Page 1

Warning label V56871

installed in this location.

If missing, it must be

replaced.

INSTRUCTION MANUAL

A07180C

Enhanced

Air Separator

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

DESCRIPTION

The Bell & Gossett Model EASB-JR Enhanced Air Separator

automatically removes entrained air bubbles in hydronic systems.

As fluid enters the EASB-JR, the velocity is slowed down creating a low pressure area. The air bubbles are then released from

fluid and collect on the coalescing medium. As the bubbles

coalesce, they will rise to the top of the air separator where they

can be released to atmosphere through the built-in automatic

air vent. The air separator has a bottom

accommodate a B&G diaphragm expansion tank. The compact

design and brass body construction make the EASB-JR ideal

for residential and commercial hydronic heating systems.

TECHNICAL SPECIFICATIONS

Available Sizes:

3

/4" NPT

1" NPT 1" Sweat

1

1

/4" NPT 11/4" Sweat

1

1

/2" NPT

2" NPT

Materials:

Body . . . . . . . . . . . . . . . . . . . . . . . .Brass

Coalescing Medium . . . . .Stainless Steel

1

/2" NPT connection to

3

/4" Sweat

Model EASB-JR

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

Chart A

Working Pressure & Temperature Limits

(Solder Type Limits Per ASTM Std. B16.18-1979)

FLOW-CONTROL TYPE OF

STYLE SOLDER PRESSURE PSI TEMPERATURE °F

NPT – 150 250

SWEAT

95-5

Tin-Antimony

MAXIMUM LIMITATIONS

150 250

Page 2

INSTALLATION INSTRUCTIONS

Enhanced Air Separators with Sweat Connections

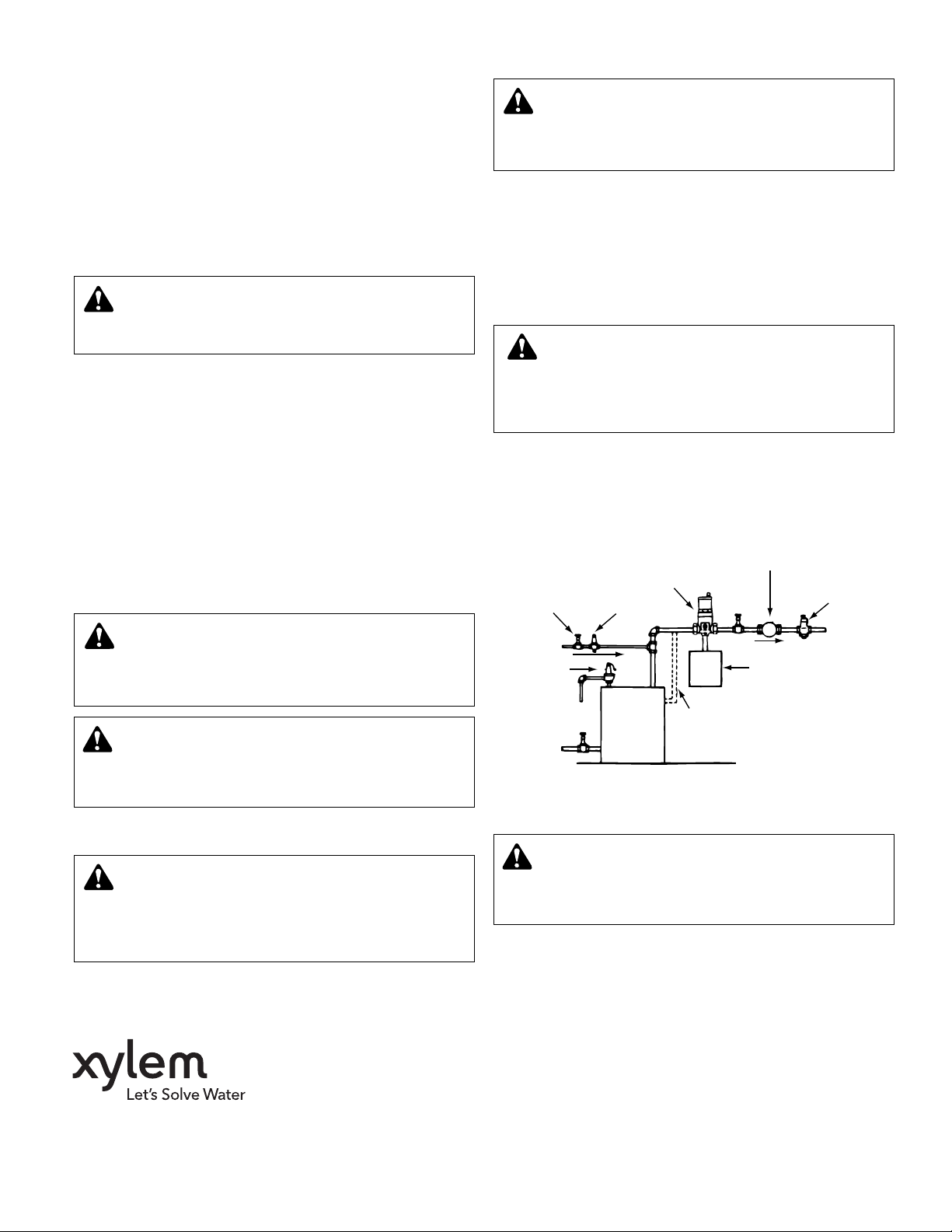

1. Install the air separator in horizontal piping so that the air

vent is in the top vertical position. The air separator is

bi-directional so that water can flow in either direction

(see Figure 1).

2. Use a torch with a sharp pointed flame.

3. Clean tube ends and air separator connection thoroughly.

4. Use 95-5 (Tin-Antimony) solder and a good grade of flux.

CAUTION: Heat associated with the use of silver solder

may damage a Air Separator voiding the warranty. Do

not use silver solder. Failure to follow these instructions could

result in proper damage and/or moderate personal injury.

5. When sweating joints, first wrap the air separator with a cool

wet rag, then direct the flame with care to avoid subjecting

the EASB-JR to excessive heat.

6. Refer to Chart A for the maximum operating pressure and

temperature based on the type of solder used.

7. After sweating the joints, check the connections for leakage.

Enhanced Air Separators with NPT Connections

1. Install the air separator in horizontal piping so that the air

vent is in the top vertical position. The use of Teflon tape

sealer or a high quality thread sealant is recommended. The

air separator is bi-directional so that water can flow in either

direction (see Figure 1).

2. Check connections for leaks.

CAUTION: The use of Teflon®impregnated pipe com-

pound and Teflon tape on pipe threads provides lubricity

which can lead to overtightening and breakage. Do not overtighten. Failure to follow this instruction can result in moderate personal injury from hot water and/or property damage.

WARNING: State of California Residents

This product contains a chemical known by the State

of California to cause cancer. This product contains a chemical known by the State of California to cause birth defects or

other reproductive harm.

CAUTION: Hot venting can be hazardous. Avoid con-

tact with venting fluid and only manually vent when

system temperature is below 100°F (38°C). Failure to follow

these instructions could result in property damage and/or

personal injury.

Turn the cap on top of the vent counterclockwise one full turn to

allow the EASB-JR to automatically remove the air from the

system. This is the normal operating position.

To shut down the automatic air vent, turn the cap tight. Be sure

to turn the cap back to the open position (one full turn) for

normal operation.

SERVICE INSTRUCTIONS

WARNING: Servicing the Enhanced Air Separator with

unit pressurized or at temperatures above 100°F

(37.8°C) can cause personal injury. Make sure pressure is

removed from unit and temperature is below 100°F (37.8°C).

Failure to follow these instructions could result in serious

personal injury or death and property damage.

The Enhanced Air Separator should not require servicing. If the

system fluid contains large amounts of contaminants, the

perforated metal strainer may become contaminated with

foreign substances. The Enhanced Air Separator cap unscrews

from the body for easy cleaning of strainer.

B&G BOOSTER

FLO-CONTROL

VALVE

TO

SYSTEM

DIAPHRAGM TYPE

EXPANSION TANK

SHUT-OFF

VALVE

CW FILL

B&G RELIEF

VALVE

RETURN

EASB-JR AIR

SEPARATOR

B&G PRESSURE

REDUCING VALVE

FLOW

BOILER

OPTIONAL SIDE

OUTLET BOILER

CONNECTION

TYPICAL INSTALLATION – FIGURE 1

OPERATING INSTRUCTIONS

CAUTION: Contaminants and scale from the system

can foul the automatic air vent operation mechanism.

Keep vent cap closed tight during the system filling to prevent contaminants from running into valve vent mechanism.

Failure to follow these instructions could result in property

damage and/or moderate personal injury.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. A07180C May 2012

CAUTION: Uncontrolled venting of water can occur

with automatic air vents if foreign material prevents

vents from closing. Unwanted flow should be directed to a

drain. Failure to follow these instructions could result in property damage and/or moderate personal injury.

Loading...

Loading...