Page 1

INSTRUCTION MANUAL

176R0649

REVISION C

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Technologic® 502 Series

Pump Controller

Page 2

WARNING

!

Eq u i p m E n t Ha z a r d !

WARNING

!

WARNING

!

dr i v E s a n d pa n E l s c o n t a i n d a n g E r o u s v o l t a g E s w H E n

c o n n E c t E d t o l i n E v o l t a g E . it i s s t r o n g l y r E c o m m E n d E d

t H a t a l l E l E c t r i c a l w o r k c o n f o r m t o t H E na t i o n a l

El E c t r i c a l co d E (nEc) a n d a l l n a t i o n a l a n d l o c a l

r E g u l a t i o n s . in s t a l l a t i o n , s t a r t -u p a n d m a i n t E n a n c E

s H o u l d b E p E r f o r m E d o n l y b y q u a l i f i E d p E r s o n n E l . fa i l u r E

t o f o l l o w t H E nEc o r l o c a l r E g u l a t i o n s c o u l d r E s u l t i n

d E a t H o r s E r i o u s i n j u r y .

Motor control equipment and electronic controls

are connected to hazardous line voltages. Extreme

care should be taken to protect against shock. The

user must be protected against supply voltage

and the motor must be protected against overload

in accordance with applicable national and local

regulations. Be sure equipment is properly grounded.

Wear safety glasses whenever working on electric

control or rotating equipment.

un i n t E n d E d st a r t !

wH E n d r i v E o r o p t i o n p a n E l i s c o n n E c t E d t o ac i n p u t

p o w E r , m o t o r m a y s t a r t a t a n y t i m E . tH E d r i v E , o p t i o n

p a n E l , m o t o r , a n d a n y d r i v E n E q u i p m E n t m u s t b E i n

o p E r a t i o n a l r E a d i n E s s . fa i l u r E t o b E in o p E r a t i o n a l

r E a d i n E s s w H E n p a n E l a n d d r i v E a r E c o n n E c t E d t o ac

i n p u t p o w E r c o u l d r E s u l t i n d E a t H , s E r i o u s i n j u r y , o r

E q u i p m E n t o r p r o p E r t y d a m a g E .

Warning Against Unintended Start

When the drive or option panel is connected to the AC

line, the motor may be started by means of an external

switch, a serial bus command, an input reference

signal, or a cleared fault condition. Use appropriate

cautions to guard against an unintended start.

gr o u n d i n g Ha z a r d !

fo r o p E r a t o r s a f E t y , i t i s i m p o r t a n t t o g r o u n d d r i v E ,

o p t i o n p a n E l , a n d m o t o r p r o p E r l y . fo l l o w t H E g r o u n d i n g

g u i d E l i n E s o f l o c a l a n d n a t i o n a l c o d E s . fa i l u r E t o

f o l l o w g r o u n d i n g g u i d E l i n E s c o u l d r E s u l t i n d E a t H o r

s E r i o u s i n j u r y .

Grounding

Proper protective grounding of the equipment must

be established in accordance with national and local

codes. Ground currents are higher than 3 mA. Use

high stranded wire whenever possible.

Safety Guidelines

1. The drive and option panel must be

disconnected from the AC line before any

service work is done.

2. DO NOT touch electrical parts of the

option panel or drive when the AC line is

connected. After the AC line is disconnected,

wait 30 minutes before touching any

electrical components.

3. The user must be protected against supply

voltage and the motor must be protected

against overload in accordance with

applicable national and local regulations.

4. While programming parameters, the motor

may start without warning. Activate the

STOP/OFF key on the control keypad when

changing parameters.

5. The STOP/OFF key on the local control

panel keypad of the drive does not isolate

the drive from the AC line voltage and is not

to be used as a safety switch.

2

Page 3

Table of Contents

Safety Guidelines ............................................................................................................................................................................... 2

Warning Against Unintended Start ...................................................................................................................................................2

Section 1 Introduction ....................................................................................................................................................................... 5

Purpose of the Manual ....................................................................................................................................................................... 5

Overview.............................................................................................................................................................................................. 5

Typical Bypass Operation .................................................................................................................................................................. 7

Overload Protection. ........................................................................................................................................................................... 7

Disconnects ........................................................................................................................................................................................ 8

Power Fusing ...................................................................................................................................................................................... 8

Drive Option Panel Congurations ................................................................................................................................................... 9

Option Panel Voltage and Frame Ratings ........................................................................................................................................9

Section 2 Pre-installation................................................................................................................................................................ 10

Pre-installation Check ...................................................................................................................................................................... 10

Installation Site Check ..................................................................................................................................................................... 10

Harsh Environments ........................................................................................................................................................................ 11

Section 3 Installation....................................................................................................................................................................... 12

Common Backpanel Mounted Units ............................................................................................................................................... 12

Branch Circuit Protection ................................................................................................................................................................ 12

Drive Fuses ....................................................................................................................................................................................... 12

Internal Option Panel Fuses ............................................................................................................................................................ 12

Tools and Equipment Required ....................................................................................................................................................... 12

Mechanical Installation .................................................................................................................................................................... 13

Lifting ................................................................................................................................................................................................. 13

Cooling .............................................................................................................................................................................................. 13

Electrical Installation........................................................................................................................................................................ 14

Wire Type Rating .............................................................................................................................................................................. 15

Terminal Tightening Torques ........................................................................................................................................................... 15

Line Input (Mains) Connection ........................................................................................................................................................ 15

Motor Wiring ..................................................................................................................................................................................... 16

Grounding (Earthing) ....................................................................................................................................................................... 17

Control Wiring ................................................................................................................................................................................... 18

Drive Control Terminals ................................................................................................................................................................... 18

MCB-101 Master Control Board ...................................................................................................................................................... 19

Pressure and Feedback Wiring ....................................................................................................................................................... 20

Control Terminal Programming ...................................................................................................................................................... 20

Serial Communication Bus Connection ......................................................................................................................................... 20

Serial Communications Programming ........................................................................................................................................... 20

Installation of Backpanel Mounted Drives and Pumps ................................................................................................................. 24

Installation of 70X Series Drives and Pumps................................................................................................................................. 25

Section 4 Start Up............................................................................................................................................................................ 28

Pre-start Procedure .......................................................................................................................................................................... 28

Inspection Prior to Start Up ............................................................................................................................................................. 29

Start Up Procedure ........................................................................................................................................................................... 30

Drive Power Up ................................................................................................................................................................................. 30

Required Drive Programming.......................................................................................................................................................... 31

System Start Up ................................................................................................................................................................................ 32

Full Speed Operation and Checkout ............................................................................................................................................... 33

Section 5 User Interface.................................................................................................................................................................. 34

Operation and Programming Through the LCP ............................................................................................................................. 34

Navigation keys ................................................................................................................................................................................ 35

Section 6 Programming and Operation ......................................................................................................................................... 36

Basic Drive Programming ............................................................................................................................................................... 36

Entering Basic Motor Data ............................................................................................................................................................... 36

Designating Master or Follower Drives .......................................................................................................................................... 36

3

Page 4

Section 7 Status Messages ............................................................................................................................................................ 48

Status Messages .............................................................................................................................................................................. 48

Section 8 Warnings and Alarms ..................................................................................................................................................... 52

System Monitoring ........................................................................................................................................................................... 52

Warning and Alarm Displays

Description and Remedy ................................................................................................................................................................. 52

Section 9 Start Up Troubleshooting

Appendix .......................................................................................................................................................................................... 62

Serial Communication Point Maps ................................................................................................................................................. 62

Protocols

Serial Communications Programming ........................................................................................................................................... 62

Metasys N2 Point Map...................................................................................................................................................................... 63

Metasys N2 Point Map (continued) ................................................................................................................................................. 64

Modbus RTU Point Map (by parameter)

Modbus RTU Point Map (by function) ............................................................................................................................................ 66

Modbus RTU Point Map (by function) ............................................................................................................................................ 67

Floor Level Network (FLN) Set-up ................................................................................................................................................... 68

Quick Start Check List

........................................................................................................................................................................................... 62

........................................................................................................................................................... 52

.............................................................................................................................................. 59

......................................................................................................................................... 65

..................................................................................................................................................................... 73

List of Figures

1-1. Technologic 502 Pump Controller .............................................................................................................................................5

1-2. Master Drive with Three Followers

1-3. Basic 3-contactor Bypass Functions

1-4. Disconnects ................................................................................................................................................................................. 8

1-5. Tier Denitions and Features

3-1. Drive Input Fuses ...................................................................................................................................................................... 12

3-2. Cooling Air Flow

3-3. Typical Unit Components

3-4. Power Connections

3-5. Input Power Panel with Line Disconnect ................................................................................................................................ 15

3-6. Wire Access Panels (bottom view)

3-7. Sample Motor Wiring

3-8. Control Terminal Access ..........................................................................................................................................................18

3-9. Drive Control Terminals

3-10. Master Board Control Terminals

3-11. Master Board Control Terminal Location .............................................................................................................................. 19

3-12. Customer Wiring Schematic Diagram, VFD with 1 Follower

3-13. Customer Wiring Schematic Diagram, VFD with 2 or 3 Followers ..................................................................................... 22

3-14. Backpanel Mounted Drives and Pumps (front and side views)

3-15. 70X Series Drive ...................................................................................................................................................................... 26

3-16. 70X Series Customer Connection Diagram .......................................................................................................................... 27

5-1. Local Control Panel................................................................................................................................................................... 34

5-2. LCP Display Area....................................................................................................................................................................... 34

7-1. Display Status Line ................................................................................................................................................................... 48

........................................................................................................................................................................ 13

......................................................................................................................................................... 13

................................................................................................................................................................... 14

................................................................................................................................................................ 16

............................................................................................................................................................ 18

............................................................................................................................................ 6

........................................................................................................................................ 7

..................................................................................................................................................... 9

.......................................................................................................................................... 16

............................................................................................................................................ 19

............................................................................................... 21

.......................................................................................... 24

List of Tables

1-3. Panel Voltage and Frame Ratings

3-1. Tools and Equipment Required

3-2. Connection Tightening Torques

3-3. Drive Control Terminal Functions ............................................................................................................................................ 19

4-1. Inspection Prior to Start Up

6-1. Quick Menu Layout

6-2. Parameter 39-** Group, Detailed Description ......................................................................................................................... 39

7-1. Status Message Denitions...................................................................................................................................................... 48

8-1. Warnings and Alarms ................................................................................................................................................................ 53

9-1. Fault Table .................................................................................................................................................................................. 59

................................................................................................................................................................... 37

4

.............................................................................................................................................. 9

............................................................................................................................................... 12

..............................................................................................................................................12

...................................................................................................................................................... 29

Page 5

Section 1 Introduction

Purpose of the Manual

This manual is intended to provide detailed information

for the installation and operation of the option

panel used in conjunction with the Technologic

502 Pump Controller. To enable efcient handling

of the equipment, requirements are provided for

mechanical installation, power and control wiring,

proper grounding, and environmental considerations.

Pre-start and start up procedures are detailed.

Also included is a detailed overview of the option

panel bypass function. In addition, programming,

identication and operation of optional components,

and basic troubleshooting instructions are included

as well.

Overview

The Technologic 502 Pump Controller is a variable

frequency drive with embedded pump control software.

It is available in several different congurations.

Type B-3 Controller (2 Pumps/1 Drive)

The type B-3 controller consists of a Technologic 502

master with embedded pump controller software,

contact motor selection, and an electronically controlled bypass. Contact motor selection allows the

controller to alternate between two motors of equal

size, a duty pump and a standby. The duty pump is

controlled to maintain a set point. Selection between

motors is made automatically by the Technologic 502

or by manual selection through a selector switch. The

bypass enables either motor to be driven by 100%

line power while bypassing the controller circuitry.

The Technologic 502 and electronically controlled

bypass are factory wired and mounted to a common

backplate.

Type C-4 Controller (2 Pumps/2 Drives)

The type C-4 bypass consists of a Technologic 502

master and (1) follower drive each with embedded

pump controller software and an electronically controlled automatic bypass. The C-4 controller allows

for duty/standby operation where only one pump is

run at any time. Selection between drive mode or

automatic bypass is determined by the master. The

bypass can also be activated manually through each

drive’s keypad.

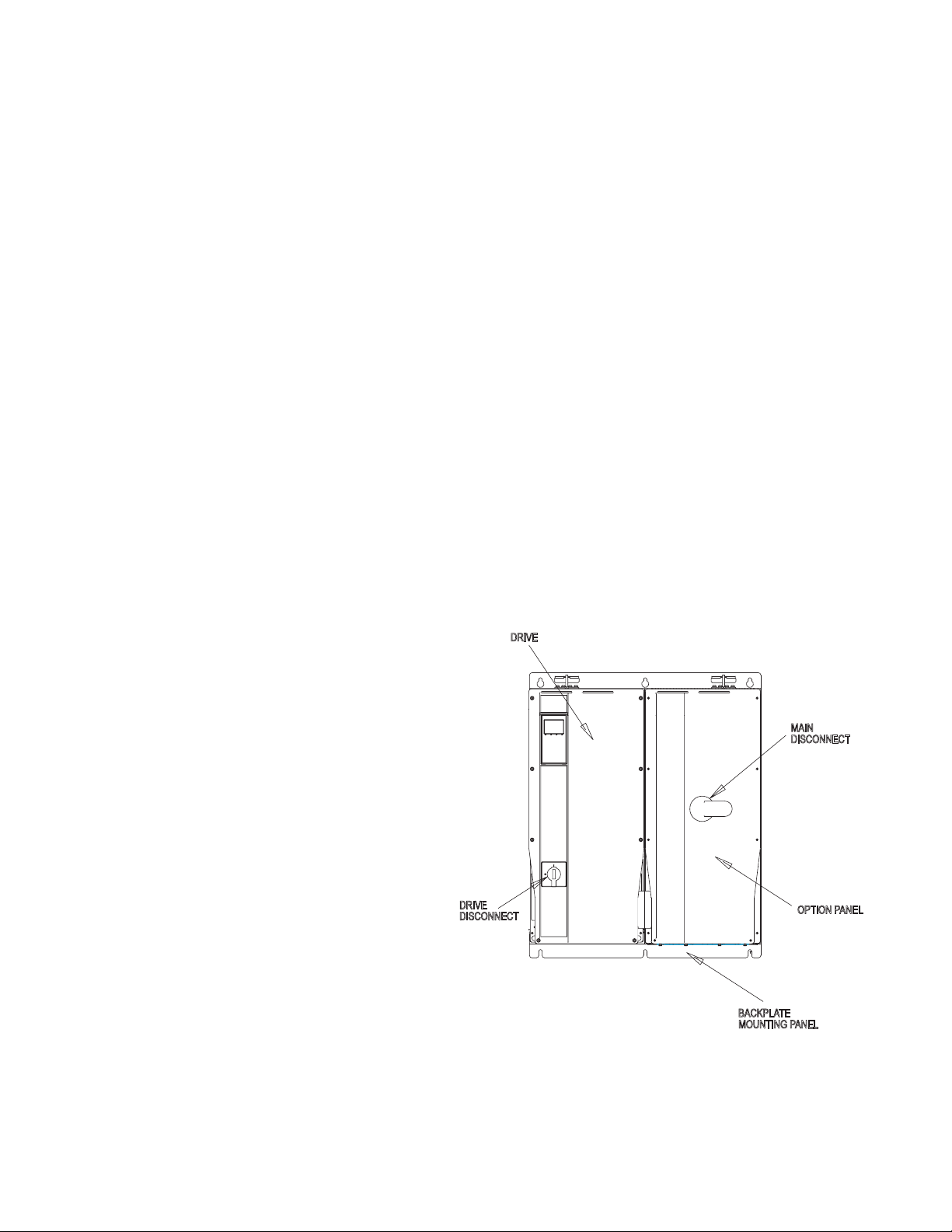

Figure 1-1. Technologic 502 Pump Controller

Drives on a common backpanel are factory-wired

between the master and follower drives and contain

a main disconnect. Congurations may include a

fused disconnect or bypass.

Type A-1 Controller (1 Pump/1 Drive)

The type A-1 consists of a stand-alone Technologic

502 master with embedded pump controller software

and an electronically controlled automatic bypass.

The bypass can also be activated manually through

the drive keypad.

Type D-4 Controller (2 Pumps/2 Drives)

The type D-4 bypass consists of a Technologic 502

master and (1) follower drive each with embedded

pump controller software and an electronically controlled automatic bypass. The D-4 controller allows

parallel operation between the master and follower

drive in response to a set point. Drive mode or automatic bypass is determined by the master. The

bypass can also be activated manually through each

drive’s keypad.

5

Page 6

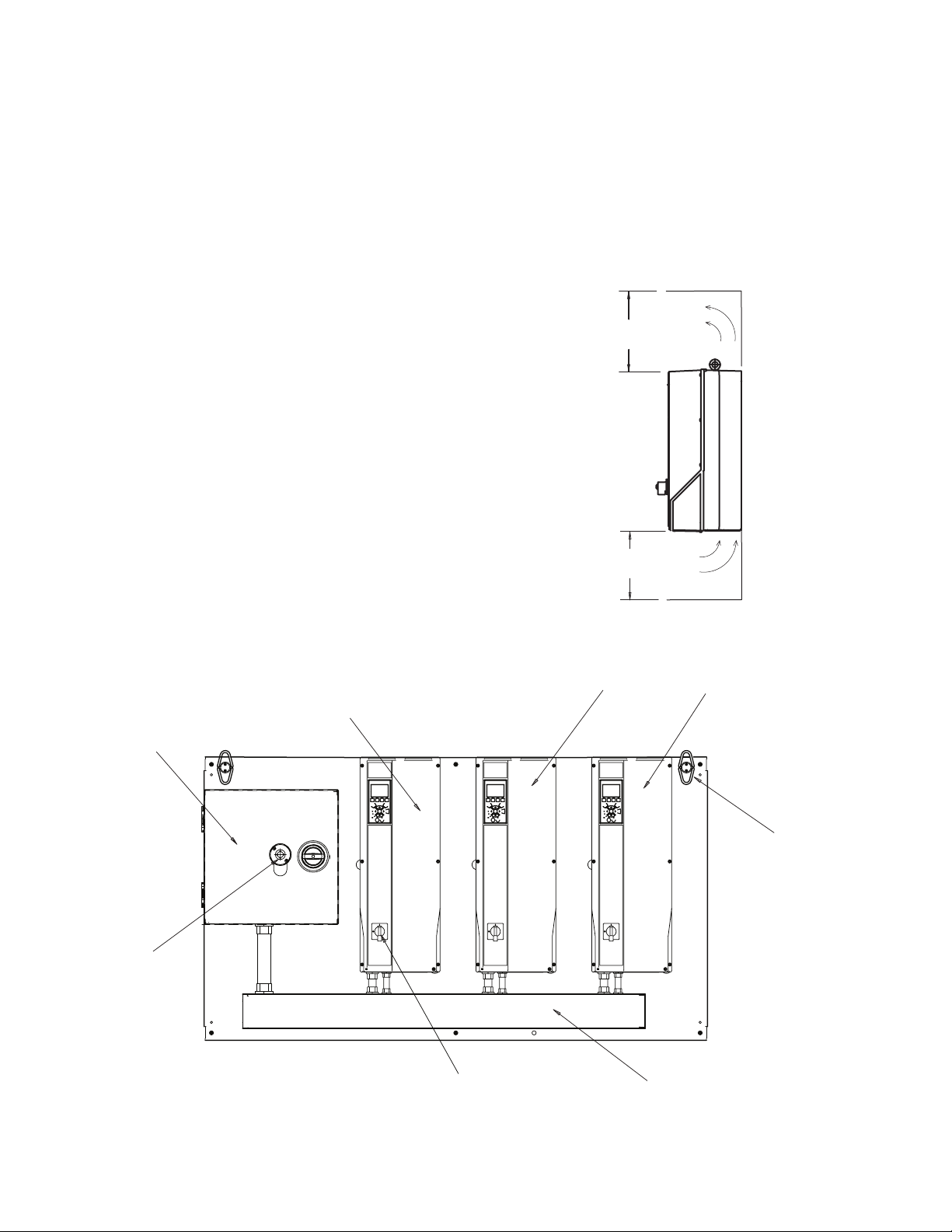

Type S-1 Controller (with or without manual by-

Input power panel

Master drive

Follower 1

Follower 2

Input power raceway to VFDs

pass)

The type S-1 controller comes in two different con-

gurations. One consists of a Technologic 502 master

with embedded pump controller software with up to

three follower drives. The other S-1 conguration is

the same with the addition of a manual bypass for the

master and a manual bypass for each follower drive.

The controller allows parallel operation between the

master and follower drives in response to a set point.

All drives will run at the same synchronized speed.

A-0 (1 Technologic 502 Master 0nly)

A-M (1 Technologic 502 Master only with manual

bypass)

C-0 (1 Technologic 502 Master with (1) follower – No

Staging)

C-M (1 Technologic 502 Master with (1) follower each

with manual bypass – No Staging)

D-0 (1 Technologic 502 Master with (up to 3) followers – Staging Allowed)

D-M (1 Technologic 502 Master with (up to 3) followers

each with manual bypass – Staging Allowed)

6

Figure 1-2. Master Drive with Two Followers

Page 7

Typical Bypass Operation

Overload Protection.

With contactors M1 and M2 closed and contactor M3

open (see Figure 1-3), the pump is controlled by the

drive. Opening contactor M2 removes power to the

pump but allows the controller to remain powered.

This is the test mode and only available in the three-

contactor conguration shown. With contactors M1

and M2 open and contactor M3 closed, the pump

runs in bypass from the line input. For a two-contactor

conguration, M1 is absent. In this case, contactors

M2 and M3 control the options for running in drive or

bypass mode. The gure illustrates a drive disconnect

and fuses.

This thermally activated device provides mechanical

overload protection for the pump(s) while in bypass

operation. It measures motor current and is factory set

to the full load amps (FLA) of the pump. A 1.2 x FLA

service factor is built-in and maintained. Should the

motor current increase above that value, the overload

will calculate the level of increase to activate timing

for the trip function. The higher the current draw, the

quicker the trip response. The overload provides

Class 20 motor protection.

Figure 1-3. Basic 3-contactor Bypass Functions

7

Page 8

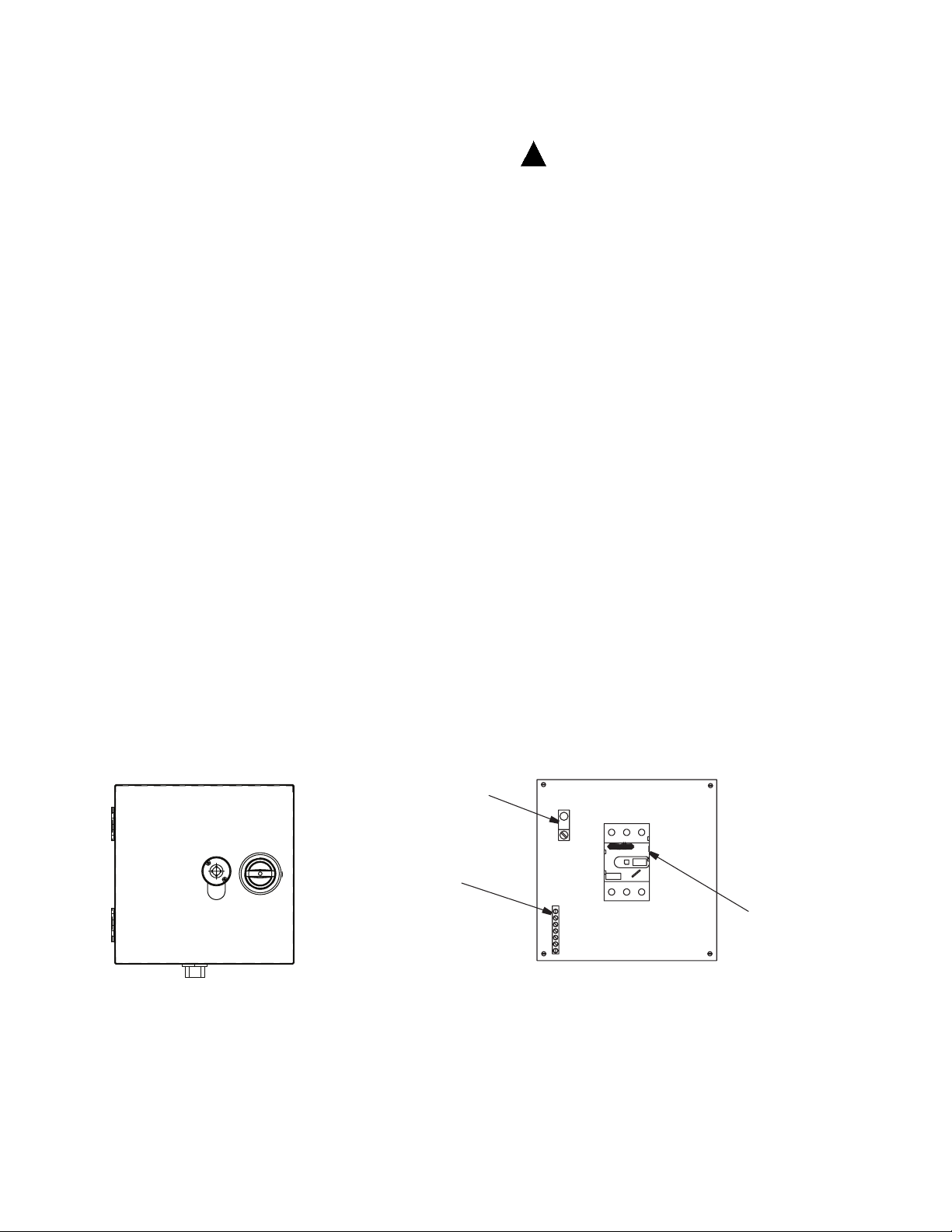

Disconnects

DRIVE

DISCONNECT

DRIVE

OPTION PANEL

BACKPLATE

MAIN

MOUNTING PANEL

DISCONNECT

Power Fusing

Main disconnect. The main disconnect removes

line input power to the controller and bypass. A main

disconnect is available in two options. For safety, the

switch must be in the OFF position before the panel

door can be opened. (See Figure 1-4.)

•

Main disconnect with built-in

fuses. Two-position (ON/OFF) ro-

tary switch, with three built-in fuses,

one on each phase.

Main disconnect with separate

•

fuses. Two-position (ON/OFF)

rotary switch with a fuse block

mounted separately from the

disconnect. Three fuses, one on

each phase, are located on the fuse

block.

Drive disconnect. Two-position (ON/OFF) rotary

switch disconnects main AC line input power to the

drive only.

Motor Alternation Selector Switch

The B3 option includes contactor motor selection. It

provides motor alternation with one drive alternating

operation between two motors. The panel mounted

Motor 1/Auto/Motor 2 selector switch provides local

control of either motor along with an auto setting that

allows auto selection through the master drive.

Two types of fusing are available for the units—main

and drive fusing. For all power fuses, use the speci-

ed fuse or an equivalent replacement only. See the

fuse ratings label on the inside cover of the unit for

ratings.

Main fusing. Main fuses are located ahead of the

drive. Main fuses are designed to protect the circuitry

within the panel but are not adequate to protect the

drive. Main fuses are dual-element, time-delay type

and mount inside the bypass enclosure.

Drive fusing. Drive fuses are located ahead of the

drive and are a fast-acting type. Drive fuses are standard in two-contactor and three-contactor bypasses.

A fuse/disconnect enclosure may be used if no options other than a fuse block and disconnect switch

are required.

8

Figure 1-4. Disconnects

Page 9

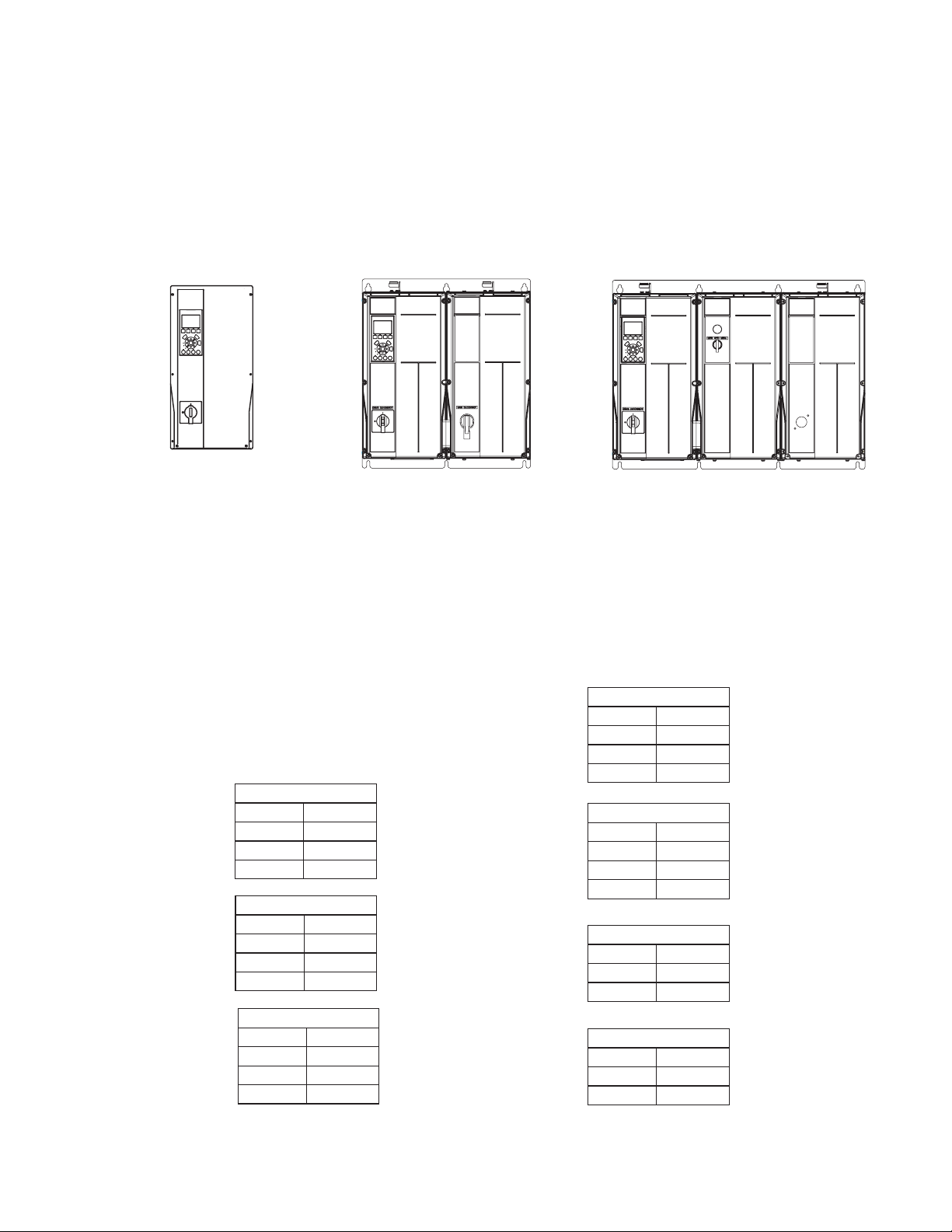

Drive Option Panel Congurations

contains the bypass as in Tier 2. Two option panels

are provided in Tier 3 with one containing the bypass

The Technologic 502 Drive Series has three tiers

of option panel enclosure types. The option panel

and the other the contactor motor selector. (See

Figure 1-5)

Tier 1 Tier 2 Tier 3

Drive with fuses

Drive with bypass Drive with bypass and contactor

and disconnect

Figure 1-5. Tier Denitions and Features

Option Panel Voltage and Frame Ratings

Table 1-1 denes the voltage and hp ratings of the

frames sizes for the drive and option panel. See the

mechanical drawing shipped with the unit for dimensions.

Frame A2 - A5

Volts VAC hp

208-230 2-5

460-480 3-10

575-600 3-10

Frame B1

Volts VAC hp

208-230 7.5-15

460-480 15-25

575-600 15-25

Frame B2

Volts VAC hp

208-230 15-20

460-480 30-40

575-600 30-40

motor selector (B3)

Frame C1

Volts VAC hp

208-230 25-30

460-480 50-75

575-600 50-75

Frame C2

Volts VAC hp

208-230 40-60

460-480 100-125

575-600 100-125

Frame D1

Volts VAC hp

460-480 150-200

575-600 150-200

Frame D2

Volts VAC hp

460-480 250-350

575-600 250-400

Table 1-1. Panel Voltage and Frame Ratings

9

Page 10

Section 2 Pre-installation

Pre-installation Check Installation Site Check

1. Compare model number to what was

ordered.

2. Ensure each of the following are rated for

same voltage:

• Power line

• Drive

• Option panel

• Motor

3. Ensure that option panel output rating is

equal to or greater than motor total full

load current for full motor performance.

• Motor power size and option panel must

match for proper overload protection.

• If panel rating is less than motor, full motor

output cannot be achieved.

4. Check motor wiring:

• Any disconnect between drive and motor

should be interlocked to drive safety

interlock circuit to avoid unwanted drive

trips.

• Because the option panel relies on the

ambient air for cooling, it is important to

observe the limitations on ambient air

temperature. Derating starts above 40°C

(104°F) and 3300 feet (1000m) elevation

above sea level.

• It is important with backpanel mounted units

to check support strength. Make sure that

the proper mounting screws or bolts are

used.

• Keep the option panel interior free from dust

and similar dirt. In construction areas, if the

unit is not powered, provide a protective

covering. It is important to ensure that the

components stay as clean as possible. It

may be necessary to clean the interior once

construction is completed.

• Keep wiring diagrams, drawings and

manuals accessible for detailed installation

and operation instructions. It is important

that the manuals be available for equipment

operators.

• Do not connect power factor correction

capacitors between drive and motor.

• Two speed motors must be wired

permanently for full speed.

• Y-start, -run motors must be wired

permanently for run.

10

Page 11

Harsh Environments

The mechanical and electrical components within

the option panel can be adversely affected due to

the environment. The effects of contaminants in the

air, either solid, liquid, or gas, are difcult to quantify

and control. Depending upon the severity of the

environment, optional NEMA 12, NEMA 3R or NEMA

4 enclosures may be used.

Airborne Liquids

Liquids in the air can condense in components. Water

vapor carried in the air is easily measured as relative

humidity, but other vapors are often more difcult

to measure or control. Steam, oil, and salt water

vapor (near sea locations) may cause corrosion of

components. In such environments, use NEMA 12

enclosures to limit the exchange of outside air into

the option enclosure. Extremely harsh environments

may require a higher level of protection.

Airborne Solids

Particles in the air may cause mechanical, electrical

or thermal failure in components. A NEMA 1 enclosure

provides a reasonable degree of protection against

falling particles, but it will not prevent the fan from

pulling dirty air into the enclosure. A typical indicator

of excessive levels of airborne particles is dust

around the fan. In dusty environments, use NEMA

12 enclosures.

Corrosive Chemicals

In environments with high temperatures and humidity,

corrosive gases such as sulfur, nitrogen and chlorine

compounds cause corrosion to occur in components.

Indications of corrosion are blackened copper or rust

on steel or oxidized aluminum. In such environments,

it is recommended that the equipment be mounted in

a cabinet with fresh air ventilation and that corrosive

compounds be kept away. A non-ventilated cabinet

tted with an air conditioner as a heat exchanger may

be used. Conformal coated circuit boards may be

specied to reduce the corrosive effects of a harsh

environment.

11

Page 12

Section 3 Installation

WARNING

!

TOOLS

Spreader bar capable of lifting up to 1000 lbs.

Max diameter 0.875 in.

Forklift, crane, hoist or other lifting device

capable of handling up to 1000 lbs. (Qualified

device operator available for operating the

equipment.)

Metric socket set: 7 - 19mm

Socket extensions: 4 & 6 in

Torx driver set: T10 - T40

Torque wrench: 6 - 170 in-lbs

Common Backpanel Mounted Units

Branch Circuit Protection

br a n c H ci r c u i t pr o t E c t i o n rE q u i r E d !

pr o v i d E b r a n c H c i r c u i t pr o t E c t i o n i n a c c o r d a n c E w i t H

t H E na t i o n a l E l E c t r i c a l co d E . fa i l u r E t o p r o v i d E b r a n c H

c i r c u i t pr o t E c t i o n in a c c o r d a n c E w i t H t H E nEc m a y

r E s u l t i n E q u i p m E n t o r p r o p E r t y d a m a g E .

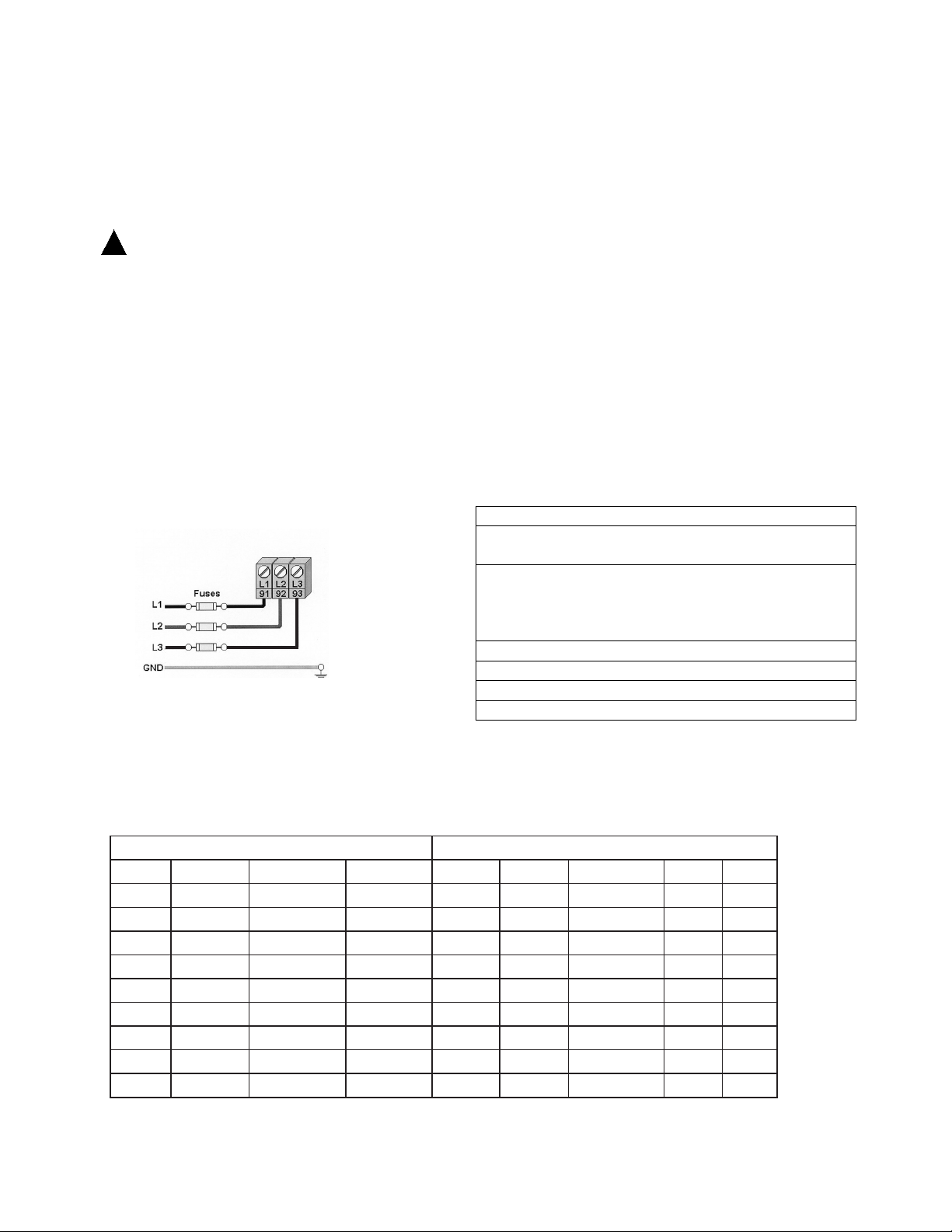

Drive Fuses

If specied as an option, drive input fuses will be

factory installed in the enclosure. If not factory supplied, they must be provided by the installer as part

of installation.

Internal Option Panel Fuses

Use the specied fuse or an equivalent replacement

only for internal option panel fuses. Fuse options

include the drive disconnect and contactor fuses.

Tools and Equipment Required

In addition to the standard tool kit, the tools and devices in Table 3-1 are recommended for installation

of the unit.

Table 3-1. Tools and Equipment Required

Figure 3-1. Drive Input Fuses

Table 3-2. Connection Tightening Torques

Power (hp) Torque (in-lbs)

Frame 200-240 V 380-480 V 525-600 V Line Motor DC Brake Ground Relay

A2 2 - 5 3 - 5 3 - 5 17 17 17 28 5

A3 5 10 5 - 10 17 17 17 28 5

A5 1.5 - 5 1.5 - 10 1.5 - 10 17 17 17 28 5

B1 7.5 - 15 15 - 25 -- 17 17 13 28 5

B2 20 30 - 40 -- 22, 40 22, 40 32 29 5

12

C1 25 - 40 50 - 75 -- 88 88 88 28 5

C2 50 - 60 100 - 125 -- 124, 212 124, 212 124 29 5

D1 -- 150-200 150-200 168 168 84 29 7

D2 -- 250-350 250-400 168 168 84 29 7

Page 13

Mechanical Installation

4.0 in min.

CEILING

FLOOR

AIRFLOW

4.0 in min.

AIRFLOW

Input power panel

Master drive

Follower 1

Follower 2

Input power raceway to VFDs

Drive disconnect

Mains (line)

disconnect

Hoist ring

Lift unit by

hoist ring only

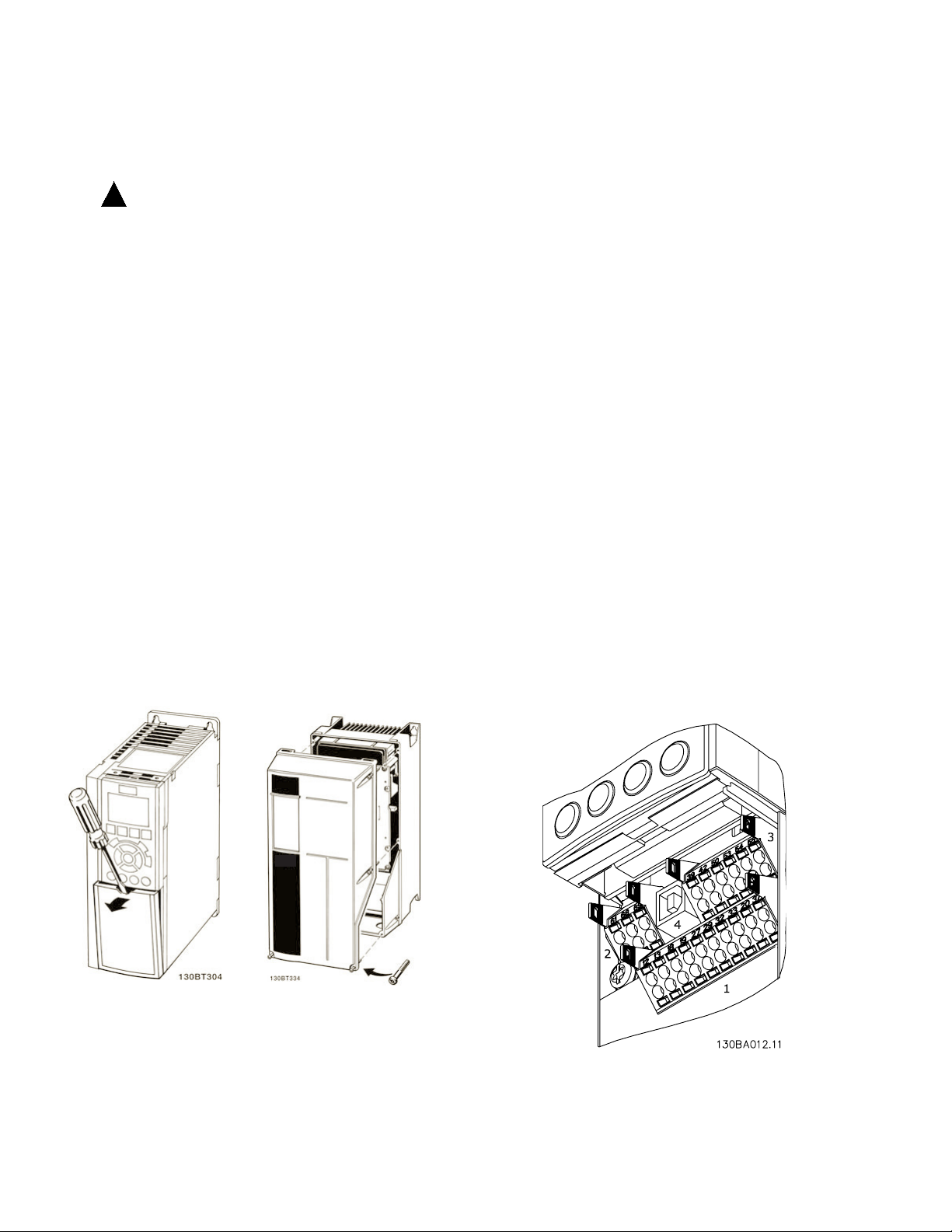

Lifting

Check the weight of unit to determine the safety of the

lifting method. (See the mechanical drawing supplied

with the equipment for unit weight.) Ensure that the

lifting device is suitable for the task. If necessary, plan

for a hoist, crane or forklift with appropriate rating to

move the units. For lifting, use hoist rings provided.

Cooling

• Mount the controller and panel vertically.

• Option panels rely on the ambient air

for cooling. It is important to observe the

limitations on ambient air temperature.

Derating start above 104oF (40oC) and 3300

feet elevation above sea level.

• Top and bottom clearance is required for

cooling (Figure 3-2). Generally, 4 to 10

inches (100 to 250 mm) minimum clearance

is required, depending upon the hp of the

unit. See the mechanical drawing shipped

with the unit for specic requirements.

Figure 3-2. Cooling Airow

Figure 3-3. Typical Unit Components

13

Page 14

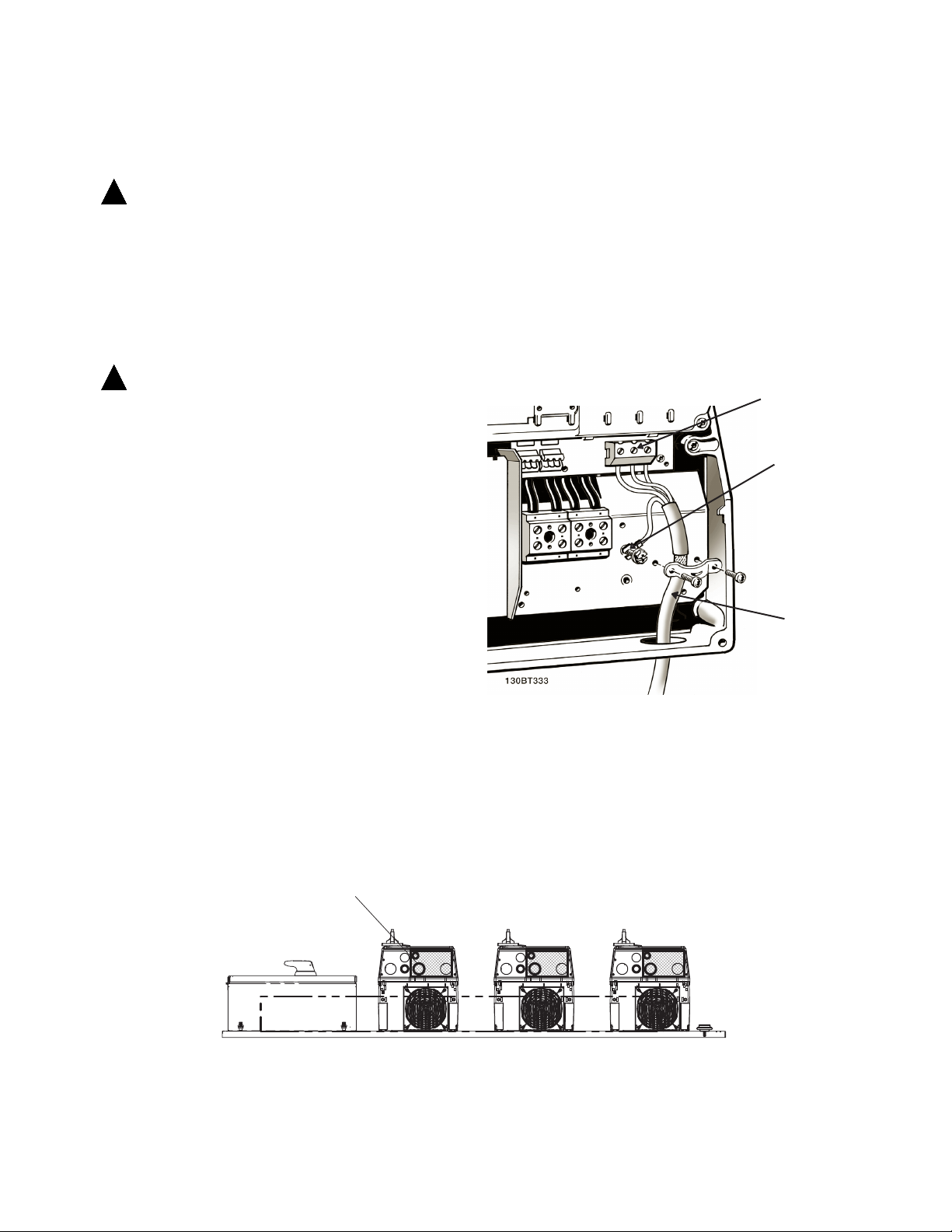

WARNING

!

WARNING

!

Electrical Installation

EquipmEnt Hazard!

rotating sHafts and ElEctrical EquipmEnt can bE

Hazardous. it is strongly rEcommEndEd tHat all

E l E c t r i c a l w o r k c o n f o r m t o a l l n a t i o n a l a n d l o c a l

r E g u l a t i o n s . in s t a l l a t i o n , s t a r t -u p , a n d m a i n t E n a n c E

s H o u l d b E p E r f o r m E d o n l y b y q u a l i f i E d p E r s o n n E l . fa i l u r E

t o f o l l o w l o c a l r E g u l a t i o n s c o u l d r E s u l t i n d E a t H o r

s E r i o u s i n j u r y .

• Motor control equipment and electronic

controls are connected to hazardous line

voltages. Extreme care should be taken to

protect against electrical hazard.

• Proper protective grounding of the

equipment must be established. Ground

currents are higher than 3 mA.

• A dedicated ground wire is required.

• Wear safety glasses whenever working on

electric control or rotating equipment.

notE

ma k E a l l p o w E r c o n n E c t i o n s w i t H m i n i m u m 75o c r a t E d

c o p p E r w i r i n g f o r i n s t a l l a t i o n s i n no r t H am E r i c a .

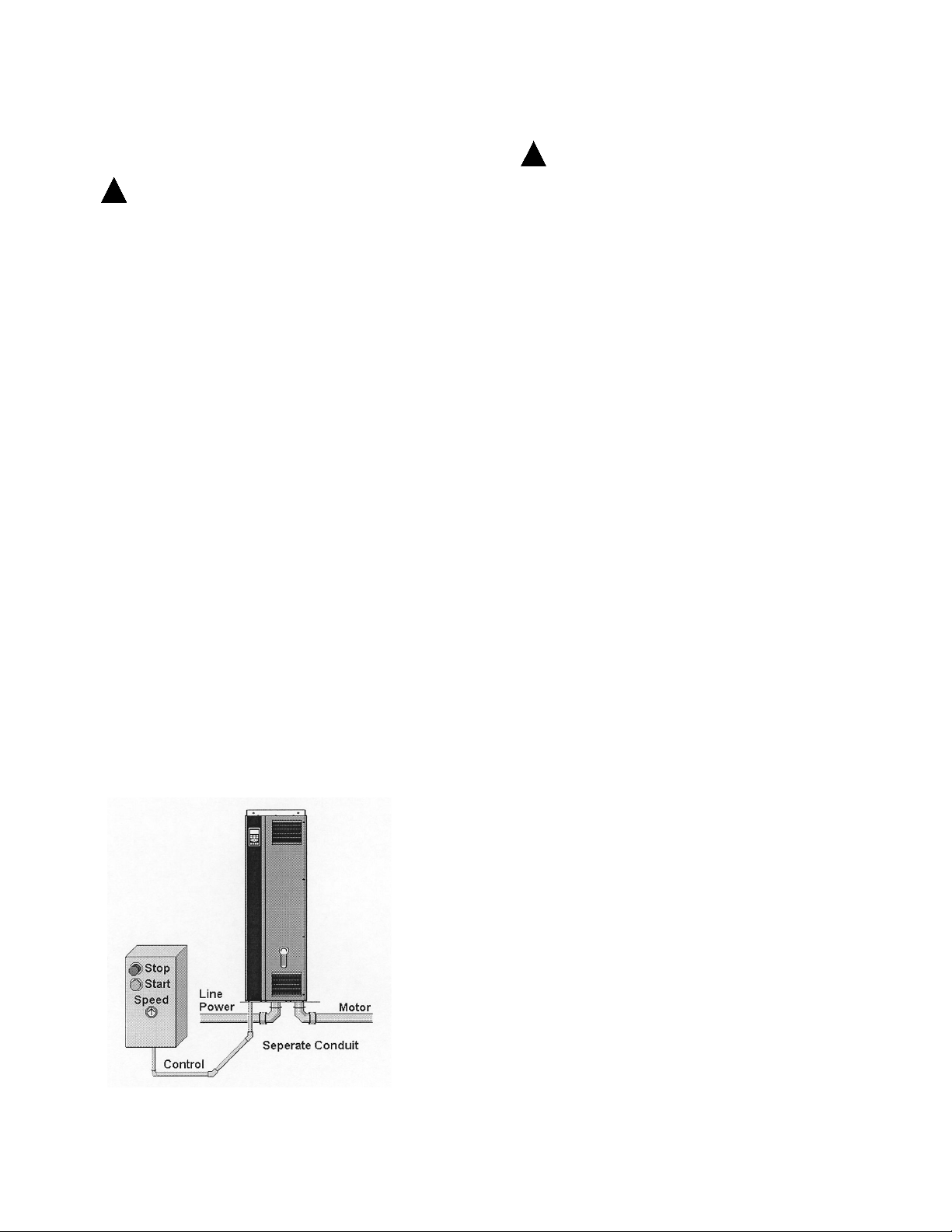

in d u c E d vo l t a g E !

ru n o u t p u t m o t o r c a b l E s f r o m m u l t i p l E d r i v E s s E p a r a t E l y .

in d u c E d v o l t a g E f r o m o u t p u t m o t o r c a b l E s r u n t o g E t H E r

c a n c H a r g E E q u i p m E n t c a p a c i t o r s E v E n w i t H t H E E q u i p m E n t

t u r n E d o f f a n d l o c k E d o u t . fa i l u r E t o r u n o u t p u t c a b l E s

s E p a r a t E l y c o u l d r E s u l t i n d E a t H o r s E r i o u s i n j u r y .

notE

ru n d r i v E i n p u t p o w E r , m o t o r w i r i n g , a n d c o n t r o l

w i r i n g i n t H r E E s E p a r a t E m E t a l l i c c o n d u i t s o r r a c E w a y s

f o r H i g H f r E q u E n c y n o i s E i s o l a t i o n . fa i l u r E t o i s o l a t E

p o w E r , m o t o r , a n d c o n t r o l w i r i n g c o u l d r E s u l t i n l E s s

t H a n o p t i m u m c o n t r o l l E r a n d a s s o c i a t E d E q u i p m E n t

p E r f o r m a n c E .

• Because the wiring from the option

enclosure to the motor carries high

frequency electrical pulses, it is important

that no other wires are run in this conduit. If

the incoming power wiring is run in the same

conduit as the motor wiring, these pulses

can couple electrical noise back onto the

building power grid.

At least three separate conduits must be connected

to the panel option. (See Figure 3-4.)

• Power wiring into the enclosure (and ground

back to the distribution panel)

14

• Power wiring from the enclosure to the

motor (and earth ground)

• Control wiring

Control wiring should always be isolated from the

high voltage power wiring.

Avoid getting metal chips into electronics.

Follow the connection procedures as illustrated in

the drawing provided with the unit.

For internal component identication, see Figure

3-5.

Figure 3-4. Power Connections

Page 15

OT 45...100 M3

Ground lug

Line (mains)

disconnect

Ground bar

L1 L2

L3

Wire Type Rating

WARNING

!

• Use wiring corresponding to the wire

rating specication provided.

• The wire rating specication is located

on the wire rating label inside the cover

of the option panel.

Terminal Tightening Torques

• Tighten all connections to the torque

specication provided in Table 3-2.

Line Input (Mains) Connection

• Size wiring based upon the input current

of the drive. Recommended wire sizes are

provided on the connection drawing of the

unit.

• Local codes must be complied with for cable

sizes.

ru n i n p u t p o w E r , m o t o r w i r i n g a n d c o n t r o l w i r i n g in

t H r E E s E p a r a t E m E t a l l i c c o n d u i t s o r r a c E w a y s f o r H i g H

f r E q u E n c y n o i s E i s o l a t i o n . fa i l u r E t o i s o l a t E p o w E r ,

m o t o r a n d c o n t r o l w i r i n g c o u l d r E s u l t i n l E s s t H a n

o p t i m u m d r i v E a n d a s s o c i a t E d E q u i p m E n t p E r f o r m a n c E .

• Connect 3-phase AC input power wire

to terminals L1, L2, and L3 on the main

disconnect located in the input power panel

(see Figure 3-3).

• Depending on the conguration of the

equipment, input power may be connected

to a circuit breaker or input disconnect.

• Use with Isolated Input Source. Many

utility power systems are referenced to earth

ground. Although not as common, the input

power may be an isolated source. All drives

may be used with an isolated input source

as well as with ground reference power

lines.

notE

sE E f i g u r E s 3-12 a n d 3-13 f o r p o w E r , m o t o r a n d c o n t r o l

w i r i n g d i a g r a m s .

Exterior

Interior

Figure 3-5. Input Power Panel with Line Disconnect

15

Page 16

Motor Wiring

WARNING

!

WARNING

!

NOTE: CONNECT MOTOR LEADS

DIRECTLY TO VFD THROUGH ACCESS

PANEL. DO NOT ROUTE THROUGH

RACEWAY.

notE

sE E fi g u r E s 3-12 a n d 3-13 f o r p o w E r , m o t o r a n d

c o n t r o l w i r i n g d i a g r a m s .

in d u c E d vo l t a g E !

ru n o u t p u t m o t o r c a b l E s f r o m m u l t i p l E d r i v E s s E p a r a t E l y .

in d u c E d v o l t a g E f r o m o u t p u t m o t o r c a b l E s r u n t o g E t H E r

c a n c H a r g E E q u i p m E n t c a p a c i t o r s E v E n w i t H t H E E q u i p m E n t

t u r n E d o f f a n d l o c k E d o u t . fa i l u r E t o r u n o u t p u t m o t o r

c a b l E s s E p a r a t E l y c o u l d r E s u l t i n d E a t H o r s E r i o u s

i n j u r y .

wi r i n g is o l a t i o n !

ru n i n p u t p o w E r , m o t o r w i r i n g a n d c o n t r o l w i r i n g in

t H r E E s E p a r a t E m E t a l l i c c o n d u i t s o r r a c E w a y s f o r H i g H

f r E q u E n c y n o i s E i s o l a t i o n . fa i l u r E t o i s o l a t E p o w E r ,

m o t o r a n d c o n t r o l w i r i n g c o u l d r E s u l t i n l E s s t H a n

o p t i m u m d r i v E a n d a s s o c i a t E d E q u i p m E n t p E r f o r m a n c E .

• Motor wiring access panels are provided at

the base of the units as shown in Figure 3-6:

• Torque terminals in accordance with the

information provided in Table 3-2.

• Motor wiring should never exceed the

following maximum distances:

1000 ft (300m) for unshielded

500 ft (150m) for shielded

• Motor wiring should always be as short as

practical.

Motor terminals

T1, T2, T3

Ground

• Connect the 3-phase motor wiring to bypass

terminals T1 (U), T2 (V), and T3 (W). See

the connection drawing provided with unit.

• Depending on the conguration of the

equipment, motor wiring may be connected

to an electrical or mechanical overload, a

contactor, or terminal block (see Figure 3-7).

Figure 3-6. Wiring Access Panels (bottom view)

Motor wiring

Figure 3-7. Sample Motor Wiring

16

Page 17

Grounding (Earthing)

WARNING

!

gr o u n d i n g Ha z a r d !

fo r o p E r a t o r s a f E t y , i t i s i m p o r t a n t t o g r o u n d d r i v E a n d

o p t i o n p a n E l p r o p E r l y . fa i l u r E t o g r o u n d d r i v E a n d o p t i o n

p a n E l p r o p E r l y c o u l d r E s u l t i n d E a t H o r s E r i o u s i n j u r y .

no t E

it i s t H E r E s p o n s i b i l i t y o f t H E u s E r o r c E r t i f i E d E l E c t r i c a l

i n s t a l l E r t o E n s u r E c o r r E c t g r o u n d i n g (E a r t H i n g ) o f

t H E E q u i p m E n t in a c c o r d a n c E w i t H n a t i o n a l a n d l o c a l

E l E c t r i c a l c o d E s a n d s t a n d a r d s .

• Follow all local and national codes for proper

electrical equipment grounding (earthing).

• Proper protective grounding of the

equipment must be established. Ground

currents are higher than 3 mA.

• A dedicated ground wire is required.

• Do not use conduit connected to the option

panel as a replacement for a ground wire.

• Do not ground one panel to another in a

“daisy chain” fashion. Each panel must have

a dedicated ground connection.

• A high strand count ground wire is preferred

for dissipating high frequency electrical

noise.

• Keep the ground wire connections as short

as possible.

notE

sE E f i g u r E s 3-12 a n d 3-13 f o r p o w E r , m o t o r a n d c o n t r o l

w i r i n g d i a g r a m s .

• Connect the ground wire directly to a reliable

earth ground. Grounding studs are provided

on the back plate of the option panel for

grounding.

17

Page 18

Control Wiring

WARNING

!

ru n i n p u t p o w E r , m o t o r w i r i n g a n d c o n t r o l w i r i n g i n

t H r E E s E p a r a t E m E t a l l i c c o n d u i t s o r r a c E w a y s f o r H i g H

f r E q u E n c y n o i s E i s o l a t i o n . fa i l u r E t o i s o l a t E p o w E r ,

m o t o r a n d c o n t r o l w i r i n g c o u l d r E s u l t i n l E s s t H a n

o p t i m u m d r i v E a n d a s s o c i a t E d E q u i p m E n t p E r f o r m a n c E .

• It is recommended that control wiring is

rated for 600 volts for 480 V and 600 V

drives and 300 volts for 200-240 V drives.

Drive Control Terminals

Denitions of the drive terminals are summarized in

Table 3-3. Figure 3-9 shows the removable controller

connectors and terminals.

• Connector 1 provides four programmable

digital inputs, two additional digital terminals

programmable as input or output, a 24 VDC

terminal supply voltage, and a common for

optional customer supplied 24 VDC voltage.

• Isolate control wiring from high power

components in the drive.

Control Wiring Access

• For units 5 hp or less (208 V) and 10 hp or

less (480 V), remove access cover plate with

screw driver. (See Figure 3-8.)

• For larger size units, remove front cover of

unit to access internally mounted control

terminals. (See Figure 3-8.)

• Connector 2 is for the serial

communications EIA-485 connector with

terminal 68 (+) and 69 (-).

• Connector 3 provides two analog inputs,

one analog output, 10 VDC supply voltage,

and commons for the inputs and output.

• Connector 4 is a USB port available for

use with the MCT-10 drive programming

software.

• Also provided are two Form C relay outputs

that are in various locations depending upon

the controller conguration and size.

Figure 3-8. Control Terminals Access

18

Figure 3-9. Drive Control Terminals

Page 19

Table 3-3. Drive Control Terminals Functions

Terminal No.

Function

01, 02, 03

04, 05, 06

Form-C relay output. Useable for AC or DC voltage and

resistive or inductive loads. See drive support materials for

details on voltage and current ratings and relay location.

12, 13

24 VDC digital sup ply voltage. Useable f or digital inputs and

external transducers. T o use the 24 VDC for digital input

common, program param eter 5-00 for PNP operation.

Maximum output current is 200 mA total for all 24V loads.

18, 19, 32, 33

Digital inputs. Selectable for NPN or PNP function in

parameter 5-00. Default is PNP.

27, 29

Digital inputs or outputs. Programmable for either. Parameter

5-01 for terminal 27 and 5- 02 for 29 selects input/output

function. Default setting is input.

20

Common for digital inputs. To use for digital input common,

program parameter 5-00 for NPN operation.

39

Common for analog output.

42

Analog output. Programm able for various functions in

parameter 6-5x. The analog signal is 0 to 20 mA or 4 to 20 mA

at a maximum of 500 Ω.

50

10 VDC analog supply voltage. 15 mA maximum commonly

used for a potentiometer or thermistor.

53, 54

Analog input. Selectable for voltage (0-10 V) or current (0- or

4-20 mA). Closed is for current and open is for voltage.

Switches are located on the drive control card behind the

removable LCP. See drive support materials for details.

55

Common for analog inputs.

61

Common for serial communication. Do not use to terminate

shields. See drive support materials for proper shield

termination.

68 (+), 69 (-)

RS-485 interface. When the drive is connected to an RS-485

serial communication bus, a drive control card switch is

provided for termination resistance. ON for term ination and

OFF for no termination. See drive support materials for details.

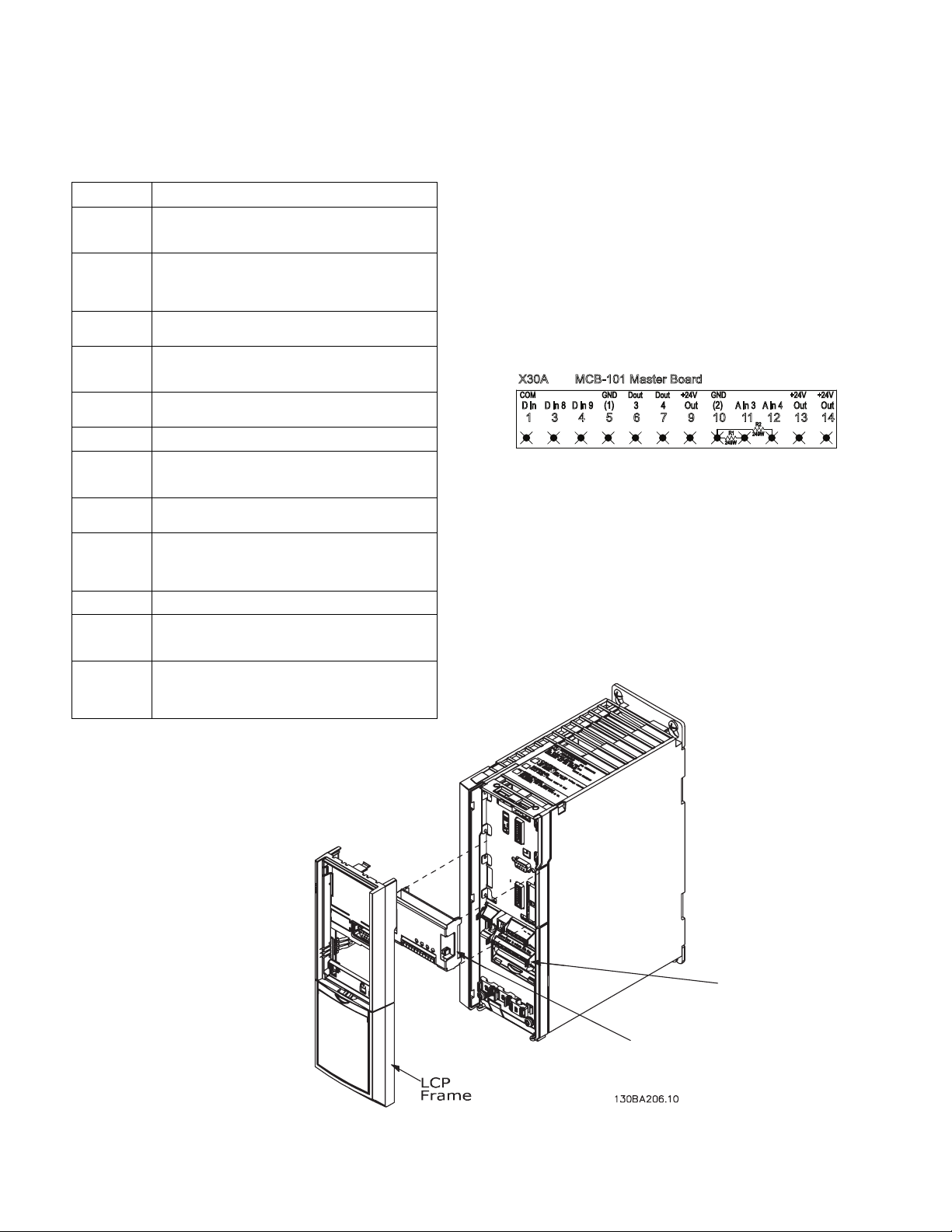

MCB101

master board

Drive terminals

R1

249W

3 4 765 9 101

MCB-101 Master Board

11 12

X30A

13 14

D in

COM

D in 8 D in 9

(1)

GND3Dout4Dout

Out

+24V

(2)

GND

A in 3 A in 4 Out

+24V

Out

+24V

R2

249W

MCB-101 Master Control Board

The Master drive only contains the MCD-101 Master

Board which features additional programmable

connection terminals (see Figure 3-10). Typically,

differential pressure switches, remote system run and

system status, and an optional low suction pressure

switch are connected to these terminals. (See Figure

3-12, Control Wiring Schematic Diagram.)

Figure 3-10. Master Board Control Terminals

notE

sE E f i g u r E s 3-12 a n d 3-13 f o r p o w E r , m o t o r a n d c o n t r o l

w i r i n g d i a g r a m s .

notE

sE E f i g u r E s 3-12 a n d 3-13 f o r p o w E r , m o t o r a n d c o n t r o l

w i r i n g d i a g r a m s .

Figure 3-11. Master Board Terminals Location

19

Page 20

Pressure and Feedback Wiring

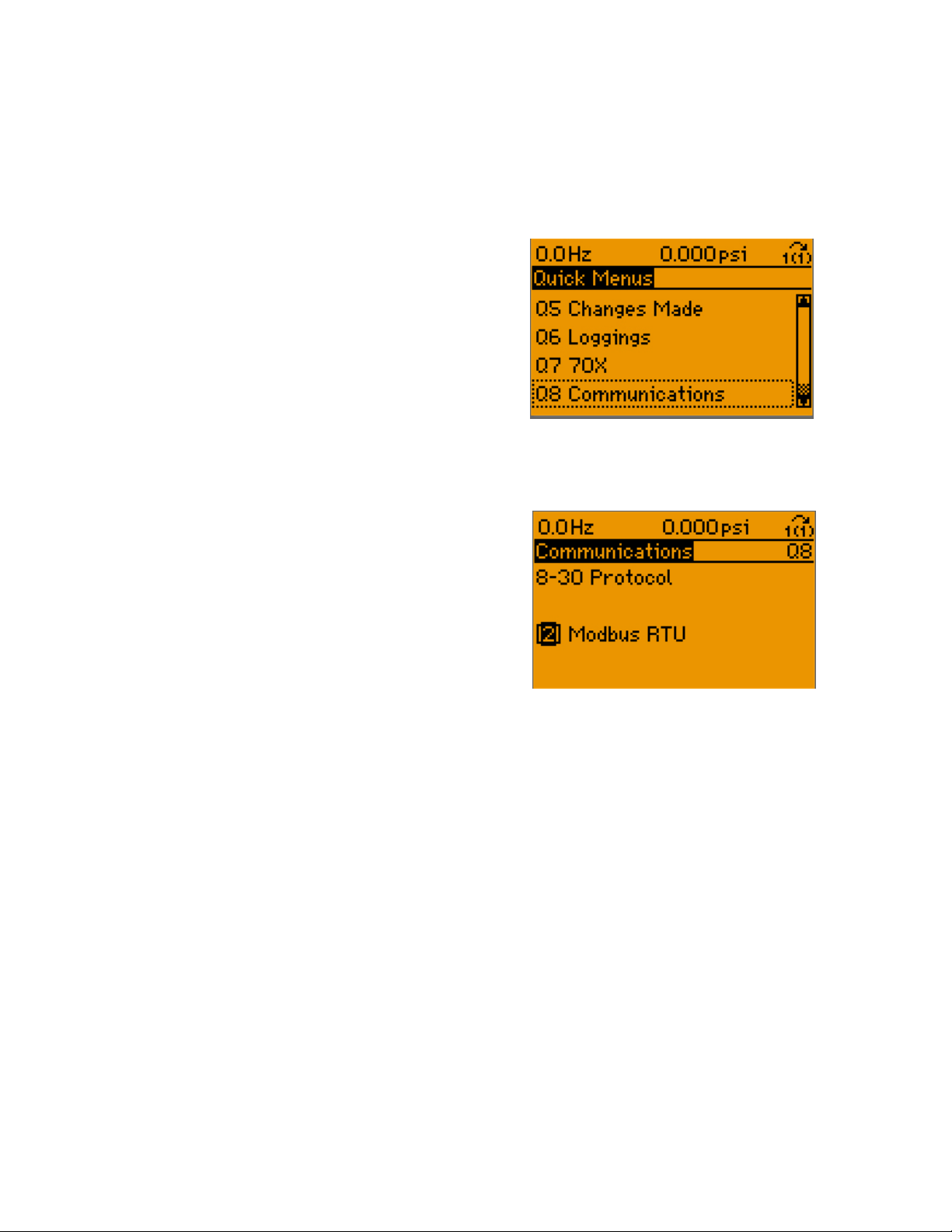

Serial Communications Programming

Connect differential pressure wiring and feedback

transmitter wiring to terminals as shown in Figure

3-9.

Control Terminal Programming

Control terminals must be programmed. Terminals

are multi-functional. Each terminal has a parameter

associated with it for setting the desired function. It is

essential for operation of the equipment that the control terminals are programmed correctly. Installation

programming for units is factory set. See programming in this manual for more details.

See Figure 3-13 for the control terminals schematic

diagram.

Serial Communication Bus Connection

The bypass reports serial communication data to host

systems through the drive. Connection to the serial

communication network is made either through the

EIA-485 terminals on the controller (Figure 3-9) or, for

other protocols, terminals located on the communication option card. For option card connection, see the

option card instructions provided with the unit.

• For bypass serial communication protocols

using the EIA-485 terminals, make connections

in the following manner.

Select the serial communication protocol type in Quick

Menu item Q8, Communications.

Press the OK key to access the parameter choices

and scroll to parameter 8-30, Protocol to select the

protocol in use.

notE

dE t a i l E d s E r i a l c o m m u n i c a t i o n i n s t r u c t i o n s a r E s H o w n in

t H E a p p E n d i x a t t H E E n d o f t H i s m a n u a l .

notE

it i s r E c o m m E n d E d t o u s E b r a i d E d -s H i E l d E d , t w i s t E d -p a i r

c a b l E s t o r E d u c E n o i s E b E t w E E n c o n d u c t o r s .

1. Connect signal wires to terminal (+) 68 and

terminal (-) 69 on control terminals of controller.

2. Terminate shield to grounded restraining clip

provided by stripping wire insulation at point of

contact.

3. If shielded cabling is used, do not connect end

of shield to terminal 61.

20

Page 21

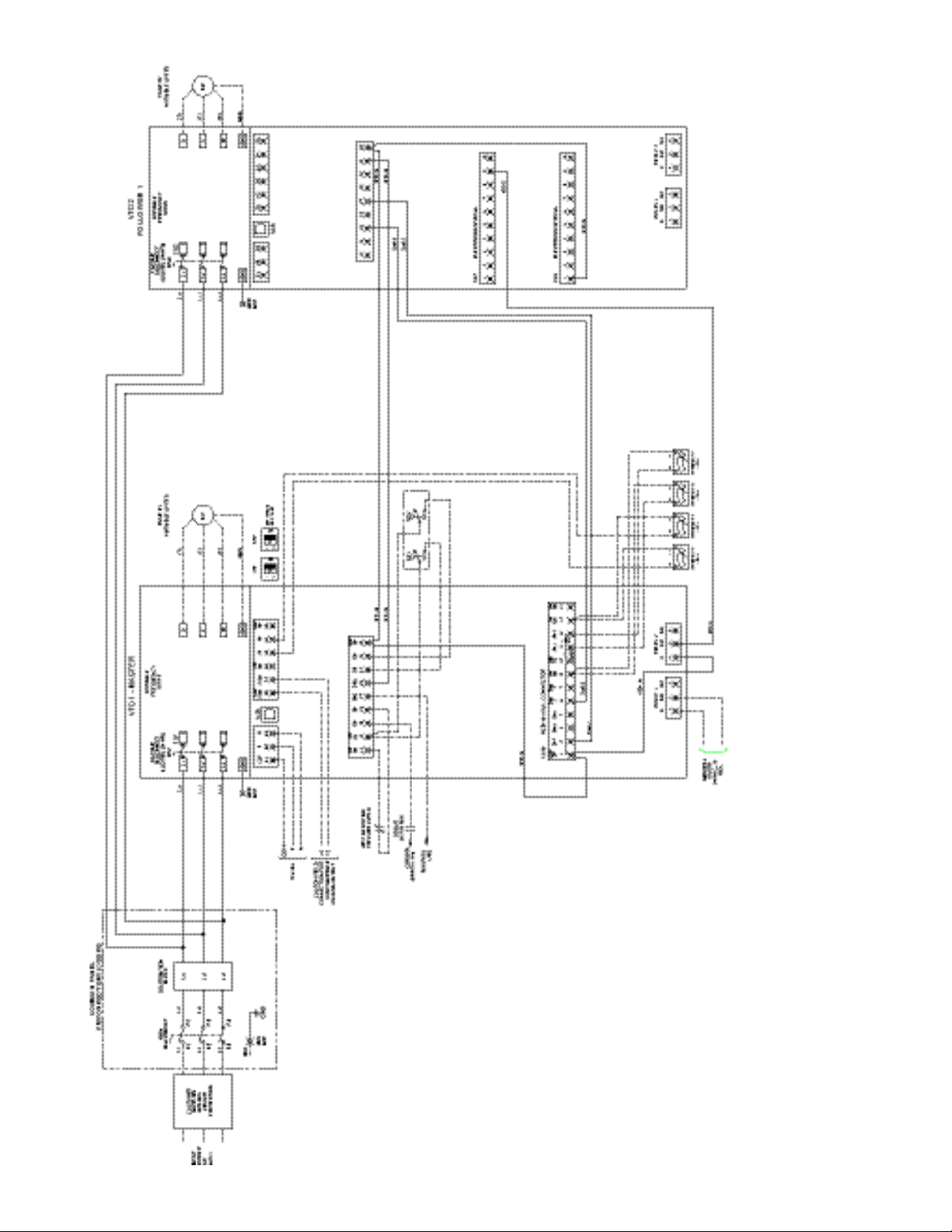

Figure 3-12. Customer Wiring Schematic Diagram, VFD with 1 Follower

21

Page 22

M1

1T1

1T2

1T3

PUMP

MOTOR #1

60 Hz

3Ø

POWER

INPUT

L13

L11

L12

DISCONNECT

L1

L2

L3

GND

BAR

GND

(T1)

(T2)

(T3)

(L1)

(L2)

(L3)

WL3

GND

VL2

L1 U

MASTER

L13

L11

L12

MAIN

GND

GND

BLOCK

DISTRIBUTION

L13

L11

L12

GND

BAR

GND

CUSTOMER

SUPPLIED

BRANCH

CIRCUIT

PROTECTION

208V-600V

POWER TO

SLAVE VFD'S

4 5 6

RELAY 2

1 2 3

RELAY 1

C NO NCC NO NC

VARIABLE

FREQUENCY

DRIVE

RS485

DP3 DP4DP2DP1

VFD4-18

2J27

GENERAL

ALARM

240VAC, 2A

MAX.

(+)

(-)

CUSTOM FIELD

CONNECTION FOR

CONFIGURABLE

ANALOG OUTPUT

P

COM

N

DISCONNECT ENCLOSURE

COMMON PANEL

USB

TO VFD4-27

2J28

VFD2-27

2K08

TO VFD3-27

2J18

VFD4-27

2K28

VFD2-18

2K07

VFD3-18

2K17

VFD1-20

VFD1-5

1R21

VFD1-4

VFD1

20333219 27 29181312

2 3 4 76 9101

MCB-101 AUX. CONNECTOR

11 12

X30A

13

Din

COM

Din 7 Din 8 Din 9 3

Dout

4

Dout

Out

+24V

(2)

GND

Ain 3 Ain 4 Out

+24V

Out

+24V

Din Din

D I/O D I/O

Din Din Din

COM

Out

+24V

61 68 69 504239 53 54 55

COM P N A Out

COM

A Out Out

+10V

Ain Ain Ain

COM

OPT. LOW SUCTION

PRESSURE SWITCH

SYSTEM RUN

REMOTE

CUSTOMER

SUPPLIED (+24V)

RUN STATUS

(+24V)

1 2

ON

1 2

ON

ON=0-20mA

OFF=0-10V

S201 S202

DS1

FU1

(LOCATED ON VFD)

DISCONNECT

V/S PUMP

R1

249W

R2

249W

2K08

VFD2-33

2L08

VFD2-20

1K18

VFD1-12

2B02 2C02 2C02

14

Out

+24V

VFD3-27

2K18

FEEDBACK Ain1

4-20mA

FEEDBACK Ain2

4-20mA

FEEDBACK Ain3

4-20mA

FEEDBACK Ain4

4-20mA

(-) (+) (-) (+) (-) (+)(-) (+)

22

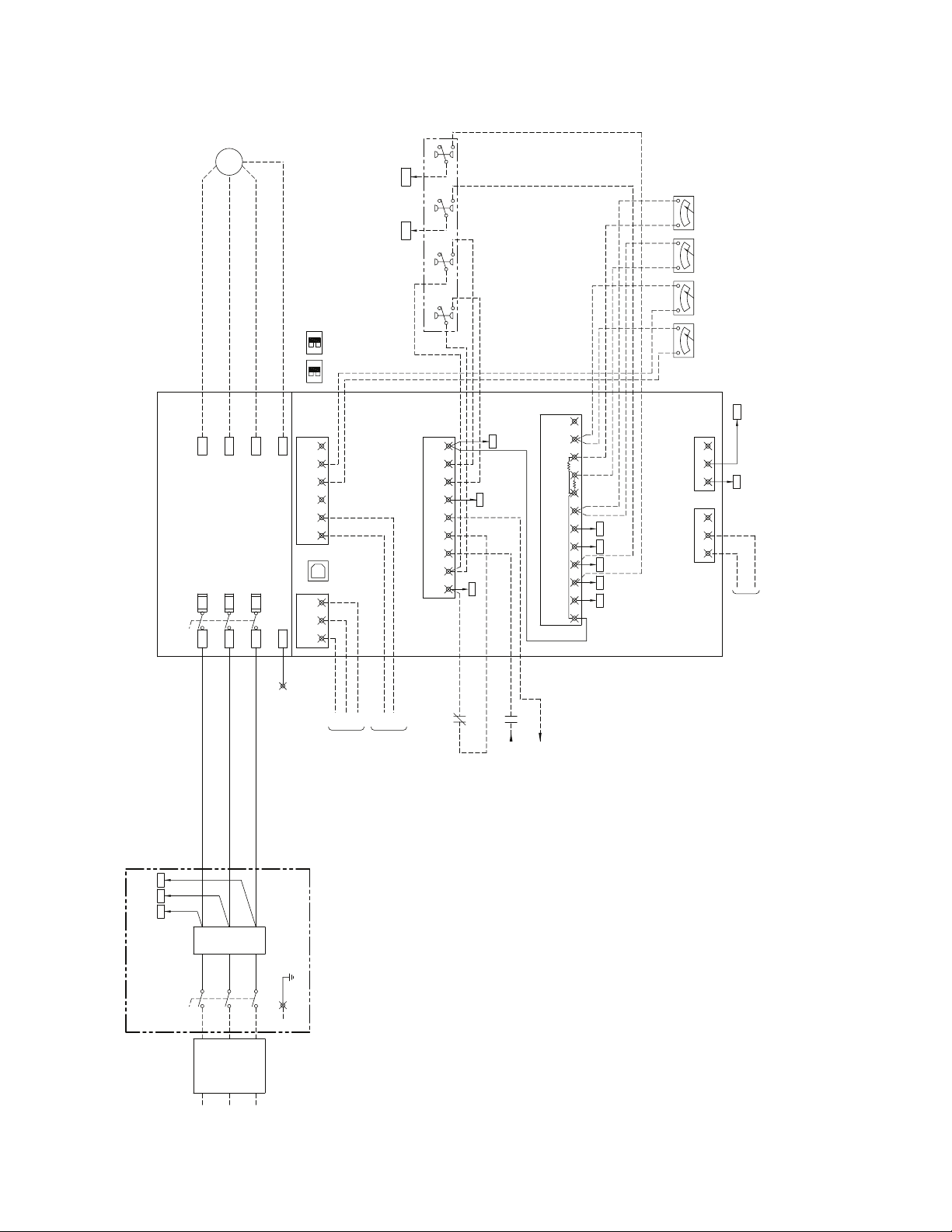

Figure 3-13.1. Customer Wiring Schematic Diagram, VFD with 2 or 3 Followers (1 of 2)

Page 23

M2

2T1

2T2

2T3

PUMP

MOTOR #2

DIST. BLK

FROM

POWER

INPUT

L13

L11

L12

W

GND

V

U

FOLLOWER 1

L13

L11

L12

GND

GND

GND

BAR

4 5 6

RELAY 2

1 2 3

RELAY 1

C NO NCC NO NC

VARIABLE

FREQUENCY

DRIVE

COMMON PANEL

LOCATED IN

ENCLOSURE

DISCONNECT

X30A-6

1N19

X30A-2

1N17

VFD1-29

1K24

VFD1-20

1L24

M4

4T1

4T2

4T3L13

L11

L12

W

GND

V

U

FOLLOWER 3 (OPT.)

GND

GND

GND

BAR

4 5 6

RELAY 2

1 2 3

RELAY 1

C NO NCC NO NC

VARIABLE

FREQUENCY

DRIVE

USB

VFD1-5

1R24

TO DP4

1I30

PUMP

MOTOR #4

M3

3T1

3T2

3T3

PUMP

MOTOR #3

W

GND

V

U

FOLLOWER 2 (OPT.)

L13

L11

L12

GND

GND

GND

BAR

4 5 6

RELAY 2

1 2 3

RELAY 1

C NO NCC NO NC

VARIABLE

FREQUENCY

DRIVE

X30A-7

1N20

TO DP3

1I29

VFD1-29

VFD1-20

VFD1-29

VFD1-20

VFD2 VFD4VFD3

61 68 69 504239 53 54 55

20

333219 27 29181312

Out

+24V

Din Din

D I/O D I/O

Din Din Din

COM

Out

+24V

COM P N A Out

COM

A Out Out

+10V

Ain Ain Ain

COM

USB

61 68 69 504239 53 54 55

20

333219 27 29181312

Out

+24V

Din Din

D I/O D I/O

Din Din Din

COM

Out

+24V

COM P N A Out

COM

A Out Out

+10V

Ain Ain Ain

COM

USB

61 68 69 504239 53 54 55

20

333219 27 29181312

Out

+24V

Din Din

D I/O D I/O

Din Din Din

COM

Out

+24V

COM P N A Out

COM

A Out Out

+10V

Ain Ain Ain

COM

L3

L2

L1

DS2

FU2

(LOCATED ON VFD)

DISCONNECT

V/S PUMP

L3

L2

L1

DS3

FU3

(LOCATED ON VFD)

DISCONNECT

V/S PUMP

L3

L2

L1

DS4

FU4

(LOCATED ON VFD)

DISCONNECT

V/S PUMP

1B09

1B09

1B10

X30A-4

1N18

X30A-3

1N18

Figure 3-13.2. Customer Wiring Schematic Diagram, VFD with 2 or 3 Followers (2 of 2)

23

Page 24

Installation of Backpanel Mounted

FLOW

FLOW

FLOW

FLOW

Drives and Pumps

notE

sE E f i g u r E s 3-12 a n d 3-13 f o r p o w E r , m o t o r a n d c o n t r o l

w i r i n g d i a g r a m s .

For Installation of drives and pumps mounted on

a common backpanel (see Figure 3-14), follow the

installation procedures in Section 3 minus the motor

wiring information since this will be factory installed.

Also, the motor and system control parameters will

be factory set for the Master drive and Followers prior

to shipping.

Follow the pre-start up and start up procedures as

described in Section 4.

24

Figure 3-14. Backpanel Mounted Drives and Pumps (front and side views)

Page 25

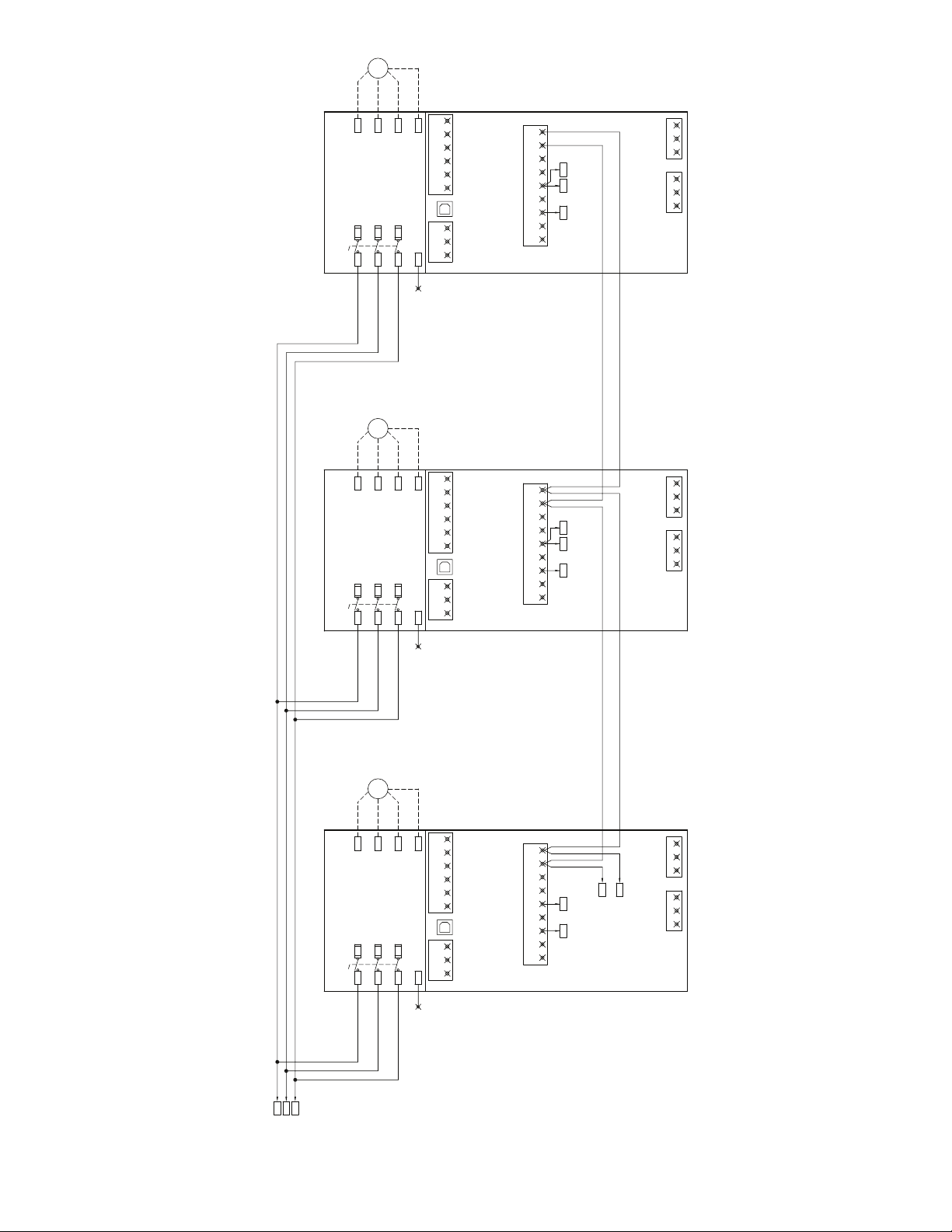

Installation of 70X Series Drives and

Pumps

A 70X conguration consists of one variable speed

pump (lead pump) connected to the 70X controller,

and from 1 to 3 constant speed pumps connected

to mains through a contactor controlled by the 70X

controller. (See Figure 3-15.)

The 70X controller monitors system pressure and

stages on and off constant speed pumps as needed

to maintain system pressure. Parameter 27-20,

Normal Operating Range % is used to dene the

acceptable deviation from the setpoint before staging

or destaging takes place. This parameter is dened

as a % of parameter 3-03, Maximum Reference.

(See Figure 3-16 for customer connection schematic

diagram.)

Staging:

When the system demand increases the 70X

controller will increase the speed of the lead pump

until it reaches its maximum speed. If the system

demand continues to increase, it will no longer be able

to maintain the desired system pressure. Once the

pressure drops below the Normal Operating Range for

the time set in parameter 39-11, Stage Proof Timer,

the controller will stage on a constant speed pump

and ramp the lead pump to its minimum speed.

De-Staging:

When system demand decreases, the 70X controller

will decrease the speed on the lead pump until it

reaches its minimum speed. If the system demand

continues to decrease, the pressure will exceed the

Normal Operating Range. If this continues for the time

set in parameter 39-14, De-Stage Proof Timer, the

controller will destage a constant speed pump and

ramp the lead pump to maximum speed.

Alternation:

Since timed alternation only applies to changing the

lead pump, it is not part of a 70X system which has

only one lead pump. It is possible however to manually

alternate constant speed pumps using the right and

left arrows on the LCP.

Pump Running Order:

Parameter 39-33, Pump Running Order can be used

to determine the sequence with which constant speed

pumps are staged on and off.

AFD Failure and Fixed Speed Only mode:

Parameter 39-40, AFD Fail Proof Timer is active

in the 70X configuration. If the AFD fails, the 70X

system will switch to Fixed Speed Only mode.

In this mode, the controller will stage on and off

constant speed pumps if the system pressure

deviates from the setpoint more than parameter

27-22, Fixed Speed Only Operating Range. Setting

27-22 to zero disables this mode.

Pump Failures:

The DP switch inputs can be used in the 70X

conguration. If a failure is detected in the lead pump,

the controller will switch to Fixed Speed Only mode as

described above. If a failure is detected in a constant

speed pump, the controller will alternate to a different

constant speed pump and mark the pump as failed.

Zone Failure Detection:

All of the normal Zone Failure detections can be used

in the 70X conguration. The loss of a single sensor will

disable that sensor. The loss of all sensors will pump

the system into jog mode. 70X jog mode will run the

designated number of pumps at full speed by default.

25

Page 26

DENOTES RECOMMENDED

WIRE ENTRY AREA

HAND AUTO

LAG PUMP #1

G

G

CS PUMP #1

CS PUMP #2

OFF

CS PUMP #1

ON

HAND AUTO

LAG PUMP #2

OFF

CS PUMP #2

ON

High and Low Suction Cut-out:

No Flow Shutdown:

The High and Low suction cut-out features can be

used in the 70X conguration. Low suction cut-out will

destage any running constant speed pumps before

turning off the lead pump.

High and Low System Pressure:

The High and Low System Pressure feature can be

used in 70X conguration. If High System Pressure

is detected all pumps will be turned off without

destaging.

The No Flow SHutdown feature can be used in the

70X conguration. It will only work when all of the

constant speed pumps are off.

26

Figure 3-15. 70X Series Drive (front and bottom views)

Page 27

60 Hz3ØPOWER

INPUT

2L1 2L32L2

L3L2L1

BLOCK

DISTRIBUTION

L13

L11

L12

CUSTOMER

SUPPLIED

BRANCH

CIRCUIT

PROTECTION

DP3 DP4DP2DP1

R1

249W

FEEDBACK 1

4-20mA

FEEDBACK 2

4-20mA

FEEDBACK 3

4-20mA

FEEDBACK 4

4-20mA

VFD1-53

1G29

VFD1-54

1F29

X2X1

H4H2H3H1

FU5

T1

FU6

M1

(A2)(A1)

X1 X2

C/S PUMP #1

CONTACTOR

1I10,1I11,1I12

G

PL1

GND

BAR

GND

OL1

C/S PUMP #1

ON

LAG PUMP #1

OFF

SS1

HAND AUTO

xoo

oox

1 2

4

(95) (96)

3

1

M2

(A2)(A1)

C/S PUMP #2

CONTACTOR

1I13,1I14,1I15

G

PL2

OL2

C/S PUMP #2

ON

LAG PUMP #2

OFF

SS2

HAND AUTO

xoo

oox

1 5

7

(95) (96)

6

1T1

1T2

1T3

PUMP #1

VARIABLE SPEED

WL3

GND

VL2

L1 U

L13

L11

1L2

DS1

GND

GND

FU1

GND

BAR

61 68 69 504239 53 54 55

20

333219 27 29181312

4 5 6

RELAY 2

1 2 3

RELAY 1

C NO NCC NO NC

VARIABLE

FREQUENCY

DRIVE

(LOCATED ON VFD)

USB

V/S PUMP VFD

C/S PUMP #1

DISCONNECT

FU2

2L11 2L312L21

M1

(L1) (L2) (L3)

2L12 2L322L22

(L1) (L2) (L3)

(T1) (T2) (T3)

(T1)

(T2)

(T3)

C/S PUMP #1

OL1

EARTH

GROUND

3L1 3L33L2

L3L2L1

C/S PUMP #2

DISCONNECT

FU3

3L11 3L313L21

M2

(L1) (L2) (L3)

3L12 3L323L22

(L1) (L2) (L3)

(T1) (T2) (T3)

(T1)

(T2)

(T3)

C/S PUMP #2

OL2

EARTH

GROUND

X2

X2

DS2 DS3

GND

DISCONNECT

5L1

5L2

2T1 2T32T2 3T1 3T33T2

GENERAL

ALARM

240VAC, 2A

MAX.

3 4 76 9101

MCB-101 AUX. CONNECTOR

11 12

X30A

RR1

(A2)(A1)

C/S PUMP #1

RUN RELAY

1K04,*,*,*

201

RR1

(X) (X)

RR2

(X) (X)

RR2

(A2)(A1)

200 202

200

1 2

ON

1 2

ON

ON=0-20mA

OFF=0-10V

S201 S202

RS485

(+)

(-)

CUSTOM FIELD

CONNECTION FOR

CONFIGURABLE

ANALOG OUTPUT

P

COM

N

C/S PUMP #2

RUN RELAY

1N04,*,*,*

FEEDBACK 2

1Q29

FEEDBACK 1

1Q28

13 14

OPT. LOW SUCTION

PRESSURE SWITCH

SYSTEM RUN

REMOTE

4L1 4L34L2

L3L2L1

C/S PUMP #3

DISCONNECT

FU4

4L11 4L314L21

M3

(L1) (L2) (L3)

4L12 4L324L22

(L1) (L2) (L3)

(T1) (T2) (T3)

(T1)

(T2)

(T3)

C/S PUMP #3

OL3

EARTH

GROUND

DS4

4T1 4T34T2

M3

(A2)(A1)

C/S PUMP #3

CONTACTOR

1I16,1I17,1I18

G

PL3

OL3

C/S PUMP #3

ON

LAG PUMP #3

OFF

SS3

HAND AUTO

xoo

oox

1 8

10

(95) (96)

9

X2

RR3

(X) (X)

RR3

(A2)(A1)

200 203

C/S PUMP #3

RUN RELAY

1P04,*,*,*

C/S PUMP 2 & PUMP 3 - OPTIONAL

Din

COM

Din 8 Din 9 3

Dout

4

Dout

Out

+24V

(2)

GND

Ain 3 Ain 4 Out

+24V

Out

+24V

Out

+24V

Din Din

D I/O D I/O

Din Din Din

COM

Out

+24V

COM P N A Out

COM

A Out Out

+10V

Ain Ain Ain

COM

CUSTOMER

SUPPLIED (+24V)

RUN STATUS

(+24V)

V/S PUMP

NOTE: *=UNUSED CONTACT

R2

249W

L13

L11

L12

2

Din 7

204

204

C/S PUMP 2 & PUMP 3 - OPTIONAL

(OPTIONAL)

(OPTIONAL)

Figure 3-16. 70X Series Customer Wiring Diagram

27

Page 28

Section 4 Start Up

WARNING

!

Pre-start Procedure

1. Input power to unit must be OFF and locked

out per OSHA requirements. Do not rely on

panel disconnect switches.

Hi g H vo l t a g E !

if i n p u t a n d o u t p u t c o n n E c t i o n s H a v E b E E n c o n n E c t E d

i m p r o p E r l y , t H E r E is p o t E n t i a l f o r H i g H v o l t a g E o n t H E s E

t E r m i n a l s . if p o w E r l E a d s f o r m u l t i p l E m o t o r s a r E

i m p r o p E r l y r u n i n s a m E c o n d u i t , t H E r E i s p o t E n t i a l f o r

l E a k a g E c u r r E n t t o c H a r g E c a p a c i t o r s w it H in o p t i o n

p a n E l , E v E n w H E n d i s c o n n E c t E d f r o m l i n E i n p u t . f o r in i t i al

s t a r t u p , m a k E n o a s s u m p t i o n s a b o u t p o w E r c o m p o n E n t s .

fo l l o w p r E -s t a r t p r o c E d u r E s d E s c r i b E d b E l o w . fa i l u r E

t o f o l l o w p r E -s t a r t p r o c E d u r E s d E s c r i b E d b E l o w c o u l d

r E s u l t i n p E r s o n a l i n j u r y o r d a m a g E t o E q u i p m E n t .

2. Use AC voltmeter to verify there is no

voltage on input terminals L1, L2, and L3,

phase-to-phase and phase-to-ground, and

output terminals T1, T2, and T3, phase-tophase and phase-to-ground.

3. Use ohmmeter to conrm continuity of motor

by measuring T1-T2, T2-T3, and T3-T1.

7. Conrm control connections terminated

per connection diagrams supplied with the

equipment.

8. Check for external devices between

drive option panel output and motor. It is

recommended that no devices be installed

between motor and drive.

9. Record motor nameplate data; hp, voltage,

full load amps (FLA), and RPM. It will be

needed to match motor and drive data later

on.

10. Conrm that incoming power matches drive

label voltage and motor nameplate voltage.

11. For multiple winding motors, motors must

be wired on run winding Delta, not Y-start

winding.

caution

Eq u i p m E n t da m a g E !

if m o t o r fla (f u l l l o a d a m p E r a g E ) is g r E a t E r t H a n u n i t

m a x i m u m a m p s , c o n t r o l l E r a n d o p t i o n p a n E l m u s t b E

r E p l a c E d w i t H o n E o f a p p r o p r i a t E r a t i n g . do n o t a t t E m p t

t o r u n u n i t . fa i l u r E t o m a t c H fla t o u n i t m a x i m u m a m p

r a t i n g m a y r E s u l t i n E q u i p m E n t d a m a g E .

4. Use ohmmeter to conrm open on input by

measuring L1-L2, L2-L3, and L3-L1. Note

that if an isolation transformer is between

the power source and panel, continuity will

be present. In this case, visually conrm that

motor and power leads are not reversed.

5. Inspect the panel for loose connections on

terminals.

6. Check for proper ground: option panel to

main building distribution ground, and to

motor ground.

28

12. Conrm motor FLA is equal to or less than

maximum option panel output current. Some

motors have higher then normal NEMA

currents.

13. Check that overload relay(s) is set for FLA of

connected motor. Service factor is built into

overload relay.

Page 29

Inspection Prior to Start Up

Before applying power to the unit, inspect the entire

installation as detailed in Table 4-1.

Table 4-1. Inspection Prior to Start Up

Inspect For Description

Auxiliary equipment

Cable routing

Control wiring

EMC considerations Check for proper installation with regard to electromagnetic capability.

Environmental conditions See equipment label for the maximum ambient operating temperature limits.

Fan clearance Cooling fan are located below the drive and require sufcient clearance for

Look for auxiliary equipment, switches, disconnects, or input fuses/circuit

breakers that may reside on input power side of drive or output side to motor.

Examine their operational readiness and ensure they are ready in all respects

for operation at full speed. Check function and installation of pressure

sensors or encoders (etc.) used for feedback to drive. Remove power factor

correction caps on motor(s), if present.

Ensure that input power, motor wiring and control wiring are in three separate

metallic conduits for high frequency noise isolation. Failure to isolate

power, motor and control wiring could result in less than optimum drive and

associated equipment performance.

Check for broken or damaged wires and connections. Check the voltage

source of the signals, if necessary. The use of shielded cable or twisted pair

is recommended. Ensure the shield is terminated correctly.

Temperature is not to exceed 104F (40ºC). Humidity levels must be less than

95% non-condensing.

fan removal. See the installation drawing supplied with the unit for clearance

requirements.

3

Proper clearance Units require top and bottom clearance adequate to ensure proper air ow for

cooling in accordance with the unit size.

Fusing and circuit

breakers

Grounding

Input and output power

wiring

Panel interior Equipment interior must be free of dirt, metal chips, moisture, and corrosion.