Page 1

VARIABLE SPEED PUMPING SYSTEMS

INSTRUCTION MANUAL

VARIABLE SPEED PUMP CONTROLLER AND

INTEGRATED AJUSTABLE FREQUENCY DRIVE

WARNING LABEL #S11550

HV 2.1-3.11

INSTALLED IN THIS LOCATION.

IF MISSING IT MUST BE

REPLACED.

INSTRUCTION MANUAL

210 980-2

HV 120-1-ENBG

26.03.2003

HV3.15-3.22

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

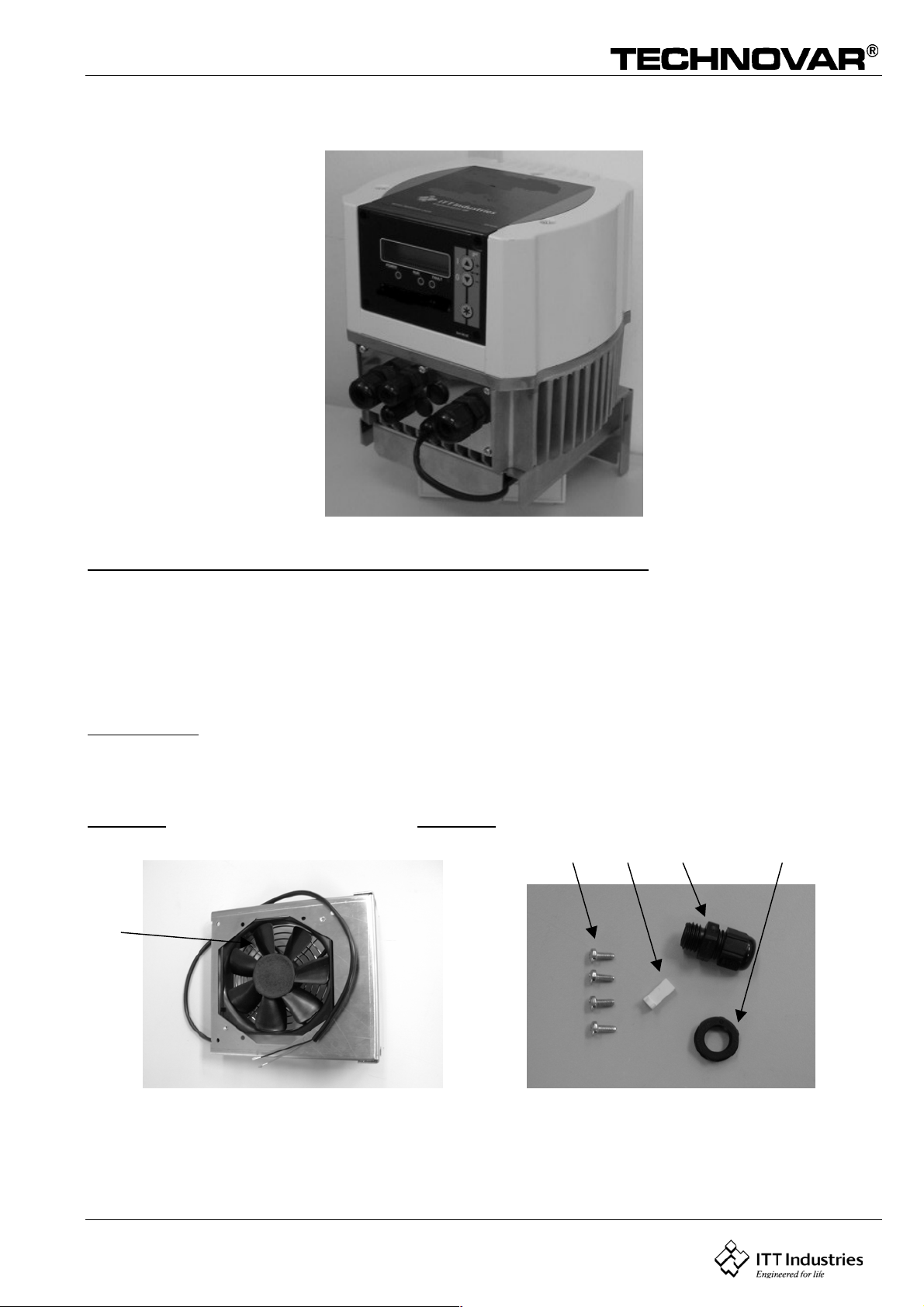

DESCRIPTION: Microprocessor based pump

controller and adjustable speed drive for variable

volume pumping systems. The controller consists

of the following components: microprocessor,

operator interface with alphanumeric display, and

membrane keypad.

OPERATIONAL LIMITS: See the control panel

nameplate for operating voltage, current draw, as

well as information on the equipment to be

connected to the control panel.

SAFETY INSTRUCTION

This safety alert symbol will be used in this

manual to draw attention to safety related

instructions. When used, the safety alert

symbol means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THE INSTRUCTION MAY

RESULT IN A SAFETY HAZARD!

Page 2

Operating Instruction

Index

1 Important safety instructions ........................................................................5

2 System Design................................................................................................ 7

3 Pressure tank ................................................................................................8

4 Technical Data - Frequency Inverter And General Data................................. 9

5 Dimensions and Weights .............................................................................11

6 Mounting the Technovar..............................................................................12

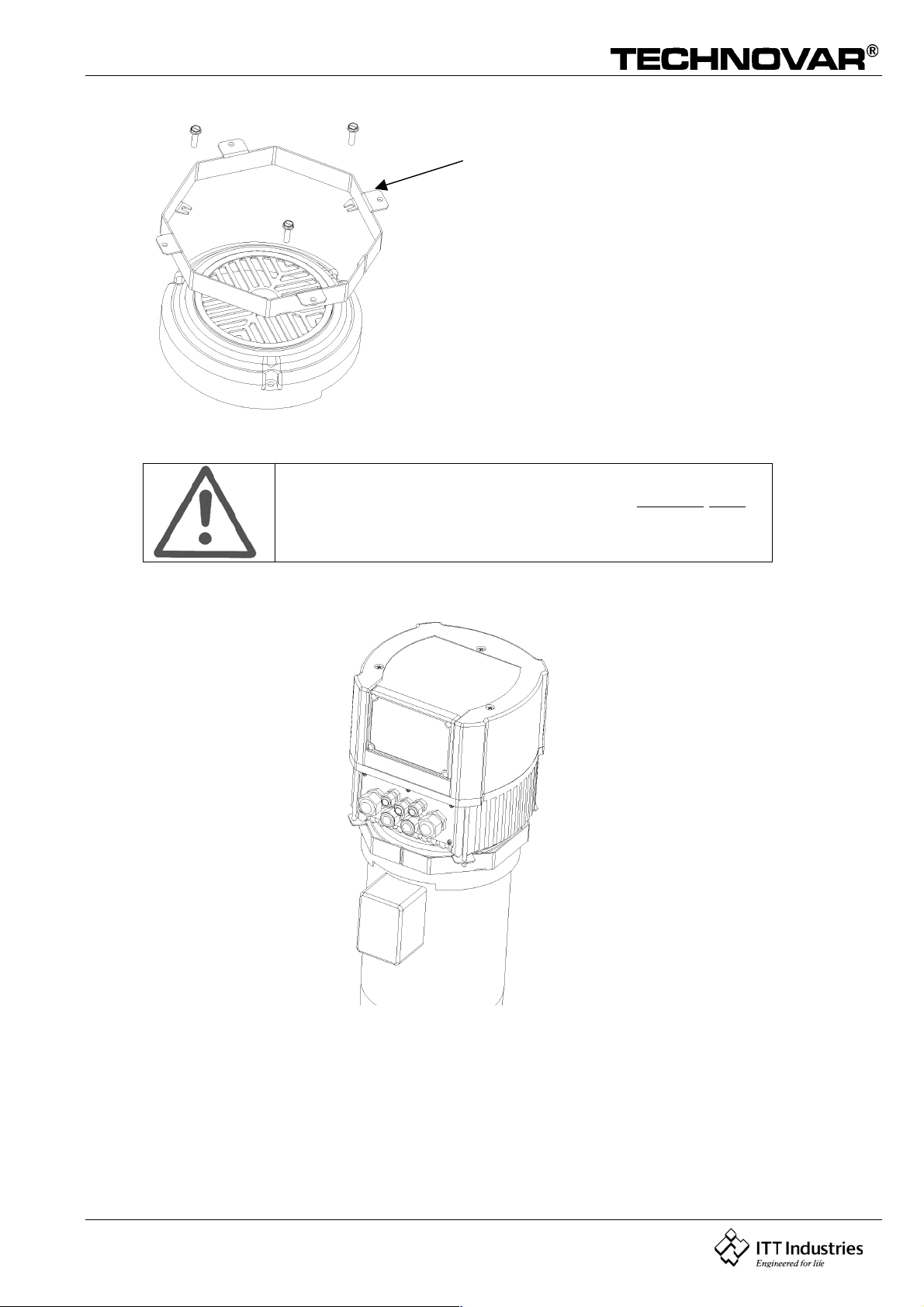

6.1Mounting the Technovar on the pump.................................................12

6.1.1 Components included............................................................................................ 12

6.1.2 Mounting .............................................................................................................. 13

6.1.3 Mounting the thermistor ....................................................................................... 23

6.2 Electric installation and wiring.............................................................24

6.2.1 Means of protection .............................................................................................. 24

6.2.2 Wiring the Technovar to the motor ....................................................................... 24

6.3 Main Voltage Terminals .......................................................................25

6.4 Control Terminals................................................................................. 26

6.4.1 Control terminals................................................................................................... 27

6.4.2 Dip-Switch on the controller board........................................................................ 28

6.4.3 Main parts from the control card........................................................................... 28

6.5 Front plate............................................................................................ 29

7 Language Selection...................................................................................... 30

8 Typical applications .....................................................................................31

8.1 Control ................................................................................................. 31

8.2 The Main Menu Setting........................................................................ 31

8.3 Single Pump – Pump Protection........................................................... 34

8.3.1 To set run out protection....................................................................................... 34

8.4 Single Pump – System Curve Compensation........................................ 36

8.4.1 Entering the compensation values......................................................................... 37

8.5 Multiple Pump - Constant Pressure and System Curve Compensation 38

9 Parameters of the main menu ..................................................................... 43

10 Settings at Secondary Menu.......................................................................46

10.1 JOG-MODE..........................................................................................46

10.2 Window - %........................................................................................ 47

10.3 Ramp Hysteresis ................................................................................. 47

10.4 Ramp 1: Fast running up time:........................................................... 47

10.5 Ramp 2: Fast running down time:...................................................... 47

10.6 Ramp 3: Slow running up time: ......................................................... 48

10.7 Ramp 4: Slow running down time: ....................................................48

2

Page 3

Operating Instruction

Ramp – Window.........................................................................................48

10.8 Maximum Frequency.......................................................................... 48

10.9 Minimum Frequency ..........................................................................49

10.10 Operation at the minimum frequency ............................................. 49

10.11 Delay time for shut off at minimum frequency ............................... 49

10.12 Boost ................................................................................................ 49

10.13 Sensor – Adjust................................................................................. 50

10.14 Sensor - Curve .................................................................................. 50

10.15 Setting of the measuring range ....................................................... 50

10.16 Operation Mode ............................................................................... 50

10.17 Control Response ............................................................................. 51

10.18 Start Value........................................................................................ 52

10.19 2nd Required Value............................................................................ 52

10.20 Configuration of 1st relay ................................................................. 53

10.21 Submenu Offset ............................................................................... 53

10.21.1 Source of the Offset input ................................................................................. 53

10.21.2 1

10.21.3 2

10.21.4 INTENSITY 1 ....................................................................................................... 54

10.21.5 INTENSITY 2 ....................................................................................................... 54

st

Offset level.................................................................................................... 53

nd

Offset level ................................................................................................... 54

10.22 Submenu Sequence control ............................................................. 54

10.22.1 Lift Value ........................................................................................................... 55

10.22.2 Fall Value ........................................................................................................... 55

10.22.3 Release frequency of the following controller.................................................... 56

10.22.4 Switch Interval................................................................................................... 56

10.22.5 Source of required value.................................................................................... 57

10.22.6 Synchronous Control ......................................................................................... 57

10.22.7 Pump status indication ...................................................................................... 58

10.22.8 Error Signals for Data Bus Interruptions............................................................. 58

10.23 Submenu - RS 485 Interface ............................................................. 59

10.23.1 Pump Address.................................................................................................... 59

10.23.2 ADC Reference................................................................................................... 59

10.24 Compensation Frequency................................................................. 59

10.25 Lift-Intensity.....................................................................................60

10.26 Analog - Output ............................................................................... 60

10.27 Unit...................................................................................................61

10.28 Automatic test run ........................................................................... 61

10.29 Submenu for manual test run.......................................................... 61

10.29.1 Activate manual test run.................................................................................... 61

10.29.2 Test Frequency................................................................................................... 61

10.29.3 Boost ................................................................................................................. 61

10.30 Submenu - Error ............................................................................... 62

10.30.1 Conveyor Limit................................................................................................... 62

10.30.2 Delay Time......................................................................................................... 62

3

Page 4

Operating Instruction

10.30.3 Automatic Error reset......................................................................................... 62

10.30.4 Erase Error memory ........................................................................................... 63

10.31 Operating Hours............................................................................... 63

10.32 Display - Contrast............................................................................. 63

10.33 Set Password .................................................................................... 63

10.34 Operating Lock .................................................................................63

10.35 Internal Heater ................................................................................. 63

10.36 Setting Default Values......................................................................64

10.36.1 Default Values Europe ....................................................................................... 64

10.36.2 Default Values USA............................................................................................ 64

10.37 Saving...............................................................................................64

11 Error Signals................................................................................................ 65

11.1 Low Water .......................................................................................... 65

11.2 Conveyor Control ...............................................................................65

11.3 Overheating – Motor .......................................................................... 65

11.4 Overheating – Inverter ....................................................................... 65

11.5 Over voltage.......................................................................................65

11.6 Under voltage..................................................................................... 66

11.7 Limit ................................................................................................... 66

11.8 Short Circuit ....................................................................................... 66

11.9 Overload............................................................................................. 66

11.10 Pressure Sensor Error I < 4 mA ...................................................... 66

11.11 Additional Error signals:................................................................... 67

12 RS 485 - Interface........................................................................................ 67

13 Auxiliary Texts.............................................................................................68

14 Maintenance ...............................................................................................73

14.1 Notes.................................................................................................. 73

Follow the Pump Operating and Maintenance Instructions

We reserve the right to alter specifications

4

Page 5

Operating Instruction

1 Important safety instructions

In addition to the instructions contained in these operating instructions please pay

attention to universal safety and accident prevention regulations.

The TECHNOVAR drive head must be disconnected from the power supply before any work

can be carried out in the electrical or mechanical part of the system.

Installation, maintenance and repair work may only be carried out by trained, skilled and

qualified personnel.

Unauthorized modifications or changes to the system make all guarantees null and void.

When in operation, the motor can be stopped by remote control, whereby the drive head and

the motor remain under voltage. For safety reasons, the unit has to be disconnected from the

power supply when carrying out work on the machinery as locking out the equipment by

switching off the release mechanism or set value cannot prevent accidental starting of the

motor.

When the drive head is connected to power supply, the components of the

power unit as well as certain components of the master control unit are also

connected to the power supply.

Touching these components seriously endangers life !

Before removing the frequency inverter cover the system must be

disconnected from the power supply. After switching off the power supply

wait at least 5 minutes before starting work on or in the TECHNOVAR drive

head (the capacitors in the intermediate circuit have to be discharged by the

installed discharge resistors first).

Voltages of up to 800 volts are possible (if there are faults it can be higher)

All work, carried out when the frequency inverter is open, may only be

performed by qualified authorized staff.

Furthermore, care must be taken not to short circuit the neighbouring

components when connecting the external control wires and that open

cable ends which are not in use are isolated.

5

Page 6

Operating Instruction

The TECHNOVAR drive head contains electronic safety devices which

switch off the control element in the event of faults, whereby the

motor has zero current but remains energized and comes to a halt. The

motor can also be halted by mechanical blocking. If it is switched off

electronically the motor is disconnected from the mains voltage

through the electronics of the frequency converter but is not potentialfree in the circuit.

In addition voltage fluctuations, especially power failures can cause the

system to switch off itself.

Repair of faults can cause the motor to start up again!

The system may only be put into operation when it has been earthened. In addition,

equipotential bonding of all pipes must be ensured.

Warns that failure to observe the precautions may cause electrical shock.

Failure to follow these instructions could result in serious personal injury or death.

Warns that failure to follow these instructions could result in serious personal

injury or death as well as property damage.

6

Page 7

Operating Instruction

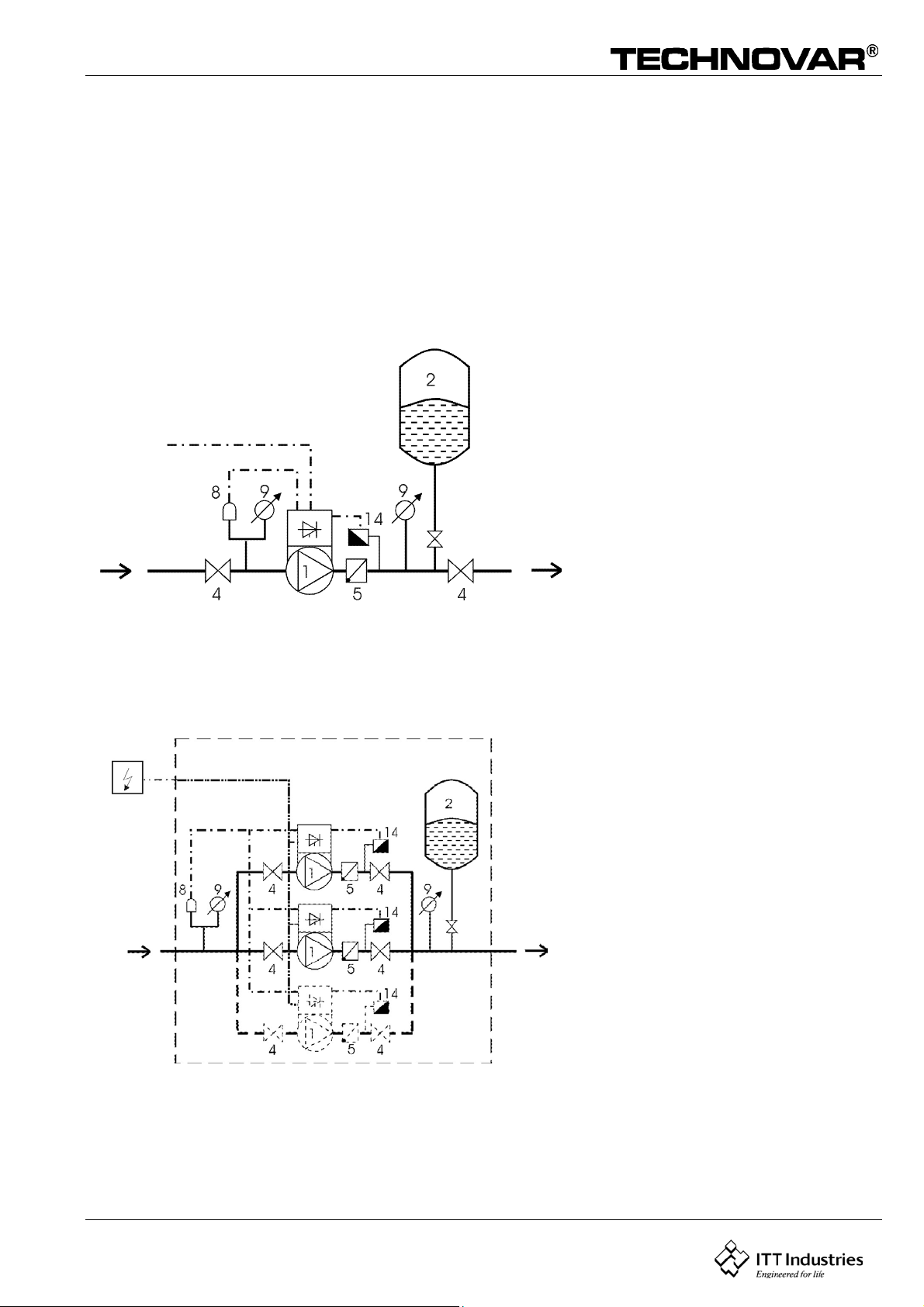

2 System Design

The following diagrams show typical single pump and multi-pump systems using the

Technovar control unit. Connection can be made directly to a water supply or water can be

drawn from a break tank or well. In the case of break tanks and wells, level switches, should

be used to shut down the pumps when water is low. In the direct connection, a pressure

switch on the suction side should be used.

(1) pump with drive head

(2) diaphragm tank

(3) distribution panel

(4) gate valve

(5) non return valve

Single Pump Layout

(8) incoming pressure control

(9) pressure gauge

(14) pressure transmitter

3

Multiple Pump Layout

7

Page 8

Operating Instruction

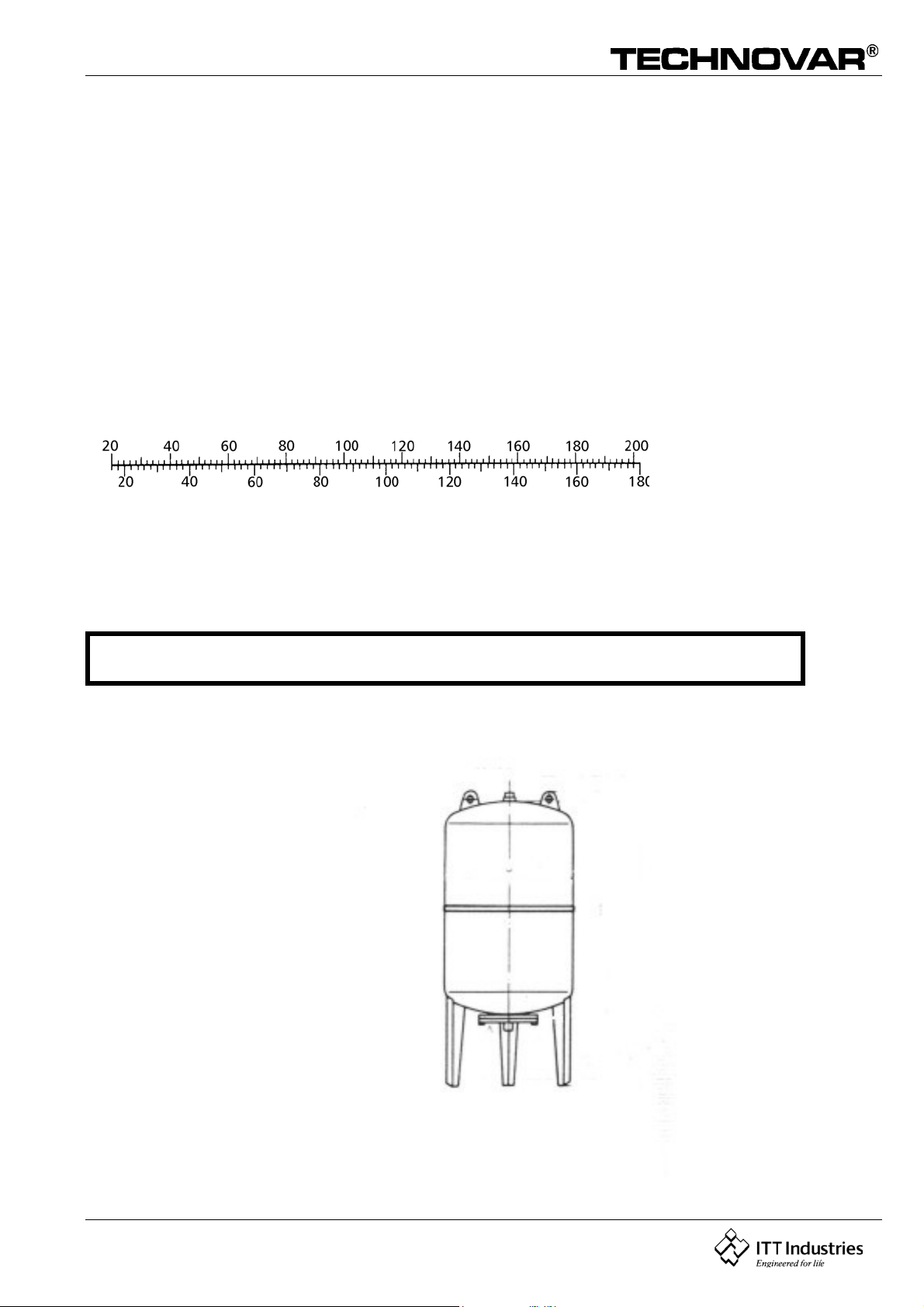

3 Pressure tank

A diaphragm pressure tank is used on the discharge side of the pump or pumps to maintain

pressure in the line when there is no demand. This will keep the pumps from continuing to

run. With the Technovar control unit, it is not necessary to have a large tank for supply

purposes.

In selecting a tank, make sure it is permit and suitable for systems pressure. The tank should

have a capacity of more than 10% of the maximum system flow rate g/min of one pump (also

in a multiple pump system!).

Pre charge the tank to the following:

Required pressure

Pre charge pressure (psi)

Note:

De-pressurize the tank prior to charging to ensure accuracy of the

pre-charged pressure.

8

Page 9

Operating Instruction

4 Technical Data - Frequency Inverter And General Data

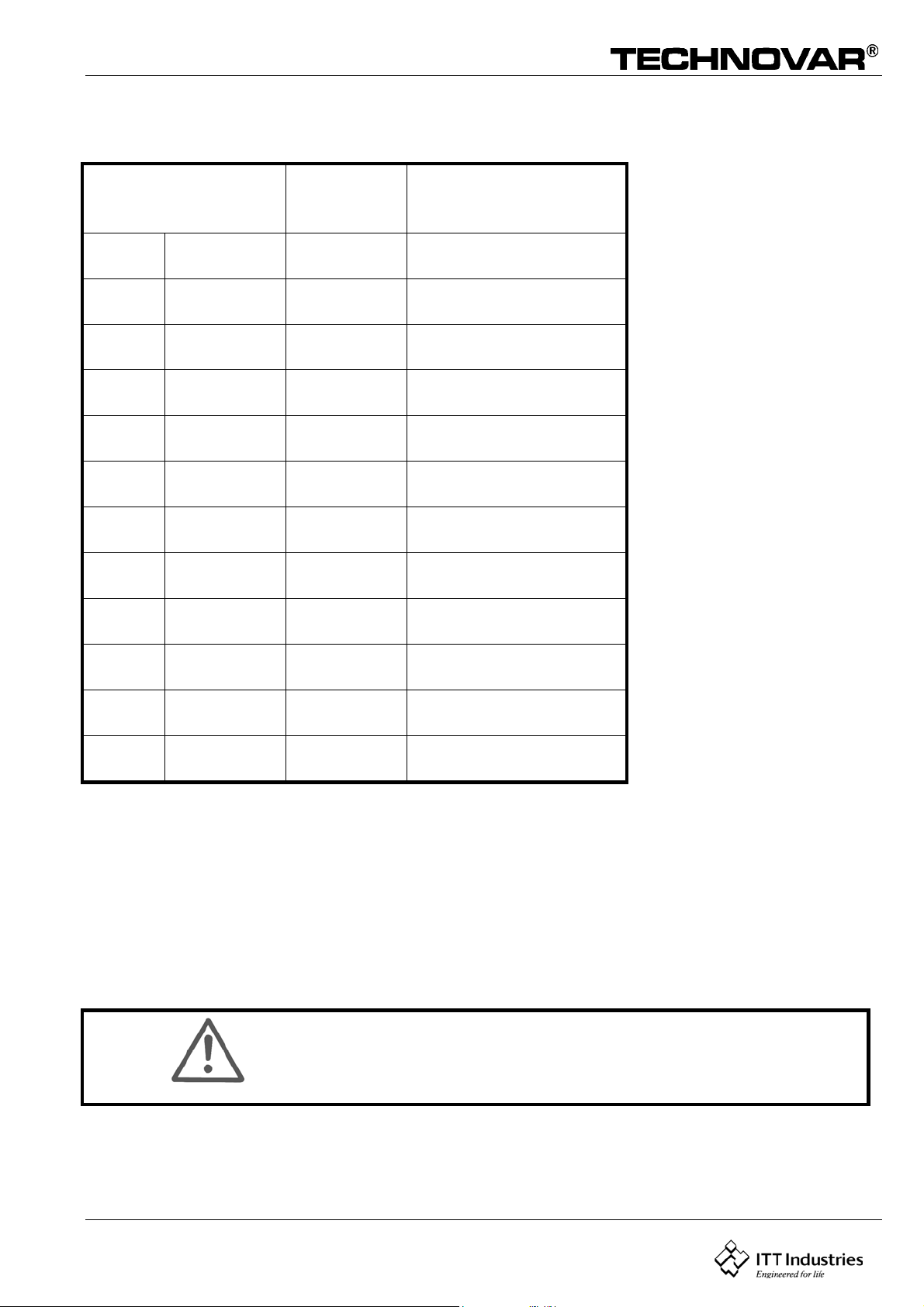

TECHNOVAR Technovar

Supply Voltage

output to

the Motor

Model

No.

nominal

Horsepower

HV 2.1 2 7 A

HV 2.2 3 10 A

Max. Current

*1x220...240VAC ±15%

*1x220...240VAC ±15%

HV 3.2 3 5,7 A 3x380...460VAC ±15%

HV 3.3 4 7,3 A 3x380...460VAC ±15%

HV 3.4 5 9 A 3x380...460VAC ±15%

HV 3.5 7.5 13,5 A 3x380...460VAC ±15%

HV 3.7 10 17 A 3x380...460VAC ±15%

HV 3.11 15 23 A 3x380...460VAC ±15%

HV 3.15 20 30 A 3x380...460VAC ±15%

HV 3.18 25 37 A 3x380...460VAC ±15%

HV 3.22 30 43 A 3x380...460VAC ±15%

Note: Consult local authorities in your jurisdiction for fuse sizing.

* Output voltage is 3 phase and requires a motor suitable for 220-240V/3/60 input power

Mains frequency: 48....62 Hz

Max. frequency: See chapter 10.8

Min. frequency: 0 – f-max see chapter 10.9

Electrical efficiency: > 95%

Please

Note!

If the motor and control unit are assembled separately keep the

motor cable as short as possible in order to avoid electromagnetic

emissions and capacitive currents. The length may not exceed 66 m.

and a shielded cable has to be used.

Protection against: Short circuit, under- and over voltage, overheating of the electronics

(overload) and additional external protective functions via PTC (motor temperature) and

low water switch.

A mains filter is fitted to ensure interference immunity.

9

Page 10

Operating Instruction

The HV-series frequency converter complies with the general EMV provisions and has been

tested according to the following standards:

· Radio Interference Suppression EN 50082 Part 2

EN 55011

· High Frequency Field Interference ENV 50204

· Electrostatic Discharge EN 61000-4

Ambient temperature: +5° C ... +40°C

Storage temperature: -25° C ... +55° C (+70°C during max. 24 hours.)

Humidity: RH max. 50% at 40°C, Unlimited

RH max. 90% at 20°C, max. 30 days per year

75% average per year (Class F, DIN 40 040)

Condensation is not permitted !

Air pollution: The air may contain dry dust as found in workshops where there is

no excessive quantity of dust due to machines. Excessive amounts

of dust, acids, corrosive gases, salts etc. are not permitted

Altitude:: max. 3280 ft. above sea level At higher altitudes the max. available

power has to be reduced. Please ask the manufacturer for further

details.

Class of protection : IP 54 3.15-3.22

Nema 4 bis 3.11

10

Page 11

Operating Instruction

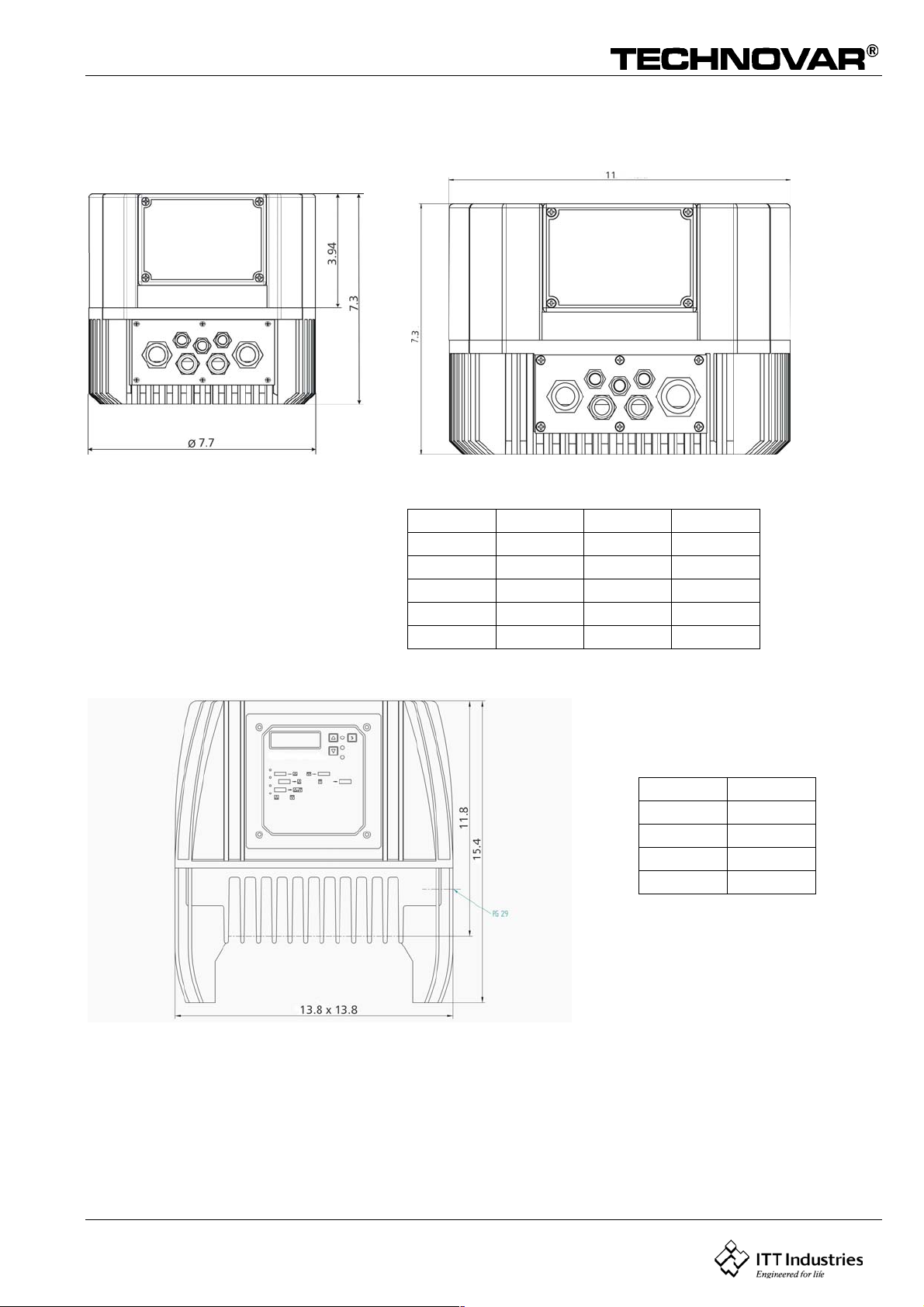

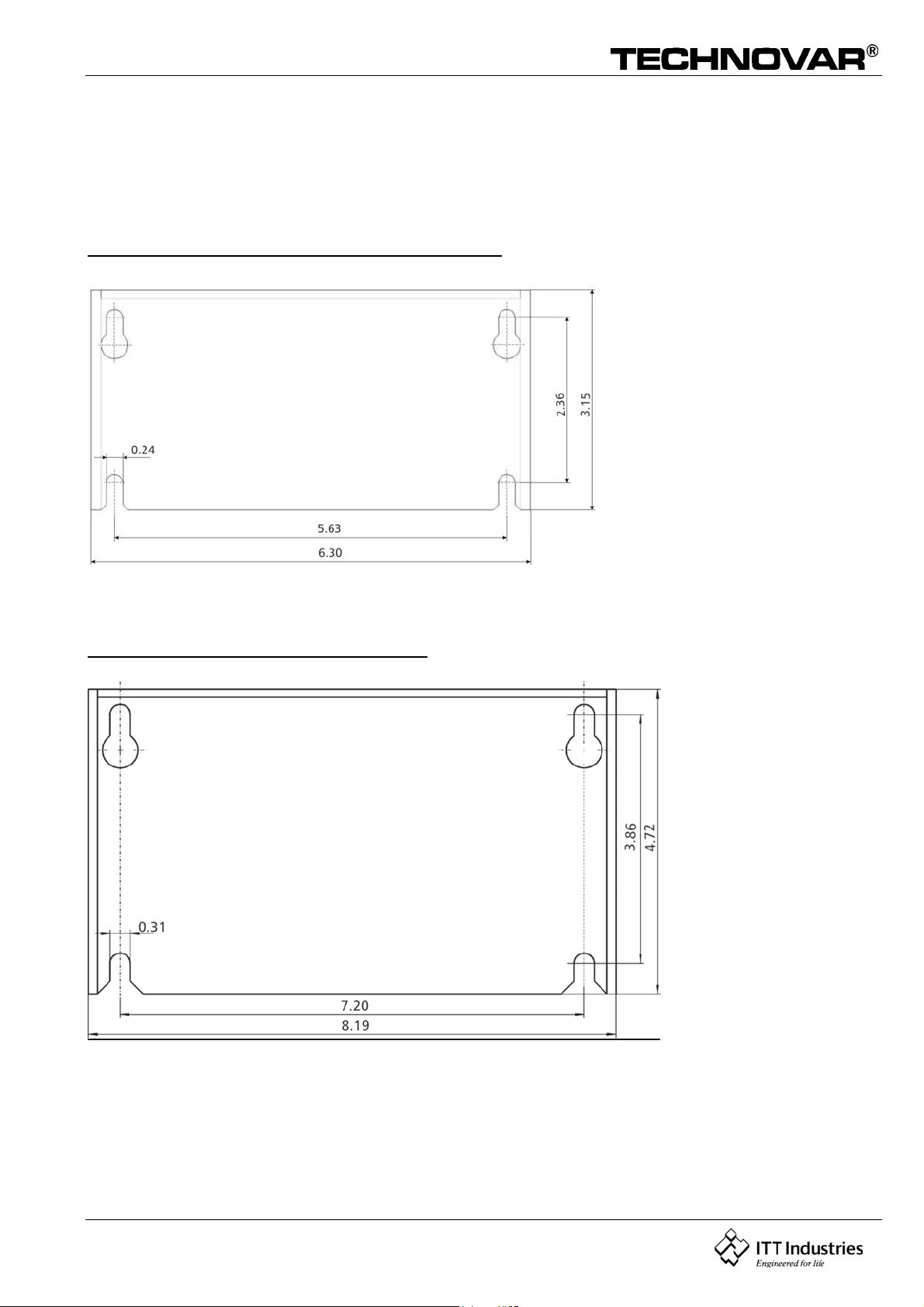

5 Dimensions and Weights

HV2.1/2.2/3.2/3.3/3.4 HV 3.5/3.7/3.11

Motorfancover max. 7.9 Ø

HV 3.15/ 3.18/ 3.22

Type: Weight: Type: Weight:

[lbs] [lbs]

HV 2.1 13 HV 3.4 13

HV 2.2 13 HV 3.5 22

HV 3.2 13 HV 3.7 22

HV 3.3 13 HV 3.11 22

Type Weight

[lbs]

HV3.15 64

HV3.18 64

HV3.22 64

all measurements in inches

Motorfancover max. 15.2 Ø

11

Page 12

Operating Instruction

6 Mounting the Technovar

6.1 Mounting the Technovar on the pump

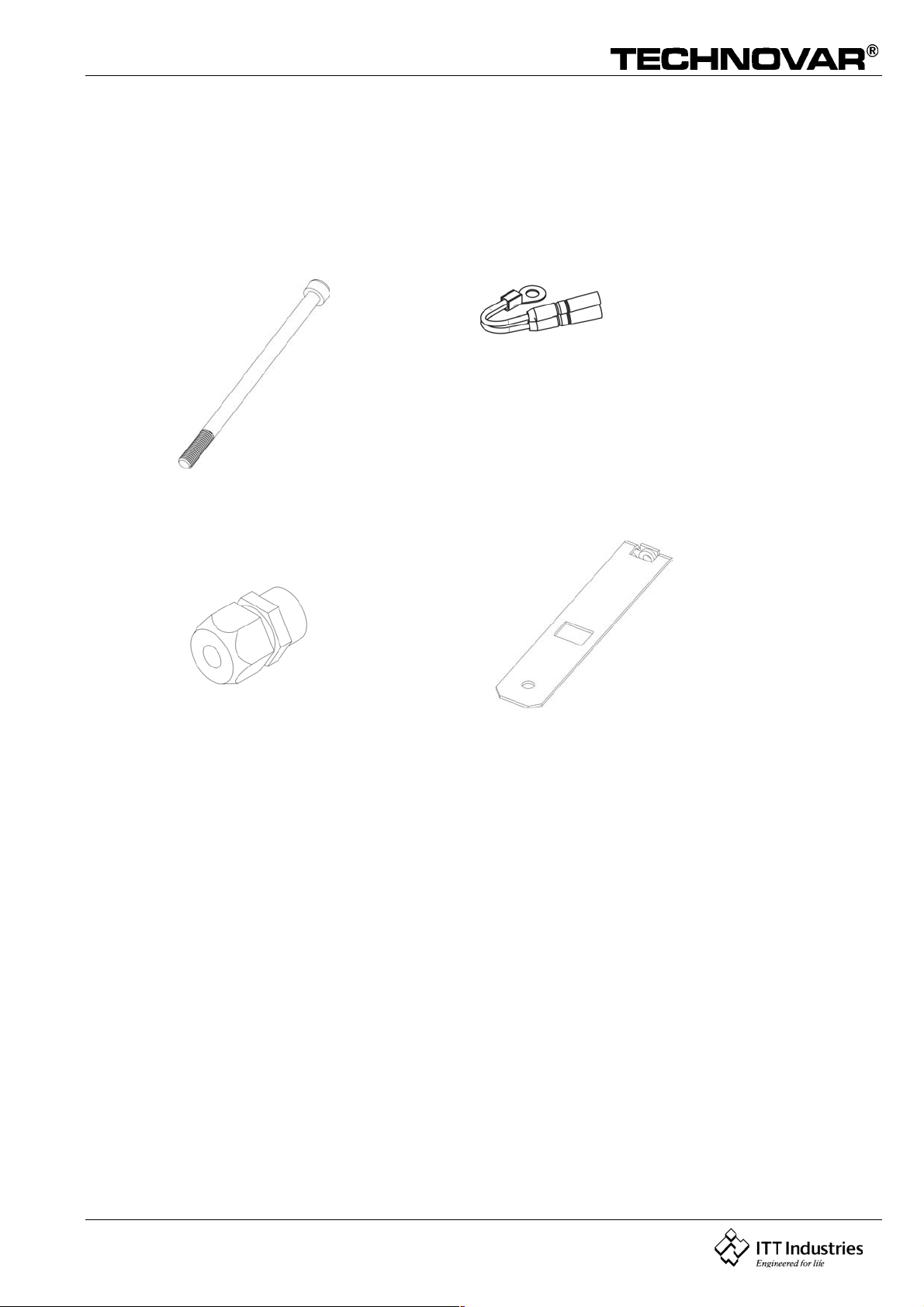

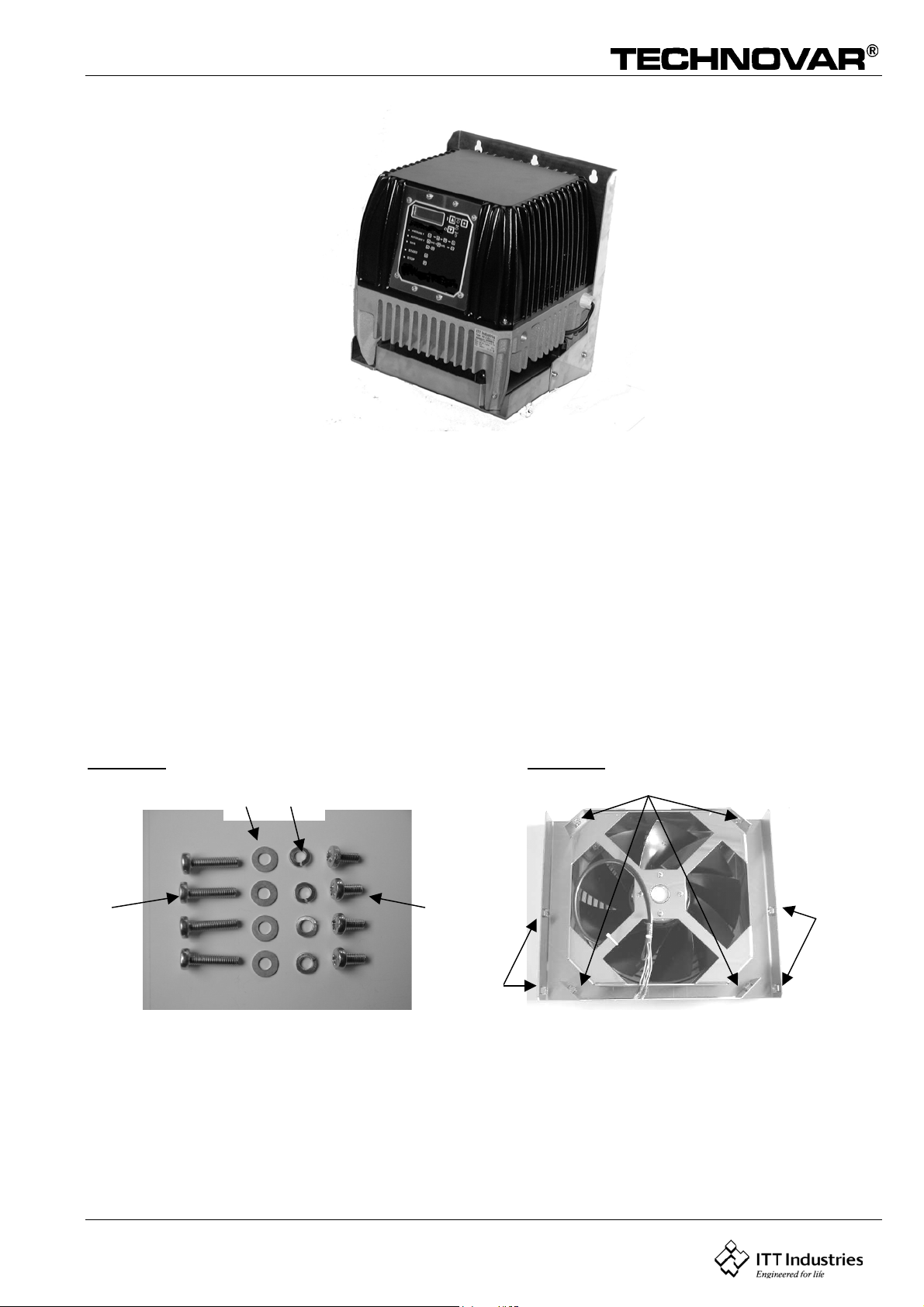

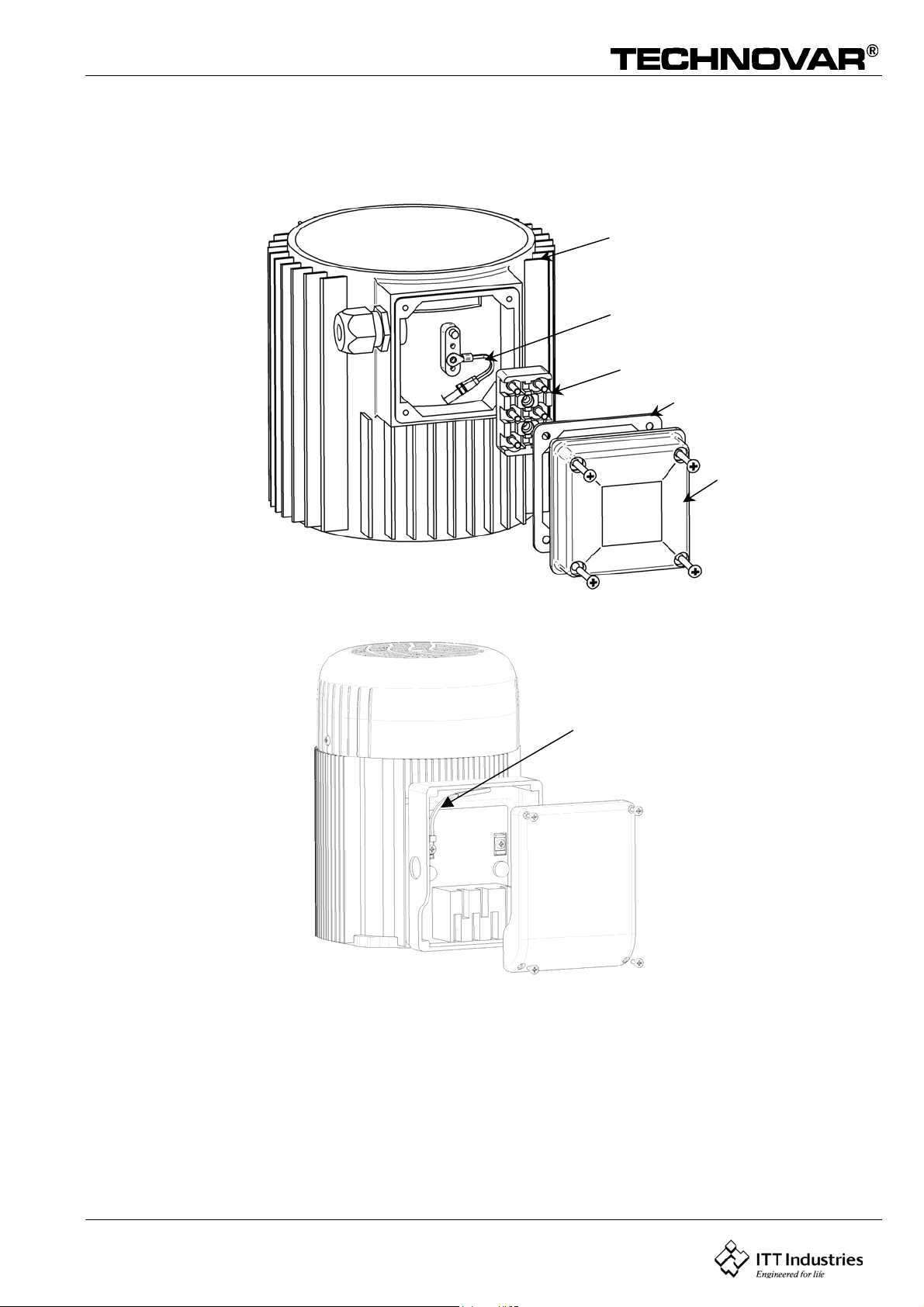

6.1.1 Components included

Thermal resistorScrew M5x90

cable gland

Mounting clamp

12

Page 13

Operating Instruction

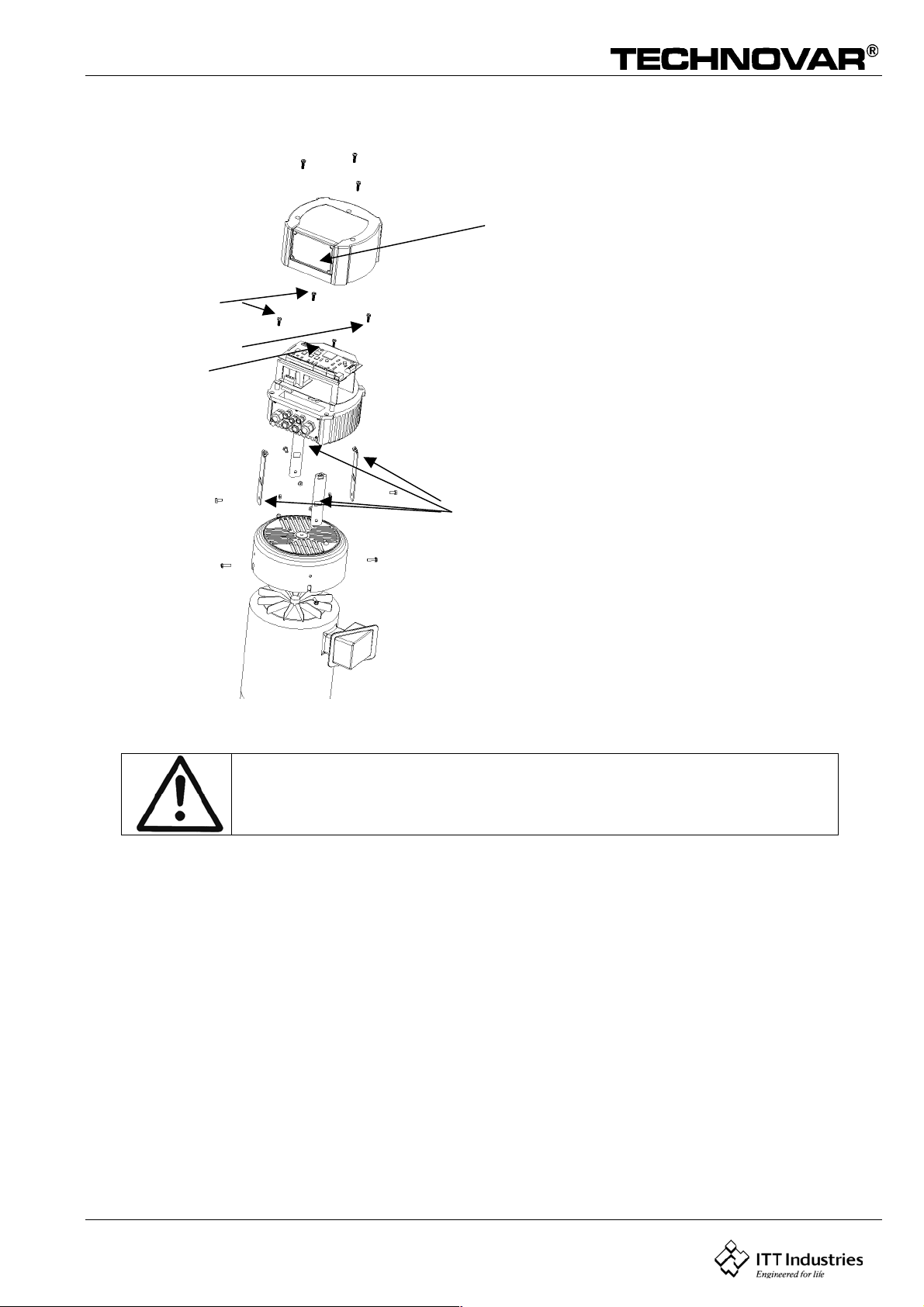

y

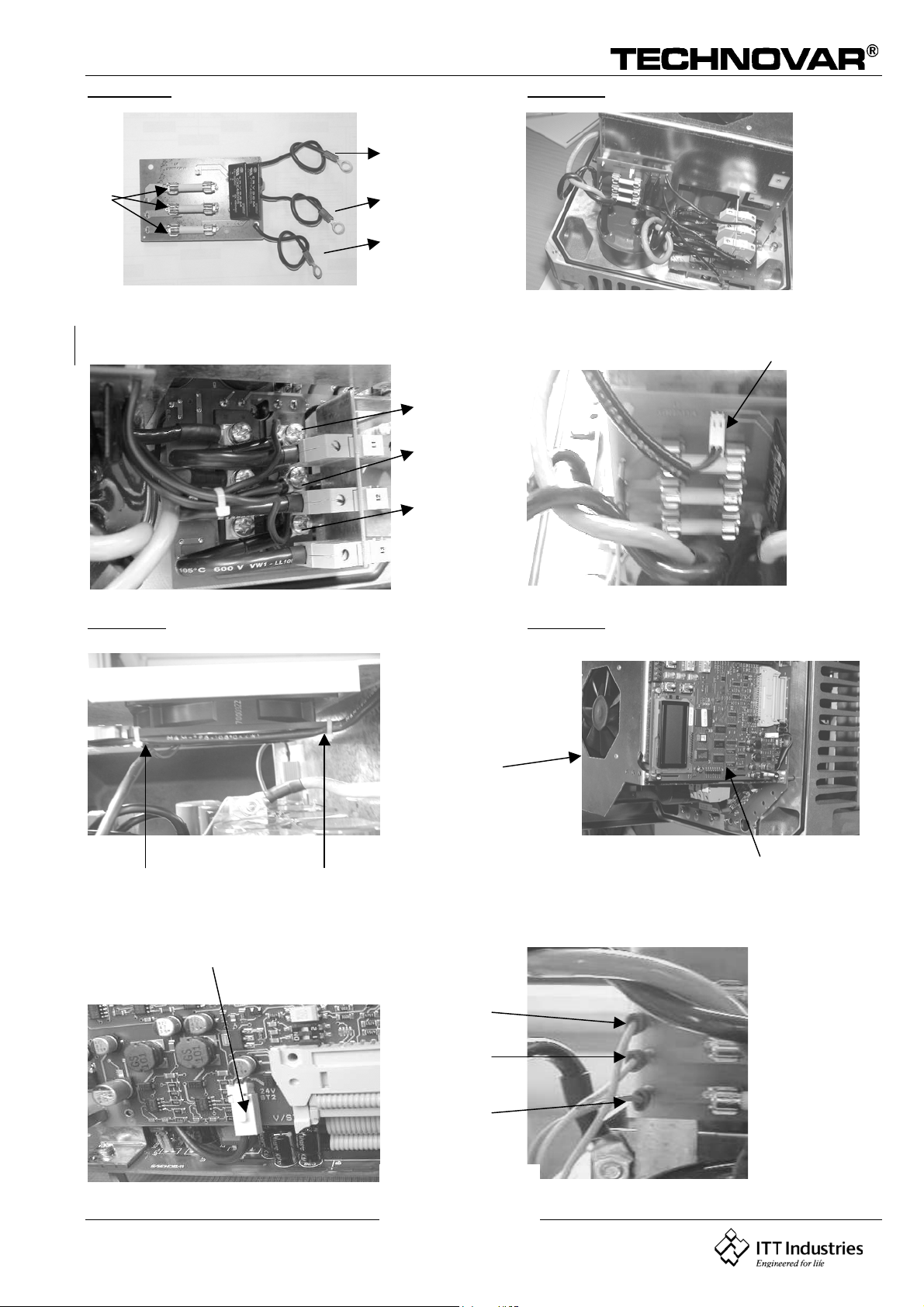

6.1.2 Mounting

HV2.1-3.11

Displa

changeable

to 180°

4 Screws

M5x90

Mounting:

u Remove the 3 screws from the

Technovar cover.

u Place the Technovar fan cover on

4 Mounting

clamps

the motor .

u Hang the 4 clamps by the

Motor fan cover and mounted

with the 4 screws.

u Mounted the cover with the

3 screws.

Don’t forget the gaskets for the 3 screws .

Ensure that there is no water on the unit before you open the cover.

Fix the display with the 4 Screws.

Thermistor

13

Page 14

Operating Instruction

Mounting ring

If you use a motor with bis HV2,2kW, you have to use a

mounting ring.

14

Page 15

Operating Instruction

A

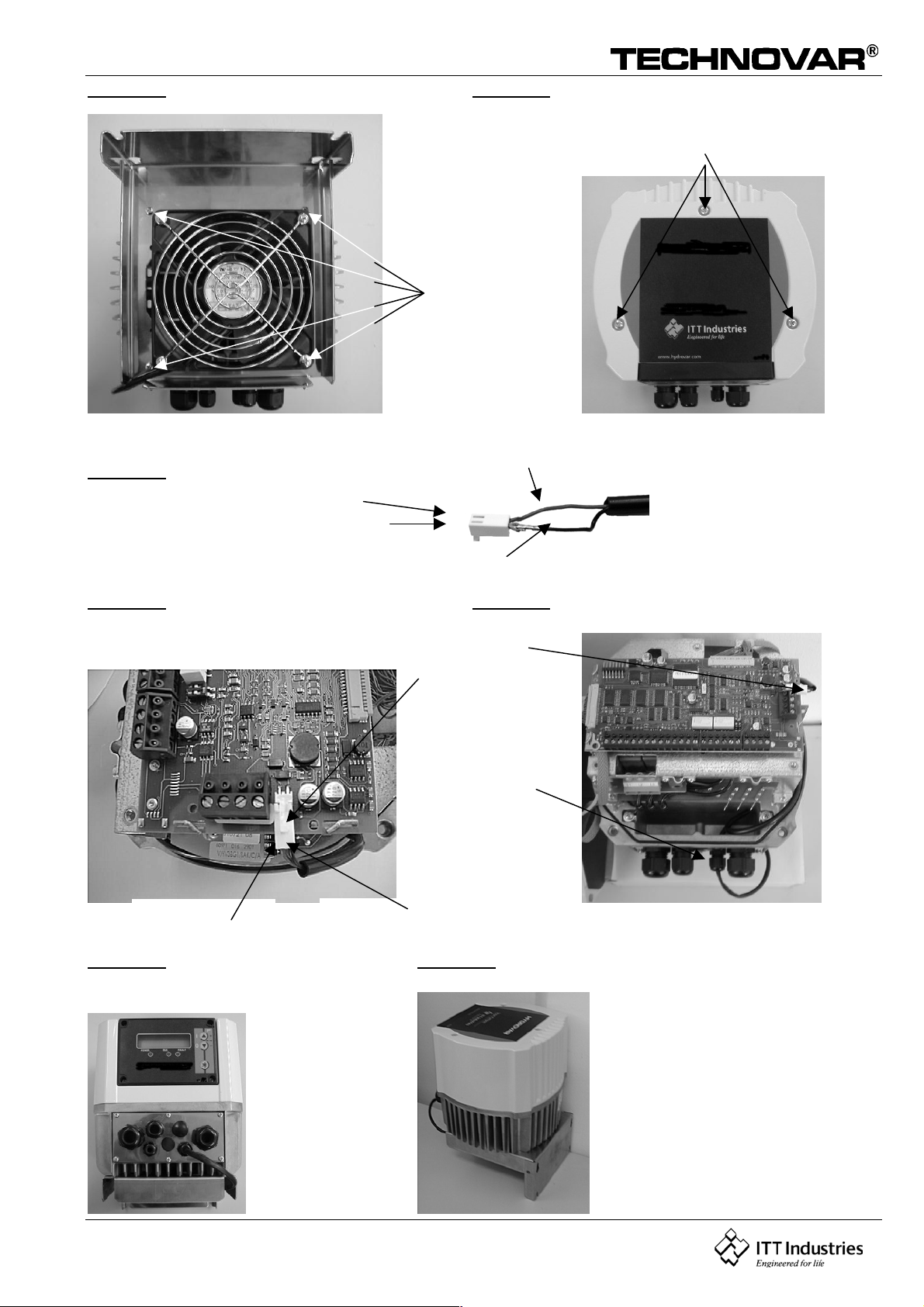

Wall mounting kit HV2.1-3.11

Included components for wallmounted kit HV2.1-3.11

1 mounting plate with fan Picture 1 A

4 M3x 8mm screws (self threading) for kit HV2.1-3.4 Picture 2 B

or M4x15mm screws (self threading) for kit HV3.5-3.11 Picture 2 B

1 Molex connector Mod. 6471-021 Picture 2 C

1 Cable gland M12x1,5 Picture 2 D

1 counter nut M12x1,5 Picture 2 E

not included: Dowels and mounting screws for mounting the kit on the wall.

Recommended diameter for this screws: Æ 5-6mm for kit HV2.1-3.4

Æ 6-8mm for kit HV3.5-3.11

Picture 1 Picture 2

BCD E

15

Page 16

Operating Instruction

Picture 3 Picture 4

Screw M3x8mm or

M4x15mm

(self threading)

Open

Picture 5

red

+ plus pole

black

Picture 6 Picture 7

Molex connector

cable gland for

fan cable

plus pole/ red

Black / minus

Picture 8 Picture 9

16

Page 17

Operating Instruction

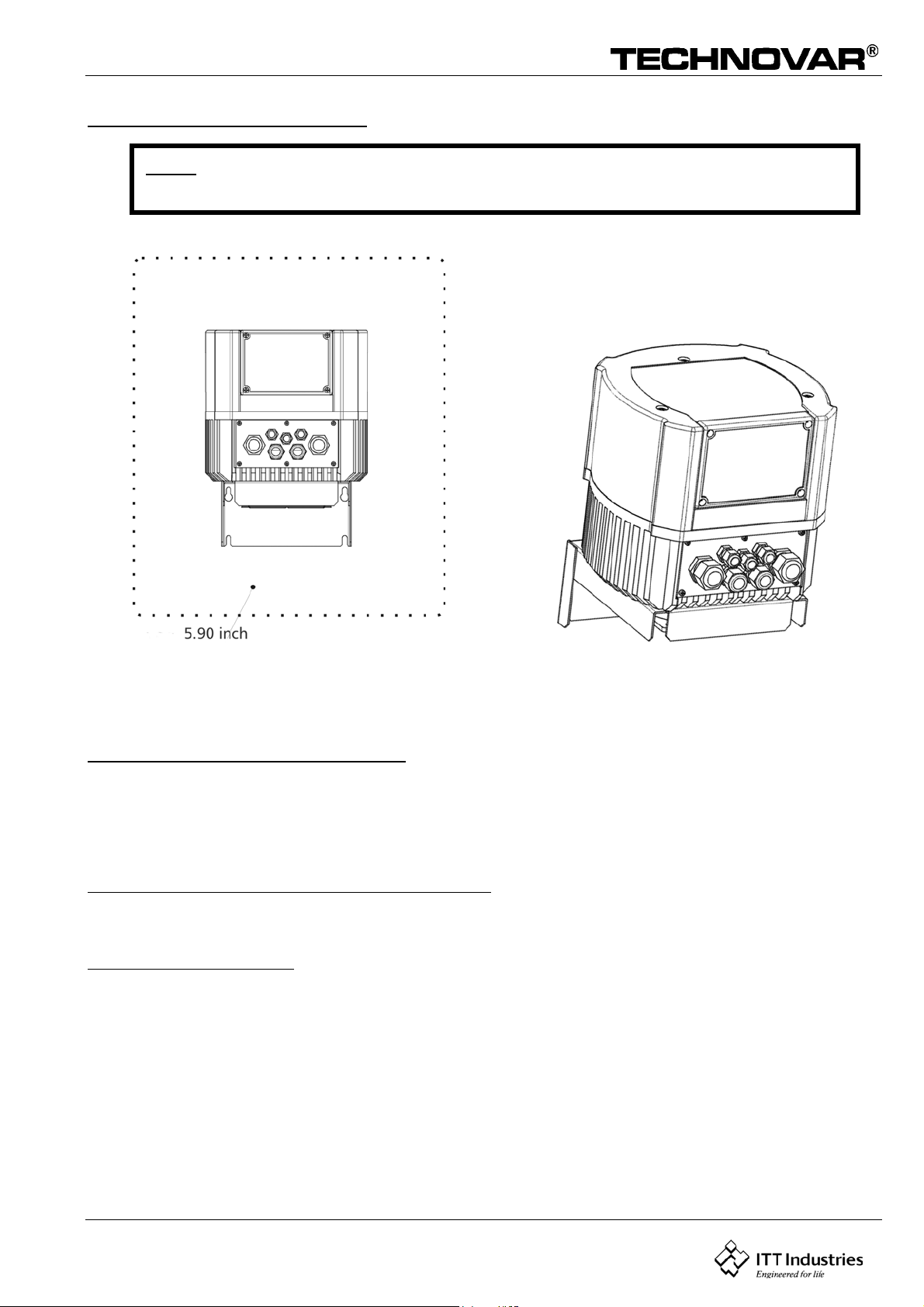

Free space for wallmounting

Note: You have to leave a free space in front of the Technovar for

configuration and for dismounting the cover.

free space required for cooling and mounting

MOUNTING INSTRUCTIONS

BEFORE REMOVING THE FREQUENCY INVERTER COVER THE SYSTEM MUST BE DIS-CONNECTED

FROM THE POWER SUPPLY. AFTER SWITCHING OFF THE POWER SUPPLY WAIT AT LEAST 5

MINUTES BEFORE STARTING WORK ON OR IN THE TECHNOVAR DRIVE HEAD.

Mounting the mounting plate on the HV 2.1-3.11

Place the heat sink of the Technovar on the mounting plate and fix them together by using the 4 self

threading M3x8mm respective M4x15mm screws (Picture 3).

Connecting the fan-cable

Remove the 3 screws holding the top cover of the Technovar and lift it carefully (picture 4).

NOTE: Take care with the connection cable to the display and the Ground-cable!

Left the cover aside.

Mount the included cable gland (Picture 2D/2E) on the cover plate and put the cable through the cable

gland. (Picture 7).

Connect the fan cable with the Molex connector (Picture 5) and then plug it into the right connection

on the control card (Picture 6).

NOTE: Take care of at the correct polarity: Red cable – plus pole

Black cable – minus pole

Fix the length of the cable inside the Technovar and tighten the cable gland to have ensure the IP55

class of protection.

17

Page 18

Operating Instruction

Afterwards replace the top cover and be careful with the connection cable to the display and the

Earth-cable. At last fix the 3 screws of the top cover.

In Pictures 8 and 9 you can see the Technovar with the mounted wallmounting-kit.

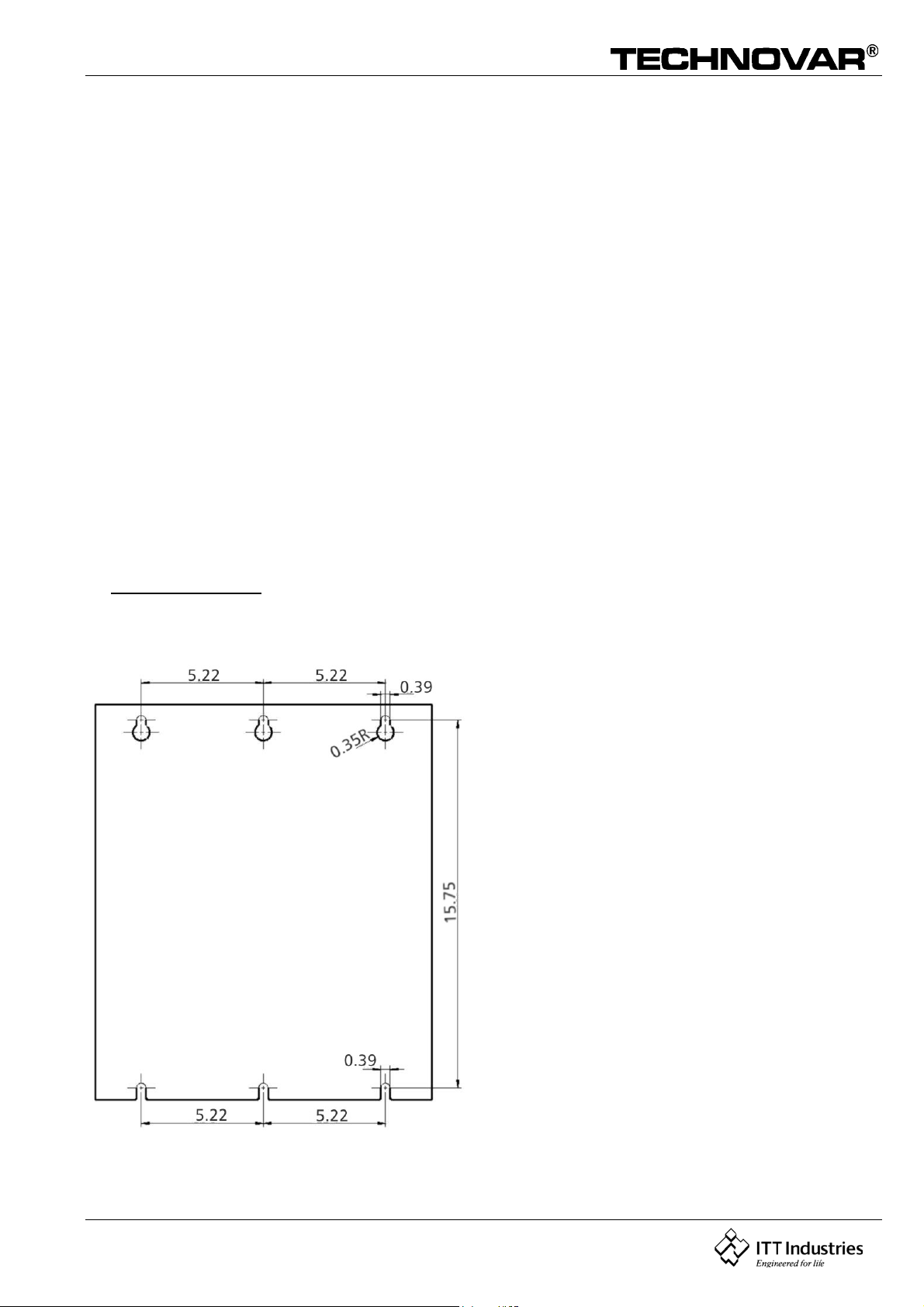

Mark the 4 holes according to the dimension drawing (see next page) on the wall and drill it with a

drilling machine. Mount the whole Technovar unit on the wall by using suitable screws.

Dimension drawing (HV2.1-3.4) (inches)

Dimension drawing (HV3.5-3.11)

18

Page 19

Operating Instruction

A

Wall mounting – kit 15/22kW

Included Components for wallmounted kit

4 long screw M6x25 Picture 1 A

4 washer Picture 1 B

4 short screw M6x12 Picture 1 C

4 washer Picture 1 D

1 AC-fan incl. connection cable Picture 2

1 fan board incl. 3 fuses T 1A/500V Picture 3 and 3 G

2 cable connector Picture 7

1 2 wire cable with connector Picture 7 and 8

1 cable gland for fan-cable Picture 12

1 wallmounted component Picture 13

Picture 1 Picture 2

B D

C

F

E

F

19

Page 20

Operating Instruction

G

Picture 3 Picture 4

L3

L2

L1

Picture 5 Picture 6

L1

L2

L3

Picture 7 Picture 8

Picture 9 Picture 10

U2

V2

W2

20

Page 21

Operating Instruction

Picture 11 Picture 12

12

Picture 13 Picture 14

Mounting the wallmounted kit on the Technovar

BEFORE REMOVING THE FREQUENCY INVERTER COVER THE SYSTEM MUST BE DIS-CONNECTED

FROM THE POWER SUPPLY. AFTER SWITCHING OFF THE POWER SUPPLY WAIT AT LEAST 5

MINUTES BEFORE STARTING WORK ON OR IN THE TECHNOVAR DRIVE HEAD.

Mounting the fan-board

Loosen the 4 main screws from the Technovar cover and also the 8 screws holding the

control-card.

Then remove the Technovar cover carefully. (Take care with the control-card and the GNDCable.)

Picture 3 shows you the fan-board (incl. the 3 fuses 1A/500V- picture 3/G) that you can fix

with the 3 plastic-distances in the 3 holes which are made for. (Picture 4)

The power supply for the fan-board comes from the connections L1, L2, L3 on the primaryside from the rectifier-board.

Please fasten the connection screw as well and connect the right cable with the right

connection

Compare the cable number and the connection number. (Picture 5).

Connecting the control-cable

21

Page 22

Operating Instruction

Connect the included 2-wire.black cable with the fan-board (Picture 6) an take it upside to

the internal fan. Then place the cable beside the internal fan and fix it with the two cableconnectors which are shown in Picture 7.

Next put the cable through the hole at the front of the Technovar and pull it below the

control card at the bottom (Picture 8).

On the frontside of the control-card is an connector for plug in the control cable what you see

in Picture 9.

Mounting the fan on the Technovar

Place the Technovar at the AC-fan that you can see the LCD-Display at the front and the

pieces for the wallmounted component are on the side (Picture 11).

Then put the fan-cable through the hole and fix it with the included cable gland from picture

12. Look that the cable goes between the heat sink and isn´t fixed from it (Picture 12).

Connect the fan-cable at the connection clamps U2, V2, W2 on the fan board and screw the

GND-cable with the GND screw (Picture 10).

Next take the four long screws M6x25mm and the lock washers (see picture 1/A and B) and fix

the Technovar on the AC-fan with the nuts you can see in picture 2/E.

At least put the wall mounted component (Picture 13) behind the Technovar and fix this 2

components with the four short screws M6x12mm and the lock washers (see Picture 1/C and

D) what you see in picture 14.

!! PLEASE NOTE: The fan is only running with the TECHNOVAR (Run Signal).

Connect the fan cable so that the fan can blow from the carriersheed through the heat sink.

Dimension drawing

22

Page 23

Operating Instruction

k

6.1.3 Mounting the thermistor

Variant A:

motor

thermistor

terminal bloc

rubber gasket

cover of the

conduit box

Variant B:

Thermistor

1. Open the cover of the conduit box and remove also the terminal block inside.

2. Fix the thermistor (Variant A or B)

3. Electrical connection of the motor cables see chapter 6.2.

4. Electrical connection to the Technovar see chapter 6.2

23

Page 24

Operating Instruction

6.2 Electric installation and wiring

6.2.1 Means of protection

Ask your power supply company which means of protection are required.

Applicable: AC and DC current-operated circuit breaker (FI), TN systems, protective

circuits.

When using a FI protection switch, make sure that it also releases in the event of

a DC fault, use for each Technovar a separate FI-switch!

6.2.2 Wiring the Technovar to the motor

Remove the 3 screws holding the top cover of the Technovar. Lift off the top carefully, take

off the connection cable to the display carefully remove the ground screw and left aside.

On the next page you can see:

(1) control card with all terminals for the control signals and the RS485 interface

(2) main card with all power components and terminals for power supply and motor

connections

24

Page 25

Operating Instruction

6.3 Main Voltage Terminals

HV2.1 / HV2.2

RS485 interface

Control terminals

Power supply

1x230 VAC

Motor connection

HV 3.2 – 3.11

RS485 interface

Control terminals

Motor connection

Power supply

3x400 VAC

HV 3.15/ 3.18/ 3.22

supply cable

The main power cable is connected to the terminals labeled L1, N for the 1x230 VAC, single

phase unit or L1, L2, L3 for the 3x400VAC, three phase unit.

RS485 interface

Control

terminals

Motor connection

Power supply

3x400 VAC

25

Page 26

Operating Instruction

6.4 Control Terminals

All externally used cables have to be shielded. Do not connect the ground of the electronic

components to other potentials (all electronic ground and GND of the RS 485-interface are

connected together internally).

For external off/on switches, contacts suitable for switching <10 VDC are necessary.

If unshielded control cables are used, signal interference may occur and interfere with

the function of the inverter.

Terminal:

Terminal:

(for dry 2 Fault signal relay CC max. 250VAC 1A free of inductivity

Contacts) 3 Fault signal relay NO max. 250VAC 1A free of inductivity

X1/ 1 GND

2 Actual value input 4...20mA, 50 Ohm load resistance

3 Power supply for external control 15VDC, max. 100mA

4GND

5 External on/off (release) Ri=10kOhm, 5 Volt DC

(gold plated contact necessary!)

6GND

7 Low water; Ri=10kOhm, 5 Volt DC

(e.g. incoming pressure switch or water level switch)

8 Thermo switch or PTC (in motor terminal box) Ri=10k, 5 VDC

9 Thermo switch or PTC

10 GND

11 Analog output 0...10 V, max. 2mA

12 Current signal input 4...20mA

13 Voltage signal input 0....10V or 2......10V

14 Digital input

X2/ 1 Fault signal relay NC max. 250VAC 1A free of inductivity

4 Pump operation

signal relay

5 Pump operation

signal relay

6 Pump operation

signal relay

NC max. 250VAC 1A free of inductivity

CC max. 250VAC 1A free of inductivity

NO max. 250VAC 1A free of inductivity

Terminal:

!! Fault relay (X2/2 - X2/3) is closed, when there is no error!!

X5-6/ 1 RS 485 SIO - LOW

2 RS 485 SIO + HIGH

3RS 485 GND

4 RS 485 + 5 VDC max. 20mA out

For supply of external interface

converter

26

Page 27

Operating Instruction

6.4.1 Control terminals

When connecting the variable speed pumps (max. 4 pumps) via the interface RS 485, the

terminals X5/1/2/3 or X6/1/2/3 of each Technovar are to be connected together by means of a

shielded cable and programmed accordingly (* Programming Sequential Operations).

27

Page 28

Operating Instruction

6.4.2 Dip-Switch on the controller board

SW4: DIP-Switch to select the switching frequency

!!Attention!!

SW4 Switching frequency

12

OFF OFF 8kHz (standard)

ON OFF 5kHz

OFF ON 4kHz

ON ON 2.5kHz

Before switching, disconnect the power supply, otherwise the

Technovar could be destroyed.

6.4.3 Main parts from the control card

Pin connection

(to Display)

40 pin connection

(to power board)

Dip-switch

24V output

(max. 800mA)

for external fan

Main supply

3x400 V

Control terminal

blocks

28

RS-485 terminals

Motor connection

Page 29

Operating Instruction

HV 3.15/ 3.18/ 3.22

Dip-switch

LCD

24V output

(max. 1A) for

external fan

Push buttons RS-485

terminals

Control terminal blocks

40 pin connection

(to power board)

6.5 Front plate

HV3.15/ 3.18/ 3.22

29

Page 30

Operating Instruction

HV 2.1-3.11

Power Run Fault

ON

OFF

Select

7 Language Selection

The information on the display can be called up in German, English, Italian, French, Spanish,

Portuguese or Dutch.

To select the desired language proceed as follows:

Briefly press + simultaneously (in 1st display); Þ the actual language will now appear

in the second line and the desired language can be selected with the button or . After

the language has been selected, press button briefly and the first menu window of the

main window will appear again. If only the language is changed it is not necessary to SAVE.

30

Page 31

Operating Instruction

8 Typical applications

8.1 Control

By means of the built-in Technovar controller acc. to constant pressure by pressure

transmitter and/or acc. to constant flow by flow-meter or orifice plate with differential

pressure transmitter and differential pressure transmitter or - if required - acc. to external

manual control by reference 4 - 20 mA DC (only for special applications).

8.2 The Main Menu Setting

There are ten display screens in the main menu which will allow you set the required system

pressure, save it, and turn the system on. Several of these display screens were already used

during the test run. After power has been turned on, the “Power on” light should illuminate

and the display should show “No Autostart – disable inverter”.

Instructions:

Check the green POWER light NO Autostart

disable inverter

Press the button to advance the display to INVERTER STOP

ON -> START

Press to advance the display to

REQUIRED VALUE

Set the desired set pressure with either or . If several pumps are connected via the RS485 interface, one pump must be ready for operation when the set pressure is changed,

otherwise the set value will not be accepted by the follow-up pumps. Afterwards the new

required pressure has to be saved in all pumps.

Press to confirm and the display changes to

AUTO – START

Select (ON) with the button or (OFF) with . Auto-start ON starts the pump automatically

again after an interruption of the power supply (power failure).

At the Auto-start setting OFF, the pump must be restarted manually by pressing the buttons

(OFF) and then (ON) after power failure.

Press and the display changes to:

Last error

REQUIRED VALUE

X.XX psi

AUTO – START

OFF

ERROR 1

...................

Note: All errors are only readable

Press the button to change to

Error before last error:

ERROR 2

...................

31

Page 32

Operating Instruction

Press the button to change to

error before error 2:

Press the button to change to

error before error 3:

Press the button to change to

error before error 4:

Press the to advance the display to:

Press the button and the display will change to

Simultaneously press buttons and until...

appears and the display jumps back to Window 1

“INVERTER STOP” after few seconds.

ERROR 3

...................

ERROR 4

...................

ERROR 5

...................

TOTAL RUN TIME

0000:00

SAVE ???

+

SAVE ???

SAVED

Warning: After each change of a setting, this has to be saved (new

values are stored in an EEPROM).

Otherwise the changes will be lost in case of a power supply

failure!

32

Page 33

Operating Instruction

Save ??

+

ÙÚ

0000 : 00

Heating

Lock Function

Conveyor - Limit

Test Run man.

ON

OFF

disab led

+

ÙÚ

Config . Req. Val. 2

Start Value

Regulation Mode

Mode

Sensor Range

OFF

disabled

Normal

Controller

20 mA = 362,6 psi

Te s t R u n

Dimension Unit

Analog - Out

Lift - Amount

after 10 0 h.

psi

Actual Value

0.0 %

0.0 Hz

Min. Frequency

60.0 Hz

Max. Frequency

70 Sec

Ramp 4

70 Sec

Ramp 3

4.0 Sec

Ramp 2

0066

Set Password

50 %

Disp. - Contrast

0000 h.

Operating Hours

Errors

SUBMENU

Tes t Run

SUBMENU

+

ÙÚ

Save ??

+

+

ÙÚ

SUBMENU

Default Values

2 Sec

Delay Time

Test - F r eq u e nc y

disab led

Error - Reset

10.0 %

30.0 H z

Boost Test - Run

Default Europe

0000

Clear Errors

ÙÚ

Default USA

Error 1 Error 2 Error 3 Error 4 Error 5 Total Run Time

Auto - Start

Required Value 1

ITT IND UST RIES

ON

126,9 ps i

x.xx psi

4.0 Sec

Ramp 1

80 %

Ramp Hystere sis

5 %

Window

JOG - Mode

0.0 Hz 319,5 p si

0000

Password

Linear

Sensor - Curve

out of range

Sensor Adjust ?

Boost

5.0 %

0 Sek

Stop - Delay Fmin

F -> 0

Config. Fmin

37.0 Hz

Frequ. - Lifting

0.0 Hz

2.0 Hz

Source Req. Value

Intensity 2

Synchron. Limit

Sync hron - Wi ndow

OFF

SUBMENU

Synch. Control

Pump - Sequ ence

+ 0.0 %

0

Busarbit - Diag.

Adr 1 fau lt

OFF

SUBMENU

RS485 - In terface

SUBMENU

Seq. Control

Offset

SUBMENU

Run Motor

Relay C onfig .

Pump - Address

Actu. Value Inc.

Offset - Input

Local

ADC Reference

5 psi

2,1psi

58.0 Hz

12 hours

Actu. Value Dec.

OFF

0.0 %

Level 1

Switch Interval

Enable Seq. CTL.

0.0 %

Level 2

Intensity 1

+ 0.0 %

Start

33

Page 34

Operating Instruction

8.3 Single Pump – Pump Protection

The Technovar has the ability to protect the pump by shutting off in low/no suction or run out

conditions.

Note:

Note:

Hold the button for 3 seconds and the display changes to

Password:

The password protection prevents untrained personal from accidentally changing of the base

settings:

Low/no suction protection depends on the installation of a suction line

pressure switch, or float switch for a tank. This switch is connected to

the Technovar. The cut out setting for a suction pressure switch should

be greater than the minimum incoming pressure, required by the pump.

Run out protection is available for one pump systems and multiple pump

systems with a common suction pipe. (described at chapter ”Conveyor

Limit” 11.30.1 In multiple pump systems with separate suction pipes,

you can not avoid dry running by measuring the system pressure,

because the pressure is produced from another pump in the system.

8.3.1 To set run out protection

PASSWORD

0000

Set ‘Password 0066’ by pressing

You will now be able to access all of the alternate menus for all Technovar optional controls.

After entering the password you have to confirm by pressing

the button to advance the display to the next window

JOG-MODE

Actual outgoing frequency and actual analog input are shown. By pressing or in this

menu, the internal controller of the Technovar will be shut off and the inverter changes to

manual mode. With the buttons and you can set any constant speed. Setting of 0,0 Hz

stops the inverter. If the JOG-MODE is left at a frequency higher than 0,0 Hz the inverter will

continue its normal automatic operation.

Press the button repeatedly until you reach

Hold the button down for 3 seconds to enter the

submenu, until the display changes to

or PASSWORD

0066

JOG – MODE

0.0 Hz X.XX psi

SUBMENU

ERRORS

CONVEYOR-LIMIT

disabled

34

Page 35

Operating Instruction

CONVEYOR-LIMIT

Disabled or adjustable between disabled...NORMALIZE. To disable the conveyor limit, press

till “disabled” is shown on the display. An adjusted value >0 has to be reached till the

programmed. “DELAY TIME”.

If this value is not reached, the failure “CONVEYOR CONTROL ERROR” will be indicated and

the pump will stop.

Press once the button and change to

DELAY TIME

The delay time is adjustable between 0 and 100 Sec. for switch-off of the Technovar in case of low

water, (Terminal X1/6-X1/7) and conveyor limit.

Press to advance the display to

ERROR-RESET

if you want to have an automatic error reset for 5 times (not for errors in the control-port),

you have to set a delay time for the automatic reset (range: 0-250 sec.).

That means after a non fatal error, the Technovar will be restarted after the set delay time.

After five consecutive errors the converter switches off.

To disable this function press until “disabled” appears.

(The internal counter of the automatic resets will be reduced by one each operating hour).

Note:

Hold down the key for 3 sec. to leave the submenu and

the display changes to

“Fatal” errors will always shut down the system at the first time.

DELAY TIME

2 Sec.

ERROR-RESET

disabled

SUBMENU

ERRORS

Press the button repeatedly until you reach

Press both buttons until the display changes to SAVE ???

After a moment, the screen will automatically return to the 1st window.

SAVE ???

+

SAVED

ITT INDUSTRIES

X.XX psi

35

Page 36

Operating Instruction

8.4 Single Pump – System Curve Compensation

The Technovar can automatically compensate for system friction losses due to increased flow.

Tables are available in most pump catalogs, indicating the amount of friction losses that can

be expected in various sizes of pipes at different flow rates. Use these tables to determine the

friction losses for the pipe size you are using at maximum flow rate.

This Diagram shows a typical system curve. The system pressure set point is shown at shutoff

and pressure increase is shown for increasing flow.

Calculate the pressure required to overcome friction losses at maximum flow.

36

Page 37

Operating Instruction

8.4.1 Entering the compensation values

Hold the button for 3 seconds and the display changes to

Password:

The password protection prevents untrained personal from accidentally changing of the base

settings:

Set ‘Password 0066’ by pressing or . PASSWORD

You will now be able to access all of the alternate menus for all Technovar optional controls.

Press the button repeatedly until you reach

FREQUENCY-LIFTING

Adjustable between 6 Hz and the set MAXIMUM FREQUENCY, this setting states at which

output frequency the set pressure should be increased. That is the speed at which the pump

works at the set pressure and at delivery rate 0

(can be read in the JOG MODE).

Press the button to change to

LIFT-ITENS.

Increasing value, when the reaches its maximum speed (maximum volume).

PASSWORD

0000

0066

FREQU.-LIFTING

37.0 Hz

LIFT-INTENS.

0.0 %

Enter settings as follows:

1. Setting the set pressure (see: Inverter main menu).

2. Enter frequency at zero demand and actual pressure = set pressure Þ FREQU. LIFTING

3. Set desired lifting at maximum speed (in %) of set pressure.

Increasing values up to 200% are allowed. If your friction losses are above 200% of your set

pressure, bigger pipes should be used.

Press the button repeatedly until you reach

Press both buttons until the display changes to SAVE ???

All new settings are stored.

After a moment, the screen will automatically return to the 1st display.

SAVE ???

+

SAVED

ITT INDUSTRIES

X.XX psi

37

Page 38

Operating Instruction

8.5 Multiple Pump - Constant Pressure and System Curve Compensation

When two, three or four Technovar controlled pumps are connected in a system, they can be

programmed to work together to maintain system pressure up to the maximum flow rate of

all pumps combined. As the first pump reaches its maximum speed and flow, the second will

automatically turn on (and so on). In addition, the sequence of the pump that will run first

(lead pump) can be automatically varied to reduce premature wear of any pump in the

system.

Hold the button for 3 seconds and the display changes to

PASSWORD

0000

Password:

The password protection prevents untrained personal from accidentally changing of the base

settings:

Set ‘Password 0066’ by pressing or . PASSWORD

0066

You will now be able to access all of the alternate menus for all Technovar optional controls.

Press the button repeatedly until you reach

MODE:

Controller

Use and to change the setting to: MODE:

Multicontroller

MODE:

Controller:

If only one TECHNOVAR pump is in operation set the Controller for a stand alone controller

function. If more than one pump are working together, connected via the RS485 interface

(follow-up pump control), the Multicontroller must be set with the buttons or .

Synch. Controller:

The Synchronous Controller mode is working in the same way like the Multicontroller. The

only difference is, that all pumps in the multi pump system are running at the same

frequency.

Actuator:

The Actuator application is only used if you have an external controller and the Technovar is

used as a standard frequency converter. In the Actuator-Mode, the internal controller is shut

off, and the output frequency is proportional to the input signal (X1/2) Þ 4-20 mA = 0 f

. The frequency changes with the programmed ramps 1 and 2. The functions of low

max

water, thermal protection and external ON/OFF are still working.

38

Page 39

Operating Instruction

...... = f

max

If Manual control is selected, the parameter REQUIRED VALUE will change to Manual

control LOCAL, where the actual frequency and the actual value is displayed (according to

the JOG-MODE in the submenu).

Now the frequency can be changed with the and buttons, and the speed of the pump

will change with the fasten ramps1 and 2. After selecting the right frequency, it can be

saved with the standard SAVE-parameter.

After a supply failure, the pump will then run with this selected frequency (depending on

the parameter AUTO-START).

In the first window, the actual frequency is displayed. The frequency can be changed

between the set minimum and maximum frequency. (CONFIG. FMIN is not active in this

mode!).

Attention

Driving the pump in a not allowed speed range can damage the motor or the

Technovar-head!

Press the button five times and you reach

SUBMENU

Seq. Control

Hold down the button for 3 seconds until the display

changes to

ACTU. VALUE INC.

5 psi

ACTUAL PRESSURE INCREASE (=LIFT VALUE):

This value, together with the fall value (ACTUAL VALUE DECREASE) determines the

increase of the required value after starting of the following pumps (see example)

39

Page 40

Operating Instruction

Generally a slight pressure drop is allowed on the first pump before the next is started.

This allows for brief systems fluctuations without pump cycling. Once the next pump

starts, however, you will want the system to resume its normal set pressure.

To do this, enter the amount of pressure drop you will

allow before the next pump starts (= value of

parameter ACTUAL VALUE DECREASE). The diagram

shows the pressure drop and increase.

To increase the pressure even more to compensate for

system loss at higher flows, enter the total of the

system drop allowed before next pump starts and the

increased pressure (ACTUAL VALUE INCREASE) desired.

Application example:

1) Pump 1 reaches the speed of ENABLE SEQ: CONTROL or more

2) Pressure falls and reaches the start-value of the 2nd pump

(= REQUIRED VALUE – ACTUAL VALUE DECREASE)

3) Pump 2 is switched on automatically

4) The required value is calculated new, after the start of the 2nd pump in the following

way!

New required value = REQUIRED VALUE – ACTUAL VALUE DECREASE + ACTUAL

VALUE INCREASE

Generally:

k ... Number of active pumps

P = P

Enter the required value by pressing the and button ACTU. VALUE INC.

Press the button to confirm and change to

ACTUAL PRESSURE DECREASE (= Fall value):

This value determines amount of pressure drop you will

allow before the next pump starts.

+ (k-1)*[lift value – fall value]

set

· Lift value = Fall value Þ Pressure constant when pumps switch on

· Lift value > Fall value Þ Pressure rises when lag-pump switches on

· Lift value < Fall value Þ Pressure falls when lag-pump switches on

7,1 psi

ACTU. VALUE DEC.

2,1 psi

40

Page 41

Operating Instruction

Enter the required value by pressing the and button ACTU. VALUE DEC.

5 psi

Press the button to change to

ENABLE SEQUENCE CONTROL: (Release frequenz)

The follow-up pump only starts, when the start-value (SET VALUE – ACTUAL VALUE

DECREASE) is reached and the lead pump has reached the programmed release-

frequency.(Adjustable from 0.0 Hz to 70 Hz).

Normally this start frequency is set 1 to 2 Hz lower than the MAX. FREQUENCY If you don’t

want to start a following pump this value has to be set higher than the MAX. FREQUENCY.

Enter the required value by pressing the and button ENABLE SEQ. CONTROL

Note:

Press button briefly to advance to

In the standard multicontroller mode, the next pump will not start until both the

system pressure drop and release frequency first pump speed have been reached.

In the synchronous control mode, the first pump only has to reach the release

frequency, then the next pump will start.

ENABLE SEQ. CTL

58.0 Hz

59.0 Hz

SWITCH INTERVAL

12 hours

SWITCH INTERVAL:

For changeover of the master pump and follow-up pumps, in order to achieve even

operating hours. Adjustable between 1 hour and 100 operating hours of the Technovar. If

an interval of more than 100 is selected, the automatic changeover is deactivated.

Manual changeover of the master pump in the 1st display by pressing the -button.

Enter the required value by pressing or button SWITCH INTERVAL

24 hours

After pressing the button for 3 seconds, you leave the sub

menu and the display changes to

41

SUBMENU

Seq. Control

Page 42

Operating Instruction

Press the button again briefly to advance to

Hold the again for 3 seconds to enter the submenu and

the display changes to

PUMP-ADDRESS:

If only one pump is used, the setting remains OFF. If several pumps are connected via the RS485 interface (max. 4) each pump must be allocated its own address number (1-4)

(each number may only be allocated once!).

Use the and button to select a “PUMP-ADDRESS” PUMP-ADDRESS

Hold the button for 3 seconds to return to

Press the button repeatedly until you reach

SUBMENU

RS485-Interface

PUMP-ADDRESS

OFF

1

SUBMENU

RS485-Interface

SAVE ???

+

Press both buttons until the display changes to SAVE ???

SAVED

All settings are stored.

After a moment, the screen will automatically return to the 1st display.

ADR X (X) P X

X.XX psi

Note:

Repeat this steps for each pump in the system. Use a different

address number for each pump!

42

Page 43

Operating Instruction

9 Parameters of the main menu

After connection of the Technovar unit to the power supply the following possible

displays become visible.

SW-Ver: VOG 120

Date: xxxx

The current software version with the date of

programming is displayed for about three seconds.

The following two displays are depending on the selected mode:

a) Active MODE = Controller:

1.

ITT INDUSTRIES

XX.X psi

This window is mentioned several times in the

Operating Instructions as 1st display at Mode Controller

Continue by pressing the -button

2.

REQUIRED VALUE 1

X.XX psi

Set the desired set pressure with either or

and then briefly press the -button.

If several pumps are connected via the RS-485 interface, one pump must be ready for

operation when the set pressure is changed, otherwise the set value will not be accepted by

the follow-up pumps. Afterwards the new required pressure has to be saved in all pumps.

If you want to change to Required Value 2 you have to close the external contact,

connected to X1/10-X1/14.

After closing this contact, the display changes from Required value 1 to

2.1 REQUIRED VALUE 2

ADC-X XX.X psi

In this window, there is shown the condition of

the second Required value.

ADC-X: This parameter shows you the source of the external or internal value

XX.X Bar: shows the actual value of the Required Value 2.

Continue by pressing the -button

b) Active MODE = Actuator:

1.

ITT INDUSTRIES

Frequency XX.X Hz

This window is mentioned several times in the

Operating Instructions as 1st display at the Mode

Actuator.

Continue by pressing the -button

2.

REQUIRED VALUE 1

X.XX psi

Set the desired set pressure with either or

and then briefly press the -button.

If several pumps are connected via the RS-485 interface, you have to set this parameter on

each pump!

43

Page 44

Operating Instruction

c) Active MODE = Synch. Controller or Multicontroller:

1.

ADR (X) P X

XX.X psi

This window is mentioned several times in the

Operating Instructions

as 1st display at the Synch. Controller or Multicontroller mode.

Continue by pressing the -button

2.

REQUIRED VALUE 1

X.XX psi

Set the desired set pressure with either or and

then briefly press the -button.

If several pumps are connected via the RS-485 interface, one pump must be ready for

operation when the set pressure is changed, otherwise the set value will not be accepted by

the follow-up pumps. Afterwards the new required pressure has to be saved in all pumps.

If you want to change to Required Value 2 you have to close the

external contact, connected to X1/10-X1/14.

After closing this contact, the display changes from Required value 1 to

2.1

REQUIRED VALUE 2

ADC-X XX.X psi

In this window, there is shown the condition of

the second Required value.

ADC-X: This parameter shows you the source of the external or internal value

XX.X Bar: shows the actual value of the Required Value 2.

Continue by pressing the -button

d) Active MODE = Actuator local:

1.

ITT INDUSTRIES

Frequency XX.X Hz

This window is mentioned several times in the

Operating Instructions as 1

st

display at the Mode

Actuator local.

Continue by pressing the

2.

ACTUATOR LOCAL

X.X Hz X.XX psi

-button

Set the desired set pressure with either or and

then briefly press the -button. If several pumps are

connected via the RS-485 interface, you have to set this parameter on each pump!

Press the button on the Technovar to change to

!! The following displays of the main menu are valid for all selected Modes !!

3.

AUTO - START

ON

Select (ON) with the button or (OFF) with .

AUTO-START ON starts the pump automatically again after a failure of the power supply.

If AUTO-START is OFF, the Technovar has to be restarted by pressing the buttons (OFF)

and then (ON) after a power supply failure.

44

Page 45

Operating Instruction

If the AUTO-START is OFF, the unit will not start again in cases of a failure or disconnection.

After restarting is following message is shown:

3.1

NO AUTOSTART

disable inverter

To restart the unit, press at first the and than to start the button.

Press and the display changes to

Note:

All errors are only readable

4. E R R O R 1

.........................

Press the button to change to

5. E R R O R 2

.........................

Press the button to change to

6. E R R O R 3

.........................

Press the button to change to

7. E R R O R 4

.........................

Here, the last error is shown

Shows the error before the last error

Shows the error before error 2

Shows the error before error 3

Press the button to change to

8. E R R O R 5

.........................

Press the button to change to

9. TOTAL RUN TIME

0000:00

operating hours.

Press the button to change to

Please Note : All changes have to be saved, that they will not be lost in

case of shut off of the power supply !!

10.

SAVE ???

+

Shows the error before error 4

Runtime of the motor.

This time is reset together with the

Simultaneously press buttons and

until...:

45

Page 46

Operating Instruction

y

11.

These parameters can also be set during operation; To do so, briefly press the

button and repeat steps 1 – 10.

Please Note: often shown display

12.

SAVE ???

SAVED

INVERTER LOCKED

enable inverter

This message appears when the connection of

terminal X1/4-X1/5 is open (external release contact).

10 Settings at Secondary Menu

Important: Before entering the secondary menu these instructions must

be read carefully to prevent incorrect settings which will cause

malfunction.

appears on the display. After five

seconds the display jumps back to the

1st display.

Secondary Menu:

Stop motor by pressing OFF

Press for 3 seconds to change to

Set ‘Password 0066’ by pressing

Note: The password must be entered at each entr

Confirm by pressing and the first

window of the sub menu is shown

In the following paragraphs all possible settings are listed (in the display, there is

shown the European default setting).

INVERTER STOP

ON -> START

PASSWORD

0000

PASSWORD

0066

J O G – MODE

0.0Hz X.XX psi

10.1 JOG-MODE

J O G – MODE

0.0Hz X.XX psi

Display and Manual Operation Mode

Actual outgoing frequency and actual analog input are

shown. By pressing

46

or in this menu, the

Page 47

Operating Instruction

internal controller of the Technovar will be shut off and the inverter changes to manual

mode. With the buttons and you can set any constant speed.

Setting of 0,0 Hz stops the inverter. If the JOG-MODE is left at a frequency higher than 0,0

Hz the inverter will continue its normal automatic operation.

Press on the Technovar to change to

10.2 Window - %

WINDOW

5%

Possible setting: between 0% - 100% of required pressure.

Press on the Technovar to change to

10.3 Ramp Hysteresis

RAMP HYSTERESIS

80%

Press on the Technovar to change to

10.4 Ramp 1: Fast running up time:

Time setting at Ramp 1, 2, 3, or 4 will influence the control of the pump and

MUST NOT BE CHANGED at normal operation. Possible setting of each ramp 0,05 - 1000

sec.

This value indicates the max. variation of the outgoing

pressure (see diagram “Ramp window”).

Level, where the fast ramp changes to the slow

ramp (see diagram “Ramp window” )

Possible setting: between 0%..100% of the window

RAMP 1

4.0 Sec

Excessively slow running up time may cause a break down of the outgoing pressure during

operation.

Press on the Technovar to change to

10.5 Ramp 2: Fast running down time:

RAMP 2

4.0 Sec

(OVERVOLTAGE) during ramp down of the pump.

Excessively slow running down time tends to generate over pressure.

Press on the Technovar to change to

Excessively fast running up time may overload the

inverter in the starting moment.

Excessively fast running down time tends to cause

oscillation or hunting or can cause an error

47

Page 48

Operating Instruction

10.6 Ramp 3: Slow running up time:

The following ramps 3 and 4 determine the speed of the internal Technovar controller

and depend on the system, which should be controlled.

RAMP 3

70 Sec

A too slow running up time can cause a break of the

outgoing pressure during variation of the demand.

A too fast running up time may lead to oscillation and/or overload of the inverter.

Press on the Technovar to change to

10.7 Ramp 4: Slow running down time:

RAMP 4

70 Sec

A too fast

A too slow

Ramp – Window

setting leads to oscillation

setting delays the switching off too much

Press on the Technovar to change to

10.8 Maximum Frequency

MAX. FREQUENCY

60.0 Hz

Possible setting between 40 and 70 Hz.

Attention: Settings higher than 60 Hz may overload the

motor!

Settings of 10% above nominal frequency cause 33% more power consumption!

Press on the Technovar to change to

48

Page 49

Operating Instruction

10.9 Minimum Frequency

MIN. FREQUENCY

0.0 Hz

Here you can set the minimum frequency between 0,0

and Max.frequency.

Attention!: If there is set f>fmin in the parameter CONFIG. FMIN the pump will not stop in

the normal mode. It will keep running with the set minimum frequency.

!! Possibility of overheating of the pump !!

Press on the Technovar to change to

10.10 Operation at the minimum frequency

CONFIG FMIN

f => fmin

If you have selected „f->0“ the frequency will go

down to the selected minimum frequency.

Then the inverter will keep running for the selected time and after this time the Technovar

will stop automatically.

If the selection is „f->f

“ you can not run the pump below the set minimum frequency. In

min

the controller, actuator and multi controller mode the pump will never run below the set

minimum frequency (the pump will only stop with an external on/off-(terminals X1/4 and

X1/5) or in case of a failure.

Press on the Technovar to change to

10.11 Delay time for shut off at minimum frequency

STOP-DELAY FMIN

5 s

After running the pump for this selected time at

minimum frequency, the pump will stop, if parameter

CONFIG. FMIN it set to f Þ 0 Adjustable between 0 and 100s.

Press

on the Technovar to change to

10.12 Boost

BOOST

5.0 %

The stated value determines the course of the

U/f-curve.

Setting of the motor starting voltage in % of rated voltage.

Settings of 0...25% of maximum output voltage are possible. However, care should be taken

that settings are kept as low as possible so that the motor does not become thermally

overloaded at lower frequencies.

Press on the Technovar to change to

49

Page 50

Operating Instruction

10.13 Sensor – Adjust

SENSOR_ADJUST?

Out of range

simultaneously. After adjustment "adjusted" appears on the display. If “out of range” is shown

on the display, no adjustment is possible

Press on the Technovar to change to

10.14 Sensor - Curve

SENSOR-CURVE

Linear

Application:

linear:Pressure control, differential pressure control, level, temperature and flow control

(inductive or mechanical).

quadratic: Flow control with an orifice plate together with a differential pressure transmitter.

Press on the Technovar to change to

Zero point adjustment of the transmitter

Depressurise the system and press buttons +

Function of the input signal (4...20mA) of the

Technovar to the actual measured value.

10.15 Setting of the measuring range

SENSOR RANGE

20mA = 362,6 psi

Adjustable range: 20 mA = 100%; corresponds to the possible adjustable ranges:

PSI: 2.9 to 1450; GAL/MIN: 9 to 10560

FT: max 3345 ft. 0 to100 %; without unit: max 1000;

Press

If only one TECHNOVAR pump is in operation set the Controller. If more than one pump work

together via the RS485 interface (follow-up pump control), the Multicontroller must be set

with the buttons or .

on the Technovar to change to

10.16 Operation Mode

MODE:

Controller

Setting the end value of the measuring transmitter,

e.g. 362 psi = 20mA of the pressure transmitter

Select with the

and buttons

Synch. Controller:

The Synchronous Controller mode is working in the same way like the Multicontroller. The

only difference is, that all pumps in the multipump system are running at the same frequency.

Actuator:

50

Page 51

Operating Instruction

The Actuator application is only used if you have an external controller and the Technovar is

used as a standard frequency converter. In the Actuator-Mode, the internal controller is shut

off, and the output frequency is proportional to the input signal (X1/2) Þ 4-20 mA = 0 - f

max

The frequency changes with the programmed ramps 1 and 2. The functions of low water,

thermal protection and external ON/OFF are still working.

.

If MANUAL CONTROL is selected, the parameter REQUIRED VALUE will change to MANUAL

CONTROL in the main menu, where the actual frequency and the actual value is displayed

(according to the JOG-MODE in the submenu).

Now the frequency can be changed with the and . buttons, and the speed of the pump

will change with the fasten ramps. After selecting the right frequency, it can be saved with

the standard SAVE.

After a supply failure, the pump will then run with this selected frequency (depending on the

parameter AUTO-START).

The frequency can be changed between the set minimum and maximum frequency.

In the 1st display, there is shown the actual frequency.

NOTE:

Attention

CONFIG. FMIN will not work in this mode.

Driving the pump in a not allowed speed range can damage the motor or the

Technovar-head!

Press on the Technovar to change to

10.17 Control Response

REGULATION MODE

Normal

Normal: Speed is increased with falling actual value

signals. (e.g.: Control at constant output pressure).

Inverse: Speed is reduced with falling actual value signal, (e.g.: Control at constant

suction pressure or at constant level).

Press on the Technovar to change to

51

Page 52

Operating Instruction

10.18 Start Value

START VALUE

disabled

between disabled and sensor range).

e.g.

required value: 72 PSI

start value: 36 PSI

If the pump system reaches the required pressure of 72 PSI and there is no

more consumption, the Technovar shuts off the pump. When the consumption increases

and the pressure goes down to or below the start value, 36 PSI, the pump will start.

Press on the Technovar to change to

10.19 2nd Required Value

CONFIG. REQ. VAL.2

OFF

Between 1st and the 2nd required value can be done over the digital input, terminal X1/14

on the control card. If this input is connected to Ground, 2nd required value active.

This parameter gives you the start value after pump

stop in percentage of the required value (adjustable

With this parameter CONFIG. REQ. VAL.2 you can

select an independent 2nd required value. The change

Possible selections:

OFF : actual value 2 is not active (no change after closing the input X1/14)

INT : internal required value 2, function and setting according to

existing required value.

EXT ADC-I : the required value 2 is made from the value of the current signal

(4-20mA) at the terminals X1/12, X1/10. 20mA is equal to the programmed

SENSOR RANGE. If the incoming current signal is below 4mA, there

will be shown an error message on the display, but no failure is indicated

(failure relay is not closed). In this case the required value 2 will be 0.

EXT ADC-U 0-10V or the required value 2 is made from the value of the voltage signal

EXT ADC-U 2-10V (0-10V or 2-10V) at the terminals X1/13, X1/10 (Ground).

10 V is equal to the programmed SENSOR RANGE.

Setting the required value2:

The active required value is shown in the actual display of the parameter required value.

Is the 2nd required value active (digital input, terminal X1/14, closed), in the first line, there is

shown Required value 2. The second line will show the source of the 2nD value, which is

selected in the parameter CONFIG. REQ VAL:2

(INT or EXT-ADC-I or EXT-ADC-U) and also the actual value of this input.

INT : you can select your value with the up- and down buttons

EXT: only display of the value of the 2nd analog input signal.

In case of saving, every time both required values are saved.

Press on the Technovar to change to

52

Page 53

Operating Instruction

10.20 Configuration of 1st relay

RELAY CONFIG.

Run Motor

Possible selections with buttons and .

Simple Multicontr. Þ allows to start / stop a

constant speed pump

Run Motor Þ motor run indication (over the relay)

If you have selected Simple Multicontr. two parameters get new functions. The start level of the

slave pump you enter at the parameter Enable Seg. Ctl. and the stop value in the parameter

Synchron. Limit.

e.g. if the speed controlled pump reaches the start level, the relay will be switched on, and will be

switched off, when the output frequency falls below the stop level.

Press on the Technovar to change to

10.21 Submenu Offset

S U B M E N U

Offset

Press for about 3 seconds to enter the

submenu and the display changes to

10.21.1 Source of the Offset input

OFFSET INPUT

Off

The second additional input can be used as required

value 2 and also for an Offset of

the 1st required value.

There are three possibilities for the source of the OFFSET INPUT:

OFF : Offset deactivated

EXT ADC-I : Offset will be calculated according to the current input (4-20mA) at the

terminals X1/12 (X1/10=Ground).

Note:

If the incoming current signal is below 4mA, there will be an error message on

the display, but no failure is shown (failure relay is not closed). In this case the

OFFSET INPUT works like external signal=0.

EXT ADC-U 0-10V: Offset will be calculated according to the voltage input (0-10V or 2EXT ADC-U 2-10V 10V) at terminals X1/13 (X1/10=Ground)

Press on the Technovar to change to

10.21.2 1st Offset level

53

Page 54

Operating Instruction

LEVEL 1

XX.X %

The level 1 is the start level of the 1st Offset.

(adjustable between 0 and 100% of the additional

analog input).

Press on the Technovar to change to

10.21.3 2nd Offset level

LEVEL 2

XX.X %

The level 2 is the start level of the 2nd Offset.

(adjustable between 0 and 100% of the additional

analog input).

Press on the Technovar to change to

10.21.4 INTENSITY 1

INTENSITY 1

+XX.X %

This is the intensity of the 1st Offset of the required

value at the zero point of the second analog input

Setting range: -200% up to +200% of the sensor range.

Press on the Technovar to change to

10.21.5 INTENSITY 2

INTENSITY 2

+XX.X %

This is the intensity of the 2

value at the maximum point of the second analog

nd

Offset of the required

Input. Setting range: -200% up to +200% of the sensor range.

To leave the submenu press the longer than 3 sec. to change to

S U B M E N U

Offset

Press on the Technovar to change to

10.22 Submenu Sequence control

S U B M E N U

Seq. Control

Programming Sequential Operations

Up to four pumps can be connected using the integrated RS-485 interface (Connection of the

terminals /1, /2 and /3 of the terminal blocks X5 or X6 of each pump together). However, the

following additional programming must be carried out in the submenu:

54

Page 55

Operating Instruction

Press for about 3 seconds to enter the submenu and the display changes to

10.22.1 Lift Value

Application Example:

1) Pump 1 reaches fmax (maximum speed)

2) Pressure falls and reaches the start-value of the 2nd pump

(= REQUIRED VALUE – ACTU. VALUE DEC.)

3) Pump 2 is switched on automatically

4) The required value is calculated new, after the start of the 2nd pump in the following

way!

New required value = REQUIRED VALUE – ACTU. VALUE DEC. + ACU. VALUE INC.

Generally:

k ... Number of active pumps (k >1)

p = p

· Lift value = Fall value Þ Pressure constant when pumps switch on

· Lift value > Fall value Þ Pressure rises when lag-pump switches on

· Lift value < Fall value Þ Pressure falls when lag-pump switches on

ACTU. VALUE INC.

5 psi

+ (k-1)*[lift value – fall value]

set

Adjustable between 0.0 to the pre-selected

Sensor range

Press on the Technovar to change to

10.22.2 Fall Value

For calculation of the set pressure after start of pumps 2 to 4

ACTU. VALUE DEC.

2.1 psi

Adjustable from 0,0 to pre-selected Sensor range

determines the start-value of the 2nd pump and the

55

Page 56

Operating Instruction

other following pumps. (Start-Value = REQUIRED VALUE –ACT. VALUE DEC.)

Press on the Technovar to change to

10.22.3 Release frequency of the following controller

ENABLE SEQ. CTL.

58.0 Hz

has reached the programmed frequency. (Adjustable from 0.0 Hz to 70 Hz).