Page 1

INSTRUCTION MANUAL

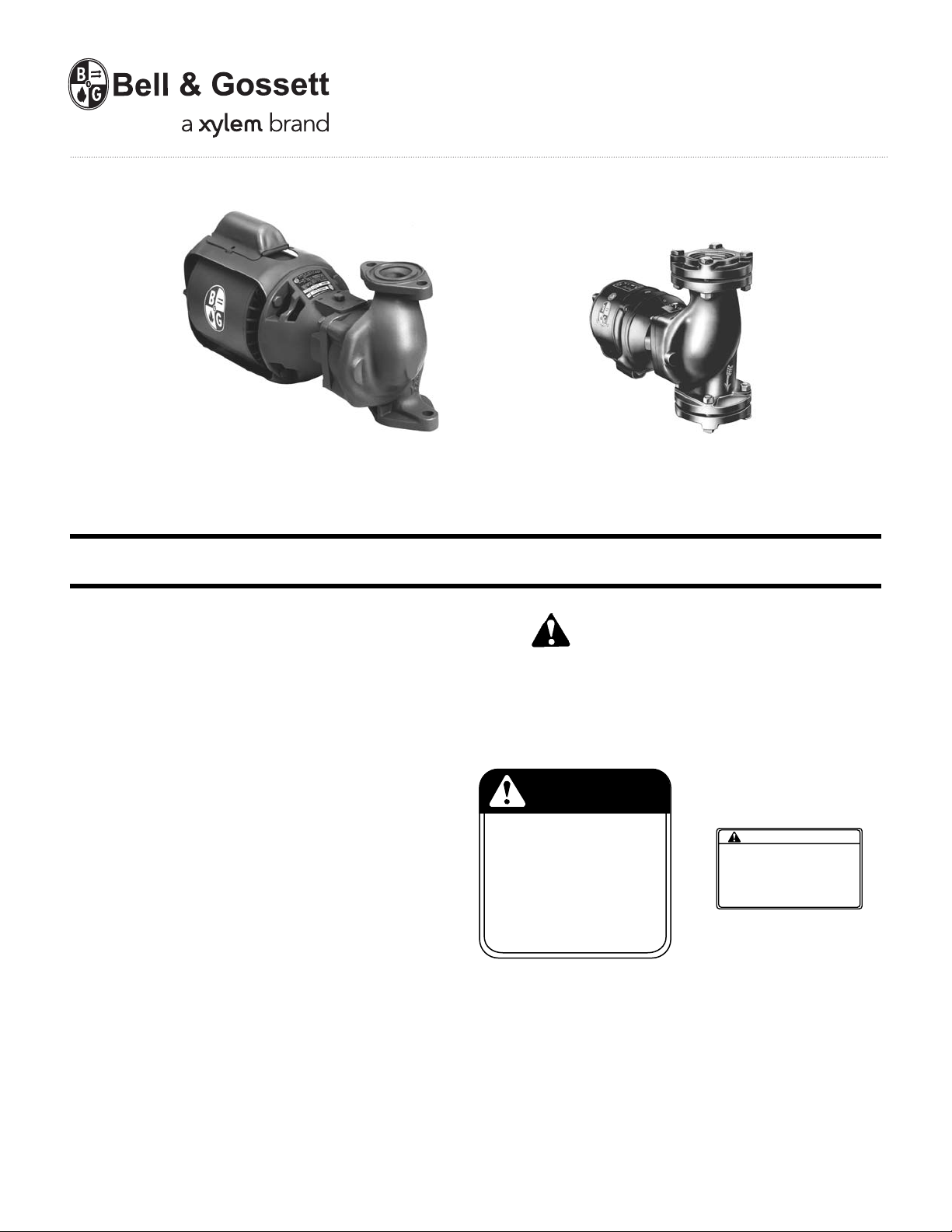

Series 100

Series HV

Series PR

Series 2"

Iron & Bronze Booster Pumps

P81748G

INSTALLER:

PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

DESCRIPTION

Bell & Gossett Booster Pumps feature oil lubricated sleeve

bearings, a carbon/ceramic seal and a noise dampening spring

coupler. Bell & Gossett Booster Pump motors are designed

specifically for quiet operation and are built with thermal protection and drip-proof construction. The motor is nonover-loading at any point on the pump curve.

This pump is nonsubmersible, for indoor use only.

PUMP APPLICATION

Bell & Gossett Pumps may be used for water circulating applications in hydronic, solar and chilled water systems. Bell &

Gossett recommends that bronze constructed pumps be used

for pumping potable water. For other applications contact your

local Bell & Gossett Representative. Note that some local

codes require using a check valve in the supply line when recirculating potable water.

It has not been investigated, nor is it intended for use in swimming pool and marine areas.

OPERATIONAL LIMITS

These pumps are designed to pump liquids compatible with

their iron or bronze body construction. Unless special provisions have been made by ITT Bell & Gossett, the operational

limits for Series 100, HV, PR and 2" Pumps are listed below.

Do not exceed these values.

Maximum Working Pressure: 125 psi

Maximum Operating Temperature: 225ºF

Electrical Rating: 115V, 60 Hz, 1PH

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on the

pump instructions decal to draw attention to safety related

instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THE INSTRUCTIONS MAY RESULT IN

A SAFETY HAZARD.

WARNING

BEFORE INSTALLING, USING OR

SERVICING THIS PRODUCT,

READ THE WARNING NOTES

AND INSTRUCTIONS IN

INSTRUCTION MANUAL.

FAILURE TO DO SO MAY

RESULT IN SERIOUS INJURY

OR PROPERTY DAMAGE

V56845

Your Booster Pump should have these warning labels affixed

near the conduit box cover. If these warnings are missing or

illegible, contact your local Bell & Gossett Representative for

replacement labels.

WARNING

RISK OF ELECTRIC SHOCK;

THIS PUMP HAS NOT

BEEN INVESTIGATED FOR

USE IN SWIMMING POOL

AND MARINE AREAS.

-NONSUBMERSIBLE PUMP-

P86313

Motors with special electrical characteristics are available on

request. Contact your local Bell & Gossett Representative for

details.

Page 2

Page 3

Page 4

WIRING INSTRUCTIONS

OPERATIONAL INSTRUCTIONS

WARNING: ELECTRICAL SHOCK HAZARD

Disconnect and lockout the power before making

electrical connections. Failure to follow these instructions

could result in serious personal injury or death.

1. Remove the screws securing the conduit box cover (wiring

compartment) and lift off the cover. Attach the appropriate

size connector to the hole in the side of the conduit box.

2. Using a minimum size 14 AWG copper electrical wire (refer

to your local code for wiring restrictions), wire the motor to

a 115 volt, 60 hertz, single phase power source.

TYPICAL WIRING INSTALLATION SCHEMATIC

POWER SOURCE: 115 VOLT, 60 HZ, 10

FUSIBLE DISCONNECT

OR CIRCUIT BREAKER

BY OTHERS

TO REMOTE

CONTROL

IF REQUIRED

L

PUMP

MOTOR

N

PUMP MOTOR

THERMALLY

PROTECTED

3. Connect the ground wire to the green screw inside the

conduit box.

NOTE: Single phase motors are protected with inherent overheating devices and do not require external overload protection.

NOTE: If a motor with special characteristics is selected, the

electrical rating of the power source must be the same as that

of the motor.

WARNING: ELECTRICAL SHOCK HAZARD

Be certain that all connections are secure and the

conduit box cover is closed before electrical power is connected. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

SYSTEM PREPARATION

1

Prior to pump start up, closed heating and cooling systems

should be flushed with clean water and drained. The system

should then be filled with clean water having a PH between 7

and 9.

LUBRICATION1

Although the new B&G pumps are test run at the factory, they

must be lubricated thoroughly before being placed in operation. Bell & Gossett supplies a high quality lubricant specifically for this purpose which can be purchased from any B&G

Representative (Part No. L23401). Proper lubrication procedurs are as follows:

1. PUMP BEARINGS – Fill the bearing frame according to the

oiling instructions decal. At the time of installation, add

approximately 1 oz. of B&G #20 weight non-detergent oil.

An SAE 20 (non-detergent) or 10W-30 oil may be substituted.

Re-lubrication is required at the start of each heating season, or every three months for continuous service. Relubricate with 1 teaspoon of oil. More frequent lubrication

may be required under adverse conditions such as high

ambient temperatures. Less frequent lubrication is required

if oil overflows from the reservoir.

2. MOTOR BEARINGS – Lubricate through the two motor oil

cups according to the lubrication decal. At the time of

installation the motor bearings use approx. 12 drops each.

At re-lubrication intervals fill each motor bearing with

approx. 6-8 drops. More or less frequent re-lubrication

may be required depending on the installation conditions.

NOTE: Over-oiling can cause motor mount deterioration and

may cause spillage onto surrounding surfaces. Deteriorated

motor mounts will lead to misalignment and excessive coupler

wear.

CAUTION: SEAL DAMAGE HAZARD

Do not run the pump dry – seal damage may occur.

Failure to follow these instructions could result in moderate

personal injury and/or property damage.

PRIMING AND STARTING

Do not run B&G circulator pumps dry. Before starting, the

pump must be filled with water. Air should be vented from the

system by means of a system air vent or by an alternate method.

SERVICE INSTRUCTIONS

1. Keep the pump and motor properly lubricated.

2. If the system is to be exposed to freezing temperatures,

drain the pump.

PERIODIC INSPECTION

Inspect the pump regularly for leaking seals, worn gaskets,

and loose or damaged components. Replace or repair as

required.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. P81748G January 2013

ADDITIONAL PUMP REPAIR

Refer to the following manuals for additional repair instructions for Bell & Gossett Iron & Bronze Booster Pumps:

Coupler & Motor Mount Replacement . . . . . .#S15900, Rev. D

Booster Pump Service Manual . . . . . . . .#HS-105-SM, Rev. 3

Loading...

Loading...