Page 1

LISTED

INSTRUCTION MANUAL

210668B

Bell & Gossett®ZoneTrol II

Models Z-4B, Z-4M, Z-6B, Z-6M,

ZV-4B, ZV-4M, ZV-6B, ZV-6M

McDonnell & Miller ZoneSmart

U

L

®

C US

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual and on the

unit safety instructions decal to draw attention to safety related

instructions. When used, the safety alert symbol means ATTEN-

TION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE T

IN A SAFETY HAZARD.

NOTICE: This instruction manual is a supplement to, not a

replacement for Instruction Manual 210667. If you do

not have all manuals necessary for installation, please

contact the point of purchase or download the necessary

manuals at www.bellgossett.com.

O FOLLOW THE INSTRUCTIONS MAY RESULT

Models ZS-4B, ZS-4M, ZS-6B, ZS-6M,

ZSV-4B, ZSV-4M, ZSV-6B, ZSV-6M

™

™

Sensors Included

The Outdoor Temperature Sensor includes a

10 kΩ thermistor which provides an accurate

measurement of the outdoor temperature. The

sensor is protected by a white U.V. resistant

PVC plastic enclosure.

The Water Temperature Sensors have a zinc

sleeve for fast response and a wide operating

range. The sensors are supplied with 10 inches

(250mm) of two conductor wire.

DESCRIPTION

The outdoor reset modules are integrated into the

McDonnell & Miller ZoneSmart or Bell & Gossett ZoneTrol II

zone controllers. By monitoring outdoor temperature and

indexing the system supply water to the varying heatloss of

the building, the reset controllers minimize fuel consumption

while maximizing occupant comfort.

The Boiler Reset Control is designed to control a single

stage, non modulating heat source in order to provide outdoor

reset.

The Mix Reset Control is designed to control the supply water

temperature to a hydronic system in order to provide outdoor

reset or setpoint operation. The control uses a variable speed

injection pump to regulate the supply water temperature, while

protecting the boiler against flue gas condensation.

SENSOR INSTALLATION INSTRUCTIONS

Outdoor Air Temperature Sensor

• Remove the screw and pull the front cover off the sensor

enclosure.

• The sensor can either be mounted directly onto a wall or a

2" x 4" electrical box.

• When the sensor is wall mounted, the wiring should enter

through the back or bottom of the enclosure. Do not mount

the sensor with the conduit knockout facing upwards as

water could enter the enclosure and damage the sensor.

• In order to prevent heat transmitted through the wall from

affecting the sensor reading, it may be necessary to install

an insulating barrier behind the enclosure.

• The sensor should be mounted on a wall which best represents the heat load on the building (a northern wall for most

buildings and a southern facing wall for buildings with large

sout h f aci ng gla ss areas). The sensor should not be

exposed to heat sources such as ventilation or window

openings.

Page 2

• The sensor should be installed at an elevation above the

Boiler supply

sensor

BOIL OUT

SUP

COM

Boiler Temp.

Sensor

Sensor

Temp. Sensor

Outdoor Temp.

Mix Supply

SYS/

BLR.

N

INJ/

MIX

120 VAC

To system

pump (if

applicable)

1/3 max.

HP*

To

injector

pump (if

applicable)

1.1A max.

ground that will prevent accidental damage or tampering.

• Connect 18 AWG or similar wire to the two terminals provided in the enclosure and run the wires from the sensor to

the control as shown in Figure 2. Do not run the wires parallel to telephone or power cables. If the sensor wires are

located in an area with strong sources of electromagnetic

interference (EMI), shielded cable or twisted pair should be

sed or the wires can be run in a grounded metal conduit. If

u

using shielded cable, the shield wire should be connected

to the Com Sen terminal on the control and not to earth

ground.

Replace the front cover of the sensor enclosure.

•

Water Temperature Sensor

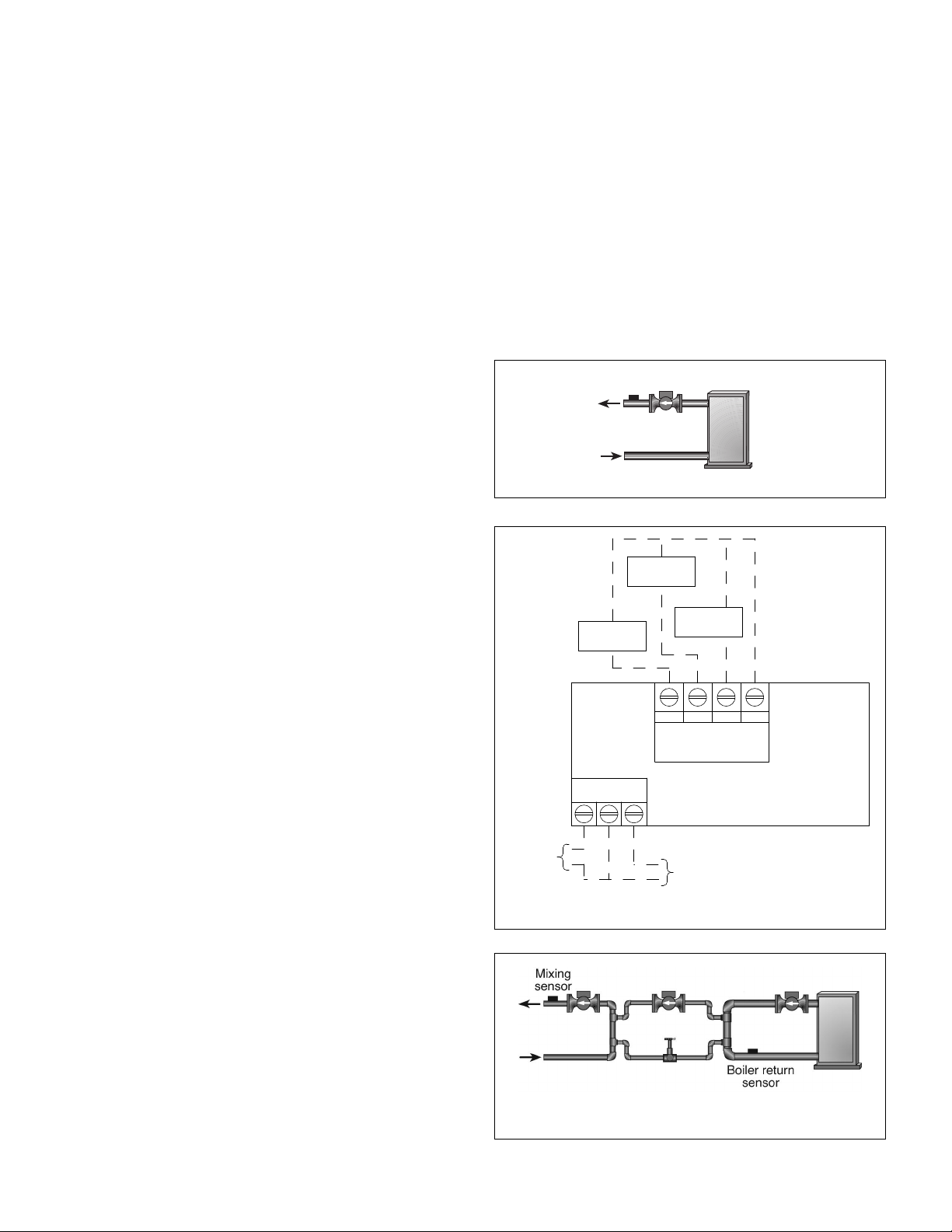

• Water temperature sensors should be located as shown in

Figures 1 (boiler reset) & 3 (mix reset).

• Sensor wiring is per Figure 2.

• The Water Temperature Sensor can be strapped directly to

the pipe using the cable tie provided. Insulation should be

placed around the sensor to reduce the effect of air currents

on the sensor measurement.

• The Water Temperature Sensor should be placed downstream of a pump or after an elbow or similar fitting. This is

especially important if large diameter pipes are used as the

thermal stratification within the pipe can result in erroneous

sensor readings. Proper sensor location requires that the

fluid is thoroughly mixed within the pipe before it reaches

the sensor.

than the BOIL MIN setting while the boiler is firing, the controller reduces the output to the variable speed injection

pump. This limits the amount of cool return water to the boiler,

and allows the boiler temperature to recover.

Exercise: The controller has a built-in exercising function. If

the pump has not been operated at least once every 3 days,

the control turns on the output for 10 seconds. This minimizes

the possibility of the pump seizing during a long period of

nactivity.

i

Warm Weather Shutdown (WWSD)

When the outdoor air temperature rises above the WWSD setting, the controller turns on the WWSD segment in the display.

When the control is in Warm Weather Shut Down, the Mixing

Demand pointer is displayed, if there is a demand. However,

the control does not operate the heating system to satisfy this

demand.

Figure 1: Sensor Location for Boiler Reset

OPERATING SEQUENCE

Boiler Reset Control

The Boiler Reset Control operates a single on / off heat source

to control the supply water temperature to a hydronic system.

The supply water temperature is based on the current outdoor

air temperature and the Characterized Heating Curve settings.

Outdoor Reset: The controller calculates a supply temperature based on the current outdoor air temperature and the

Characterized Heating Curve settings. The burner on the boiler

is then cycled to maintain the water temperature required

based on the heating curve.

Warm Weather Shutdown: When the outdoor air temperature

rises above the WWSD setting, the controller turns on the

WWSD segment in the display. When the control is in Warm

Weather Shut Down, the Boiler Demand pointer is displayed, if

there is a demand. However, the control does not operate the

heating system to satisfy this demand.

Mix Reset Control

The Mix Reset Control uses a variable speed injection pump

to control the supply water temperature to a hydronic system.

The supply water temperature is based on either the current

outdoor temperature, or a fixed setpoint.

Outdoor Reset: The controller calculates a mixing supply

temperature based on the current outdoor air temperature and

the Characterized Heating Curve settings.

Variable Speed Injection: circulator is connected to the controller. The controller increases or decreases the power output

to a standard wet rotor circulator when there is a mixing

demand. The circulator speed varies to maintain the correct

mixed supply water temperature at the mix sensor. A visual

indication of the current variable speed output is displayed in

the LCD in the form of a horizontal bar graph.

Boiler Protection (BOIL MIN): The controller is capable of

providing boiler protection from cold mixing system return

water temperatures. If the boiler sensor temperature is cooler

Figure 2: Sensor and Mix Pump Wiring

Figure 3: Pump Terminology and Sensor Location

on systems using Mix or Injection Pump

*Do not exceed the maximum combined load.

Page 3

Boiler Reset Control Set-Up Parameters

ADJUST

ROOM

°

F

ADJUST

DSGN

OUTDR

°F

A

DJUST

DSGN

BOIL

°F

ADJUST

BOIL

°F

MIN

ADJUST

DIFF

BOIL

ADJUST

ADJUST

°F

Display Parameter Definition Range Notes Setting

Field

ROOM DESIGN The room design 35°F to 100°F If the original heating system design

TEMP temperature used (1°C to 37°C) criteria are unknown, the ROOM

in the original heat DESIGN TEMP should be set to the

loss calculation for estimated highest typical (non setthe building back) thermostat setting

OUTDOOR The outdoor design -60°F to +45F If the original heating system design

DESIGN TEMP temperature used (-51°C to 7°C) criteria are unknown, the OUTDOOR

in the original heat DESIGN TEMP should be set to the

loss calculation for estimated lowest expected outdoor

he building temperature based on geographical

t

location

BOILER DESIGN Supply water tem- 70°F to 210°F Recommended Settings

TEMP perature required (21°C to 93°C) High Mass Radiant (e.g., concrete):

to heat the building 120°F (49°C)

when outdoor Low Mass Radiant (e.g., wood floor):

temperature is equal 140°F (60°C)

OUTDOOR DESIGN Fancoil: 190°F (88°C)

TEMP Fin Tube Convector: 180°F (82°C)

Radiator: 160°F (71°C)

Baseboard: 150°F (66°C)

BOILER Minimum water OFF Recommended Settings

MINIMUM temperature to be 80°F to 180°F Cast iron boiler: 150°F

TEMP returned to boiler (27°C to 82°C) Copper tube boiler: 140°F

Condensing boiler: OFF

Electric boiler: OFF

Note: Refer to boiler installation

instructions to determine the minimum

allowable return temperature

BOILER The range of tem- ADJ The controller calculates a boiler

DIFFERENTIAL perature deviation 2°F to 42°F target temperature based on

TEMP allowed above and (1°C to 23°C) multiple variables. The BOILER

below boiler target DIFFERENTIAL TEMP is the range

temperature around the target temp in which the

supply temperature is allowed to float.

For example, with a target temperature

of 150°F and a BOILER DIFFERENTIAL

TEMP of 10°F, the supply temp will vary

between 145° and 155°F. Using the

Auto Differential (ADJ) setting is recommended for optimum performance

WARM Outdoor tempera- 35°F to 100°F When the outdoor temperature exceeds

WEATHER ture above which (1°C to 37°C) the WWSD setting, the controller will not

SHUTDOWN the controller will OFF enable the boiler. It is typical to set the

TEMP not activate the WWSD value equal to the ROOM

boiler DESIGN TEMP. The OFF setting defeats

the WWSD logic

ENGLISH/ Parameters to be °F or °C

METRIC displayed in

Farenheit or

Celsius

ESCAPE Exit set up menu — To escape the set up menu, press either

the or key

Page 4

Boiler Reset Controller Display Parameters

VIEW

VIEW

OUTDR

VIEW

OUTDR

VIEW

B

OIL

V

IEW

BOIL

ADJUST

ROOM

°F

ADJUST

DSGN

OUTDR

°F

Display Parameter Notes

OUTDOOR Current outdoor air temperature as measured by the outdoor sensor. This is also the

TEMP default display for the control

BOILER Current boiler supply water temperature as measured by the boiler sensor

TEMP

BOILER Target boiler supply is the temperature the control is currently trying to maintain at the

TARGET TEMP boiler sensor

Boiler Reset Controller Fault Messages

Display Fault Notes

EEPROM The control was unable to read a piece of information from its EEPROM. This error can

FAULT be caused by a noisy power source. The control will load the factory defaults and stop

OUTDOOR The control is no longer able to read the outdoor sensor due to a short circuit. In this

SENSOR case, the control assumes an outdoor temperature of 32°F (0°C) and continues operation.

SHORT Check wiring between outdoor sensor and control unit. Verify all connections and inspect

CIRCUIT wire insulation and sensor for damage. To clear the error message from the control after

OUTDOOR The control is no longer able to read the outdoor sensor due to an open circuit. In this

SENSOR OPEN case, the control assumes an outdoor temperature of 32°F (0°C) and continues operation.

CIRCUIT Check wiring between outdoor sensor and control unit. Verify all connections and inspect

BOILER The control is no longer able to read the boiler sensor due to a short circuit. In this

SENSOR case, if the BOIL MIN adjustment is set to OFF the control does not operate the Boiler

SHORT contact. If the BOIL MIN adjustment is not set to OFF and a boiler demand is present,

CIRCUIT the Boiler contact will operate for up to 10 minutes of a 20 minute cycle. Check wiring

BOILER The control is no longer able to read the boiler sensor due to a short circuit. In this

SENSOR case, if the BOIL MIN adjustment is set to OFF the control does not operate the Boiler

OPEN contact. If the BOIL MIN adjustment is not set to OFF and a boiler demand is present,

CIRCUIT the Boiler contact will operate for up to 10 minutes of a 20 minute cycle. Check wiring

operation until all the settings are verified

the sensor has been repaired, press the Item button

for broken wire or damaged sensor. To clear the error message from the control after

the sensor has been repaired, press the Item button

between outdoor sensor and control unit. Verify all connections and inspect wire

insulation and sensor for damage. To clear the error message from the control after

the sensor has been repaired, press the Item button

between outdoor sensor and control unit. Verify all connections and inspect wire

insulation and sensor for damage. To clear the error message from the control after

the sensor has been repaired, press the Item button

Mix Reset Control Set-Up Parameters

Display Parameter Definition Range Notes Setting

ROOM DESIGN The room design 35°F to 100°F If the original heating system design

TEMP temperature used (1°C to 37°C) criteria are unknown, the ROOM

OUTDOOR The outdoor design -60°F to +45F If the original heating system design

DESIGN TEMP temperature used (-51°C to 7°C) criteria are unknown, the OUTDOOR

Field

in the original heat DESIGN TEMP should be set to the

loss calculation for estimated highest typical (non setthe building back) thermostat setting

in the original heat DESIGN TEMP should be set to the

loss calculation for estimated lowest expected outdoor

the building temperature based on geographical

location

Page 5

Mix Reset Control Set-Up Parameters (continued)

ADJUST

BOIL

°F

MIN

ADJUST

°F

ADJUST

VIEW

VIEW

OUTDR

Display Parameter Definition Range Notes Setting

Field

MIX DESIGN MIX water tempera- 70°F to 220°F Recommended Settings

TEMP perature required (21°C to 93°C) High Mass Radiant (e.g., concrete):

to heat the building 120°F (49°C)

when outdoor Low Mass Radiant (e.g., wood floor):

temperature is equal 140°F (60°C)

UTDOOR DESIGN Fancoil: 190°F (88°C)

O

TEMP Fin Tube Convector: 180°F (82°C)

Radiator: 160°F (71°C)

Baseboard: 150°F (66°C)

OILER Minimum water OFF Recommended Settings

B

MINIMUM temperature to be 80°F to 180°F Cast iron boiler: 150°F

TEMP returned to boiler (27°C to 82°C) Copper tube boiler: 140°F

Condensing boiler: OFF

Electric boiler: OFF

Note: Refer to boiler installation

instructions to determine the minimum

allowable return temperature

WARM Outdoor tempera- 35°F to 100°F When the outdoor temperature exceeds

WEATHER ture above which (1°C to 37°C) the WWSD setting, the controller will not

SHUTDOWN the controller will OFF enable the boiler. It is typical to set the

TEMP not activate the WWSD value equal to the ROOM

boiler DESIGN TEMP. The OFF setting defeats

the WWSD logic

ENGLISH/ Parameters to be °F or °C

METRIC displayed in

Farenheit or

Celsius

ESCAPE Exit set up menu — To escape the set up menu, press either

the or key

Mix Reset Control Display Parameters

Display Parameter Notes

OUTDOOR Current outdoor air temperature as measured by the outdoor sensor. This is also the

TEMP default display for the control. (OUTDOOR DSGN ≠ OFF)

MIX Current mixed supply water temperature as measured by the mixing sensor

TEMP

MIX TARGET Target mixed supply is the temperature the control is currently trying to maintain at the

TEMP mixing sensor

BOILER Current boiler temperature as measured by the boiler sensor. (Boiler sensor is present)

TEMP

Mix Reset Fault Messages

Display Fault Notes

EEPROM The control was unable to read a piece of information from its EEPROM. This error can

FAULT be caused by a noisy power source. The control will load the factory defaults and stop

OUTDOOR The control is no longer able to read the outdoor sensor due to a short circuit. In this

SENSOR case, the control assumes an outdoor temperature of 32°F (0°C) and continues operation.

SHORT Check wiring between outdoor sensor and control unit. Verify all connections and inspect

CIRCUIT wire insulation and sensor for damage. To clear the error message from the control after

operation until all the settings are verified

the sensor has been repaired, press the Item button

Page 6

Mix Reset Fault Messages (continued)

Display Fault Notes

OUTDR

BOIL

BOIL

MIX

MIX

VIEW

OUTDOOR The control is no longer able to read the outdoor sensor due to an open circuit. In this

SENSOR OPEN case, the control assumes an outdoor temperature of 32°F (0°C) and continues operation.

CIRCUIT Check wiring between outdoor sensor and control unit. Verify all connections and inspect

for broken wire or damaged sensor. To clear the error message from the control after

the sensor has been repaired, press the Item button

VIEW

BOILER The control is no longer able to read the boiler sensor due to a short circuit. In this

SENSOR case, if the BOIL MIN adjustment is set to OFF the control does not operate the Boiler

SHORT contact. If the BOIL MIN adjustment is not set to OFF and a boiler demand is present,

CIRCUIT the Boiler contact will operate for up to 10 minutes of a 20 minute cycle. Check wiring

between outdoor sensor and control unit. Verify all connections and inspect wire

insulation and sensor for damage. To clear the error message from the control after

the sensor has been repaired, press the Item button

VIEW

BOILER The control is no longer able to read the boiler sensor due to a open circuit. In this

SENSOR case, if the BOIL MIN adjustment is set to OFF, the control does not operate the Boiler

OPEN contact. If the BOIL MIN adjustment is not set to OFF, and a boiler demand is present,

CIRCUIT the Boiler contact will operate for up to 10 minutes of a 20 minute cycle. Check wiring

between outdoor sensor and control unit. Verify all connections and inspect wire

insulation and sensor

for damage. To clear the error message from the co

the sensor has been repaired, press the Item button

VIEW

MIX SENSOR The control is no longer able to read the mixing sensor due to a short circuit. In this

SHORT CIRCUIT case, the control will operate the injection pump at a fized output as long as there is a

mixing demand. Check wiring between sensor and control unit. Verify all connections

and inspect wire insulation and sensor for damage. To clear the error message from the

control after the sensor has been repaired, press the Item button

VIEW

MIX SENSOR The control is no longer able to read the mixing sensor due to a open circuit. In this

OPEN CIRCUIT case, the control will operate the injection pump at a fized output as long as there is a

mixing demand. Check wiring between sensor and control unit. Verify all connections

and inspect wire insulation and sensor for damage. To clear the error message from the

control after the sensor has been repaired, press the Item button

ntrol after

Sensor Resistance Chart

Temperature Resistance Temperature Resistance Temperature Resistance Temperature Resistance

°F °C °F °C °F °C °F °C

-50 -46 490,813 20 -7 46,218 90 32 7,334 160 71 1,689

-45 -43 405,710 25 -4 39,913 95 35 6,532 165 74 1,538

-40 -40 336,606 30 -1 34,558 100 38 5,828 170 77 1,403

-35 -37 280,279 35 2 29,996 105 41 5,210 175 79 1,281

-30 -34 234,196 40 4 26,099 110 43 4,665 180 82 1,172

-25 -32 196,358 45 7 22,763 115 46 4,184 185 85 1,073

-20 -29 165,180 50 10 19,900 120 49 3,760 190 88 983

-15 -26 139,402 55 13 17,436 125 52 3,383 195 91 903

-10 -23 118,018 60 16 15,311 130 54 3,050 200 93 829

-5 -21 100,221 65 18 13,474 135 57 2,754 205 96 763

0 -18 85,362 70 21 11,883 140 60 2,490 210 99 703

5 -15 72,918 75 24 10,501 145 63 2,255 215 102 648

10 -12 62,465 80 27 9,299 150 66 2,045 220 104 598

15 -9 53,658 85 29 8,250 155 68 1,857 225 107 553

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. 210668B May 2012

Loading...

Loading...