Page 1

INSTRUCTION MANUAL

6-71-075-003

REVISION A

Autocirc® Instant Hot Water Pump

Models e3-4_/BDPQC and e3-4_/BDPRC

Page 2

Page 3

Preparation for Installation:

Assemble the parts and tools required:

• Autocirc pump package includes the pump with a built-in timer, a 6ft. cord, and

wall mounting bracket.

• Two stainless steel flexible hoses (1/2” x 3/8”) - length as required. (sold separately)

• Adjustable wrench and screwdriver.

• Select the sink under which the Autocirc pump is to be located (the sink where hot

water takes longest to arrive).

This pump must be installed in accordance with AS3500.

This pump has been tested using water only. Its suitability for use with liquids other than

water is the end user’s responsibility.

Australia

U.L. Caution

Installation

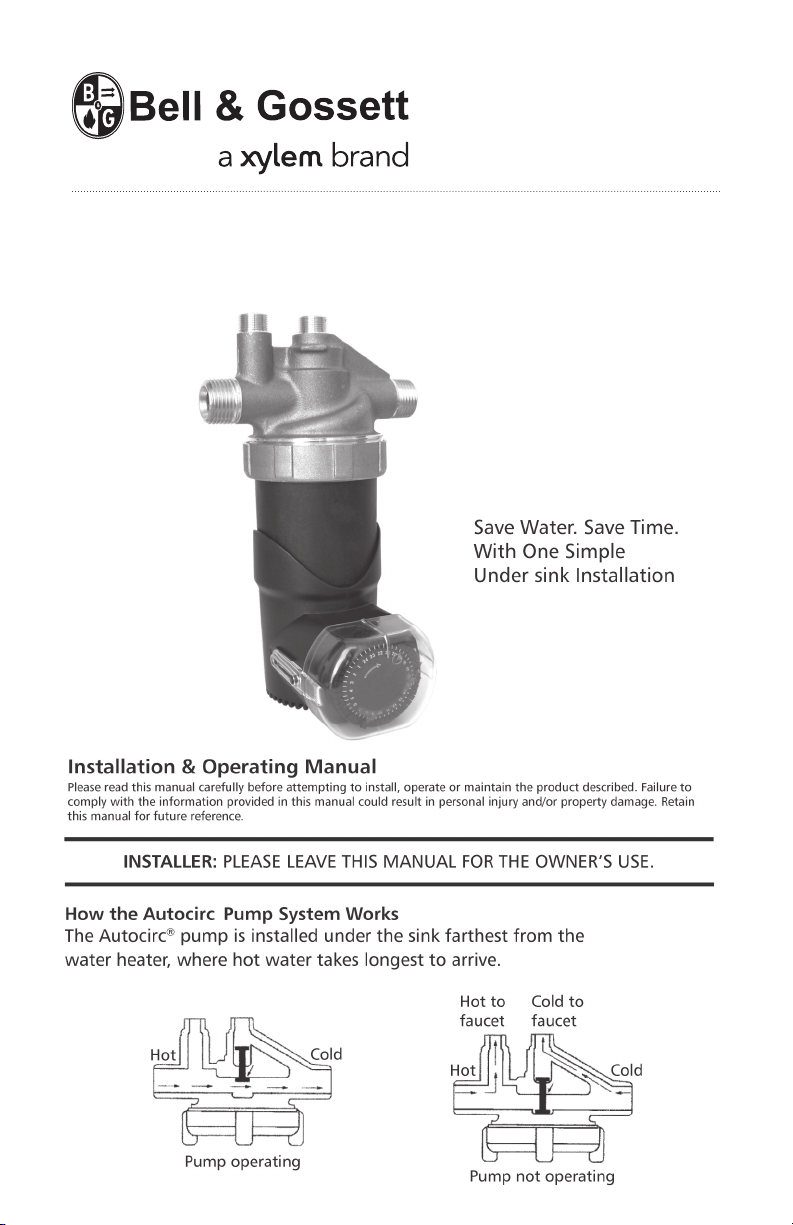

Step 1

If not already available, install a 115 Volt/ 60Hz

outlet within six (6) feet of the installation site (the

faucet/tap farthest from the water heater), as the

Autocirc is supplied with a 6 ft. long, grounded

cord. The Autocirc pump requires only 14 watts and

0.3 amps of power (see Fig. 1).

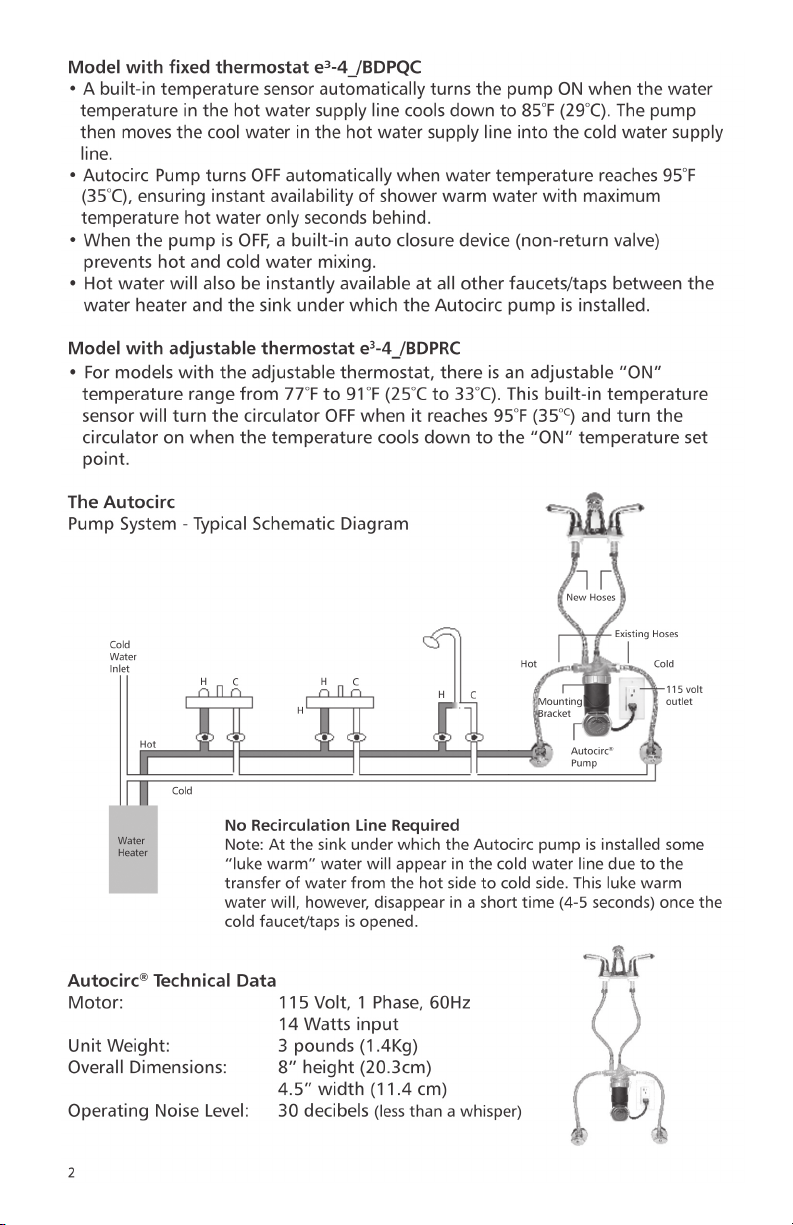

Step 2

Fasten the Autocirc to the wall under the sink using

the wall bracket provided in the Autocirc kit. Be sure

Figure 1

the pump timer is turned toward the front and is

accessible for setting and changing the time (see

Fig. 2). The pump must be installed only in a vertical

position as shown.

CAUTION: Do Not fasten pump to a thin wood panel

wall as this might create a vibration noise when the

pump is operating.

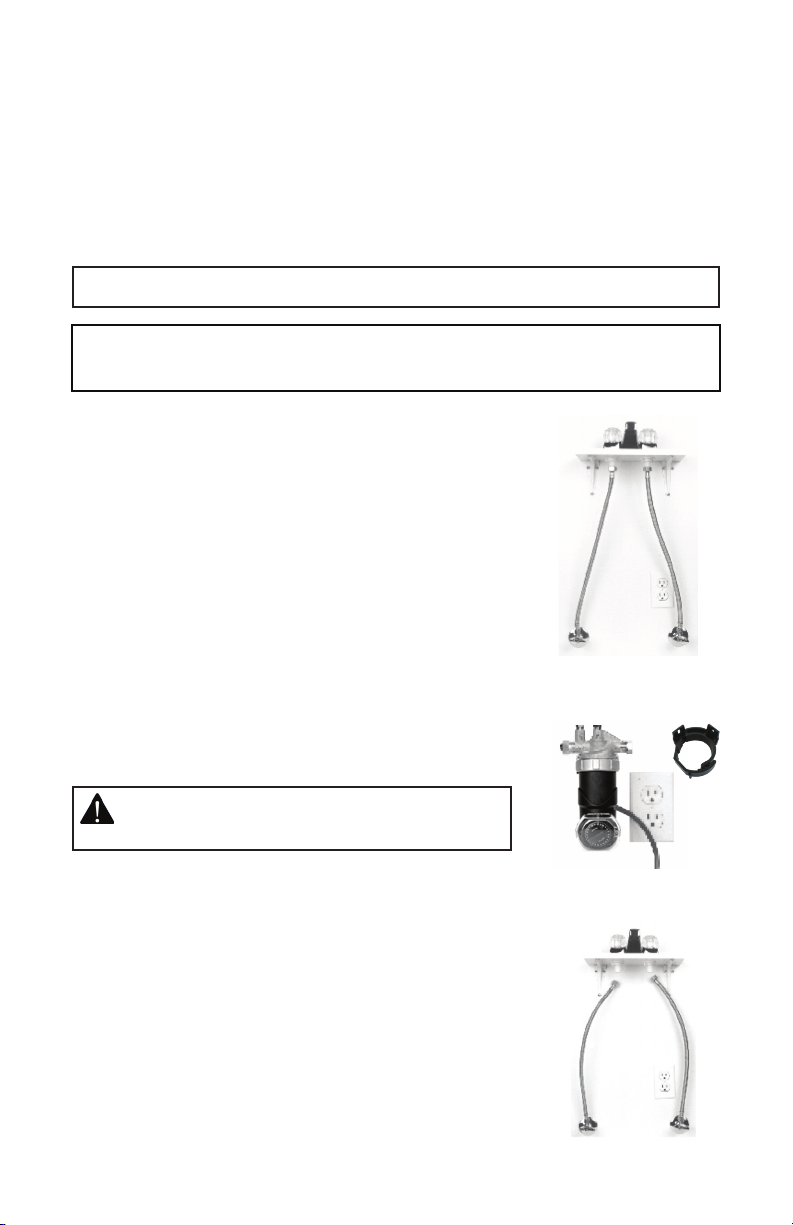

Step 3

Figure 2

Close the under sink hot and cold water riser

shut-off valves and open the hot and cold water

faucets/taps to relieve the water pressure. Close the

water faucets/taps.

Note: in some older homes, the riser shut-off valves

may be difficult to shut off completely. If this is the

case turn the water off at the main water inlet valve

to the house.

Remove the existing flexible line connection to the hot

and cold water faucet/tap threaded nipples (see Fig. 3).

Figure 3

3

Page 4

Note: If felt necessary, replace these existing flexible

hoses with new stainless steel braided flexible hoses

in the lengths required.

Step 4

Screw on the two existing 1/2” hose connections to

the corresponding hot and cold sides of the pump

housing (see Fig. 4). Be sure not to “kink” these

existing hose lines during bending which may

prevent adequate flow and/or cause the valves to

break.

Note: It is recommended that the rubber washers

in the hose connections be inspected to ensure

they are in reusable condition. If not, they should

be replaced.

Step 5

Screw on the 3/8” end of the purchased flexible

hoses to the 3/8” connections on the pump housing.

Screw on the 1/2” end of these same two hoses to

the underside of the hot and cold water faucets/taps

making sure to match the hot and cold sides marked

on the pump housing with the corresponding faucet/

tap. Be sure the hot side connection hose is attached

to the hot water faucet/tap and the cold water side

connection is attached to the cold water faucet/tap.

Be sure the hoses used are long enough to allow the

pump to be positioned as originally planned. ( see

Fig. 5)

Figure 4

Figure 5

Step 6

Be sure the screw ring attaching the motor to the pump housing is securely

hand tightened. Do not over tighten the screw ring. Open the faucet/tap hot

and cold riser shut off valves to insure there are no water leaks at any

connections.

CAUTION: Fasten screw ring until tight to prevent leakage.

Step 7

Plug the pump cord into the wall outlet and start up the pump system (see

next page).

Note: The above installation method applies to most situations where faucets/

taps are connected to the hot and cold water supply lines with braided flexible

hose/shut off valve arrangements. If the under sink arrangement is different

(i.e. the risers are hard copper or plastic), then other parts may be required for

the installation.

4

Page 5

Page 6

Page 7

Page 8

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem, Inc. 6-71-075-003A July 2012

Loading...

Loading...