Page 1

INSTRUCTION MANUAL

A91590B

DB-3/4"

Differential By-Pass Valve

3/4" x 3/4" NPT Male Connections

Operational Limits

Max. Temperature 230°F (110°C)

Max. Pressure 150psig (10 Bar)

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

NOTE: This product is not intended for use in potable

water applications.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENT ION! BECOME ALERT! YOUR

SAFETY IS I N V O LV E D ! FAI L U RE TO F O L L O W T HESE

INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

DESCRIPTION

The Bell & Gossett DB differential by-pass valve is used in

systems where various heating loads may be simultaneousl

excluded from the circuit because of the closing of control or

zone valves.

It ensures a recirculation proportional to the number of valves

which close, avoiding noises and maintaining the head of the

pump at a constant value.

TECHNICAL SPECIFICATIONS

Connections: 3/4" x 3/4" NPT Male

Materials: – Body Brass

Medium: Water and glycol solutions up to 50%

Maximum Workin

Maximum Working Temperature: 230°F (110°C)

Maximum Flow Rate: 9 GPM

Adjustment Range: 2 to 10 PSI (0.15 to 0.7 Bar)

– Seals EPDM

– Spring Stainless Steel

– Knob ABS

g Pressure: 150 PSI (10 Bar)

INSTALLATION INSTRUCTIONS

CAUTION: All work must be performed by qualified

personnel trained in the proper application, installation,

and maintenance of systems in accordance with all applica-

y

ble codes and ordinances.

WARNING: System fluids are under pressure or temp-

erature can be hazardous. Be sure the pressure has

been reduced to zero and the system temperature is below

100°F (38°C). Failure to follow these instructions could result

in property damage and/or personal injury.

WARNING: State of California Residents

This product contains a chemical known by the State

of Califor nia to cause cancer. This products contains a

chemical known by the State of California to cause birth

defects or other reproductive harm.

Page 2

INSTALLATION INSTRUCTIONS (cont'd) INSTALLATION INSTRUCTIONS (cont'd)

CAUTION: Overtightening and breakage can occur

with the use of PTFE pipe joint compounds. PTFE

provides lubricity so that care must be exercised not to over

tighten joints. Failure to follow these instructions could result

in property damage and/or moderate personal injury.

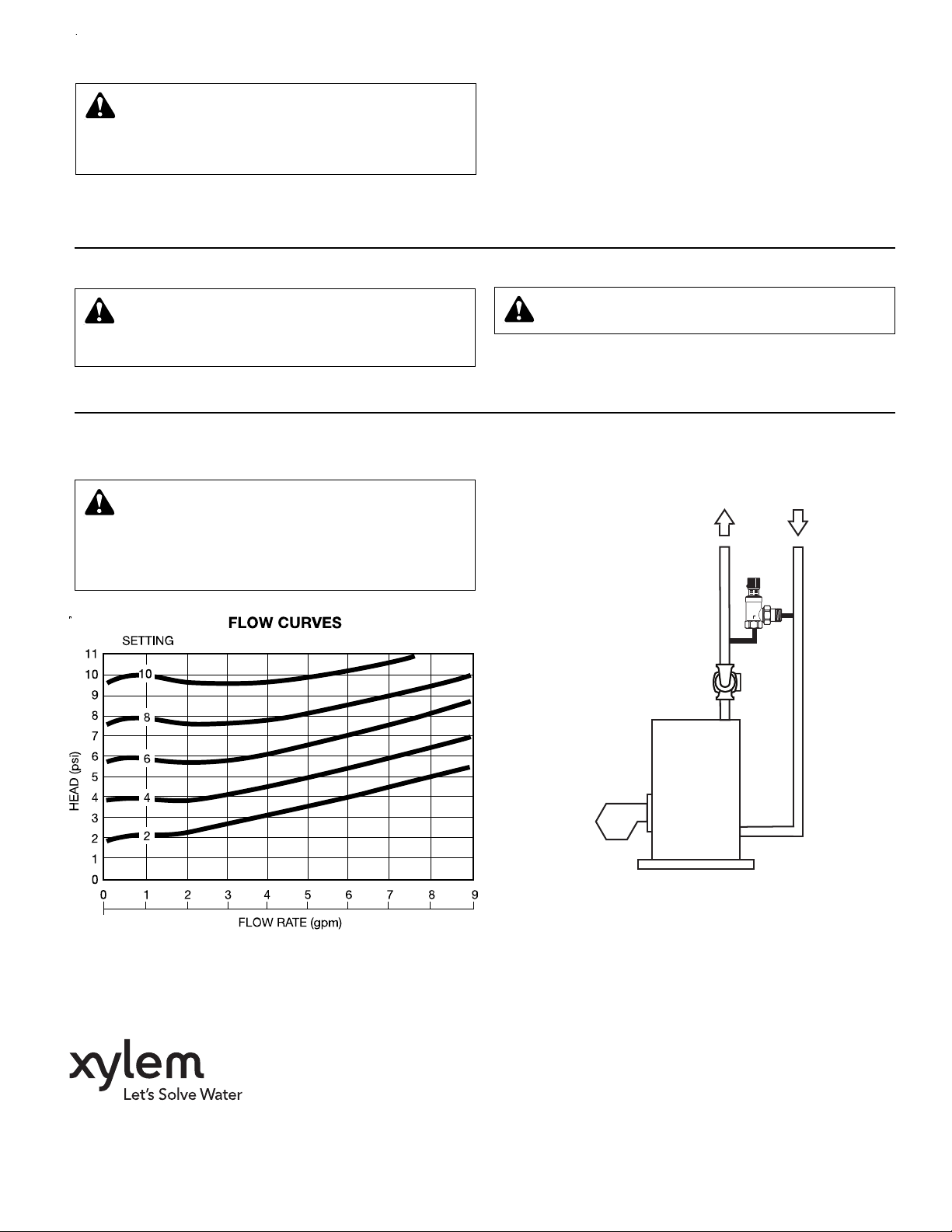

The by-pass valve should be installed after the pump between

the supply and return piping. It can be installed either in the horizontal or vertical position provided it is in accordance with the

direction of flow as indicated by the arrow on the valve body

(see Figure 1). With all valves open, set the bypass valve to

maximum pressure

(clockwise). Gradually open the bypass

valve (counterclockwise) until flow begins in the bypass valve.

Increase the pressure setting by 1/2 to 1 psi or turn knob clockwise 1/2 revolution so the water stops flowing through the

bypass valve.

OPERATING INSTRUCTIONS OPERATING INSTRUCTIONS

CAUTION: If the by-pass valve is not installed, com-

missioned and maintained properly, according to the

instructions contained in this manual, it may not operate correctly and may endanger the user.

SERVICE INSTRUCTIONS

There is no service required for the differential by-pass valve.

CAUTION: Corrosion or leakage of the differential by-

pass valve can cause damage or injury, Periodically

inspect the differential by-pass valve for signs of leakage or

corrosion. If noted, the differential by-pass valve must be

replaced. Failure to follow these instructions could result in

property damage and/or moderate personal injury.

CAUTION: Make sure that all the connecting pipework

is water tight.

Turn the knob to the desired value of the graduated scale; the

values correspond to the discharge pressure of the pump.

Lock

the setscrew located on the knob.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. A91590B October 2012

TYPICAL INSTALLATION

FIGURE 1

Loading...

Loading...