Bell & Gossett 87, 67, 17Sr, 17Jr, 4V Installation Manual

...

BELL & GOSSETT

Bell & Gossett

ITT Fluid Technology Corporation

Miscellaneous Accessories

INSTRUCTION MANUAL

A90602

REVISION B

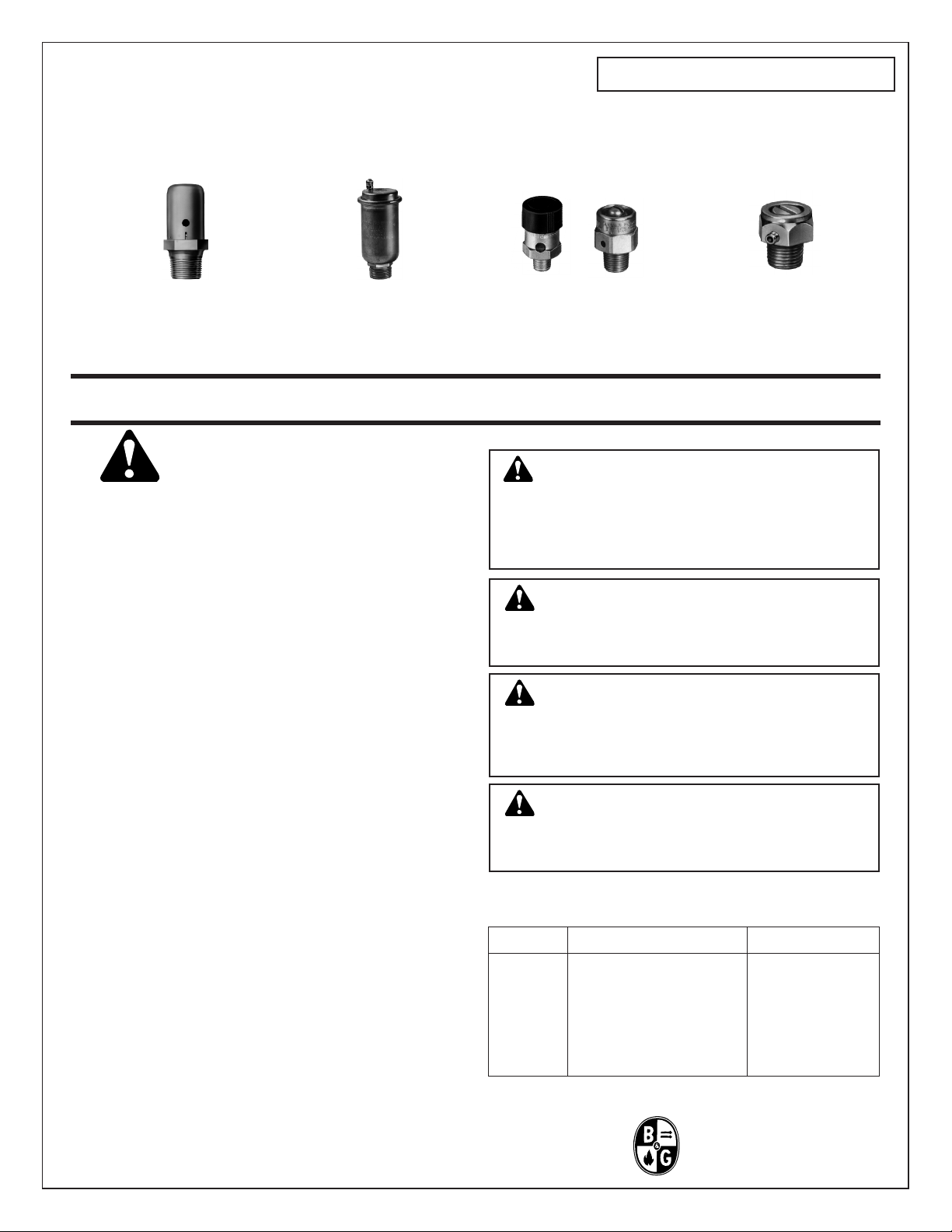

No. 26 Vacuum

Breaker

Nos. 87, 67 and 7

Automatic Air Vents

Nos. 17 Sr. and 17 Jr.

Automatic Air Valves

No. 4V

Coin-Operated

Air Vent

Installation, Operation and Maintenance Instructions

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

DESCRIPTION

Air vents are designed to vent the accumulation of troublesome air whenever it can be trapped.

The No. 87, 67 and 7 models are automatic air vents of float

type while the No. 17 Sr. and 17 Jr. automatic models are

hygroscopic in operation.

The No. 4V air vent is a manual type vent specially designed

for radiators.

The No. 26 vacuum breaker is designed to protect closed

vessels and piping systems against collapse when induced

vacuum exceeds design conditions. When used on steam

systems the vacuum breaker permits the normal return of

condensate to the boiler.

INSTALLATIONS INSTRUCTIONS

1. Install air vent in hydronic piping system or in hydronic system components where air is expected to accumulate and

must be removed for proper hydronic system operation.

Vacuum breakers are installed in steam systems or other

systems where vacuum from condensing steam or from

other sources must be controlled.

2. #7, #67 and #87 air vents are float type and must be

installed in the vertical position with vent connection pointing up.

3. The #87 air vent can be installed on 1/2" nipple or into a 3/4"

NPT female connection.

4. The #17 Sr and #17 Jr air vents will function better if

installed on a 1/2" or 3/4 5 5" to 6" long NPT nipple.

OPERATIONAL LIMITS

Model No. Pressure psig (Bar) Temperature ˚F (˚C)

CAUTION: Uncontrolled venting of water can

occur with automatic air vents if foreign material

prevents vent from closing. A No. 113023 overflow connector and 1/4" OD copper tube should be used to direct

unwanted flow to a drain. Failure to follow these instructions could result in property damage and/or moderate

personal injury.

CAUTION: Pipe compound can foul the air vent or

vacuum breaker operating mechanism. Use pipe

joint compound sparingly on male pipe threads only.

Failure to follow these instructions could result in property

damage and/or moderate personal injury.

CAUTION: Overtightening and breakage can

occur with the use of teflon pipe joint compounds.

Teflon provides lubricity so that care must be exercised

not to overtighten joints. Failure to follow these instructions could result in property damage and/or moderate

personal injury.

CAUTION: Venting hot water or steam can cause

injury. When working near any air vent or vacuum

breaker be careful not to get inline with vent connection.

Failure to follow these instructions could result in property

damage and/or moderate personal injury.

87 150 (10.3) 240 (116)

67 35 (2.4) 240 (116)

7 75 (5.1) 240 (116)

17Sr 30 (2.1) 225 (107)

17Jr 30 (2.1) 225 (107)

4V 150 (10.3) 250 (121)

26 2" Hg Vacuum to 150 (10.3) 240 (116)

© COPYRIGHT 1992, 1996 BY ITT INDUSTRIES, INC.

OPERA

Bell & Gossett

ITT Fluid Technology Corporation

TING INSTRUCTIONS

CAUTION: Dirt and scale from the system can foul

the automatic air vent operating mechanism. On

#7, #67 and #87 air vents keep vent cap closed tight during system filling to prevent dirt from running into valve

vent mechanism. Failure to follow these instructions

could result in property damage and/or moderate personal

injury.

1. Automatic air vents can be used for automatically or manually venting hydronic systems. To manually operate the #7,

#67 and #87 vents press down on the vent stem (tire type

valve).

CAUTION: Hot venting water can be hazardous.

Avoid contact with venting fluid and only manually

vent when system temperature is below 100˚F (38˚C).

Failure to follow these instructions could result in property

damage and/or personal injury.

To shutoff #7, #67 and #87 vents so they can not vent

automatically, (only those without overflow connector

installed), screw cap on top of vent down tight. For normal

automatic venting open cap only about one full turn so that

there is a slow release of air. A fast release of air will allow

dirt or scale to foul the vent mechanism. The small hole in

the side of the cap allows air to escape with cap in place.

When an overflow connector and tube to a safe drain is

used, continuous automatic venting is provided.

2. The #4V coin operated air vent is a manual vent and is

opened by the use of a coin or screwdriver inserted and

turned in the slotted screw on top of the vent. The vent is

opened and air bled off until water appears. Vent is then

closed by securely tightening the vent screw.

3. The #17 Sr and #17 Jr automatic air vents are not float

types and operate hygroscopically. Air is allowed to escape

but water is not. Both vents have a manual venting feature

which is operated by screwing the black plastic cap

halfway up on the #17 Sr or by opening the screw in the

center of the #17 Jr two turns maximum.

CAUTION: Hot venting water can be hazardous.

Avoid contact with venting fluid and only manually

vent when system temperature is below 100˚F (38˚C).

Failure to follow these instructions could result in property damage and/or personal injury.

Screwing the black plastic cap on the #17 Sr all the way up

cuts off manual venting but allows venting to continue.

Turning the black plastic cap all the way down on the #17

Sr closes the vent to both automatic and manual venting.

The automatic venting of the #17 Jr can not be shutoff.

Manual venting is stopped by screwing down the center

vent screw tightly.

4. The #26 vacuum breaker can be adjusted to open at any

vacuum between 1/4" Hg and 20" Hg. This is accomplished

by pulling off the brass cover and adjusting the position of

the brass nuts. The top nut is a jam nut used for locking

the set position. Threading the nuts down will increase the

vacuum at which the vent opens and threading the nuts up

will decrease the vacuum at which the vent opens. After

adjustments are made make sure the jam nut is tightened

against the spring nut so that it is locking the set position.

Replace the protective cover.

SERVICE INSTRUCTIONS

There is no service required for any of the air vents or vacuum

breaker.

CAUTION: Corrosion or leakage of vents or vacuum

breaker can cause damage or injury. Periodically

inspect the air vents or vacuum breaker for signs of leakage or corrosion. If noted the vent or vacuum breaker

must be replaced. Failure to follow these instructions

could result in property damage and/or moderate personal

injury.

For further information, contact ITT Bell & Gossett, 8200 N. Austin Avenue, Morton Grove, IL 60053,

Phone (847) 966-3700 – Facsimile (847) 966-9052.

PRINTED IN U.S.A. 5-96

Loading...

Loading...