Bell 501-259-101 Service Manual

BELLSYSTEM PRACTICES SECTION 501-259-101

AT&TCo Standard Issue 9, June 1979

P-TYPE RINGERS

IDENTIFICATION AND MAINTENANCE

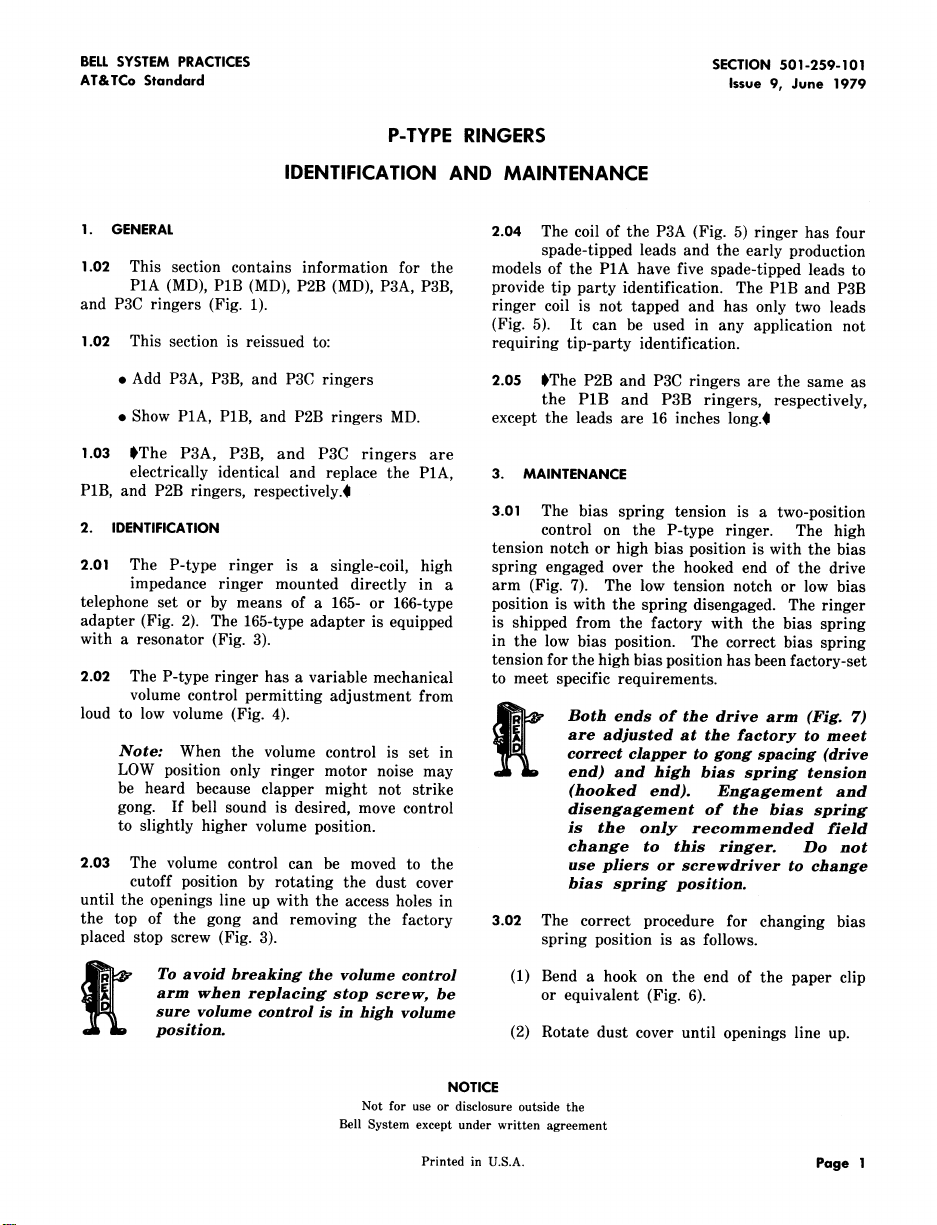

1. GENERAL 2.04 The coil of the P3A (Fig. 5) ringer has four

1.02 This section contains information for the models of the P1A have five spade-tipped leads to

P1A (MD), P1B (MD), P2B (MD), P3A, P3B, provide tip party identification. The P1B and P3B

and P3C ringers (Fig. 1). ringer coil is not tapped and has only two leads

1.02 This section is reissued to: requiring tip-party identification.

. Add P3A, P3B, and P3C ringers 2.05 SThe P2B and P3C ringers are the same as

. Show P1A, P1B, and P2B ringers MD. except the leads are 16 inches long.i

1.03 SThe P3A, P3B, and P3C ringers are

electrically identical and replace the P1A, 3. MAINTENANCE

P1B, and P2B ringers, respectively.0

2. IDENTIFICATION control on the P-type ringer. The high

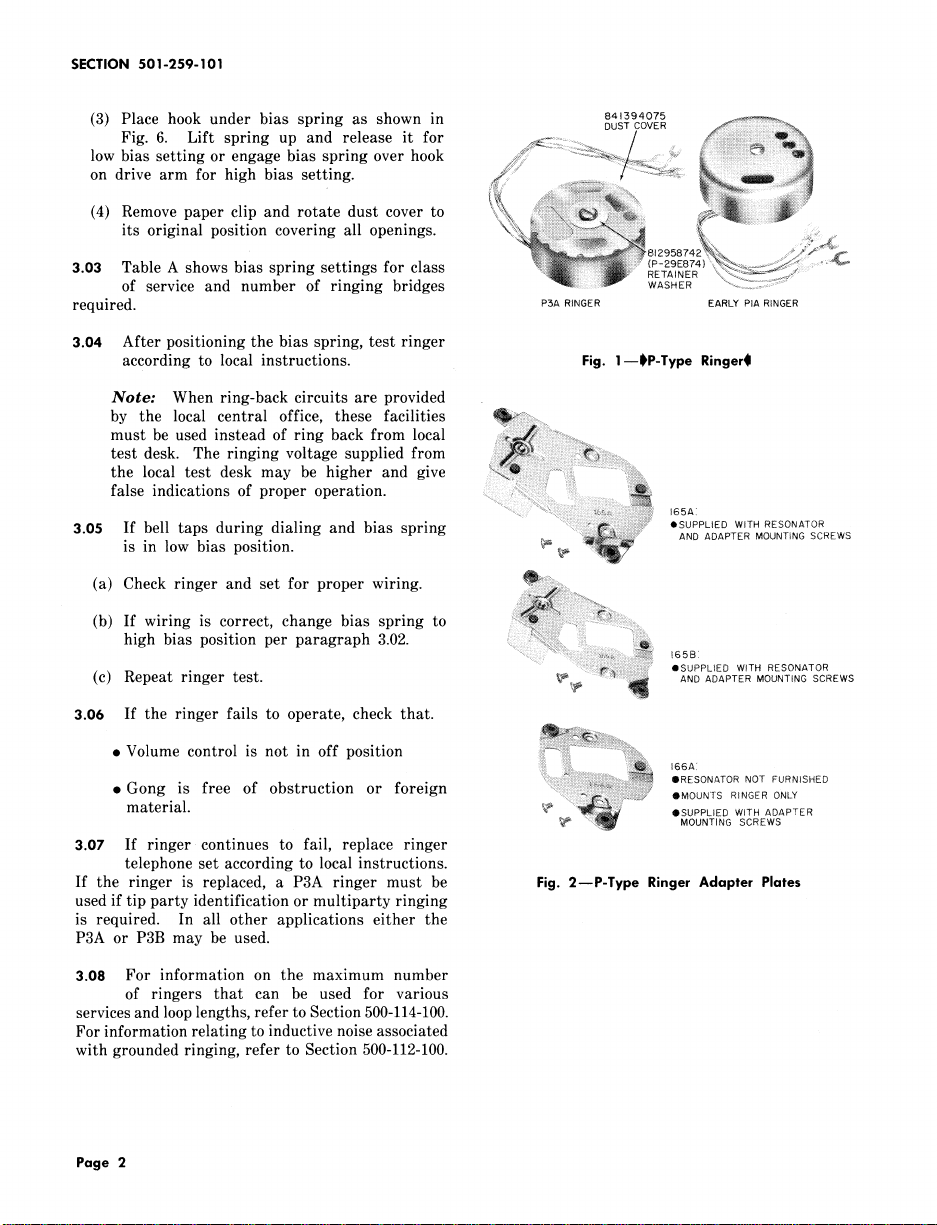

2.01 The P-type ringer is a single-coil, high spring engaged over the hooked end of the drive

impedance ringer mounted directly in a arm (Fig. 7). The low tension notch or low bias

telephone set or by means of a 165- or 166-type position is with the spring disengaged. The ringer

adapter (Fig. 2). The 165-type adapter is equipped is shipped from the factory with the bias spring

with a resonator (Fig. 3). in the low bias position. The correct bias spring

2.02 The P-type ringer has a variable mechanical to meet specific requirements.

volume control permitting adjustment from

loud to low volume (Fig. 4). _ Both ends of the drive arm (Fig. 7)

Note: When the volume control is set in correct clapper to gong spacing (drive

LOW position only ringer motor noise may end) and high bias spring tension

be heard because clapper might not strike (hooked end). EngaKement and

gong. If bell sound is desired, move control disenKaKement of the bias sprinK

to slightly higher volume position, is the only recommended field

2.03 The volume control can be moved to the use pliers or screwdriver to change

cutoff position by rotating the dust cover bias spring position.

until the openings line up with the access holes in

the top of the gong and removing the factory 3.02 The correct procedure for changing bias

placed stop screw (Fig. 3). spring position is as follows.

spade-tipped leads and the early production

(Fig. 5). It can be used in any application not

the P1B and P3B ringers, respectively,

3.01 The bias spring tension is a two-position

tension notch or high bias position is with the bias

tension for the high bias position has been factory-set

are adjusted at the factory to meet

change to this ringer. Do not

arm when replacinK stop screw, be or equivalent (Fig. 6).

sure volume control is in high volume

To avoid breaking the volume control (1) Bend a hook on the end of the paper clip

position. (2) Rotate dust cover until openings line up.

NOTICE

Not for use or disclosure outside the

Bell System except under written agreement

Printed in U.S.A. Page I

SECTION 501-259-101

(3) Place hook under bias spring as shown in 841394o75 _ .....

DUST COVER

Fig. 6. Lift spring up and release it for _ ............ / Si:_ii:_:_:_'_'_::::_:::__,

low bias settingor engage bias spring over hook _ ::_>_ : :_

on drive arm for high bias setting. (_i_ _i_ii_ ::: _

its original position covering all openings. _!!i if? ii:i:_ iNi!ii'::'::i.........

(4) Remove paper clip and rotate dust cover to _'_i!)_})..?_iii::__ _i:i_ :_ !i_i%, ......................._::,:_#;;_

3.03 Table A shows bias spring settings for class %if!i _ iii;i_!_i_:?ii;i:_ii::::_:iii!!::RETAINER(P-29E874):"ii_'___[_/_:::_:_:_:;: ...........',:_

of service and number of ringing bridges _ .... _" WASHER ==========================......

_._4,_:::':::::18I295874

required. P3A RINGER EARLY PIA RINGER

3.04 After positioning the bias spring, test ringer

according to local instructions. Fig. 1--1_P-Type Ringer_l

Note: When ring-back circuits are provided

by the local central office, these facilities _iiiii_i:,i::..........

must be used instead of ring back from local _!_: :i:::

test desk. The ringing voltage supplied from _il..... i i i_!!!iii!i!!!iii_....................

the local test desk may be higher and give ....:::i_ ....{:'i_i_::_,

false indications of proper operation.

3.05 If bell taps during dialing and bias spring .......... 165A:

• SUPPLIED WITH RESONATOR

is in low bias position. _'_ __ ANDADAPTERMOUNTINGSCREWS

(a) Check ringer and set for proper wiring. :_i i!;_:.........

_i_ !:.iiii:_.......

(b) If wiring is correct, change bias spring to .......

i!_:_.

high bias position per paragraph 3.02. i_iii!!_il;i

(c) Repeat ringer test. _p ANDADAPTERMOUNTINGSCREWS

................ i_ii _ii_ _s:

i ,SUPPLIED WITH RESONATOR

3.06 If the ringer fails to operate, check that.

• Gong is free of obstruction or foreign ii:_i_iiiiiiiii::i!i!iii_ii_':ii',:_i;i_!iiiiiii_::_............ IIRESONATORNOTFURNISHED

material. _ ,SUPPLIED WITH ADAPTER

.......: _::_::_i_[iiiiiiiiiiiiiiiiiiiiiiiii!_!!ii_i?___ $MOUN'_SR_NGERONLY

''::::!_ MOUNTING SCREWS

3.07 If ringer continues to fail, replace ringer

telephone set according to local instructions.

If the ringer is replaced, a P3A ringer must be Fig. 2--P-Type Ringer Adapter Plates

used if tip party identification or multiparty ringing

is required. In all other applications either the

P3A or P3B may be used.

3.08 For information on the maximum number

of ringers that can be used for various

services and loop lengths, refer to Section 500-114-100.

For information relating to inductive noise associated

with grounded ringing, refer to Section 500-112-100.

Page 2

Loading...

Loading...