

Ê

SERIES

Ê

MODEL

Ê

SERIAL

GPM PSI PUMP

POWER V. PH. HZ60

CONTROL V. PH. 1 HZ60

TOTAL LARGEST MOTOR

F.L. AMP F.L. AMP

Morton Grove, Illinois 60053

ALVE.

DN0124

DN0019 UNITS LESS PANEL

Ê

TM

Ê

TM

Ê

Ê

Ê

Ê

Ê

Ê

CAUTION

DO NOT RUN PUMP DRY,

SEAL DAMAGE MAY OCCUR.

INSPECT PUMP SEAL

REGULARL

REPLACE AS REQUIRED

FOR LUBRICATION

REQUIREMENTS,

SERVICE INSTR

FAILURE TO FOLLOW

INSTR

UCTIONS COULD

RESUL

T IN INJURY OR

PROPER

TY DAMAGE.

P70644 ALL UNITS

Ê

TM

Y FOR LEAKS,

CONSULT

UCTIONS.

Ê

Ê

Ê

Ê

Ê

.

P70644

Page 2

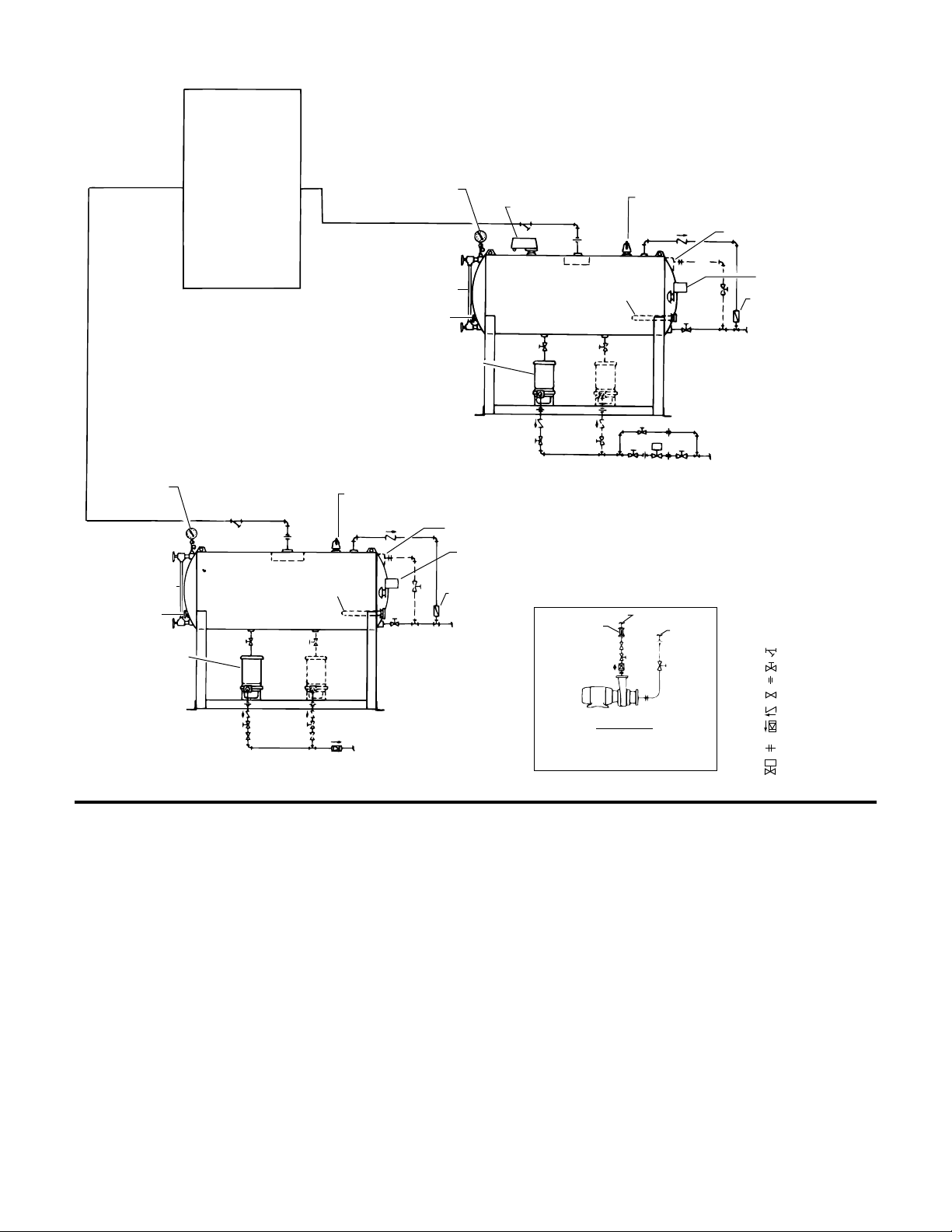

MECHANICAL DRAIN

VALVE (OPTIONAL)

FLOAT SWITCH

FOR STAND BY

THERMOSTATIC

VENT TRAP

TO DRAIN

PUMP

DISCHARGE

DOMESTIC SERIES B35

CENTRIFUGAL PUMP

(SERIES DB PUMP

OPT., SEE DETAIL AA)

GAUGE

GLASS

DIAL

TEMP.

GAUGE

ANODE

COMPOUND GAUGE

PROPORTIONING

REGULATOR

PRESSURE RELIEF VALVE,

PIPE TO DRAIN (PITCH DOWN)

STEAM

ABSORPTION UNIT

OR

CONVERTER

OR

FAN COIL UNIT

OR

STEAM PROCESS

EQUIPMENT

COMPOUND

GAUGE

GAUGE

GLASS

DIAL

TEMP.

GAUGE

DOMESTIC SERIES B35

CENTRIFUGAL PUMP

(SERIES DB PUMP

OPT., SEE DETAIL AA)

PUMP

DISCHARGE

TO DRAIN

ANODE

THERMOSTATIC

VENT TRAP

PRESSURE RELIEF VALVE

PIPE TO DRAIN (PITCH DOWN)

MECHANICAL DRAIN

VALVE (OPTIONAL)

FLOAT SWITCH

PUMP DISCHARGE

FLEXIBLE

PUMP

CONNECTOR

PUMP

SUCTION

LEGEND:

“Y” STRAINER

GATE VALVE

UNION

PLUG COCK

CHECK VALVE

NON SLAM

CHECK VALVE

FLANGE

PROPORTIONING

CONTROL VALVE

DETAIL AA

DETAIL OF RECOMMENDED PIPING TO

SERIES DB HIGH PRESSURE PUMP

1DPD22

1DPD32

High Temperature Condensate Units

Series SA and SA-P

REPRESENTATIVE PIPING DIAGRAMS

SERIES SA-P

DESCRIPTION OF EQUIPMENT

The Series SA, and SA-P units consists of an ASME Code

stamped steel receiver (permitting operating under pressure up

to 15 psig [1.0 Bar] and equivalent temperature up to 250°F

[121°C]). Series B35 centrifugal pump(s) designed for 2 ft. (0.6M)

NPSH, corrosion inhibitor (anode), water level gauge, thermometer, pressure relief valve, thermostatic air vent trap, compound gauge, valve(s) in pump suction, and a drain (gate)

valve. Occasionally, Series SA units are fully vented; these

receivers feature ASME Code construction except the code

stamped is omitted. In addition to the above components, the

Series SA-P employs a proportioning regulator and valve (electric or pneumatic). The Series SA unit uses float switch controls.

Control panels and components supplied per specification.

When Series SA units are furnished with ASME Code stamped

receivers, relief valve and air vent trap to permit pressurization,

then the receiver inlet is directly connected to the outlet of the

steam absorption unit or other steam process equipment with-

2

SERIES SA

out steam traps in the return line. When used in this manner, a

separate SA unit is usually required for each independently

controlled heating unit.

It is, however, possible to use a single SA unit with multiple

heating units. Detailed information and drawings will be furnished on request.

The relief valve on the unit is set at 15 psi (1.0 Bar) and rated at

1900 pph (862 Kg/hr) steam. Any additional system protection

must be provided as required by others.

PRELIMINARY INSPECTION

Assure that there is no shipping damage.

Assure that nameplate ratings agree with job specifications and

actual conditions.

HANDLING

Use care in installing unit.

Page 3

CAUTION: UNIT LIFTING EYE

Use unit lifting eyes only to lift unit as shipped from

factory. Unit must be empty and disconnected from pipes,

anchors and other restraints. Use proper rigging pr

ocedures. Failure to follow these instructions could result in

injury or property damage.

LOCATION

Place unit for easy access to all parts. Allow adequate space

for servicing. Check ambient conditions.

NOTICE / TEMPERATURE LIMITS

Motors are designed to operate in 104°F (40°C) max. ambient.

Insulate or ventilate as required.

WARNING: EXPLOSIBLE

Do not exceed pressure rating of unit (normally 15 psi

[1.0 Bar]). Do not alter or defeat relief valve (must be 15 psi

[1.0 Bar] max.). Pipe relief valve discharge to a safe location.

Failure to follow these instructions could result in serious

injury or death.

PIPING (General)

Pipe the unit per the Elementary Piping Diagram. Locate and

support piping so as to not load the pump discharge.

RETURNS

Gravity return lines from system should be properly pitched to

drain to unit by gravity. A “Y” strainer and gate valve should be

installed in the return line.

PIPING (Relief Valve)

The discharge from the relief valve should be piped to a location for safe for potential full flow steam. There must also be

provision for drainage of the liquid discharged.

WARNING: RELIEF VALVE REQUIRED

For sale operation the system requires a relief valve

set at 15 psi (1.0 Bar) or less. The relief valve discharge must

be piped to a location where 15 psi (1.0 Bar) steam can be

safely discharged. Do not restrict, reduce or valve the relief

valve discharge line. Failure to follow these instructions

could result in serious injury or death.

WARNING: LIMITED PRESSURE RELIEF

VALVE CAPACITY

The pressure relief valve supplied on the unit may not be

sufficient to relieve rated capacity of the unit or full output of

the boiler. Relief valve supplied is rated at 1900 pph (862

Kg/hr) steam. The tank is rated to withstand 125 psi (8.5 Bar),

but the operating pressure must not exceed 15 psi (1.0 Bar).

Professional system design or evaluation, by others, must

evaluate the upstream system and provide for necessary

additional protection. Discharge thru the pressure relief

valve is a symptom of a system failure. The unit must be

valved off immediately. Failure to follow these instructions

could result in serious injury, death or extensive property

damage.

THERMOSTATIC VENT TRAP OR ATMOSPHERIC VENT

Connect piping from drain line, thermostatic vent trap, and

mechanical drain valve (if so equipped) to drain. Occasionally,

Series SA units are furnished fully vented, without thermostatic

vent trap. Oversize vent openings are then supplied; install full

size vent pipe to atmosphere.

CAUTION: NOT A CHEMICAL PUMP

Inject boiler feed compounds from chemical feed tank

into boiler feed piping – never into condensate tank. Failure

to follow these instructions could result in injury or property

damage.

FLOAT SWITCHES & MECHANICAL ALTERNATORS

Float switch and/or displacer switches, standard or proportional,

are provided to meet system r

Floats are locked in place to prevent damage during ship

equirements.

ment.

Remove shipping locks. Check factory settings. Floats and

mechanical alternators are adjustable for various levels of operation. The lead pump should start with tank 3/4 full and shut of

at 2" (51mm) or more above pump inlet. Lag pump should start

before the tank overflows. Settings should avoid “short

cycling” of the pump.

Displacer positions are adjusted by removing the contr

oller

from the top of the tank and changing cable lengths.

PROPORTIONING ELECTRIC REGULATOR

AND PROPORTIONING (SLIDE WIRE) ELECTRIC VALVE

The regulator is actuated by a float-operated mechanism. Its

function is to regulate the action of the proportioning type of

motor operated valve, so the amount of flow through the valve

is in balance with the water level change.

By accurately following the changes in the water level, the float

actuates a potentiometer slide wire located in the proportioning

regulator. Connected to a similar potentiometer in a relay and

valve operator, the regulator causes the valve to open, close, or

hold in a fixed position.

PNEUMATIC PROPORTIONING

REGULATOR AND CONTROL VALVE

The pneumatic proportional control utilizes controlled air pressure to modulate the discharge valve opening. An air pressure

switch set a 2-3 psi (0.1-0.2 Bar) starts and stops the pump(s)

while the discharge valve is essentially closed.

DISCHARGE CONNECTION – SERIES SA AND SA-P UNITS

A check valve, gate valve and square head steam plug cock

should be located close to pump in discharge line. The plug

cock(s) may be omitted on Series SA-P units equipped with

proportioning discharge valves. If discharge line is more than

100 ft. (30M) long, it should usually be one size larger than the

pump tapping. When the pump is to discharge to a vented

receiver at approximately the same elevation, the steam pressure in the receiver may be greater than the static head at the

pump discharge causing condensate and steam to be forced

through the pump. This condition can be corrected by installing

a back-pressure valve with a spring pressure approximately

equal to the maximum receiver pressure.

ELECTRICAL WIRING & CONTROLS

Connect power wiring per NEC. Recheck nameplate vs. specifications and conditions. All single phase motors have internal

thermal protection.

WARNING: HIGH VOLTAGE ELECTRICITY

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

f

3

Page 4

Three phase motors must use starters with properly sized overload relays. Overload relays furnished are designed for manual

reset.

A variety of electrical controls are available to meet system

specifications. Wiring diagrams are enclosed in electrical

panels when the panels are furnished as part of the unit.

Consult wiring diagrams for specific electrical control

information.

INSULATION

Series SA units frequently handle condensate at temperatures

up to 250°F (121°C). Insulating the receiver and return piping

will effectively conserve heat otherwise lost through radiation

and convection from the receiver shell and reduce ambient

temperatures.

PUTTING THE UNIT INTO SERVICE

1. Assure that the unit is piped in accordance with instructions

on pages 2, 3 and 4.

WARNING: EXPLOSIBLE

Do not exceed 15 psi (1.0 Bar) rated pressure. Do not

restrict relief valve dischar

follow these instructions could result in serious injury or

death.

2. Check floats and alternators for fr

3. Check power leads in accordance with wiring diagram

enclosed in control cabinet (when furnished).

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

4. Install drain plugs.

5. Fill receiver half full of water to prime pump(s) and prevent

possible damage to pump seals. Avoid freezing conditions

after unit receiver has been filled.

6. Check for proper rotation of all three phase motors. Rotation

must be clockwise looking down on the motor as indicated

by directional arrow on pump casting. If pump runs backwards, interchange two wires (3 phase only).

ge. Open valves slowly. Failure to

ee operation.

CAUTION: DO NOT REVERSE

Reverse operation can cause extensive damage to

pumps. Jog the motor to test for direction of rotation. Failure

to follow these instructions could result in injury or property

damage.

7. Throttle plug cock in discharge line until pressure at pump

(while pump is discharging) approaches pump rated pr

sure. Tighten plug nut to secure adjustment.

CAUTION: DO NOT RUN DRY

SEAL DAMAGE MAY OCCUR.

Inspect pump seal regularly for leaks. Replace as required.

Failure to follow these instructions could result in injury or

property damage.

8. Remove start-up label (below) from panel (if applicable) after

complying with instructions.

ELECTRICIAN / INSTALLER / OPERATOR

Remove and destroy this tag after –

1.Assuring that all pumps rotate clockwise per arrows cast

on volutes. (Jog pump momentarily to test – interchange

any two motor power wires to reverse 3Hp motors.)

2.Assuring that shipping locks have been removed from all

float switches.

9. If possible, observe operation thru several cycles.

.

es-

OPERATION AND MAINTENANCE

Operators must be familiar with all sections of this manual to

understand the operation of the unit.

Hot water, steam and electricity can be hazardous.

SAFETY INSTRUCTIONS

SEE COVER OF THIS MANUAL

WARNING: EXPLOSIBLE

Do not exceed 15 psi (1.0 Bar) rated pressure. Do not

restrict relief valve discharge. Open valves slowly. Failure to

follow these instructions could result in serious injury or

death.

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

Check motor nameplate for any lubrication requirements.

Pumps require no lubrication.

4

NOTICE / AUTO RESTART

Single phase motors will restart automatically after

thermal overload protector trips.

Overload thermal relays in starters must be reset manually.

A properly installed unit should function unattended for long

periods of time. Periodic checks to assure proper operations

are highly recommended. Refer to trouble shooting section

when necessary.

A variety of control options are available and are furnished in

accordance with user specifications. Refer to wiring diagrams

(when furnished) to determine control switch settings.

The inlet strainer (when furnished) is intended to protect the

pump and system. Periodic cleaning should be included in the

maintenance schedule. Check frequently in new systems.

CAUTION: SUBSEQUENT DAMAGE

A unit showing symptoms of possible problems (overflow, noise, leaks, vibrations, continual operation, etc.) must

be corrected immediately. Failure to follow these instructions may result in full liability for subsequent injury or property damage.

Page 5

MAINTENANCE PROCEDURE FOR RED LINE GAGE GLASS

PYREX® Tubular Glass

Nut

Insure Clearance Between

Glass Surface and the

Upper and Lower Fixtures

Tie Rod

Gland

Packing

WARNING: EXPLOSIBLE

Improper installation or maintenance of tubular glass

can cause immediate or delayed glass breakage resulting in

bodily injury. To avoid br

eakage observe the following Do’s

and Do Not’s and Use and Care Instructions, as well as

tubular gage manufacturer’s instructions. If a gage glass

breaks, contained substances can be released and glass

can be blown out of the unit with great force. Always wear

safety glasses when looking toward a gage or working on a

gage glass assembly. Guard against the possibility of fir

e

and explosion. Protect glass from impact, scratches, other

surface damage and sudden temperature changes. These

can weaken or stress the glass and lead to breakage.

Failure to observe the following Do’s and Do Not’s can result

in glass breakage and its explosive release of pressurized

system contents and flying glass particles.

DO NOT’S

DO NOT work on any gage until you have carefully read these

warnings & instructions.

DO NOT reuse any tubular glass, packing, or seals.

DO NOT use glass that is scratched, chipped, or otherwise

damaged. Used glasses may contain damage and are poor

safety risks.

DO NOT exceed the glass or gage manufacturer’s recommended working pressure or maximum recommended gage

glass length.

DO NOT bump, impact or scratch the glass.

DO NOT tighten gland nut and packing beyond gage manufac-

turer’s recommendations.

DO NOT operate gages unless gage valve sets are equipped

with drain vent and safety ball check.

DO NOT attempt to clean glass while the unit is in operation.

Cleaning should be done without removing the gage glass.

DO NOT attempt to inspect the glass, to adjust tie rods, pack-

ing nuts or glands, to inspect or tighten other fittings without

isolating the gage from the pressure vessel and opening the

drain vent.

DO NOT weld, impact, or sandblast in the gage glass area

without protecting the glass.

DO NOT have glass-to-metal contact.

DO NOT subject gage glass to bending or twisting stresses.

DO NOT allow the gage glass to contact the bottom of the

packing gland.

DO’s

DO inspect the gage glass daily, keep maintenance records,

and conduct routine replacements.

DO install protective guards where necessary to protect

personnel.

DO protect the outside of the gage glass from sudden temper

ature changes, such as drafts, water spray, etc.

DO remove all deposits from the seal areas, the gland nuts,

glands (where used) and use new packing before installing a

tubular gage glass.

DO examine gage glass for damage and seals for hard deposits

and tears.

DO verify that the tubular gage glass, gland, nuts, packing, etc.

are the correct size and type before installing.

DO ensure that system is protected by safety shut-off system

(e.g. safety ball check).

MAINTENANCE

Examine the gage glass regularly for any signs of clouding,

scratching, erosion, or corrosion. In new processes, the glass

should be inspected daily until the need for replacement

becomes apparent. This will help establish the routine inspection and routine replacement cycles.

CLEANING

Keep gage glass clean using non-abrasive commercial glass

cleaners. Where regular cleaners do not seem to work, use

dilute acids such as Hydrochloric (muriatic) acid. Always

observe safety rules when handling hazardous cleaning solutions. Never use wire brushes, metal scrapers, or harsh abrasives which could scratch the glass.

INSPECTION

Scratches, corrosion, chips, surface flaws, or nicks on the surface or edges weaken the gage glass. To examine for these,

shine a very bright concentrated light (“Burton Lite” or powerful flashlight) at about 45° angle. Anything which glistens and

catches the fingernail or any star-shaped or crescent-shaped

mark which glistens, is cause for replacement. Any gage glass

which appears cloudy or roughened and will not respond to

cleaning procedures, should be replaced.

STORING

Keep gage glasses in original packaging until ready to install.

HANDLING

Avoid bumping, chipping, or scratching glass. Any glass-toglass contact can cause scratches and must be avoided.

-

INSTALLATION

Always follow tubular gage manufacturer’s recommended procedures for glass replacement.

Before installing a gage glass, remove all deposits from the seal

contact surfaces of the gland nut and the gland (where used).

Check sealing surfaces for cleanliness and smoothness. Once

a gage glass has been removed from its mounting, regardless

of the reason for its removal. Discard the glass and replace with

a new piece.

Always use new packing, seals, and/or O-rings (if required)

when replacing a tubular gage glass. Used packing seals and

O-rings will not properly support the gage glass or provide the

proper pressure seal without stressing the glass.

5

Page 6

1. Hold fittings rigidly to prevent misalignment, which can

cause severe bending stresses in the glass, when packing

nuts are tightened.

2. Provide metal washers so nuts can be tightened without

twisting packing or tube.

3. Provide positive, but not excessive, clearance between

glass, packing nuts, and bearing washers.

4. Keep glass short enough to allow for expansion.

5. Provide positive clearance between the ends of the gage

glass and the metal fittings. Glass-to-metal contact will

keep the gage glass from expanding and cause breakage.

6. Tighten packing nuts enough to prevent leakage, but not so

much that you hinder expansion and contraction. Follow

gage manufacturer’s r

7. Generally, you can use cylindrical or conical rubber pack

ings for LOW and MEDIUM pressures. HIGHer pressures

and HIGH temperatures may require specialized packings.

In all cases you should follow the recommendations of the

gage manufacturer.

ecommendations.

-

TROUBLE SHOOTING PROCEDURES

All units are thoroughly tested at the factory before shipment.

They should operate satisfactorily without further adjustment if

properly installed and providing they have not been damaged

by rough handling in transit. If system or unit performance is

not satisfactory, refer to the following check list.

Pump Will Not Start

1. The power supply has been interrupted, disconnect switch

is open, or selector switch is improperly positioned.

2. Incorr

3. Incorr

4. The overload r

5. Check pump contr

6. Wiring to control cabinet is incorrect or connections are

7. The strainer is dirty thus retarding flow. Clean periodically.

Pump Runs Continuously

1. Pump is running backward. Rotation of three phase motors

2. The total required pressure at the pump discharge is greater

3. A valve in the discharge line is closed or throttled too

4. The impeller eye is clogged.

5. Pump is too small for system.

Condensate Pump is Noisy

1. The pump is working against a lower pressure than

ect voltage for motor. Check voltage and wiring with

motor characteristics.

ect starter coil for power supply.

reset. Ambient temperatur

loose.

may be corrected by interchanging any two of the three

wires. Rotation should be clockwise looking down on motor.

than the pressure for which the pump was designed. Check

the total pressure which includes atmospheric pressure, the

friction head and the static head.

tightly. Check valve is installed backwards.

designed for. While pump is discharging, adjust plug cock in

discharge line until pressure at pump approaches pump

rated pressure.

elays the starter have tripped out and must be

e may be too high.

ols or other controls for proper operation.

2. Excessive condensate temperature. Correct system conditions. However, this applies to certain units only; others are

designed to handle boiling water.

3. Magnetic hum or bearing noise in motor. Consult motor

manufacturer’s authorized service station nearest unit

location.

4. Starter chatters. Trouble is caused by low line voltage, poor

connections, defective starter coil, or burned contacts.

5. Pump is running backwar

The System is Noisy

1. Banging in the steam main is usually caused by steam

“imploding” in condensate lying in low points in lines. These

problems can be eliminated by dripping low points, pr

supporting the pipe, or by increasing the pitch of the lines.

2. Impr

3. The piping is too small to drain properly.

Steam Flow is Restricted

1. Thermostatic vent not open when cold.

2. Valve closed between vent line and drain or checkvalve

Relief Valve Discharging

1. Incoming steam pressure exceeds 15 psi (1.0 Bar) –

SA-P Pumps Don't Start or Run Continuously

1. If pneumatic system, check pressure setting or pneumatic

2. If electric, check displacer adjustments.

oper dripping of the steam mains and risers; where

there is a rise in the steam main, or where it branches off into

a riser, a drip trap must be installed in the drain line.

installed backwards.

upstream pressure must not exceed 15 psi (1.0 Bar). Correct

system.

pressure switch. Air pressure to engage switch at 2-3 psi

(0.1-0.2 Bar).

d.

operly

6

Page 7

7

DEALER SERVICING

If trouble occurs that cannot be rectified, contact your local

B&G r

epresentative. He will need the following information in

order to give you assistance.

1. Complete nameplate data of pump and motor. SEE RATING

NAMEPLATE.

2. Suction and discharge pipe pressure gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pump hook-up and piping.

1. Close pump isolation valve or system return line valve.

Operate pump momentarily to discharge as much water as

possible. Close pump discharge valve.

2. Shut-off and lock out power.

3. Make sure unit is cool enough that pump can be handled

safely. Open drain to remove remaining liquid.

4. Carefully remove pump drain plug and bleed line. Wait for

complete drainage.

5. Loosen both the discharge connection and the suction

housing to pump volute fasteners. Assure that pressure is

relieved per caution note.

6. Complete the removal of the above hardware. Remove

pump/motor assembly and place on work bench.

7a. Remove the suction housing capscrews and separate the

pump/motor assembly from the suction housing. Note, the

diffuser should separate from the suction housing to allow

the pump/motor assembly to be removed.

7b. Remove propeller, propeller stem and diffuser from the

assembly as follows:

(1) Threaded Motor Shafts (3Hp and less). Remove pro-

peller lock nut. Remove propeller with propeller stem as

an assembly with the diffuser. To install a new propeller,

remove the propeller set screws and separate from the

stem.

(2) Keyed Motor Shafts (5Hp and larger). Remove propeller

set screws. Remove propeller, remove diffuser, and

unscrew the propeller stem.

Morton Grove, Illinois 60053

TM

TM

SERIES

MODEL

SERIAL

GPM PSI PUMP

CFM IN HG. PUMP

DWGS

POWER V. PH. HZ60

CONTROL V. PH. 1 HZ60

TOTAL LARGEST MOTOR

F.L. AMP F.L. AMP

DN0016

PUMP SERVICE INSTRUCTIONS FOR SERIES B35 PUMPS AS USED ON SA & SA-P UNITS

CAUTION: PRESSURIZED SYSTEM

Operating system may contain very hot water and

steam under pressure. Close inlet and open drains before

servicing. When servicing, loosen screws and move components to assure pressure is relieved before removing screws.

Keep drains open during servicing. Failure to follow these

instructions could result in injury or property damage.

CAUTION: HOT SURFACES

Surfaces are hot when system is in operation. Do not

touch hot receiver, let unit cool before servicing. Failure to

follow these instructions could result in serious injury or

death.

WARNING: HIGH VOLTAGE

Disconnect and lock out power before connecting or

servicing unit. Failure to follow these instructions could

result in serious injury or death.

HEAVY DUTY

BALL BEARING MOTOR

WATER SLINGER

MECHANICAL SEAL

STAINLESS STEEL SHAFT

MOTOR BRACKET

PUMP VOLUTE W/WEAR RING

IMPELLER

IMPELLER

AXIAL FLOW PROPELLER

PROPELLER SET SCREW

SUCTION HOUSING

Page 8

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. DN0130D November 2012

Loading...

Loading...