Bell 501-250-303 Service Manual

BELLSYSTEM PRACTICES SECTION 501-250-303

AT&TCo Standard Issue 4, September 1978

RINGERS--C-TYPE

MAINTENANCE

1. GENERAL 1.04 Development of network-type wall telephone

1.01 This section contains procedures, methods, it necessary to change the frame of C4A ringer.

and requirements recommended for maintenance This change provides clearance for volume-adjusting

of C-type ringers, arm.

1.02 This section is reissued to: 1.05 $The C4B ringer is the same as the C4A

• Update Fig. 1, 2, and 3 to show latest the slate and slate-red leads have been eliminated.

version of C4A ringer

• Add information on C4B, C5A, and CSB replacement for the C4A in all locations

ringers where tip party identification is not required.

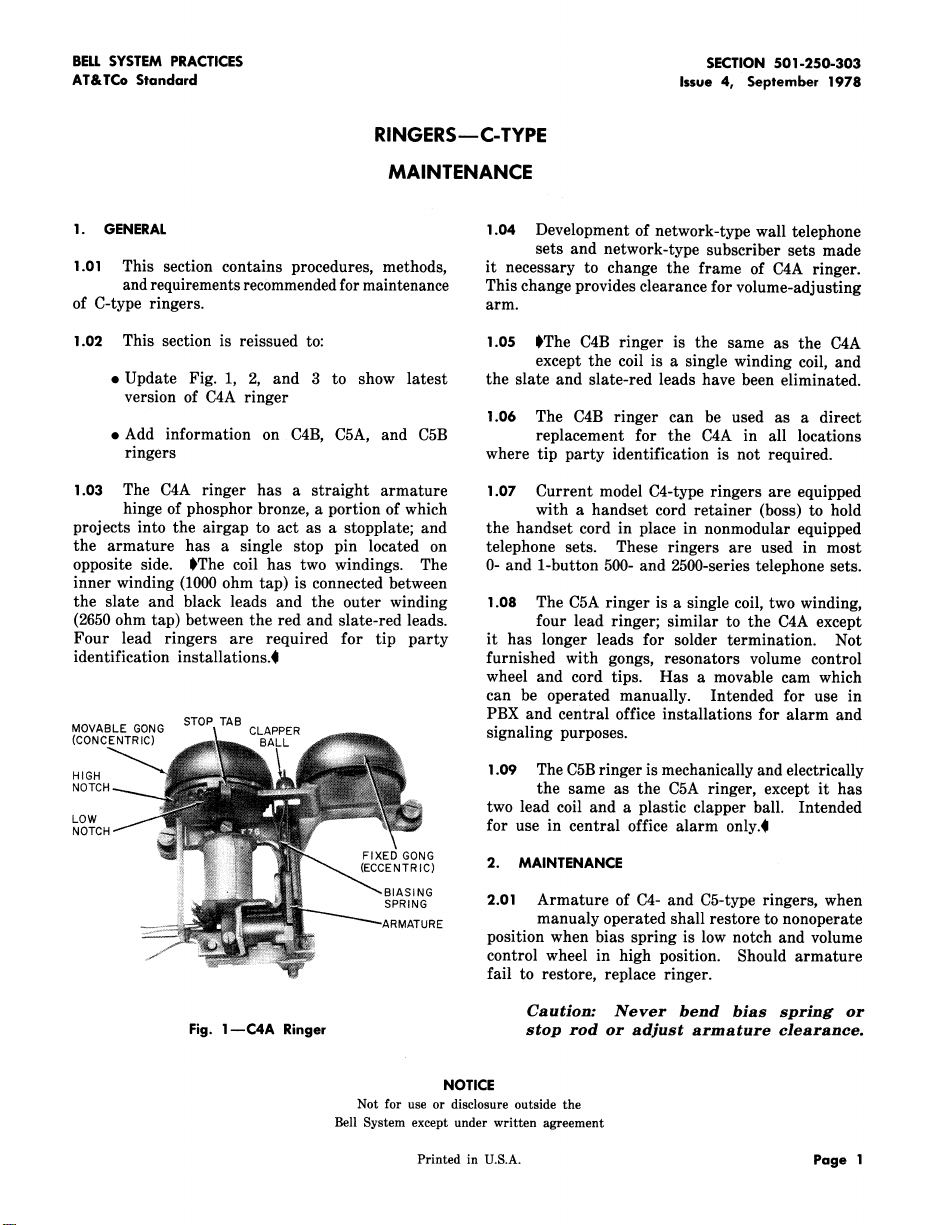

1.03 The C4A ringer has a straight armature 1.07 Current model C4-type ringers are equipped

hinge of phosphor bronze, a portion of which with a handset cord retainer (boss) to hold

projects into the airgap to act as a stopplate; and the handset cord in place in nonmodular equipped

the armature has a single stop pin located on telephone sets. These ringers are used in most

opposite side. $The coil has two windings. The 0- and 1-button 500- and 2500-series telephone sets.

inner winding (1000 ohm tap) is connected between

the slate and black leads and the outer winding 1.08 The C5A ringer is a single coil, two winding,

(2650 ohm tap) between the red and slate-red leads, four lead ringer; similar to the C4A except

Four lead ringers are required for tip party it has longer leads for solder termination. Not

identification installations.Q furnished with gongs, resonators volume control

MOVABLEGONG CLAPPER signaling purposes.

(CONCENTRIC)

HIGH 1.09 The C5B ringer is mechanically and electrically

NOTCH the same as the C5A ringer, except it has

LOW for use in central office alarm onlyAI

NOTCH

STOPTAB PBX and central office installations for alarm and

FIXEDGONG

(ECCENTRIC) 2. MAINTENANCE

BIASING

_i_i 'ARMATURE manualy operated shall restore to nonoperate

SPRING 2.01 Armature of C4- and C5-type ringers, when

sets and network-type subscriber sets made

except the coil is a single winding coil, and

1.06 The C4B ringer can be used as a direct

wheel and cord tips. Has a movable cam which

can be operated manually. Intended for use in

two lead coil and a plastic clapper ball. Intended

position when bias spring is low notch and volume

control wheel in high position. Should armature

fail to restore, replace ringer.

Fig. 1--C4A Ringer stop rod or adjust armature clearance.

NOTICE

Not for use or disclosure outside the

Bell System except underwritten agreement

Printed in U.S.A. Page 1

Caution: Never bend bias sprinK or

SECTION 501-250-303

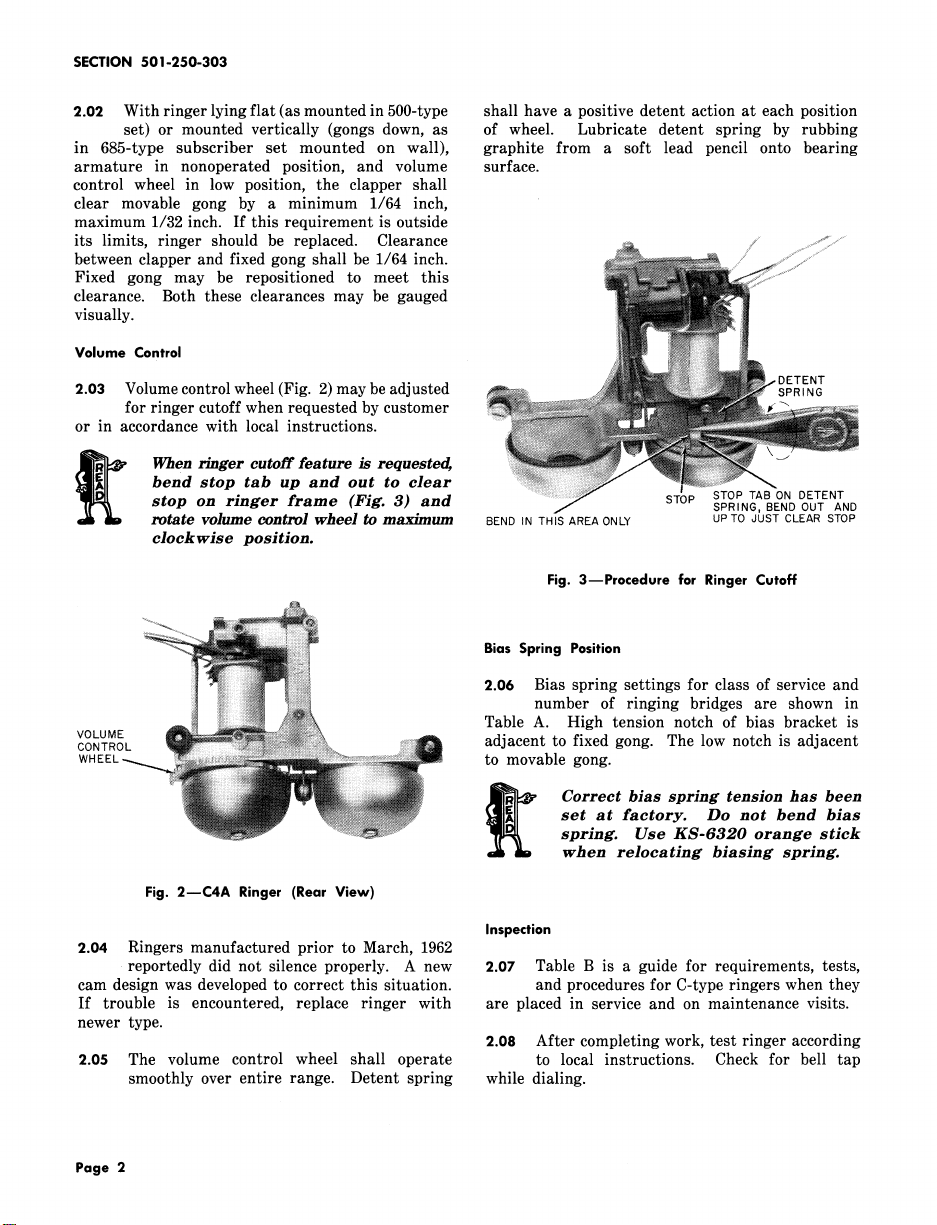

2.02 With ringer lying flat (as mounted in 500-type shall have a positive detent action at each position

set) or mounted vertically (gongs down, as of wheel. Lubricate detent spring by rubbing

in 685-type subscriber set mounted on wall), graphite from a soft lead pencil onto bearing

armature in nonoperated position, and volume surface.

control wheel in low position, the clapper shall

clear movable gong by a minimum 1/64 inch,

maximum 1/32 inch. If this requirement is outside

its limits, ringer should be replaced. Clearance J .... ,./_ ...........

between clapper and fixed gong shall be 1/64 inch.

_? ..................ii,:s :_

Fixed gong may be repositioned to meet this

clearance. Both these clearances may be gauged

visually.

Volume Control

2.03 Volume control wheel (Fig. 2) may be adjusted SPRING

DETENT

for ringer cutoff when requested by customer

or in accordance with local instructions.

bend stop tab up and out to clear

stop on ringer frame (Fig. 3) and STOP STOPTABONDETENT

When ringer cutoff feature is requeste_

rotate volume control wheel to maximum BEND IN THIS AREA ONLY UP TO JUST CLEAR STOP

SPRING, BEND OUT AND

clockwise position.

Fig. 3--Procedure for Ringer Cutoff

Bias Spring Position

2.06 Bias spring settings for class of service and

number of ringing bridges are shown in

Table A. High tension notch of bias bracket is

VOLUME adjacent to fixed gong. The low notch is adjacent

CONTROL

WHEEL to movable gong.

set at £aetory. Do not bend bias

spring. Use KS-6320 orange stick

Correct bias spring tension has been

when relocating biasing spring.

Fig. 2--C4A Ringer (Rear View)

Inspection

2.04 Ringers manufactured prior to March, 1962

•reportedly did not silence properly. A new 2.07 Table B is a guide for requirements, tests,

cam design was developed to correct this situation, and procedures for C-type ringers when they

If trouble is encountered, replace ringer with are placed in service and on maintenance visits.

newer type.

2.08 After completing work, test ringer according

2.05 The volume control wheel shall operate to local instructions. Check for bell tap

smoothly over entire range. Detent spring while dialing.

Page 2

Loading...

Loading...