Page 1

INSTRUCTION MANUAL

210667C

Bell & Gossett®ZoneTrol II

Models Z-4, Z-4B, Z-4M, Z-6, Z-6B, Z-6M

McDonnell & Miller ZoneSmart

U

L

®

C US

LISTED

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual and on the

unit safety instructions decal to draw attention to safety related

instructions. When used, the safety alert symbol means ATTEN-

TION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THE INSTRUCTIONS MAY RESULT

IN A SAFETY HAZARD.

DESCRIPTION

The Bell & Gossett ZoneTrol II and McDonnell & Miller ZoneSmart Pump Controllers are

circulating pumps in hydronic systems.

Model Current Zones HP/Pump

Z-4 / ZS-4

Z-6 / ZS-6 6

20 amps maximum combined load.

T-stat Number of Max.

0.085

FEATURES

• Indicator lights visible without removing cover.

Power LED will illuminate when input power is applied to the

controller. Zone LEDs will illuminate when relay is energized.

• PRIORITY: This is typically used in domestic hot water

applications where it may be desirable to give hot water

production a priority over space heating requirements for a

certain period of time. Zone 1 is the priority zone and the

functionality is enabled via DIP switch 1. The priority timer is

selectable for 30 or 60 minutes, via DIP switch 3.

• PURGE: In normal operation, the last circulator will stop and

the boiler will shut down as soon as there is no longer a call

for heat. If the purge functionality is enabled via DIP switch

2, the boiler will shut down, but the circulator will continue

to run for 90 seconds to extract additional BTUs from the

boiler.

designed to control 120 VAC

Max.

4

Models ZS-4, ZS-4B, ZS-4M, ZS-6, ZS-6B, ZS-6M

1/3

™

™

• EXERCISE: When the exercise functionality is enabled via

DIP switch 4, each circulator will run for 10 seconds after

every 72 hours of inactivity. This prevents scale and other

deposits from accumulating around the rotating parts and

ensures a trouble free start up at the beginning of each

heating season.

DIP SWITCH SETTINGS

Switch ON OFF

1

2 Purge On Purge Off

3 Priority 30 minutes Priority 60 minutes

4 Exercise On Exercise Off

5 Reset Normal

6 Power Delay On Power Delay Off

Slave Master

Priority Off Priority On

OUTDOOR RESET

For controll ers with intergal outdoor reset con troller,

please refer to Instruction Manual 210668. This document

can be downloaded at www.bellgossett.com or

www.mcdonnellmiller.com.

MECHANICAL INSTALLATION INSTRUCTIONS

The pump controller should be securely mounted on a wall

near the pumps using four #8 screws (not included).

WARNING: Electrical Shock Hazard

Electrical connections are to be made by a qualified

electrician in accordance with all applicable codes, ordinances and good practices Disconnect and lock out the

power before making electrical connections. Failure to follow these instructions could result in serious personal injury

and/or death.

ELECTRICAL INSTAL LATION INSTRUCTIONS

1. Disc onnect the electr ica l supply to the pump bef ore

installing the controller.

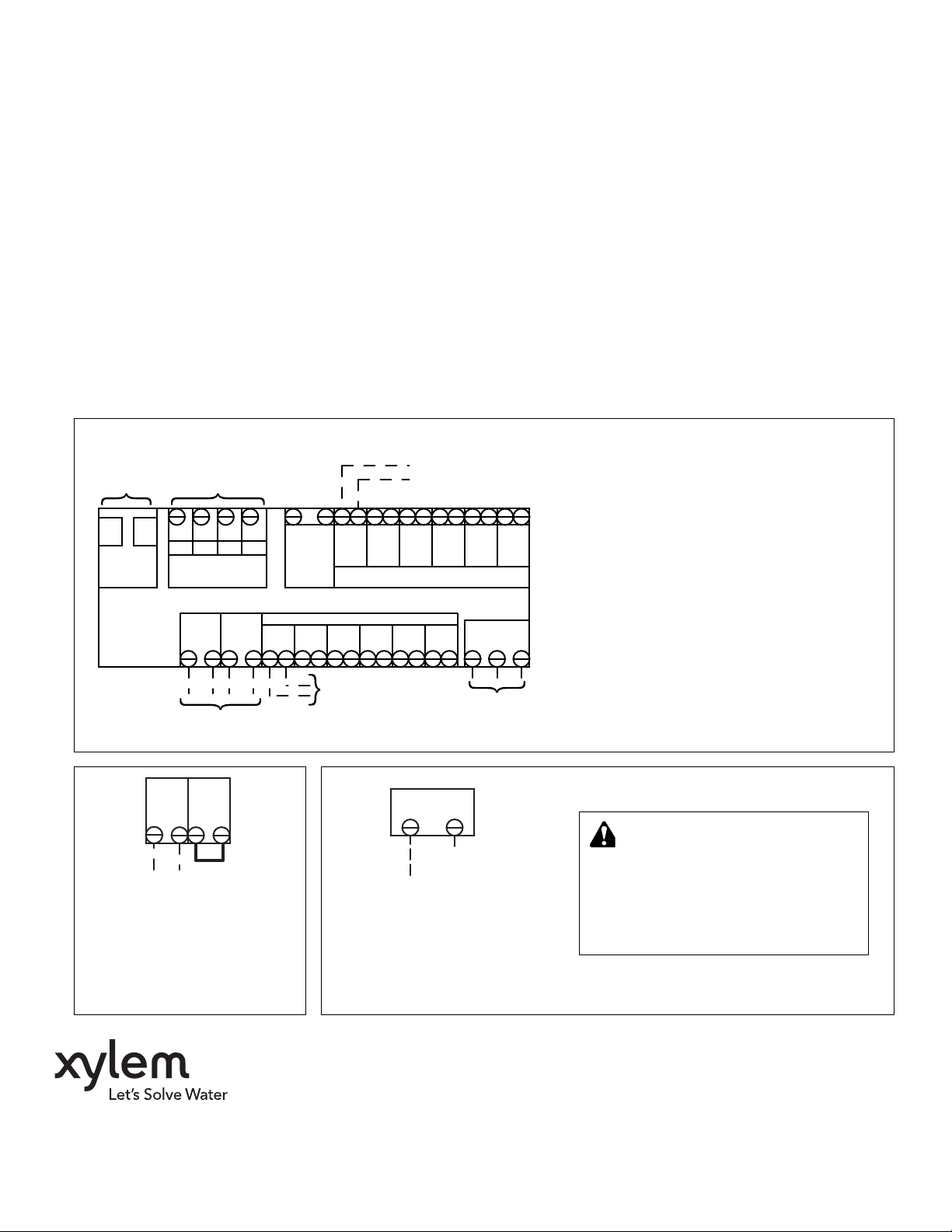

2. Refer to the applicable wiring diagram

- Figure 1A: Cold Start Boiler

- Figure 1B: Tankless Coil

3. Verify that the circulator(s) do not exceed the electrical rating of the controller.

Page 2

Used only with optional reset

RW

LNG

4. Make electrical connections according to the applicable

wiring diagram. Run the pump power through the holes in

the controller chassis to the applicable L/N terminals. Keep

120 VAC and 24 VAC wiring separate. All 120 VAC wiring

should be 14 AWG (minimum) copper electrical wi re.

Perform all wiring in accordance with applicable codes.

5. If the priority function is to be enabled, the priority zone

(e.g., Domestic Hot Water) pump should be wired to the

Zone 1 L/N terminals.

6. Run the thermostat wires through the grommet(s) in the

controller chassis and connect to the appropriate R/W terminals. If the priority function is to be enabled, the priority

zone (e.g., Domestic Hot Water) T-Stat should be wired to

the Zone 1 R/W terminals. Keep 24 VAC wiring separate

from 120 VAC wiring.

NOTE: During the initial power-up

of the zone controller,

some “power stealing” thermostats may require up to 3

minutes to function properly. If the installation requires the

pump relays and X-X relay to be held open during this

power-up sequence, the installer can position DIP switch

6 to the “ON” position. This will cause the controller to

suspend relay operation during the thermostat power-up

period. Normal operation and cycling of the heating system

will resume after the 3 minute time period. This applies to

initial power-up only and does not affect normal system

operation.

EXPANSION

The 4 and 6 zone controllers can be connected together to

accommodate larger systems. A six conductor straight pinned

cable with two male RJ-11 terminations is required for connection of multiple controllers. This cable can be ordered from

your distributor as McDonnell & Miller part number 109454.

The “master” controller should have DIP switch 1 set to the

OFF position. “Slave” controllers should have DIP switch 1 set

to the ON position. If the Priority function is to be enabled

(e.g., domestic hot water production) Zone 1 on the Master

controller will be the priority zone.

GENERAL WIRING DIAGRAM

Refer to Instruction Manual 210688 for units with outdoor reset controller.

For connection

of additional

controllers

EXPANSION

Figure 1A: Cold Start Boiler

control - refer to

instruction

manual 210668

for details

BOIL OUT SUP COM

INSOLATED END

SWITCH

X X ZC ZR

Refer to Fig 1A for cold start or

Fig. 1B for tankless coil application

X X ZC ZR

}

Jumper

To TT

on boiler

When a thermostat calls for heat,

the corresponding circulator will

start and the XX end switch will

close to enable the boiler.

RW

RW

ZONE 1

HN

24 VAC

ZONE 2LNZONE 3LNZONE 4LNZONE 5LNZONE 6

ZONE 1

LN

ZONE 2

CIRCULATORS

To zone

circulators

Figure 1B: Tankless Coil

When a thermostat calls for heat,

the corresponding circulator will

start when the boiler temperature

reaches the low limit setting.

}

RW

ZONE 3

THERMOSTATS

ZC ZR

To ZC on

aquastat

To

thermostats

RW

RW

ZONE 4

ZONE 5

LN

To ZR on

aquastat

ZONE 6

General Wiring Diagram

(6 zone controller shown)

120 VAC

Input Power

120/1/60

WARNING: Electrical Shock Hazard

When wiring per the Tankless Coil

Application, pump controller and boiler

aquastat must be on the same circuit and

have a common disconnect. Failure to follow these instructions may introduce a

secondary source of power resulting in

personal injury or death.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. 210667C May 2012

Loading...

Loading...