Page 1

INSTALLATION,

OPERATION AND

MAINTENANCE

INSTRUCTIONS

10-001-265

REV 5

TECHNOFORCE

Pump Controller

VARIABLE SPEED PUMPING SYSTEMS

Page 2

TECHNOFORCE Installation, Operation, and Maintenance

Page 3

Table of Contents

1. Introduction and safety.....................................................................................................................................................1

1.1 Introduction ....................................................................................................................................................................1

1.2 Safety ................................................................................................................................................................................1

1.3 Safety terminology and symbols ..................................................................................................................................1

1.4 Environmental safety .....................................................................................................................................................2

1.5 Recycling guidelines .......................................................................................................................................................2

1.6 User safety .......................................................................................................................................................................3

1.7 Product warranty ............................................................................................................................................................4

2. Transportation and storage .............................................................................................................................................5

2.1 Inspect the delivery ........................................................................................................................................................5

2.2 Transportation guidelines ..............................................................................................................................................5

2.3 Storage guidelines ...........................................................................................................................................................5

3. Product description ...........................................................................................................................................................6

3.1 General description ........................................................................................................................................................6

3.2 Operational limits ..........................................................................................................................................................6

3.3 Nameplate information .................................................................................................................................................6

3.4 Main parts and functions ...............................................................................................................................................7

3.5 Glossary of terms...........................................................................................................................................................8

Table of Contents

4. Installation ...........................................................................................................................................................................9

4.1 Field connections ............................................................................................................................................................9

4.2 Earth (ground) connections ..........................................................................................................................................9

4.3 Sensor and control wiring .............................................................................................................................................9

4.4 Pump package location guidelines ............................................................................................................................ 10

4.5 System piping and unit installation – nal checklist............................................................................................... 11

4.6 Electrical wiring and control setting – nal checklist ............................................................................................ 11

4.7 Operator interface ....................................................................................................................................................... 12

4.8 LEDs ............................................................................................................................................................................. 14

4.9 I/O................................................................................................................................................................................. 14

4.10 Set up and features .................................................................................................................................................... 15

4.10.0 Sensor Setup ................................................................................................................................................. 15

4.10.1 Pump Set Up ................................................................................................................................................ 16

4.10.2 System Setup ................................................................................................................................................ 17

4.10.3 Stage/Destage .............................................................................................................................................. 18

4.10.4 VFD ............................................................................................................................................................... 19

4.10.5 Exercise ......................................................................................................................................................... 21

4.10.6 Alternation .................................................................................................................................................... 21

4.10.7 Timed Auto Alternation ............................................................................................................................. 21

4.10.8 Scheduled Auto Alternation ....................................................................................................................... 21

4.10.9 Daily Alternation ......................................................................................................................................... 22

4.10.10 Weekly Alternation .................................................................................................................................... 22

4.10.11 Monthly Alternation ................................................................................................................................. 22

4.10.12 Alternation Basis ....................................................................................................................................... 23

4.10.13 PID .............................................................................................................................................................. 23

4.10.14 Reset Totals ................................................................................................................................................ 23

4.10.15 Date, Time Alternation............................................................................................................................. 24

4.10.16 Password ..................................................................................................................................................... 24

4.10.17 Input/Output (I/O) Setup ...................................................................................................................... 25

4.10.18 Communications ........................................................................................................................................ 26

4.10.19 BACnet MS/TP ......................................................................................................................................... 26

4.10.20 JC Metasys N2 ........................................................................................................................................... 26

4.10.21 Modbus ....................................................................................................................................................... 27

TECHNOFORCE Installation, Operation, and Maintenance

Page 4

Table of Contents

4.10.22 Analog Input Override ............................................................................................................................. 27

4.10.23 Dynamic Flow Loss Compensation ....................................................................................................... 27

4.10.24 Save/Load ................................................................................................................................................... 29

4.10.25 Save to Flash............................................................................................................................................... 29

4.10.26 Load from Flash ........................................................................................................................................ 30

4.10.27 Load Default .............................................................................................................................................. 30

4.10.28 Display ......................................................................................................................................................... 30

4.10.29 Test Set Up ................................................................................................................................................. 31

4.10.30 Digital Input Test ...................................................................................................................................... 31

4.10.31 Digital Output Test ................................................................................................................................... 31

4.10.32 Analog Input Test ......................................................................................................................................31

4.10.33 Analog Output Test .................................................................................................................................. 31

4.10.34 LED Test .................................................................................................................................................... 32

4.10.35 Key Test ...................................................................................................................................................... 32

4.10.36 Display Test ................................................................................................................................................ 32

4.10.37 Communications Test ............................................................................................................................... 32

4.10.38 VFD Comm ............................................................................................................................................... 32

4.10.39 Alarms/Events Set Up ............................................................................................................................. 33

4.10.40 Pump Failure .............................................................................................................................................. 33

4.10.41 Low System Pressure ................................................................................................................................ 34

4.10.42 High System Pressure ............................................................................................................................... 34

4.10.43 Low Suction Pressure ............................................................................................................................... 35

4.10.44 High Suction Pressure .............................................................................................................................. 36

4.10.45 No Flow Shut Down ................................................................................................................................ 36

4.10.46 Low Level ................................................................................................................................................... 37

4.10.47 High Level .................................................................................................................................................. 38

4.10.48 VFD/Comm Failure ................................................................................................................................. 38

4.11 Q-Start ......................................................................................................................................................................... 39

5. Operation ........................................................................................................................................................................... 40

5.1 Normal Scrolling Operation ..................................................................................................................................... 40

5.2 Types Of Programs .................................................................................................................................................... 41

5.2.0 CO Operation .................................................................................................................................................. 41

5.2.1 Local Automatic Operation ........................................................................................................................... 41

5.2.2 Remote Automatic Operation ....................................................................................................................... 42

5.2.3 DO Operation ................................................................................................................................................. 42

5.2.4 Local Automatic Operation ........................................................................................................................... 42

5.2.5 Remote Automatic Operation ....................................................................................................................... 42

5.3 Pump Rotation ............................................................................................................................................................ 43

5.4 Hand Manual Operation ........................................................................................................................................... 43

5.5 SetPoint Modication ................................................................................................................................................ 43

5.6 Process Variable Monitoring .....................................................................................................................................44

5.7 Alarms/Events ........................................................................................................................................................... 44

5.8 Quick Access ............................................................................................................................................................... 45

6. Maintenance ..................................................................................................................................................................... 46

6.1 Preface .......................................................................................................................................................................... 46

6.2 Technical overview ..................................................................................................................................................... 46

6.3 Digital inputs .............................................................................................................................................................. 46

6.4 Digital outputs ............................................................................................................................................................ 46

6.5 Analog inputs .............................................................................................................................................................. 46

6.6 Memory ....................................................................................................................................................................... 46

6.7 CPU .............................................................................................................................................................................. 46

6.8 Power supply ............................................................................................................................................................... 47

6.9 Protection .................................................................................................................................................................... 47

6.10 Instruments and their use ....................................................................................................................................... 47

6.11 Field repair ................................................................................................................................................................ 48

6.12 Program updating .................................................................................................................................................... 48

TECHNOFORCE Installation, Operation, and Maintenance

Page 5

Table of Contents

6.13 Troubleshooting ....................................................................................................................................................... 49

6.14 Program Type and Version Number..................................................................................................................... 50

6.14.0 Log Menu ..................................................................................................................................................... 50

6.14.1 Alarm Log .................................................................................................................................................... 50

6.14.2 Pump log menu ........................................................................................................................................... 50

6.14.3 Pump log ...................................................................................................................................................... 51

6.14.4 Pump Run Time ......................................................................................................................................... 51

6.14.5 Pump On/Off Times ................................................................................................................................ 51

6.14.6 Data Log ...................................................................................................................................................... 51

6.14.7 Sensor ........................................................................................................................................................... 51

6.14.8 Totalized Value ............................................................................................................................................ 52

6.14.9 Operation ..................................................................................................................................................... 52

6.14.10 Operation Mode Change ......................................................................................................................... 52

6.14.11 Power Cycles ............................................................................................................................................. 52

6.13.12 Events ......................................................................................................................................................... 53

6.14.13 System On/Off ........................................................................................................................................ 53

6.14.14 Alternation ................................................................................................................................................. 53

6.14.15 System Reset .............................................................................................................................................. 53

6.14.16 Events ......................................................................................................................................................... 54

6.14.17 VFD ............................................................................................................................................................ 54

6.14.18 Exercise ...................................................................................................................................................... 54

6.14.19 Set Point ..................................................................................................................................................... 54

6.14.20 Service Log ................................................................................................................................................ 55

6.14.21 Error Log ................................................................................................................................................... 55

6.14.22 Operation Hours ...................................................................................................................................... 55

6.14.23 Destage Speed ........................................................................................................................................... 55

6.14.24 Run Time Setpoint ................................................................................................................................... 55

6.15 Maintenance (physical) ............................................................................................................................................ 56

7. Appendix ............................................................................................................................................................................ 57

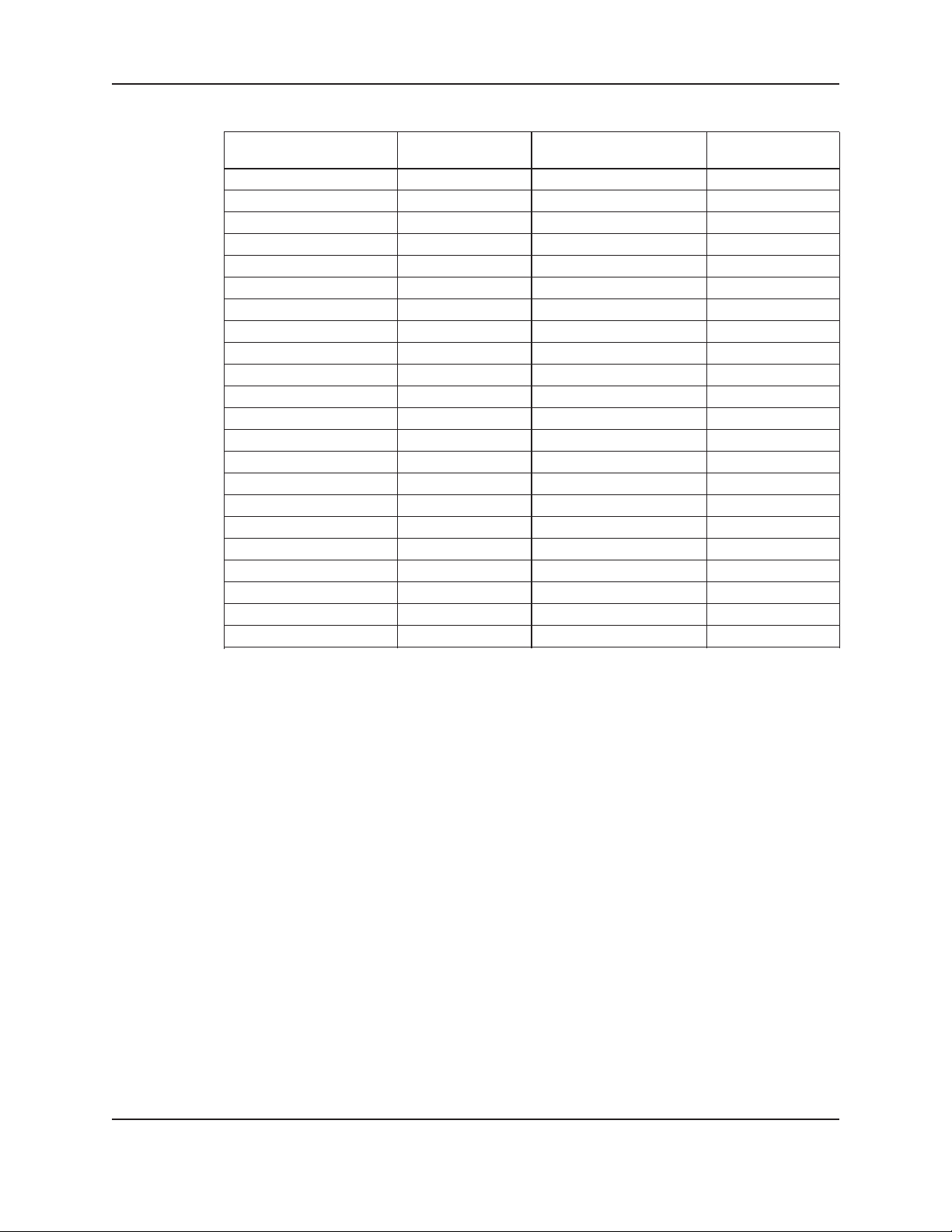

7.1 Valid I/O Codes .......................................................................................................................................................... 57

7.2 BACnet Protocal Implementation Conformance Statement ................................................................................ 58

7.3 TechnoForce BACnet Communications Objects List for Application Version 1.16 or above ....................... 61

7.4 TechnoForce MODBUS Communication Points .................................................................................................. 63

7.5 TechnoForce Metasys N2 Communication Points ................................................................................................ 65

7.6 Quick Access Number Table ..................................................................................................................................... 67

7.7 Wiring Diagrams .......................................................................................................................................................... 68

8. Symbols .............................................................................................................................................................................. 69

TECHNOFORCE Installation, Operation, and Maintenance

Page 6

TECHNOFORCE Installation, Operation, and Maintenance

Page 7

1. Introduction and Safety

1.1 Introduction

1.1.0 Purpose of the manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the product. Improper use of the product can cause

personal injury and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the location of the unit.

The information contained in this manual is intended to assist operating personnel by providing information on

the characteristics of the purchased equipment.

It does not relieve the user of the responsibility to adhere to local codes and ordinances and the use of accepted

practices in the installation, operation and maintenance of this equipment.

Further information pertaining to the installation, operation, and maintenance of your TechnoForce pump

controller can be found in the IOMs for the associated equipment provided Maintenance section for a list of

relevant manuals.

Equipment cannot operate well without proper care. To keep this unit at top efciency, follow the recommended

installation and servicing procedures outlined in this manual.

Introduction and Safety

1.2 Safety

WARNING:

• The operator must be aware of safety precautions to prevent physical injury.

• Any pressure-containing device can explode, rupture, or discharge its contents if it is

over-pressurized. Take all necessary measures to avoid over-pressurization.

• Operating, installing, or maintaining the unit in any way that is not covered in this manual could

cause death, serious personal injury, or damage to the equipment. This includes any modication

to the equipment or use of parts not provided by Xylem. If there is a question regarding the

intended use of the equipment, please contact an Xylem representative before proceeding.

• This manual clearly identies accepted methods of disassembling units. These methods must be

adhered to. Trapped liquid can rapidly expand and result in a violent explosion and injury. Never

apply heat to impellers, propellers, or their retaining devices to aid in their removal.

• Do not change the service application without the approval of an authorized Xylem

representative.

1.3 Safety terminology and symbols

1.3.0 About safety messages

It is extremely important that you read, understand, and follow the safety messages and regulations carefully

before handling the product. They are published to help prevent these hazards.

• Personal accidents and health problems

• Damage to the product

• Product malfunction

TECHNOFORCE Installation, Operation, and Maintenance

1

Page 8

Introduction and Safety

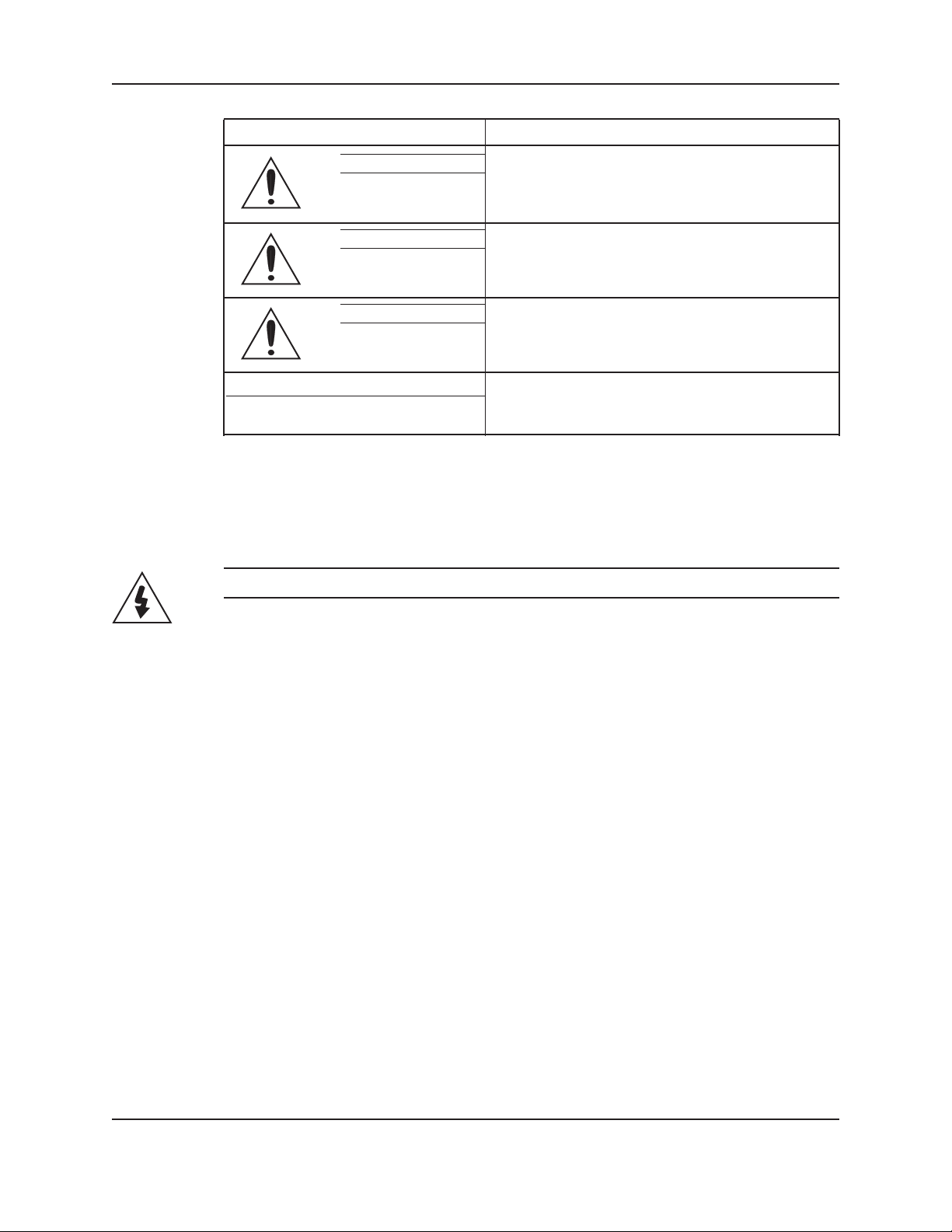

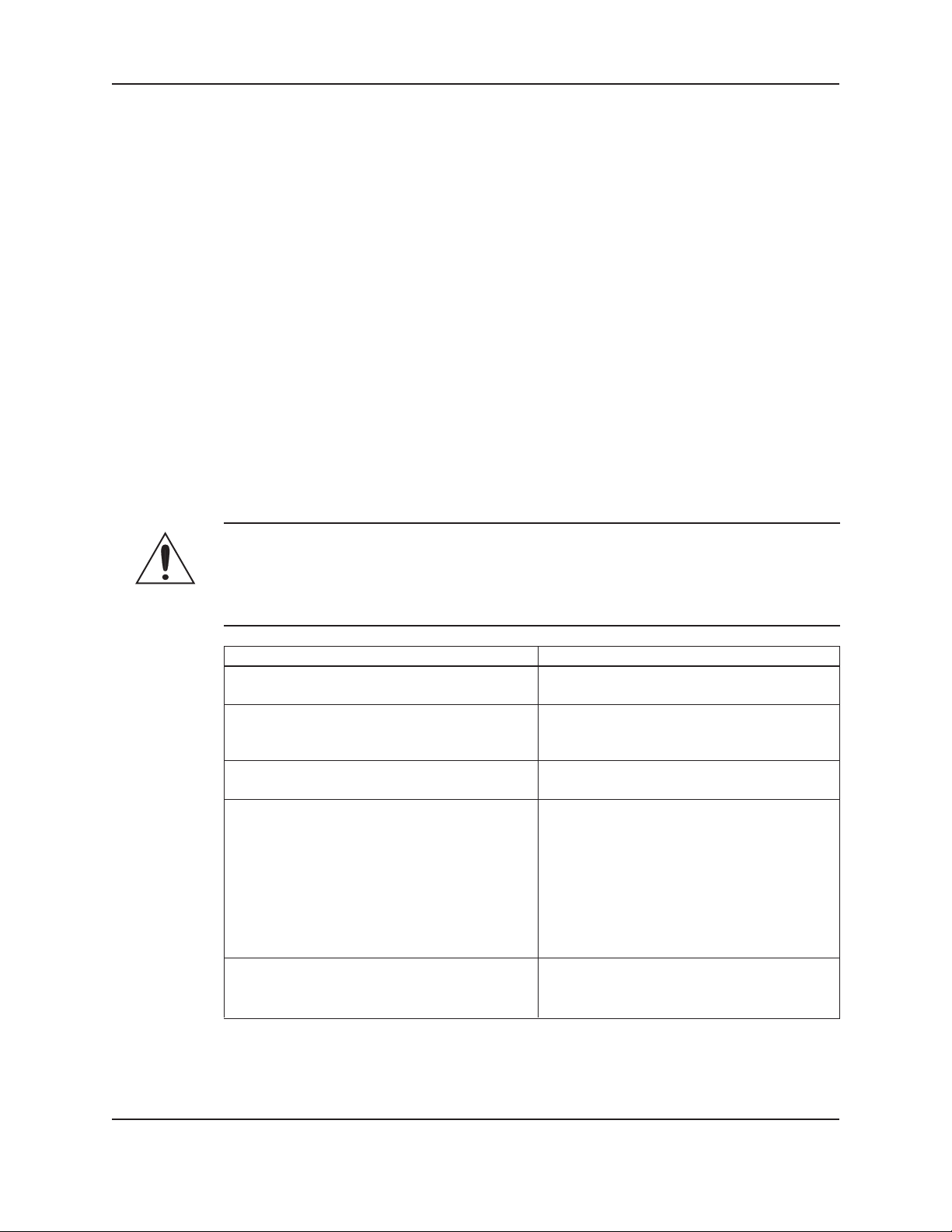

1.3.1 Hazard levels

Hazard level Indication

DANGER: A hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING: A hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: A hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE: • A potential situation which, if not avoided, could

result in undesirable conditions.

• A practice not related to personal injury.

1.3.2 Hazard categories

Hazard categories can either fall under hazard levels or let specic symbols replace the ordinary hazard level

symbols.

Electrical hazards are indicated by the following specic symbol.

Electrical Hazard:

These are examples of other categories that can occur. They fall under the ordinary hazard levels and may use

complementing symbols:

• Crush hazard

• Cutting hazard

• Arc ash hazard

1.4 Environmental safety

1.4.0 The work area

Always keep the station clean to avoid and/or discover emissions.

1.4.1 Waste and emissions regulation

Observe these safety regulations regarding waster and emissions:

• Appropriately dispose of all waste.

• Handle and dispose of the processed liquid in compliance with applicable environmental regulations.

• Clean up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

1.4.2 Electrical installation

For electrical installation recycling requirements, consult your local electric utility.

1.5 Recycling guidelines

Always follow local laws and regulations regarding recycling.

2

TECHNOFORCE Installation, Operation, and Maintenance

Page 9

1.6 User safety

1.6.0 General safety rules

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc ash hazards.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

1.6.1 Safety equipment

Use safety equipment according to the company regulations. Use this safety equipment within the work area:

• Helmet

• Safety goggles

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• First-aid kit

• Safety devices

NOTICE:

Never operate a unit unless safety devices are installed. Also see specic information about safety devices in other

chapters of this manual.

Introduction and Safety

1.6.2 Electrical connections

Electrical connections must be made by certied electricians in compliance with all international, national, state,

and local regulations. For more information about requirements, see sections dealing specically with electrical

connections.

1.6.3 Precautions during work

Observe these safety precautions when you work with the product or are in connection with the product:

• Never work alone.

• Always wear protective clothing and hand protection.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Beware of the risk of a sudden start if the product is used with an automatic level control.

• Beware of the starting jerk, which can be powerful.

• Rinse the components in water after you disassemble the pump.

• Do not exceed the maximum working pressure of the pump.

• Do not open any vent or drain valve or remove any plugs while the system is pressurized. Make

sure that the pump is isolated from the system and that pressure is relieved before you disassemble

the pump, remove plugs, or disconnect piping.

• Never operate a pump without a properly installed coupling guard.

TECHNOFORCE Installation, Operation, and Maintenance

3

Page 10

1.6.4 Wash the skin and eyes

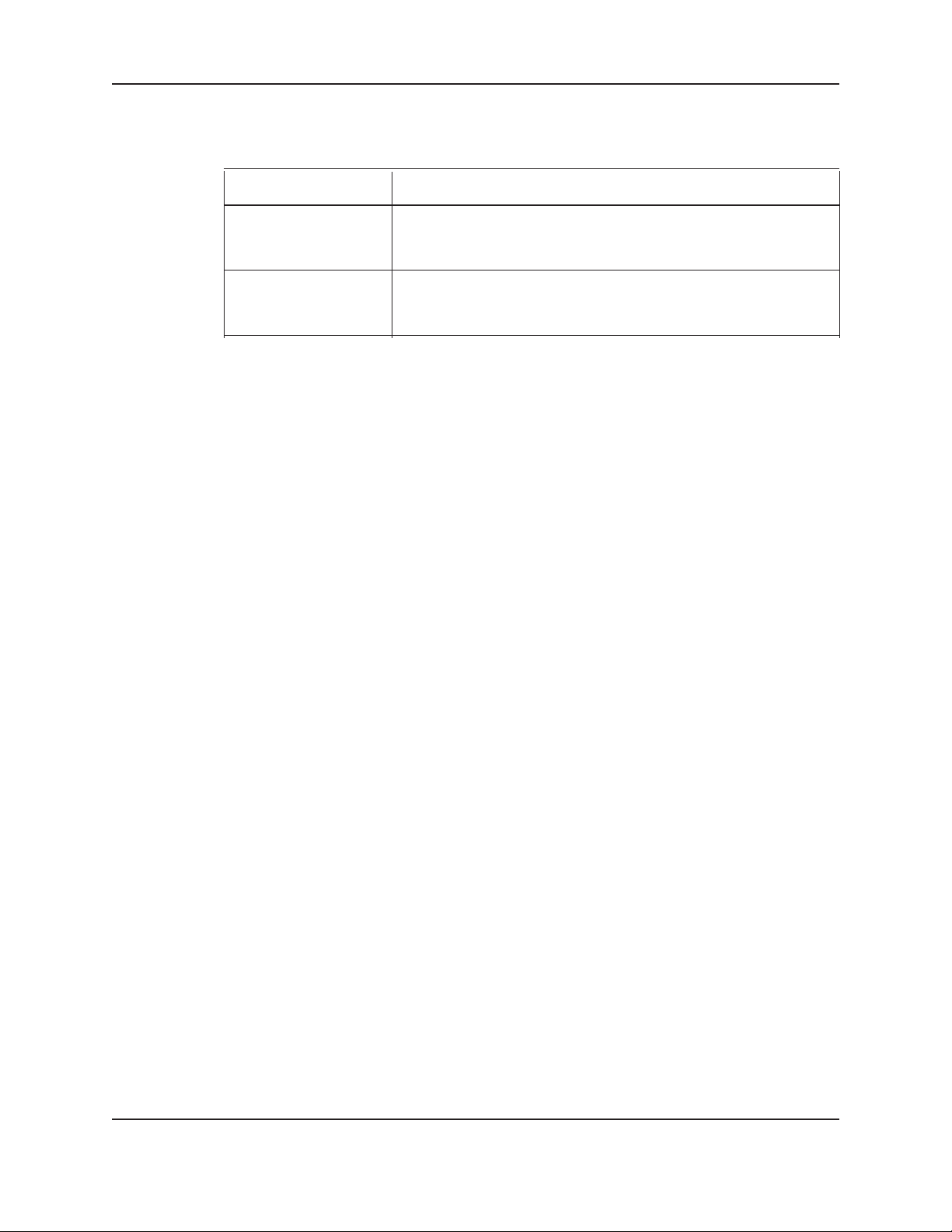

Do the following if chemicals or hazardous uids have come into contact with your eyes or your skin:

If you need to wash Then . . .

your . . .

Eyes 1. Hold your eyelids apart forcibly with your ngers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

Skin 1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least one minute.

3. Seek medical attentions, if required.

1.7 Product warranty

1.7.0 Coverage

Xylem undertakes to remedy faults in products from Xylem under these conditions:

• The faults are due to defects in design, materials, or workmanship.

• The faults are reported to an Xylem representative within the warranty period.

• The product is used only under the conditions described in this manual.

• The monitoring equipment incorporated in the product is correctly connected and in use.

• All service and repair work is done by Xylem-authorized personnel.

• Genuine Xylem parts are used.

• Only Ex-approved spare parts and accessories authorized by Xylem are used in Ex-approved products.

1.7.1 Limitations

The warranty does not cover faults caused by these situations:

• Decient maintenance

• Improper installation

• Modications or changes to the products and installation made without consulting Xylem

• Incorrectly executed repair work

• Normal wear and tear

Xylem assumes no liability for these situations:

• Bodily injuries

• Material damages

• Economic losses

1.7.2 Warranty claim

Xylem products are high-quality products with expected reliable operation and long life. However, should the need

arise for a warranty claim, then contact your Xylem representative.

Introduction and Safety

4

TECHNOFORCE Installation, Operation, and Maintenance

Page 11

2. Transportation and Storage

2.1 Inspect the delivery

2.1.0 Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the distributor.

2.1.1 Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact your sales representative if anything is out of order.

2.2 Transportation guidelines

2.2.0 Lifting methods

Transportation and Storage

WARNING:

• Assembled units and their components are heavy. Failure to properly lift and support this

equipment can result in serious physical injury and/or equipment damage. Lift equipment only at

the specically identied lifting points. Lifting devices such as eyebolts, slings, and spreaders must

be rated, selected, and used for the entire load being lifted.

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods and wear

steel-toed shoes at all times.

• Care should be taken to prevent damage due to dropping or jolting when moving the controller.

Transportation damage should be brought to the carrier’s attention immediately upon receipt.

2.3 Storage guidelines

2.3.0 Storage location

The product must be stored in a covered and dry location protected from extreme cold, heat, dirt, and vibrations.

NOTICE:

• Protect the product against humidity, heat sources, and mechanical damage.

• Do not place heavy weights on the packed products.

2.3.1 Long-term storage

If the controller is stored for more than 6 months, these requirements apply:

• Store in a covered and dry location.

• Store the unit free from heat, dirt, and vibrations.

• Recommended storage includes but not limited to a tarp over the unit.

Extended storage of VFDs may require special attention prior to start-up. See manufacturer’s IOM for

details.

TECHNOFORCE Installation, Operation, and Maintenance

5

Page 12

3. Product Description

3.1 General description

3.1.0 Description

The controller is a specic purpose programmable pump controller. This provides:

• Optimum pump control without the cost of general purpose control hardware.

• Software dedicated and established for the unit.

• Unique analog input protection of other members of the control family. In the event of a short

circuit condition, the current limit circuitry prevents failure of the analog input components.

NOTICE:

• Your controller should have a safety instruction decal. If the decal is missing or illegible, contact

your representative for a replacement.

3.2 Operational limits

3.2.0 Temperature and ventilation

All electrical equipment is susceptible to failure if operated in ambient temperatures outside of its rating. The

OPERATING temperature range for this unit is 0 to 40°C. The relative humidity should not exceed 90% noncondensing. The unit should not be operated outside these extremes.

Product Description

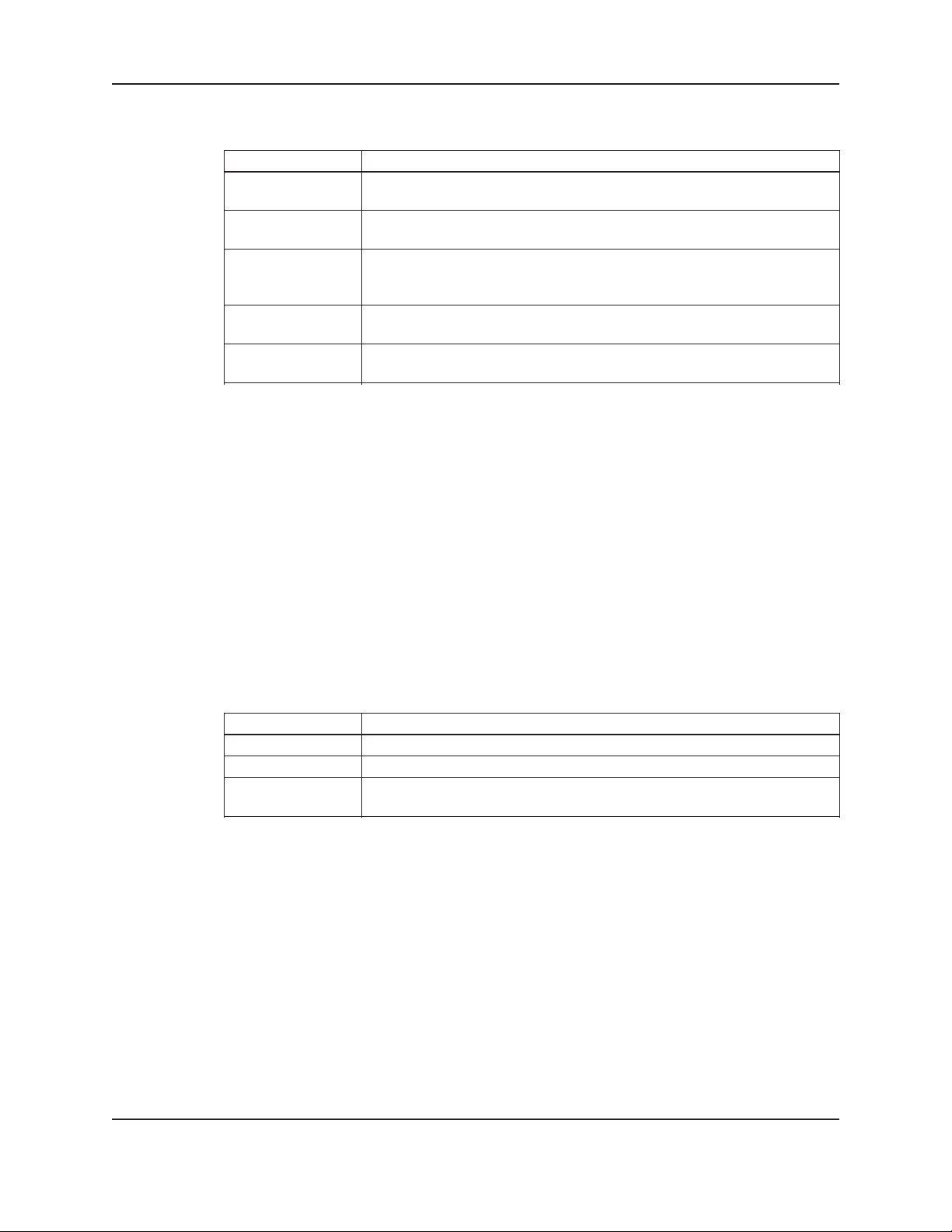

3.3 Nameplate information

3.3.0 Important information for ordering

Every pump station has a nameplate that provides information about the pump station. The pump station

nameplate is located on the inside of the control enclosure door.

When ordering spare parts, be prepared to identify the nameplate information when contacting the factory.

• Model

• Size

• Serial number

• Item numbers of the required parts

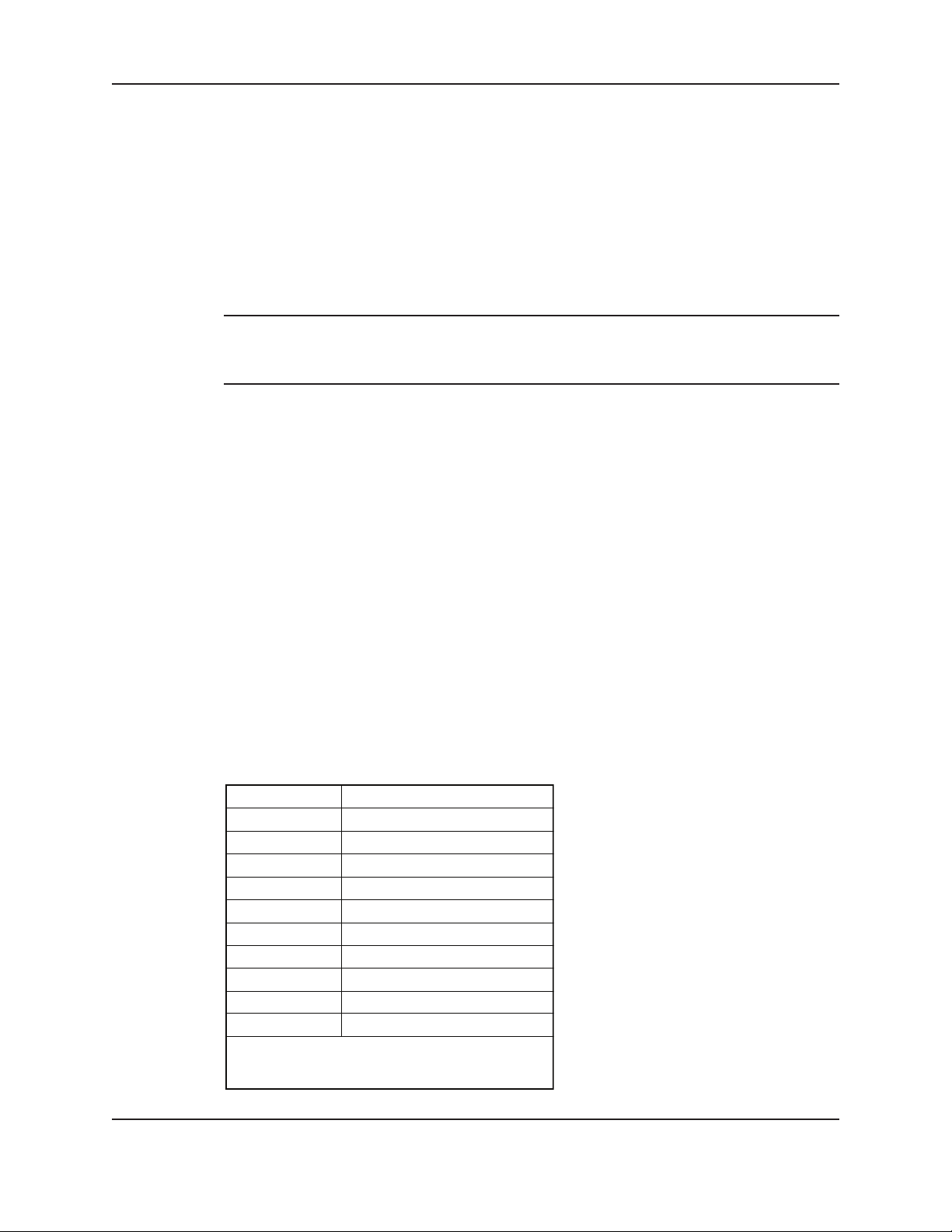

Model Number

Serial Number

Station Voltage

System FLA

SCCR

Largest Motor HP

Station Flow

Suction Pressure

Discharge Pressure

Pump Boost

Date Code

Residential & Commercial Water

Dallas, Texas, U.S.A

6

.

TECHNOFORCE Installation, Operation, and Maintenance

Page 13

Nameplate Data Explanation

Model Number The manufacturer’s number to indicate the particular type of product which

has been acquired.

Serial Number A set of characters that uniquely identies a single unit and can be used for

traceability and warranty purposes.

Station Voltage The rated voltage at which the station has been designed for. Should match the

application site supply voltage.

System FLA The full-load-amperage at which the station can operate.

SCCR “Short-Circuit Current Rating”. Represents the maximum level of short-circuit

current that a component or assembly can withstand.

Largest Motor HP The rated HP for the largest Pump in the system.

Station Flow The designed duty point, in GPM, LPH, etc.

Suction Pressure The line pressure on the input side of the pump station.

Discharge Pressure The line pressure on the output side of the pump station.

Pump Boost The difference between the input side of the pump station and the output side

of the pump station.

Date Code Marking of products to indicate their date of manufacture.

3.4 Main parts and functions

Product Description

3.4.0 Input voltage

The VFD and TechnoForce Pump Controller can be set up to operate across a broad range of voltages. It was

factory set to operate on the voltage shown on the nameplate. Check the VFD nameplate for the proper input

and output voltages before wiring the VFD.

The voltage tolerance is +10/-5% and phase to phase voltage must not have an imbalance greater than 5 VAC.

3.4.1 Ground connections

A grounding terminal is provided for a dedicated ground wire connection. All provisions of the National Electrical

Code and local codes must be followed.

WARNING:

• Conduit grounds are not adequate. A separate ground wire must be attached to the ground lug provided in

the enclosure to avoid potential safety hazards.

3.4.2 Power wiring

Power wire types and sizes must be selected based upon conformance with the National Electrical Code and all

local codes and restrictions. In addition, only copper (Cu) wire rated for 75°C (minimum) may be used for the

power connections. Refer to the input current as listed on the nameplate afxed to the enclosure door when

sizing wire.

3.4.3 Output/motor disconnect

It is necessary that any device which can disconnect the motor from the output of the VFD be interlocked to the

emergency shutdown circuits of the VFD. This will provide an orderly shutdown if the disconnecting device is

open circuited while the VFD is in operation. Failure to provide this interlock may result in damaged components

due to improper installation.

CAUTION:

• Metal lings can create electrical short circuits. Do not drill, saw, le or perform any operation

on the VFD conduit entry plate while attached to the VFD.

TECHNOFORCE Installation, Operation, and Maintenance

7

Page 14

Product Description

3.4.4 Analog signals

Shielded cable (#22 AWG, Belden type 8762, Alpha #2411, or equal) should be installed for all D.C. control

wiring. The shield must be terminated in the Controller panel. Do not connect the shield at the other end of the

cable! Insulate the shield so that no electrical connection is made at the other end of the cable. A twisted pair of

#22 AWG conductors (Belden 8442, or equal) can be used in place of shielded cable. The cable length must be

limited to 5,000 feet for #22 AWG wire.

3.4.5 Field connection diagrams

Refer to the pump Installation, Operation, and Maintenance Manual for specic details unique to the pump.

Refer to the ow sensor/transmitter Installation, Operation, and Maintenance manual for specic details unique to the

ow sensor/transmitter.

Job specic wiring and dimensional drawings and typical eld connection diagram should be reviewed prior to unit

installation and operation.

3.5 Glossary of terms

VFD Variable Frequency drive; converts a constant power input into a variable power output for the motor;

a device for controlling motor speed.

Alternation Process of determining which pump will serve as lead pump and which pump will serve as lag pump.

Destage To turn off a lag pump.

EOC End of curve; point at which a pump is staged or destaged.

Lag pump Standby pump which activates only when lead pump alone cannot efciently provide sufcient

pressure or ow rate.

Lead pump Duty pump which runs continuously until a standby pump is required.

LED Light emitting diode, located on OIP and controller.

OIP Operator Interface Panel.

PID Proportional Integral Derivative; 3 variables required for error control.

PV (Process Signal generated by a sensor which is set up to control the system.

Variable)

Proof timer Minimum time period before controller acknowledges an input; time period for which a signal must

be stable before it is accepted by the controller as a sustained and valid signal.

RTC Real time clock.

Stage To start a lag pump.

SP Set point.

HD Hard Deck.

8

TECHNOFORCE Installation, Operation, and Maintenance

Page 15

4. Installation

4.1 Field connections

4.1.0 Diagrams

Review the wiring diagrams and dimensional drawings before you install and operate the unit.

4.1.1 Electrical precautions

WARNING:

• Prevent electrical shocks. Disconnect the power supply before beginning installation. FAILURE

TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL INJURY,

DEATH AND/OR PROPERTY DAMAGE.

• Each motor must have a properly sized drive. Ground fault protection should be sized properly.

Refer to local electrical codes for sizing and selection.

• Refer to the motor manufacturer’s IOM for specic installation information.

• Motor can start automatically. Keep hands away from output shaft until motor is completely

stopped and input power is removed from the motor control panel. Lockout main power switch

while working near motor shaft.

• The use of motor disconnect switches is acceptable. Consult the factory for proper interlocking

with variable frequency drives.

• Motor control equipment and electronic controls are connected to hazardous line voltages.

When servicing electronic controls, there will be exposed components at or above line potential.

Extreme care should be taken to protect against shock. Stand on an insulating pad and make

it a habit to use only one hand when checking components. Always use accurate test meters

when checking electrical components. Always work with another person in case of an emergency.

Disconnect power when performing maintenance. Be sure equipment is properly grounded. Wear

safety glasses whenever working on electronic control or rotating equipment.

Installation

DANGER:

• Troubleshooting live control panels exposes personnel to hazardous voltages. Electrical

troubleshooting must only be done by a qualied electrician. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL INJURY, DEATH, AND/OR

PROPERTY DAMAGE.

4.2 Earth (ground connections)

WARNING:

• Conduit grounds are not adequate. A separate ground wire must be attached to the ground lug

provided in the enclosure to avoid potential safety hazards. Failure to follow these instructions

could result in serious personal injury or death, property damage.

A grounding terminal is provided for a dedicated earth (ground) wire connection. You must follow all provisions

of the National Electrical Codes and local codes.

4.3 Sensor and control wiring

The following sections are based on the installation of standard TechnoForce product. Because of customized

software and hardware, the installing contractor should base all wiring connections on the wiring diagrams that

accompany each controller. These sections are meant to complement, not replace, those wiring diagrams.

TECHNOFORCE Installation, Operation, and Maintenance

9

Page 16

Differential pressure switches are installed to sense the increase in pressure between the pump suction and

discharge gauge taps and are used to determine whether a pump is running. Each switch should be wired from

the normally closed contact.

To control variable frequency drives it is necessary to wire RS485 with each VFD.

With certain bypass and control methods it is necessary to disable the adjustable frequency drive from running.

This is accomplished by wiring from the terminals to each VFD’s interlock terminals. Should this wiring be

required, any jumpers which may be found on the VFD’s interlock terminals should be removed.

The control family may be provided with the capability to accept many analog inputs. Typically all analog inputs

must be 4-20mA and powered by the 24VDC power supply in the controller. All shields must be grounded in the

controller only to prevent ground loops and improper signals.

Hardwire communications refers to the capability of the Controller to communicate with an energy management

system. Standard communication features are listed below:

Remote Start/Stop – Remove the jumper from Terminal 200 and install a switch as indicated on the wiring

diagram. CLOSED CONTACT of this switch will provide the start signal.

Remote Alarm Indication – A digital output rated 2.5 AMPs at 240V is supplied. This output closes to indicate

an alarm condition exists.

User Congurable I/O – The Controller comes equipped with the capability to dene the operation of any

unused input or output signal. Refer to System Set Up I/O menus.

4.4 Pump package location guidelines

Installation

WARNING:

• Assembled units and their components are heavy. Failure to properly lift and support this equipment can

result in serious physical injury and/or equipment damage. Lift equipment only at the specically identied

lifting points. Lifting devices such as eyebolts, slings, and spreaders must be rated, selected, and used for the

entire load being lifted.

Guideline Explanation

Make sure that the space around the pump This facilitates ventilation, inspection,

package is sufcient. maintenance, and service.

If you require lifting equipment such as hoist or This makes it easier to properly use the lifting

tackle, make sure that there is enough space above equipment and safely remove and relocate the

the pump package. components to a safe location.

Protect the unit from weather and water damage This is applicable if nothing else is specied.

due to rain, ooding, and freezing temperatures.

Do not install and operate the equipment in closed Acceptable devices:

systems unless the system is constructed with • Pressure relief valves

properly-sized safety devices and control devices. • Compression tanks

• Pressure controls

• Temperature controls

• Flow controls

If the system does not include these devices,

consult the engineer or architect in charge before

you operate the pump.

Take into consideration the occurrence of The best pump location for noise and vibration

unwanted noise and vibration. absorption is on a concrete oor with subsoil

underneath.

10

TECHNOFORCE Installation, Operation, and Maintenance

Page 17

4.5 System piping and unit installation – nal checklist

1. Check that the unit base is properly leveled, grouted and secured.

2. Check that all lubrication points are properly lubricated per motor manufacturer’s instructions.

3. Check that the shut-off valves to the transmitters open.

4. Check that the shut-off valves to the pump suction open.

5. Check that the shut-off valves to the discharge line open.

6. Check that the piping is properly supported to prevent strains on the unit.

7. Check that the system, including pumps and valving, are purged of debris and air.

CAUTION:

• Seal damage may occur. Do not run pumps dry. Fill and vent the pump volute prior to operation.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE

AND/OR MODERATE PERSONAL INJURY.

4.6 Electrical wiring and control settings – nal checklist

1. Check the unit nameplate or motor terminal connection to ensure the feeder line voltage

corresponds to the unit voltage

WARNING:

• Electrical shock hazard. Inspect all electrical connections prior to powering the unit. Wiring connections

must be made by a qualied electrician in accordance with all applicable codes, ordinances, and

good practices. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS

PERSONAL INJURY, DEATH, AND/OR PROPERTY DAMAGE.

Installation

2. Check that feeder wires are correctly sized for the load.

3. Check that the fuses are correctly sized. They must not exceed 1.75 times the full load current of

the motor. Usual sizing is 1.15 to 1.5 times the full load current.

DANGER:

• High voltage 3 phase power can kill. Disconnect and lockout power prior to servicing. FAILURE TO

FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING:

• Conduit grounds are not adequate. A separate ground wire must be attached to the ground lug provided in

the enclosure to avoid potential safety hazards. FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS PERSONAL INJURY, DEATH, AND/OR PROPERTY DAMAGE.

4. Check that the unit is properly grounded.

5. Make sure all the power terminals in the control panel have been tightened.

TECHNOFORCE Installation, Operation, and Maintenance

11

Page 18

4.7 Operator interface panel

4.7.0 Diagrams

The OIP consists of a 4 x 20 character LCD screen and a 26 button keypad with LEDs which display system

status.

Installation

4.7.1 Key functionality

The names of the keys on the Operator Interface Panel (OIP) are shown as CAPITAL LETTERS in this

manual. Table 1 shows the functionality of the keys on the OIP.

12

TECHNOFORCE Installation, Operation, and Maintenance

Page 19

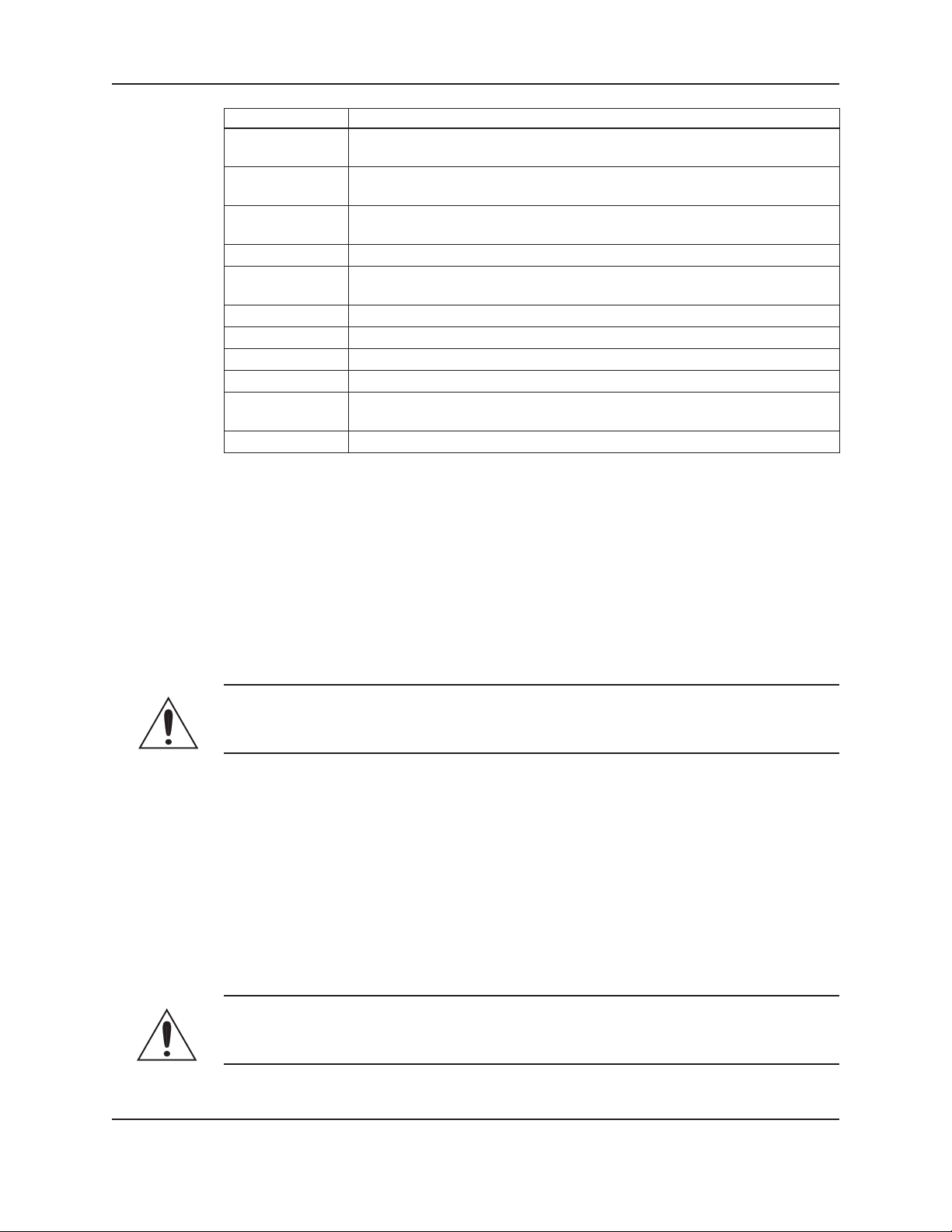

4.7.2 Table 1 Key Functionality

Key Name Functionality

START/STOP Starts or stops the system.

AUTO/ MANUAL Toggles the operation mode. The system must be stopped to change the

operation mode.

PUMP 1-6 ENABLE Enables or disables the corresponding pump. Pumps cannot be disabled

while they are failed.

RESET/ SILENCE This key is used to reset alarms and events. When the A/V Alarm relay

output is set. Pressing of this key resets the alarms and events.

HELP Press the HELP button, from the status screens, to view alarms or events

while the HELP LED is ashing. While in the Alarm screen, press the HELP

button again to view help messages for active alarms. Press HELP any other

time to view screen specic help messages.

PV/1 Press PV from the status screens, to bring up the process variable screen

SETPT/2 Press SET PT from the status screens, to bring up the set point menu shown in

section 5.5

SETUP/3 Press SETUP, from the status screens, to bring up the Setup Menu shown in

section 4.10

ALT/4 Press ALT, from the status screens, to manually alternate the pump staging

sequence.

LOG/5 Press LOG, from the status screens, to bring up the Log Menu, shown in

section 6.14.0

YES/7 Press YES at OK prompts to accept values and proceed

INFO/8 Press INFO, from the status screens, to bring up the program type and version

number shown in section 6.14

NO/0 Press NO at OK prompts to edit the parameters

ENTER Conrms entries

CLEAR Clears entries or used to exit some screens

PREV/( ) Navigates to neighboring screens

NEXT/( ) Navigates to neighboring screens

UP (▲) Used to modify values and navigate to neighboring screens

DOWN (▼) Used to modify values and navigate to neighboring screens

Note: Setting the display contrast.

The Contrast on the display is set at the factory. However, the user can make a different

contrast setting as desired. To do this press “Enter”. while holding down this key, the “UP” and

“DOWN” key can be used to set contrast.

ENTER + UP... increase contrast

ENTER + DOWN... reduce contrast

▲

Installation

▲

TECHNOFORCE Installation, Operation, and Maintenance

13

Page 20

4.8 LEDs

4.9 I/O

4.9.0 Analog Inputs

4.9.1 Digital Inputs

Installation

Table 2 gives the meaning of the LED states.

LED Description

START/STOP On = Start

Off = Stop

AUTO/ MANUAL On = Auto

Off = Manual

PUMP 1-6 On = Pump On

Off = Pump Disabled

Blink = Pump Ready, Blink Fast = Pump Failed

RESET/ SILENCE Off = OK

Blink = Reset Required

HELP Off = OK

Blink = Event/Alarm(press HELP from the status screens to view)

The TechnoForce Pump Controller is equipped with 4 analog input channels. The analog inputs must provide

a 4-20mA signal. Typically, analog inputs will be powered by the 24V power supply within the panel. For analog

inputs which source their own power, consult factory.

Shielded 22 AWG cable should be installed for all analog input wiring. The shield must be terminated in the

TechnoForce Pump Controller. Do not connect the shield at the other end of the cable! Insulate the shield so

that no electrical connection is made at the other end of the cable. A twisted pair of #22 AWG conductors can

be used in place of shielded cable. The cable length must be limited to 2,500 feet for #22 AWG wire.

The TechnoForce Pump Controller is equipped with (12) 24VDC digital input channels. This signal voltage must

be obtained from the 24VDC power supply mounted to the subpanel. It is not recommended that other power

sources be used without factory approval. All digital inputs are automatically assigned based on Table 3. See the

typical wiring diagram in Appendix.

Table 3: Digital Inputs Functionalities

Functionality DI # Description

Start/Stop Sw 1 Remote contact can be used to start/stop the system.

DP 1-6 2-7 Differential pressure switches

Optional DI 8-12 User can select the function of optional input in IO setup, see

section 4.10.17.

# 22 AWG cable should be installed for all eld wiring to digital inputs.

4.9.2 Digital Output Module

The digital output consists of 1 normally open and 1 normally closed contact for each output rated at 2.5A at

240V. Customer connections are made directly to the terminals mounted on the digital output module. Refer to

section 4.10.17 for relay output setup.

14

TECHNOFORCE Installation, Operation, and Maintenance

Page 21

4.10 Set up & features

Note: Many sections of the Set up & Features show a path for navigation. An example is shown below to

understand the given path.

Example for system setup path.

Path: Status Screen / Setup(3) / System(3)

To follow the above path press the SETUP/3 key from the system status screen. Then press the SETUP/3 key

for number 3 which is a selection number for system and press ENTER key. It will lead to the system setup

screen.

Upon powering up the controller, the display will light and show the following screen:

<TECHNOFORCE PUMP>

CONTROLLER

MM/DD/YY HH:MM:SS A/P

STOP MANUAL NORM

The current date and time will be displayed on the third line.

Press the SETUP/3 key once and the following MAIN SET UP menu items will be displayed:

SELECTION: # 0=EXIT

1 = SENSORS 4 = TEST

2 = PUMPS 5 = ALRM/EVT

3 = SYSTEM 6 = Q-START

Installation

4.10.0 Sensor Setup

Press the PV/1 key at the Main Set Up menu display. Then press the ENTER key.

The SENSOR SET UP MENU will be displayed as shown below:

AI 1 TYPE: $$$

SPAN= ### ZERO= ##

< OK $ (Y/N) >

To accept the current values, press YES/7 key and then press the ENTER ke y.

To set up each eld, press the NO/0 key and then press the ENTER key.

The current TYPE eld starts blinking. Press the up (▲) and down (▼) keys to navigate to the desired TYPE

and then press the ENTER key to conrm selection.

The following selections are valid:

SYS (System Pressure)

SUC (Suction Pressure)

RESYS (Redundant System Pressure)

FLOW (System Flow)

PRESS (For Monitor only)

NONE

If RESYS is selected as a desired eld, the following screen will get displayed:

ACTIVE SENSOR ##

DRIFT THRESHOLD ##%

DRIFT PR TM ###s

OK $ (Y/N)

TECHNOFORCE Installation, Operation, and Maintenance

15

Page 22

Installation

RESYS MENU ITEMS

Menu Item Variable Default Range Field

Value

RESYS Active Sensor : ## 1 1-4

Enter the active system pressure sensor number

Drift Threshold: ##% 5 0-100

Pressure difference limit between the active and

redundant pressure sensor in %

Drift Pr Tm : ##s 0 0-999

Proof timer prior to give warning when exceed the

drift threshold limit, in seconds

To set up each eld, press the NO/0 key and then press the ENTER key.

The ACTIVE SENSOR eld will start blinking. Change the current value in Active Sensor eld by pressing

desired numeric Keys and then press ENTER key to conrm.

Press ENTER key to accept the current DRIFT THRESHOLD value. To change the value in DRIFT

THRESHOLD eld, press the desired Numeric Keys and then press ENTER to conrm.

Press ENTER key to accept the current value of DRIFT PR TM. To change the value in DRIFT PR TM

eld press the desired Numeric Keys and then press ENTER to conrm.

To accept the current values, press YES/7 key and then press ENTER key. The screen will go back to the

SENSOR SET UP menu displayed above.

Press the NEXT/( ) key if additional sensors need to be set up. Repeat the above steps for all remaining

sensors.

Pressing YES/7 key and then the ENTER key at the SENSOR SET UP screen will take the display back to

the MAIN SET UP screen.

▲

4.10.1 Pump set up

Paths: Status Screens / Set up(3)

Press the SET PT/2 key at the Main Set Up menu screen. Then press the ENTER key.

The PUMP SET UP MENU will get displayed as shown below:

SELECTION: # 0= EXIT

1 = NUMBER OF PUMPS

2 = PUMP NAMEPLATE

3 = RESET PUMP TIME

To change the values in NUMBER OF PUMPS eld, press PV/1 key then press the ENTER key. The

following menu will get displayed:

TOTAL PUMPS: #

STANDBY PUMPS: #

OK $ (Y/N)

To set up each eld, press the NO/0 key and ENTER key. Modify the values as desired using the appropriate

numeric key. The pump number is limited to the maximum number of pumps.

To accept the current values, press YES/7 key and then press ENTER ke y.

The screen will go back to the PUMP SET UP MENU display.

To change the values in PUMP NAMEPLATE eld, press SET PT/2 key then press the ENTER key. The

following menu will get displayed:

<PUMP 1 NAMEPLATE>

AMPS: ###.# HP: ###.#

VOLTS: ### Hz: ##

Spd: #### OK $ (Y/N)

16

TECHNOFORCE Installation, Operation, and Maintenance

Page 23

Installation

To set up each eld, press the NO/0 key and ENTER key. Modify the values as desired using the appropriate

keys. Modify the values as desired for pump 1.

Note: For example, to enter a value of 3.5 Amps, go to the amps eld, press numerical key 3 and

press enter. Then press key 5 and enter.

To change the values for other pumps, press the NEXT/( ) key. This is only applicable if the total numbers of

pumps selected in TOTAL PUMPS: # eld are more than 1.

Note:

All values will be copied to the next screen by pressing NEXT/( ) key. They will only be copied the rst time

the screens are visited. To edit the values, press the NO/0 key and ENTER key. Modify the values as desired.

To conrm the modied values, press YES/7 key and then press ENTER ke y.

The screen will go back to the PUMP SET UP MENU display.

To change the values in RESET PUMP TIME eld, press the SETUP/3 key then press the ENTER key. The

following menu will get displayed:

RESET PUMP TIME?

P1: N P2: N P3: N

P4: N P5: N P6: N

OK $ (Y/N)

To reset the pump(s) run time, press NO/0 key and ENTER.

By default, N will be displayed next to the pump elds (P1: , P2: etc.) depending upon number of pumps

selected. N corresponding to P1: eld will start blinking. To reset the pump run time for pump 1, press the

YES/7 key and ENTER. Similarly modify the values for the rest of the pumps as applicable.

Note: This selection is only valid for the pumps selected. For example, if the number of pumps selected is 2, the

following screen will get displayed:

RESET PUMP TIME?

P1: N P2: N P3: N/A

P4: N/A P5: N/A P6: N/A

OK N (Y/N)

To conrm all the selections made, press YES/7 key and then press ENTER key. The screen will go back to the

PUMP SET UP MENU display.

Pressing the NO/0 key and then ENTER key at the PUMP SET UP screen will take the display back to the

MAIN SET UP screen.

▲

▲

4.10.2 System set up

Paths: Status Screens / Set up(3)

Press the SETUP/3 key at the Main Set Up menu screen. Then press the ENTER ke y.

The rst screen will get displayed as shown below:

< SELECTION: # >

1 = STAGE/DESTAGE

2 = VFD

3 = EXERCISE 0 = EXIT

Press the NEXT/( ) key to go to the next screen. The display now shows:

< SELECTION: # >

4 = ALTERNATION 5=PID

6 = RESET TOTALS

7 = DATE, TIME 0 = EXIT

Press the NEXT/( ) key to go to the next screen. The display now shows:

< SELECTION: # >

8 = PASSWORD 0 = EXIT

TECHNOFORCE Installation, Operation, and Maintenance

▲

▲

17

Page 24

9 = I/O SETUP

10 =COMMUNICATIONS

Press the NEXT/( ) key to go to the next screen. The display now shows:

< SELECTION: # >

11 = SPECIAL FUNCTIONS

12 = SAVE/LOAD

13 = DISPLAY 0 = EXIT

Pressing the NEXT/( ) key again will take the screen back to the rst screen.

Use the appropriate numeric key to select the desired menu, then press the ENTER key. A detailed description

of each menu follows. For example, to select the STAGE/DESTAGE menu, press the PV/1 key and then press

the ENTER ke y.

4.10.3 Stage/ destage menu

Paths: Status Screens / Set up(3) / System(3) / StageDestage(1)

The rst screen has been displayed below:

< SELECTION: # >

1 = PV STAGE 0=EXIT

2 = PV DESTAGE

3 = EOC STAGE

Press the NEXT/( ) key to go to the next screen.

The display now shows:

< SELECTION: # >

4=EOC DESTAGE 0=EXIT

5=FLOW DESTAGE

6=POWER LIMIT STAGE

By pressing the appropriate numeric key and ENTER key, the setup can be completed.

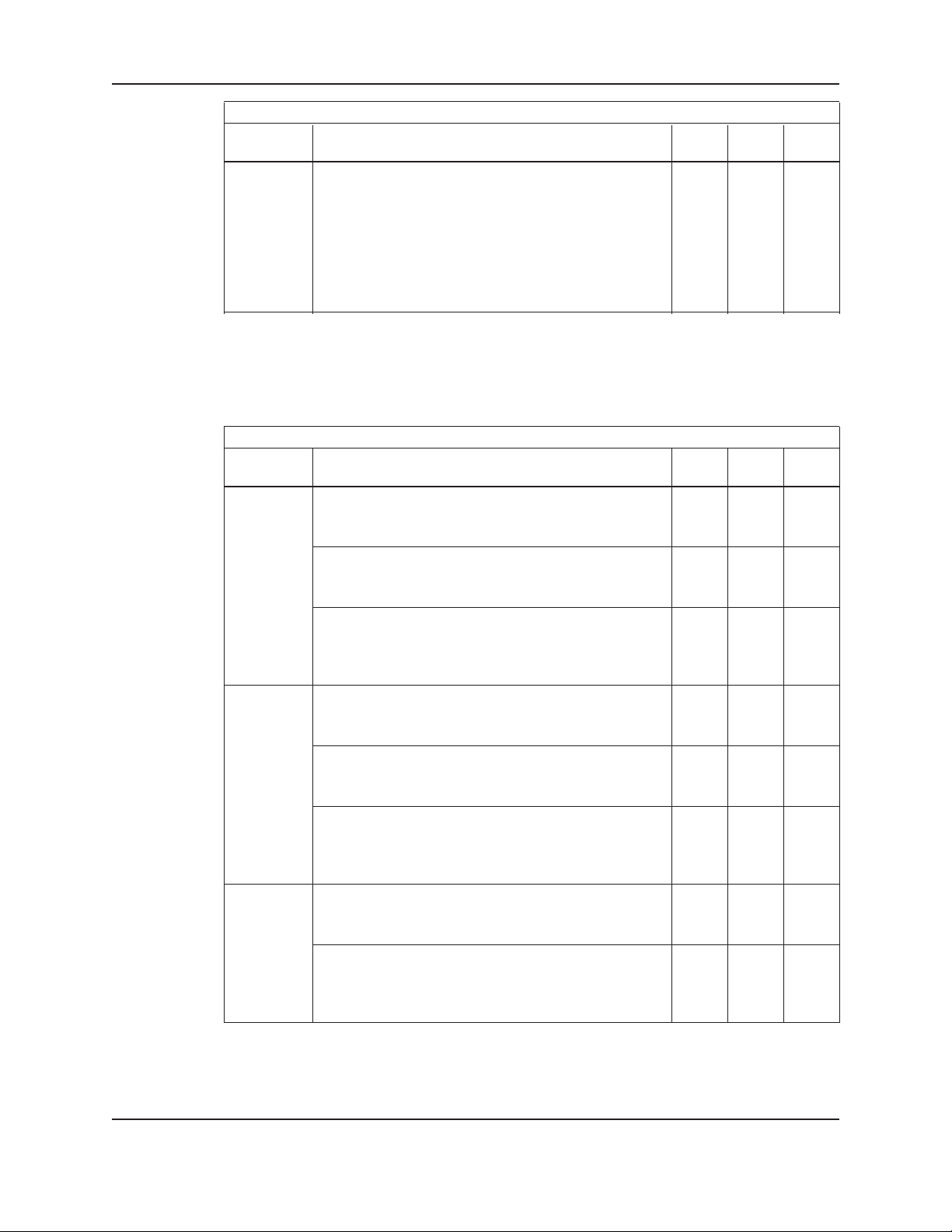

See the following table for all STAGE/DESTAGE menu items.

Menu Item Variable Default Range Field

Value

PV Stage Stg Spd: ##% 95 0-100

The maximum speed at which the lead pump will

operate prior to starting a lag pump, %.

Stg Proof Timer: ### s 30 0-999

Proof timer prior to starting lag pump, seconds.

Stab Timer: ###s 60 0-999

Staging stabilization time, delay prior to calculating

destage value, seconds.

▲

▲

▲

STAGE/DESTAGE SETUP MENU ITEMS

Installation

18

TECHNOFORCE Installation, Operation, and Maintenance

Page 25

Installation

STAGE/DESTAGE SETUP MENU ITEMS (continued)

Menu Item Variable Default Range Field

Value

PV Destage Destage: ###% 85 0-100

Enter the percentage of the stabilized speed at which

the lag pump will stop, %.

Destg Pr Timer: ### s 30 0-999

Proof timer prior to stopping lag pump, seconds.

HD Spd: ### % 50 0-100

The lowest speed at which parallel pumps will operate

prior to destaging the lag pump, %. It must be

greater or equal to minimum frequency.

HD Pr Tm: ### s 30 0-999

The proof timer prior to destaging the lag pump when

operating below the HD speed, seconds.

EOC Stage Pump Max Flow: ##### 0 0-65,

(Flow meter The maximum allowable ow in GPM prior to starting a

required) lag pump. A value of 0 disables this function.

Stg Proof Tm: ###s 30 0-999

Proof timer prior to end of curve staging, seconds.

EOC Destage Destage Flow: ### % 45 0-100

(Flow meter Enter the percent of stabilized ow at which the lag

required) pump is destaged, %.

Destage Pr TM: ###s 30 0-999

Proof timer prior to destaging lag pump, seconds.

Flow DeStage Flow Destage: #####GPM 0 0-65,

The total ow above which the lag pump will be

forced to destage. A value of “0” disables this function

De-Stage Pr Tm: ###s 30 0-999

Proof timer prior to Flow destaging lag pump in seconds

Force Destg Tmr: ###m 0 0-999

The time after which the lag pump will be forced

to destage. A value of “0” disables this function

Power Limit Enable Power Stage N Y/N

Stage Limit $ (Y/N)

Exit: $(Y/N)

Reads motor current entered in pump set up to stage on

next pump after a xed time delay should current limit

be reached.

535

535

4.10.4 VFD menu

Paths: Status Screens / Set up(3) / System(3) / VFD(2)

The rst screen has been displayed below:

<Selection:# >

1 = VFD Setup

2 = VFD Set Parameter

3 = VFD Read Parameter

Press the NEXT ( ) key to go to the next screen.

The display now shows:

<Selection: # >

4 = All SYS SEN Fail

TECHNOFORCE Installation, Operation, and Maintenance

▲

19

Page 26

Installation

Use the appropriate numeric key to select the desired menu, then press the ENTER key. See the following table

for all VFD menu items.

VFD Menu Items

Menu Item Variable Default Range Field

Value

VFD Setup Accel Tm: ## 5 0-1800

Drive acceleration time in seconds from zero to

maximum frequency ramp

Decel Tm: ## 5 0-1800

Drive acceleration time in seconds from maximum to

zero to maximum frequency ramp

Freq Max : ## 60 0-60

Enter the maximum limit for the drive output frequency

Freq Min : 30

Enter the minimum limit for the drive output frequency

VFD Set VFD: # 0 0-65,

Parameter The VFD number in which the parameter needs to be set. 535

ADDRESS:

Enter the parameter code from the parameter list

available in the ABB user’s manual supplied.

RESOLUTION: #

Enter the value of parameter “Resolution” from the

parameter list available in the ABB user’s

manual supplied.

VALUE:

Enter the desired parameter value.

VFD Read VFD: # 0 0-65,

Parameter The VFD number from which the parameter needs

to be read.

ADDRESS:

Enter the parameter code from the parameter list

available in the ABB user’s manual supplied.

RESOLUTION: #

Enter the resolution from the parameter list available

in the ABB user’s manual supplied.

OFFSET:

Enter the lower limit of the parameter “Range” from

the parameter list available in the ABB user’s

manual supplied.

READ:

Press YES/7 key and ENTER key to read the

parameter values

All Sys Sen PUMP SPEED: 100 0-100

Fail Enter the % speed for the drive(s) to operate at in the

event that all system sensor fail.

NO OF PUMP RUN: 1 1-6

Enter the number of pumps that should operate at the

above speed in the event that all system sensor fail.

535

20

TECHNOFORCE Installation, Operation, and Maintenance

Page 27

Note:

1. Use the (▲) and (▼) keys to select the appropriate resolution values

2. Use the Next/( ) key and Prev/( ) key to select the desired sign(+ or -) for VALUE and OFFSET

variables

4.10.5 Exercise menu

Paths: Status Screens / Set up(3) / System(3) / Exercise(3)

See the following table for all EXERCISE menu items.

Menu Item Variable Default Range Field

Value

EXERCISE Period : #Hrs 0 0-999

Amount of time between automatic exercising of the

pumps, in seconds. A value of 0 disables pump exercising

Duration : ###s 0 0-999

Amount of time pumps will be exercised, all pumps

which have not run in the last period will be exercised

simultaneously

Pump exercising will ensure that no pumps go for long periods of time without running. Note that automatic

alternation can also provide this functionality. Pump exercising will only occur when the system is started and in

automatic operation. All pumps which need exercising will exercise on startup.

▲

▲

Exercise Menu Items

Installation

4.10.6 Alternation menu

Paths: Status Screens / Set up(3) / System(3) / Alternation(4)

The following ALTERNATION menu options are available:

4.10.7 Timed auto alternation

See the following table for TIMED AUTO ALTERNATION menu items.

Timed Auto Alternation Menu Items

Menu Item Variable Default Range Field

Value

Timed Auto Period: #Hrs 168 0-999

Alt Time between pump alternations when using “Timed

Auto Alternation”, in hours. A value of 0 will disable

this function

Duration: ###s 10 0-99

Amount of time that the running pumps will remain on

during alternation, in seconds

4.10.8 Scheduled auto alternation menu

See the following table for SCHEDULED AUTO ALTERNATION menu items.

Scheduled Auto Alternation Menu Items

Menu Item Variable Default Range Field

Value

Scheduled Scheduled Alt: 0 0-3

Auto Alt Pump alternates based on the “Period” selected -

Daily: alternates daily based on the “Time”;

Weekly: alternates weekly based on the “Day” and

“Time”;

Monthly: alternates monthly based on the “Day” and

“Time”.

Note: At any time, only one of the 3 period based variables can be enabled.

TECHNOFORCE Installation, Operation, and Maintenance

21

Page 28

4.10.9 Daily alternation

The Daily Alternation screen is displayed below:

Daily

Alt. Time: HH:MM

Enable: $ (Y/N)

OK? $(Y/N)

To edit the alternation time, press the NO/0 key and ENTER key. Modify the values as desired.

Enter the Alternation Time in 24Hr format (range being 0:00-23:59) at which pumps will alternate daily. Press

YES/7 key to enable Daily alternation. Press the YES/7 key again to conrm the selection.

4.10.10 Weekly alternation

The Weekly Alternation screen is displayed below:

Alt. Day of week: #

1=Mon...7=Sun

Time HH:MM (0-23)

Enable: $(Y/N)

OK? $(Y/N)

To edit the displayed values, press the NO/0 key and ENTER key. Modify the values as desired.

Enter the Alternation Day of Week (1= Monday…….7=Sunday) on which the pumps will be alternated.

Enter the Alternation Time in 24Hr format (range being 0:00-23:59).

Press YES/7 key to enable Monthly alternation. Press the YES/7 key again to conrm the selection.

Installation

4.10.11 Monthly alternation

The Monthly Alternation screen is displayed below:

Alt. Day of Month: #

(1-31)

Time HH:MM (0-23)

Enable: $(Y/N) OK? $(Y/N)

To edit the displayed values, press the NO/0 key and ENTER key. Modify the values as desired.

Enter the Alternation Day of Month (1, 2, 3, 4….31 etc.) on which the pumps will be alternated.

Enter the Alternation Time in 24Hr format (range being 0:00-23:59).

Press YES/7 key to enable Monthly alternation. Press the YES/7 key again to conrm the selection.

If 29,30 or 31 is entered as the day, the sequence will automatically alternate on the last day of the month.

Note:

In case Timed Auto Alt is in enabled state and Scheduled Auto Alt also gets enabled, Timed Auto Alt will get

disabled and a warning message “Timed Alteration will be disabled” will be displayed on the screen. Press

CLEAR key to go back to the ALTERNATION menu.

22

TECHNOFORCE Installation, Operation, and Maintenance

Page 29

4.10.12 Alternation basis

See the following table for ALTERNATION BASIS menu items.

Menu Item Variable Default Range Field

Value

Alternation 1=Pump Sequence 1 1-2

Basis (The next pump in sequence will become the lead pump

after alternation)

2=Pump Run Time

(The pump with the lowest run time will become the

lead pump after alternation)

4.10.13 PID menu

Paths: Status Screens / Set up(3) / System(3) / PID(5)

See the following table for all PID menu items.

Menu Item Variable Default Range Field

Value

PID PID-P ### 300 0-999

Enter the desired proportional value.

PID-I ### 1 0-999

Enter the desired integral value.

PID-D ### 15 0-999

Enter the desired derivative value.

SP Deviation ### 0 0-999

Enter the value for the number of PV units at which a

dead band will be created around the setpoint. The PID

will be modied within the dead band per the index

setting below.

Index ### 0 0-999

Enter a value to buffer the response of the PID while

operating in the dead band dened above.

Index = 1 (no impact)

Index = 999 (maximum buffer.)

Start Up ## 5 0-60

Start up delay in seconds

Installation

Alternation Basis Menu Items

PID Menu Items

4.10.14 Reset totals menu

Paths: Status Screens / Set up(3) / System(3) / Reset Totals(6)

See the following table for all RESET TOTALS menu items

Reset Totals Menu Items

Menu Item Variable Default Range Field

Value

RESET RESET TOTAL KW-HRS $ N Y or N

TOTALS Press YES/7 key and ENTER key to reset the total

KW-HRS

RESET TOTAL FLOW $ N Y or N

Press YES/7 key and ENTER key to reset the total Flow

TECHNOFORCE Installation, Operation, and Maintenance

23

Page 30

4.10.15 Date, time menu

Paths: Status Screens / Set up(3) / System(3) / Date, Time(7)

See the following table for all DATE, TIME menu items

Date, time Menu Items

Menu Item Variable Default Range Field

Value

Date/Time MM

Enter the current month using both digits,

example Jan. should be entered as 01.

DD

Enter the current date using both digits, example

the 6th should be entered as 06.

YYYY

Enter the current year using all 4 digits.

HH

Enter the hours using the 24 hour format,

example 9:00 p.m. should be entered as 21.

MM

Enter the minutes using both digits.

Display 24 Hour Fmt: ? (Y/N) N Y or N

Press YES/7 key and ENTER key to display the

time in the 24 hour format. Press NO/0 key and

ENTER key to display the time in

AM/PM format.

Daylite Savings Tm: ?(Y/N) N Y or N