Page 1

INSTRUCTION MANUAL

A85524C

Rolairtrol

Air Separator

2", 21/2", 14" THROUGH 24"

R AND RL MODELS

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw attention to safety

related instructions. When used, the safety alert symbol means ATTENTION!

BECOME ALERT ! YOUR SAFET Y IS INVOLVE D! FAILURE TO FOL LOW

THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

WARNING: Carefully read the Instruction Manual to avoid serious

personal injury and property hazards and to ensure safe use and

proper care of this product.

DESCRIPTION

The Rolairtrol Air Separator is an ASME vessel designed with tangential openings to create a low velocity vortex where air is separated and removed from the

circulating water. The Rolairtrol is designed and constructed per ASME Section

VIII, Division I. This product is intended for hot and chilled water systems.

NOT FOR USE IN DOMESTIC (POTABLE) WATER SYSTEMS

DANGER: Rolairtrol Air Separator is for use in closed loop systems

only. Domestic, potable or fresh water can cause serious corrosion in a

tank. This can result in leakage and property damage. Do not use for

domestic, potable or fresh water. Failure to follow this instruction will result

in serious personal injury and property damage.

OPERATIONAL LIMITS

Maximum Operating Temperature: 350°F

Maximum Operating Pressure: 125 PSIG

CAUTION: Hot uninsulated surfaces can cause burns to the skin. Do

not touch hot surfaces. Failure to follow these instructions could

result in moderate personal injury.

INSTALLATION INSTRUCTIONS

1. Refer to Figures 1 and 2 for the proper installation of the Rolairtrol.

CAUT ION: Use un it liftin g lugs on ly to lift un it as shi pped from

factory. Unit must be empty and disconnected from pipe, and other

restraints. Use proper rigging procedures. Failure to follow these instructions could result in injury or property damage.

®

2" PLUG FOR RL

3" THROUGH 12"

R AND RL MODELS

WARNING: Wet weight of Rolairtrols can exceed strength of sup-

ports. Make sure the provisions are made to support the wet weight

and not just the dry weight (see Table 1). Failure to follow these instructions could result in serious personal injury or death and property damage.

WARNING: This product must be installed by a qualified professional.

Failure to follow the instruction in accompanying manual may cause

a leakage or explosion which may result in serious injury or death and

property damage.

WARNING: The use of improper mating flanges, connectors, gaskets

or bolting can cause flange or connector failure resulting in the loss

of hot or cold system fluid. Use only companion cast iron ANSI flanges or

connectors with appropriate gaskets and properly tightened bolts. Failure

to follow this instruction can result in serious personal injury and/or property damage.

2. Rolairtrol sizes through an “R-8” or “RL-8” can be supported in the piping system as long as pipe hangers are attached to the tangential nozzles as close

to the Rolairtrol shell as possible. Sizes larger than an “R-8” or “RL-8” will

need to have additional supports, such as a cradle under the Rolairtrol acting

on a diameter as close to the Rolairtrol outside diameter as possible or facto

installed support brackets.INSTALLATION INSTRUCTIONS

Note: Welding to the pressure vessel boundary will void the ASME stamp.

3. Model “R” Rolairtrol Air Separators have strainers which must be removed

and cl ean ed after 24 hours of op era tion, 30 days of operati on and as

required to maintain proper system air separation. Before installing the model

“R” Rolairtrol refer to Table 2 for minimum distances t

between the blowdown connection or end of the pipe plug and the floor or

other equipment for strainer removal.

4. A manual blowdown valve (MBV-1) can be added to the blowdown connection. The function of the MBV-1 is to facilitate the purging of sediment from

the vessel.

5. A manual blowdown valve (MBV-1) can be added to the 3" through 12" tanks

of the R models, by removing the 3" pipe plu

sized reducer.

WARNING: CALIFORNIA PROPOSITION 65 WARNING!

This product contains a chemical known by the State of California to

cause cancer and to cause birth defects or other reproductive harm.

g and replacing with the proper

o be maintaine d

3" PLUG FOR R

ry

Cv, APPROXIMATE VOLUME AND WEIGHT (Table 1)

size (inches) 22

R vol. (gal) 23713 25 34 90 150 291 472 723 1149 1577 1958 2463

R Cv 44 64 119 257 398 632 1020 1789 2665 1445 1885 2340 2945 3725 4325

R dry wt. (lbs) 55 90 130 170 220 295 460 845 1165 1780 2425 3410 5310 6400 7500

R wet wt. (lbs) 70 115 188 278 429 579 1211 2097 3588 5719 8458 12998 18470 22740 28054

RL vol. (gal) 23713 25 34 90 150 291 472 723 1149 1577 1958 2463

RL dry wt. (lbs) 50 85 115 155 205 280 420 800 1110 1780 2425 3410 5310 6400 7500

RL wet wt. (lbs) 65 110 173 263 414 564 1171 2052 3538 5719 8458 12998 18470 22740 28054

RL Cv 55 80 215 370 580 850 1445 2340 3300 3900 5100 6410 8000 10000 11700

1

/2 3456810 12 14 16 18 20 22 24

DISTANCE IN INCHES REQUIRED TO REMOVE STRAINER (Table 2)

size (inches) 22

distance 8.5 8.5 12 14 16 19 23 28 31 37 42 52 56 60 64

1

/2 3456810 12 14 16 18 20 22 24

Page 2

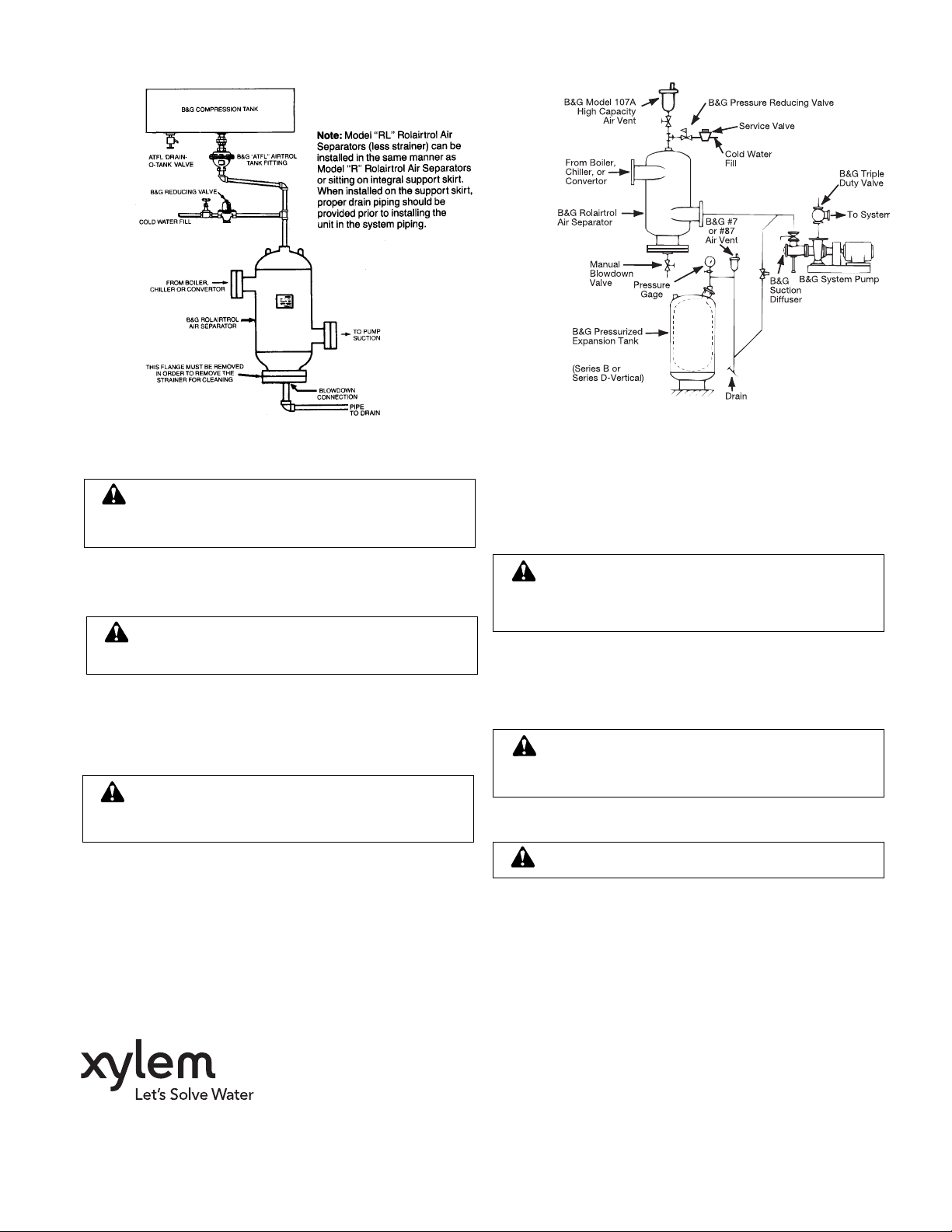

TYPICAL HYDRONIC HEATING/COOLING APPLICATIONS

Fig. 1 Air Control

Fig. 2 Air Elimination

SERVICE INSTRUCTIONS

WARNING: Leakage, corrosion or indications of damage are signs of

an impending serious failure of the Rolairtrol. Periodically inspect for

damage and if noted the Rolairtrol must be serviced or replaced. Failure to

follow these instructions could result in serious personal injury or death

and property damage.

The strainer in the R series Rolairtrol may need to be cleaned periodically. This is

particularly true during the initial start-up period. The need to clean the strainer

will be evidenced by a high pressure drop across the Rolairtrol or by pump cavitation problems. To clean the strainer:

a) Allow the system water temperature to cool below 100°F.

WA RN I NG : Wat er a t tem pe ratur es a bo ve 100°F can be very

hazardous. Allow system water temperature to cool down below

100°F before blowing down Rolairtrol. Failure to follow these instructions

could result in serious personal injury or death and property damage.

b) Open the blowdown drain valve for

accumulated dirt from the strainer. If it does not then the strainer must be

removed from the Rolairtrol for cleaning. This can be accomplished by closing the isolation valves to isolate the Rolairtrol from the system. Make sure

the water temperature in the Rolairtrol is below 100°F. Open the blowdown

valve on the bottom of the Rolairtrol to drain the unit. Make sure that all flow

from the blowdown valve has stopped. If water continues to flow, the isolation valves must be repaired or replaced before proceeding.

WARNING : System fluid under pressure and/or high temperature

can be very hazardous. Before proceeding to service strainer, reduce

system pressure to zero or isolate the Rolairtrol from the system. Allow the

system to cool below 100°F. Failure to follow these instructions could

result in serious personal injury or death and property damage.

a few seconds. This should dislodge

c) For 2", 2

d) For 3" through 12" of the R models, remove the 3" pipe plug that holds the

e) Do not use any open flame devices (torches, solder guns, etc.) which may

1

the strainer housing cover in place on the bottom of the Rolairtrol. Remove the

cover and strainer. Clean the strainer and reinstall in the Rolairtrol. Replace

the cover gasket with a new one and reinstall the cover making sure that the

flange bolts are tightened in a criss-cross pattern to the proper torque. Close

the blowdown valve and open the isolation valves to return the Rolairtrol to

normal operation. Check the gasket for signs of leakage. If found, additional

slight tightening of bolts may be required.

strainer in place on the bottom of the Rolairtrol. Remove and clean the strainer,

reinstall them making sure that the strainer goes through the strainer guide

and the pipe plug is tightened. Close the blowdown valve and open the isolations to return the Rolairtrol to normal operation. Check the pipe plug for

signs of leakage. If found, additional slight tightening of pipe plug may be

required.

thermally degrade the painted or galvanized surfaces and cause the release

of harmful decomposition products, which may be harmful if breathed.

/2" and 14" through 24" models, remove the flange bolts that hold

WARNING: The use of improper mating flanges, connectors, gaskets

or bolting can cause flange or connector failure resulting in the loss

of hot or cold system fluid. Use only companion cast iron ANSI flanges or

connectors with appropriate gaskets and properly tightened bolts. Failure

to follow this instruction can result in serious personal injury and/or property damage.

CAUTIO N: The use of Teflon®* impregnated pipe compound and

Teflon®tape on pipe threads provides lubricity which can lead to

overtightening and breakage. Do not overtighten. Failure to follow this

instruction can result in moderate personal injury from hot water and/or

property damage.

WARNING: Failure to follow these instructions could result in serious

personal injury or death.

*Teflon is a registered trademark of E.I. DuPont de Nemours and Company.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. A85524C May 2012

Loading...

Loading...