Page 1

WARNING LABEL PART NO. 9015-463 INSTALLED IN THIS

LOCATION. IF MISSING, IT MUST BE REPLACED.

INSTRUCTION MANUAL

A01500I

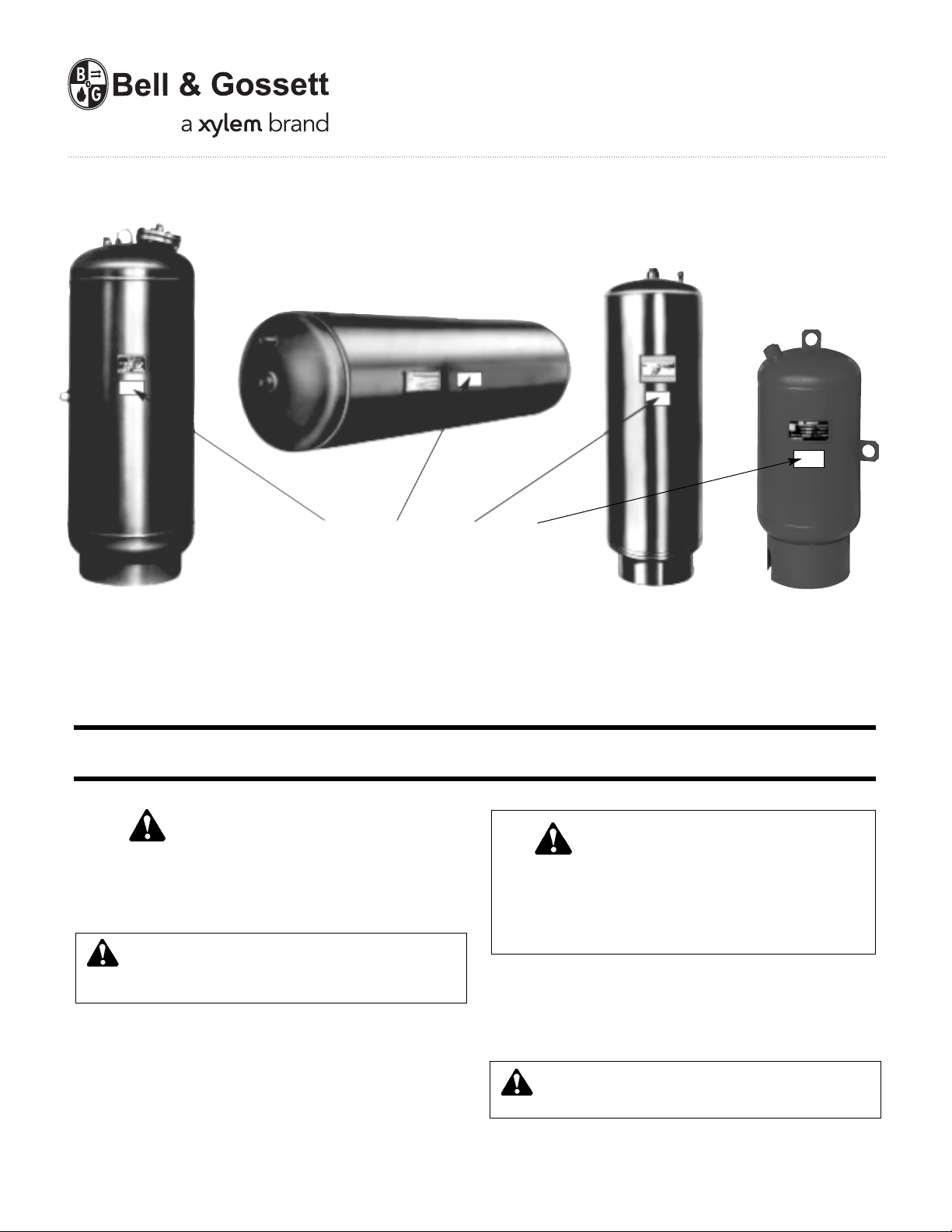

Series "B"

Series "D"

Series "B-LA"

Pressurized Expansion Tanks (ASME)

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual to draw attention to

safety related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A

SAFETY HAZARD.

WARNING: Explosion Hazard

Failure to follow instructions in the accompanying product

manual can cause rupture or explosion, possibly causing serious or

fatal injury, leaking or flooding and/or property damage.

DESCRIPTION

Precharged Expansion Tanks contain either a bladder or a diaphragm

to separate the air charge from the system water. Tanks are designed

to absorb the expansion forces of heating/cooling system water while

maintaining proper system pressurization under varying operating

conditions.

DANGER: Series “B”, “D”, & “B-LA” are for use in closed loop

systems only. Domestic, potable or fresh water can cause serious

corrosion in a tank. This can result in leakage and a potential

explosion. Do not use for domestic, potable or fresh water. Failure

to follow this instruction will result in serious personal injury or

death and property damage.

OPERATIONAL LIMITS

Maximum Operating Pressure: 125 psi (or as stamped on nameplate)

Maximum Operating Temperature: 240ºF

Minimum Operating Temperature: 35°F (non-glycol application)

safe use and proper care of this product.

NOT FOR USE IN DOMESTIC

(POTABLE) WATER SYSTEMS

18°F (glycol application)

WARNING: Carefully read the Instruction Manual to avoid

serious personal injury and property hazards and to ensure

Page 2

2

POINT OF CONNECTION

A. General

The Series B and Series D tanks work equally well when installed in the

vertical or horizontal position. When Series B tank is installed horizontally,

the system connection must be located below the centerline of the tank.

The Series B-LA tanks must be installed in vertical position. They cannot

be installed in the horizontal position.

The pressurized expansion tank-to-system piping differs from the

“standard” compression tank piping in several major aspects:

1. Air from the system must be purged to the atmosphere and not allowed

to enter the tank.

2. Tank-to-system piping must not be pitched-up to the tank.

3. Shut-off and drain valves or tank purge valve B&G TPV must be

installed in the tank-to-system piping in order to properly check and

recharge the tank air after the system has been filled with water.

4. Airtrol Tank Fitting (ATF or ATFL) is not required.

B. Piping

Typical tank-to-system and air vent piping are illustrated by Figures 1 thru

6. Some general notes regarding this piping are listed below:

1. The connection point from tank-to-system represents the point of no

pressure change. This means that the expansion tank must be

connected as close as possible to the suction side of the system

circulating pump for proper system operation.

2. The branch piping to the tank must be attached to the main to minimize

the possibility of air and debris entering the tank piping. If connected

to the horizontal main, do not use top (12 o'clock) and bottom (6 o'clock)

positions. Side connections are the proper positions. If connection

must be made at the bottom, a dirt trap leg with a flushing drain valve,

such as shown in Figure 4, should be installed.

3. Table A shows the recommended pipe sizes. Note that the MBH

column represents the output of the heat generator (firing rate, etc.).

The pipe sizes are selected for very low pressure loss in the tank-tosystem piping to accommodate system operating pressures within

10% of the relief valve setting. However, if the actual system operating

pressure is less than 80% of the relief valve setting, the tabulated pipe

size above 1" may be reduced by one size.

Pipe sizes 1" or less must not be changed due to the greater possibility

of fouling in the smaller pipes.

4. In order to change the tank air charge pressure it is necessary to isolate

the tank circuit from the main system piping. A high quality, gate type

or TPV, lock-shield valve must be used for this purpose. The lockshield for the valve stem will eliminate tampering of this normally open

valve during normal system operation.

5. In addition to the lock-shield valve above TPV or a drain valve,

automatic air vent and a pressure gauge must be installed in the piping.

The drain valve is used for flushing (item 2 above) and to drain the

water out of the tank for proper air charging.

6. Tank sizing calculations are based on minimum temperature rise of the

air in the tank. For this reason, an anti-thermosyphon loop must be

formed in the tank-to-system piping to minimize the effects of gravity

(thermal) circulation into the tank. A drop leg from 12" to 20" long is

usually sufficient. It is also suggested that this piping and tank not be

insulated (heating systems only).

7. Allow an overhead clearance for the Series B of at least 36" to remove

the bladder through the flanged opening in case replacement is

required. For bladder replacement of the Series B-LA tanks, the tank

must be removed from the system.

INSTALLATION

1. Note location of system connection, air charge valve and drain

connection on tank.

2. Remove the plug or pipe cap from the system connection.

3. Remove the 11/2" NPT plug covering the air charge valve.

4. Before making any connection to the tank, check the tank and air

charge (use an accurate pressure gauge). The air pressure must be

equal to the minimum system pressure at the tank location.

5. After making sure the air charge is correct, replace the 11/2" plug over

the air valve.

6. The tank may now be piped to the system (use the suggested tank

piping diagram on page 4 and 5).

7. Using table A, select appropriate pipe size. Connection to each tank

must have a lock shield gate valve or TPV and union to allow isolation

and removal if required. Make up and fill valves, whether manual or

automatic, should be tied into the connecting line. This will ensure that

pump operation will not affect valve operation.

CAUTION: Pump cavitation and unbalanced circuits can result

from improper tank location. Connect tank as close to suction

side of system circulating pump as possible. Failure to follow this

instruction could result in property damage and/or moderate personal

injury.

WARNING: This product must be installed by a qualified

professional. Failure to follow the instruction in accompanying

manual may cause a rupture or explosion which may result in serious

injury or death and property damage.

WARNING: CALIFORNIA PROPOSITION 65 WARNING!

This product contains a chemical known by the State of

California to cause cancer and to cause birth defects or other

reproductive harm. (California Installer/Contractor – California law

requires that this notice be given to consumer/end user of this product.

CAUTION: A blocked connection to the expansion tank will

cause system to become overpressurized resulting in periodic

discharge of system relief valve. This periodic discharge will require that

fresh water be added to the system to maintain pressure. The resulting

addition of fresh water will cause corrosion in system components. The

use of a bottom connection to the main requires the use of dirt trap leg

with a flushing drain valve. Failure to follow these instructions could

result in property damage and/or moderate personal injury.

WARNING: System overpressurization will result if expansion

tank isolation valve is not kept open during normal operation.

Provisions must be made to lock this valve open during normal system

operation. Failure to follow these instructions could result in serious

personal injury or death and property damage.

WARNING: Do not locate this product where leaking or flood

could cause damage to the surrounding property. A drip pan

connected to an adequate drain must be installed if leaking or flooding

could cause property damage. Failure to follow this instruction could

result in property damage.

CAUTION: Lack of or improperly sized air vent will cause

system circulation problems. An automatic air vent must be

installed in the line to the expansion tank and at air separating devices

as shown in Figures 1 thru 6. These must be sized to vent off any

accumulated air. Failure to follow these instructions could result in

property damage and/or moderate personal injury.

Page 3

3

OPERATING INSTRUCTIONS

1. Check the expansion tank pre-charge before the system is filled with

water. The charge is 12 psig unless noted otherwise on the tank label.

Check to make sure this is the correct precharge pressure specified for

the system. Precharge should match system fill pressure at point of

tank installation. If increasing precharge, the tank must be connected

immediately to the system. The tank should not be isolated at this

condition. Failure to do so could result in damage to the bladder and

void all warranties.

2. If the tank pre-charge pressure needs to be changed on a dry system

follow the following procedure:

a. Check the expansion tank air pressures at the precharge connection

with an accurate tire type pressure gauge. The pre-charge

connection is the same kind of connection found on automobile

tires.

b. If the pressure is low, charge the tank with nitrogen gas or with oil-

free compressed air. Check the pressure frequently during this

process as you would when filling a tire with air.

3. If, after the system has been filled with water and operating, it is found

that the expansion tank pre-charge must be changed use the following

procedure:

a. Turn off the heat source and allow the system water to cool

to ambient temperature.

b. Close the lock-shield valve in the tank-to-system piping.

c. Open the drain valve or TPV to empty the water from the tank.

d. Check the tank air pressure at the pre-charge connection with

an accurate tire type air gauge.

e. Refer to 2b above.

f. Close the drain valve, open the lock-shield valve and turn on

the heat source.

g. Relock the lock-shield valve.

SERVICE INSTRUCTIONS

1. Check the expansion tank periodically for signs of external leakage or

corrosion, If found, the tank must be replaced.

2. If the tank fails to hold the pre-charge pressure it could be the result of

one of the following.

a. Leakage of air valve. Do not depend on the valve cap to seal leak.

1. Refer to items 3a thru 3d under operating instructions to

prepare the tank so that the air valve core can be changed.

2. If only gas escapes, unscrew the air valve core and replace

with a tire type/Schrader valve core. If liquid escaped refer

to 2b below.

3. Refer to 3e thru 3g under operating instruction to complete

the service procedure.

b. The bladder or diaphragm is leaking as indicated by liquid on

the gas side or the inability of the tank to maintain its gas

cushion. If the tank is a diaphragm type, the tank must be

replaced. Diaphragm tanks can be identified by the model

numbers beginning with a “D” and the absence of a large

flanged opening to remove the bladder. If the tank is a bladder

type, the bladder can be replaced as follows:

1. Refer to items 3a thru 3c under operating instructions to

prepare the system for replacement of the bladder.

2. Depress the center valve core stem on the air side of the

tank, as with a tire valve, to slowly vent off the air or gas

charge.

3. Remove the bolts from the flanged cover to gain access to

the bladder. Series B-LA tanks must be disconnected

from the system. Remove the bottom drain plug to drain fluid.

4. Pull the bladder from the tank through the flanged opening.

5. Make sure all flange surfaces are clean and free of

corrosion so that the new bladder will seal properly. If

corroded, the tank must be replaced.

6. Install the new bladder in the tank by stuffing through the

flange opening in the reverse manner that the old bladder

was removed. The Partial Acceptance tank has a support

pipe, which the bladder will fit around. Insert the new

bladder into bottom of the tank. To make system connection,

align elbow with hole in skirt.

7. Replace the flanged cover and tighten the bolts in a

crisscross pattern. Take care not to exceed the allowable

torque of the bolts. Screw in drain plug.

8. Refer to item 3e thru 3g under operating instructions to

place the system back in operation.

9. Check for gas leaks around the flange connection. If leaks

are found, lightly tighten bolts in a criss-cross pattern,

again being careful not to exceed the allowable torque of

the bolts. If leaking continues, the expansion tank will have

to be replaced.

DANGER: Signs of leakage or corrosion are indications

the tank may explode. Periodically check the expansion tank for

signs of external leakage or corrosion. If found, the tank must be

replaced. Failure to follow these instructions will result in serious

personal injury or death and property damage.

WARNING: Improper use of air charging valve during venting of

air pressure from tank will create a hazardous condition due to

the escape of high velocity gas and/or liquid. Depress the center valve

core stem, as with a tire valve, to slowly vent off gas pressure. Do not

remove the valve core until pressure in the expansion tank has reached

zero. Failure to follow these instructions could result in serious

personal injury or death and property damage.

IMPORTANT: Expansion tank cannot be properly air charged other

than at ambient temperature.

WARNING: Residual system pressure is a serious hazard when

attempting to replace tank bladder. Make sure that all fluid has

stopped draining from the drain valve and the system pressure is zero.

If leaking continues from the drain valve, the lock-shield isolation valve

must be replaced before proceeding. Failure to follow these

instructions could result in serious personal injury or death and

property damage.

DANGER: Excessive pressure can cause tank to explode.

Exercise care when filling a tank with air so the pressure does

not exceed that required or does not exceed the working pressure of

the tank as stamped on the nameplate. Failure to follow these

instructions will result in serious personal injury or death and property

damage.

WARNING: Removing the bladder housing cover with an air

charge or pressure still in the tank can cause the cover to be

blown off. Make sure that all gas charge pressure and system pressure

is removed from the tank before loosening or removing cover bolts.

Failure to follow these instructions could result in serious personal

injury or death and property damage.

Page 4

4

B & G Pressure

Reducing Valve

with Check

Cold

Water

Fill

B & G

Model 107A

High Capacity

Air Vent

From

Boiler

or HX

B & G

Rolairtrol

Air

Separator

Drain

Valve

Lock-Shield

Valve

2

3

B & G Suction

Diffuser

B & G

System

Pump

To System

B & G Triple Duty Valve

See Table A for Pipe Size

1

1

Pre-Charging Air

Connection

B & G Pressurized Tank (Series D)

Tanks May be Floor Mounted

with BLZ Leg Assemblies

See Fig. 1 for Series B Tank Mounting

B & G #7 or #87

Air Vent

Pressure

Gage

Cold

Water

Fill

From

Boiler

or HX

B & G Pressure Reducing Valve

with Check

B & G

Model 107A

High Capacity

Air Vent

B & G Rolairtrol

Air Separator

Drain

Valve

Lock-Shield

Valve

See Table A for

Pipe Sizing

B & G #7

or #87

Air Vent

Pressure

Gage

Tank Purge

Valve

B & G

Suction

Diffuser

B & G System Pump

To System

B & G Triple Duty Valve

A

lte

rn

a

te

Pre-Charging

Air Connection

B & G Pressured

Expansion

Tank

(Series B or

Series D-Vertical)

Tank Purge

Valve

FIGURE NOTES

1. Tank connection locations may vary depending on the type of tank to be installed.

2. Provide an anti-thermosyphon loop with a minimum drop of 12" to prevent gravity heating of the tank.

3. Figures 1 and 2 show where a tee would be located if multiple expansion tanks are installed.

Figure 1

Vertical Tank Installation with Rolairtrol Air Separator

Figure 2

Horizontal Tank Installation with Rolairtrol Air Separator

Fitting

Size, in.

No. of Vents

Recommended

1, 1 /

1 / , 2

2 / , 3

1 B & G Model 107 A

1

2

Pre-Charging Air

Connection

1

1

B & G Pressurized Tank (Series D)

Tanks May br Floor Mounted

with BLZ Leg Assemblies

See Fig. 1 for Series B Tank Mounting

B & G #7 or #87

Air Vent

Pressure

Gage

B & G #7 or #87

Air Vents

See Table

Above

B & G Pressure

Reducing Valve

with Check

Air

Eliminator

Fitting

Cold

Water

Fill

B & G Flo-Control Valve

or Triple Duty Valve

See Table A

on Page 5

For Pipe Size

B & G System Pump

To System

Dirt Leg

8" Long Minimum

Drain

Valve

2

Lock-Shield

Valve

From System

Drain

Pipe

B & G

Relief Valve

Boiler

1

2

1

2

1

2

Tank

Purge Valve

Figure 3 - Typical Piping with IAF In-Line

Air Separator and Airtrol Boiler Fitting

Figure 4 - Tank Installation with IAS

In-Line Air Separator

Cold

Water

Fill

Drain

Pipe

From System

Tank or

Boiler

B & G Pressure Reducing Valve

with Check

B & G

Relief Valve

B & G Model 107 A

High Capcity

Air Vent

Typical Piping

with Airtrol Boiler Fitting

B & G

Airtrol

Boiler

Fitting

Manual

Vent

IAF 2" to IAF 4"

Follow

Figure 1 or 2

for Tank and

Pump Piping

B & G Model 107 A

High Capcity Air Vent

B & G

Relief Valve

When Required

Manual

Vent

B & G Pressure

Reducing Valve

with Check

Cold

Water Fill

From Boiler

or Heat

Exchanger

Page 5

5

PIPING DIAGRAMS

Figure 5: Suggested Piping Diagram

Tank with Bottom System Connection

Pump

Figure 6: Alternate Piping Diagram

Tank with Bottom System Connection

MBH 100 150 200 250 300 100 150 200 250 300 100 150 200 250 300

1,000

1

/2

1

/2

1

/2

1

/2

1

/2

1

/2

1

/2

1

/2

3

/4

3

/4

1

/2

3

/4

3

/4

3

/4 1

2,000

1

/2

1

/2

1

/2

1

/2

3

/4

1

/2

3

/4

3

/4

3

/4 1

3

/4

3

/4 111

1

/4

3,000

1

/2

1

/2

3

/4

3

/4

3

/4

3

/4

3

/4 1113/4 111

1

/4 11/4

4,000

1

/2

3

/4

3

/4

3

/4 1

3

/4 1111

1

/4 111

1

/4 11/4 11/4

5,000

1

/2

3

/4

3

/4 113/4 111

1

/4 11/4 11

1

/4 11/4 11/4 11/4

6,000

1

/2

3

/4 1113/4 11

1

/4 11/4 11/4 11

1

/4 11/4 11/2 11/2

7,000

3

/4 1111

1

/4 11

1

/4 11/4 11/4 11/4 11/4 11/4 11/4 11/2 2

8,000

3

/4 1111

1

/4 11

1

/4 11/4 11/4 11/2 11/4 11/4 11/2 11/2 2

9,000

3

/4 111

1

/4 11/4 11

1

/4 11/4 11/4 11/2 11/4 11/4 11/2 22

10,000

3

/4 111

1

/4 11/4 11

1

/4 11/4 11/2 11/2 11/4 11/2 222

12,000 1 1 11/4 11/4 11/4 11/4 11/4 11/2 11/2 21

1

/4 11/2 222

14,000 1 11/4 11/4 11/4 11/2 11/4 11/4 11/2 221

1

/4 2222

1

/2

16,000 1 11/4 11/4 11/4 11/2 11/4 11/2 11/2 221

1

/2 222

1

/2 21/2

18,000 1 11/4 11/4 11/2 11/2 11/4 11/2 2221

1

/2 222

1

/2 21/2

20,000 1 11/4 11/4 11/2 11/2 11/4 11/2 2221

1

/2 22

1

/2 21/2 21/2

EQUIVALENT LENGTH UP TO 10' EQUIVALENT LENGTH 11' TO 30' EQUIVALENT LENGTH 31' TO 100'

MAX. AVERAGE DESIGN TEMP. ºF. MAX. AVERAGE DESIGN TEMP. ºF. MAX. AVERAGE DESIGN TEMP. ºF.

TABLE A - MINIMUM PIPE SIZE FROM TANK TO SYSTEM (IN INCHES)

Supply

Triple Duty

Valve

Air

Separator

Drain

Suction

Diffuser

Air

Eliminator

Return

Drain

Isolation

Valve

C.W.S.

Automatic

Fill Valve

Pump

Supply

Triple Duty

Valve

Air

Separator

Drain

Suction

Diffuser

Air

Eliminator

Alternate Air Separator Location

Isolation

Valve

Return

Highest Point in System

Point of Lowest Solubility

Return

Drain

C.W.S.

Automatic

Fill Valve

Page 6

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. A01500I May 2012

Loading...

Loading...