Page 1

Document Number

121-044-00

Page

1 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA APPROVED

ROTORCRAFT FLIGHT MANUAL

SUPPLEMENT

Bell Helicopter Models

206L, 206L-1, 206L-3, 206L-4, 407

R/N ______________ S/N _______________

Page 2

Document Number

121-044-00

Page

2 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

INTRODUCTION

This supplement must be attached to the appropriate Bell FAA

approved Rotorcraft Flight Manual when an Onboard Systems

200-195-00 or 200-196-00 Cargo Hook Suspension Kit is

installed in accordance with Supplemental Type Certificate

(STC) NO. SR00418SE. The information contained herein

supplements or supersedes the basic manual only in those areas

listed herein. For limitations, procedures and performance

information not contained in this supplement, consult the basic

Rotorcraft Flight Manual and Rotorcraft Flight Manual

Supplement – Cargo Hook issued by Bell Helicopter.

The 200-195-00 and 200-196-00 Cargo Hook Suspension Kits

include the cargo hook, suspension beam assembly, and pillow

blocks. The suspension beam assembly supports the cargo

hook and allows it to align itself with a load. The pillow

blocks support each end of the suspension beam assembly and

attach to the rotorcraft’s hard points. In addition the kits

include the external manual release cable and external

electrical harness. These items interface with the fixed cargo

hook provisions on the rotorcraft.

The 200-196-00 kit includes a load weigh system. The load

weigh system consists of a cockpit-mounted indicator, a load

cell above the cargo hook, and the interconnecting wiring

harness.

Page 3

Document Number

121-044-00

Page

3 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

1. LIMITATIONS

1-3. Types of Operation

The basic Rotorcraft Flight Manual and Rotorcraft Flight

Manual Supplement – Cargo Hook issued by Bell Helicopter

remain applicable. With a load attached to the cargo hook,

operation shall be conducted in accordance with the respective

national operational requirements. For US operators FAR Part

133 is applicable. This cargo hook is approved for non-human

cargo, class B and C rotorcraft load combinations only.

The load weigh indicator (included with kit P/N 200-196-00)

shall be operated in accordance with Section 4 of Owner’s

Manual 120-055-00.

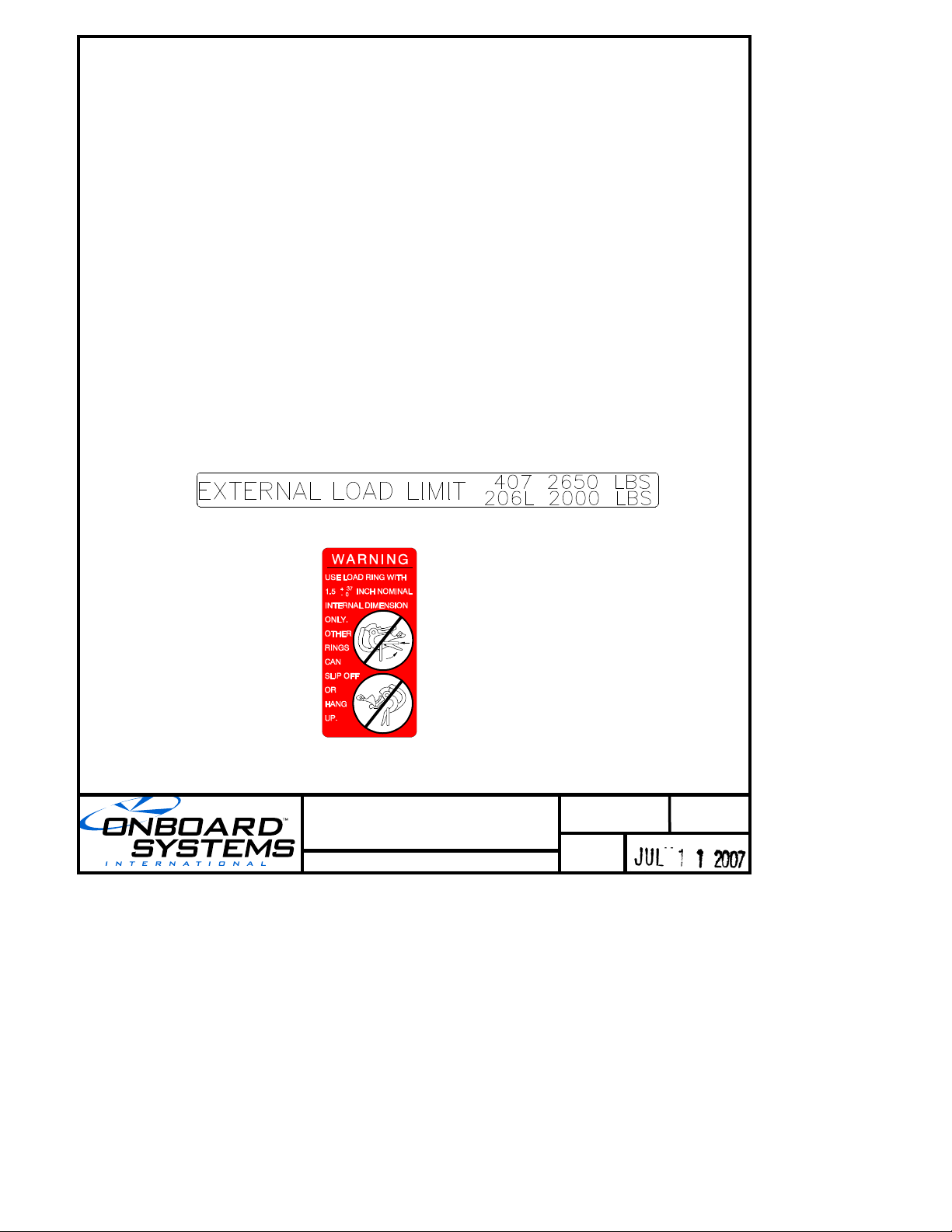

1-20 Placards

When an Onboard Systems kit P/N 200-195-00 or 200-196-00

is installed the following placards apply.

Mounted on suspension beam assembly:

Mounted on the bottom of the cargo hook:

Page 4

Document Number

121-044-00

Page

4 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

TURN THE WEIGHING SYSTEM OFF WHEN

NAVIGATION EQUIPMENT IS IN USE. NO AIRCRAFT

OPERATION SHOULD BE PREDICATED ON THE

READING OF THE ONBOARD WEIGHING SYSTEM.

ELECTRONIC WEIGHING SYSTEM

1-20 Placards continued

When an Onboard Systems kit P/N 200-196-00 is installed the

following placards apply.

Mounted adjacent to the Onboard Systems load weigh indicator

in full view of pilot or co-pilot:

Mounted adjacent to the power switch and the circuit breaker

in full view of the pilot and co-pilot.

2. NORMAL PROCEDURES

2-3 Pre-flight Check

Consult the Rotorcraft Flight Manual Supplement – Cargo

Hook issued by Bell Helicopters for additional procedures.

Before each Cargo Hook use perform the following

procedures. If the procedures are not successful do not use the

equipment until the problem has been corrected.

1. Inspect all cargo hook fasteners to ensure that they are

tight.

2. Visually inspect the electrical connector for damage and

security.

3. Operate the cargo hook keeper manually and check that it

snaps back to its normal position on the load beam.

Page 5

Document Number

121-044-00

Page

5 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

2. NORMAL PROCEDURES continued

2-3 Pre-flight Check continued

4. Inspect the cargo hook case and covers for cracks and

damage.

5. Inspect the cargo hook load beam for gouges and cracks.

6. Cycle the cargo hook manual release system to ensure

proper operation.

The cargo hook interfaces with the

rotorcraft’s internal manual release system as

supplied by Bell Helicopter. Consult the

Flight Manual Supplement – Cargo Hook for

operation of manual release system.

7. Cycle the cargo hook electrical release system to ensure

proper operation.

The cargo hook interfaces with the rotorcraft’s

internal electrical release system as supplied

by Bell Helicopter. Consult the Flight Manual

Supplement – Cargo Hook for operation of the

electrical release system.

Page 6

Document Number

121-044-00

Page

6 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

2. NORMAL PROCEDURES continued

2-3 Pre-flight Check continued

8. Move the cargo hook and the suspension system throughout

their full ranges of motion to ensure the manual release cable

and electrical harnesses have enough slack. The cable or

electrical harnesses must not be the stops that prevent the

cargo hook or suspension from moving freely in all directions.

9. Move the cargo hook back and forth on the suspension beam to

ensure that it rolls freely and that there are no obstructions

within the beam.

When an Onboard Systems 200-196-00 Cargo Hook Suspension

System with Load Weigh is installed, perform the following

additional procedure:

1. Zero the load weigh system or tare the weight on the cargo

hook that is not wanted, such as the weight of a cargo net or

long line, by depressing the zero button on the indicator.

Page 7

Document Number

121-044-00

Page

7 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

2. NORMAL PROCEDURES continued

Cargo Hook Rigging

Extreme care must be exercised in rigging a load to the Cargo

Hook. If the load ring is too big it may work its way around the

end of the load beam and be supported for a time on the keeper

and then fall free. If the load ring is too small it may jam itself

against the load beam during an attempted release.

The following illustrations show recommended rigging

configurations and potential difficulties that must be avoided.

The examples shown on the following pages

are not intended to represent all problem

possibilities. It is the responsibility of the

operator to ensure that the cargo hook will

function properly with the rigging.

Page 8

Document Number

121-044-00

Page

8 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

Secondary Ring or Shackle

5/8" Max. cross section

Load

Primary Ring

Incorrect Rigging

Incorrect Rigging

Correct Rigging

Multiple Rings

on Load Beam

Multiple Rings

on Primary Ring

1.50"

Primary Ring I.D.

1.87"

2. NORMAL PROCEDURES continued

Figure 1

Page 9

Document Number

121-044-00

Page

9 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

Load Ring flips over

the Load Beam and

gyrates.

The flip over often occurs

with long line operations

during landings and take offs.

Load Ring moves

inward and bears

against the keeper

The Keeper is forced

to rotate allowing the

Ring to slip off

2. NORMAL PROCEDURES continued

Un-Commanded Release Due to Too Large of a Load Ring

Load rings that are too large will cause an un-commanded

release. The ring will flip over the end of the load beam and

flip the keeper up and then fall free. Only correctly sized

load rings must be used. See example below.

Figure 2

Page 10

Document Number

121-044-00

Page

10 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

Jammed Ring

Sling Load

Load hang-up due to

multiple rings on

load beam

Sling Load

Jammed Rings

2. NORMAL PROCEDURES, continued

Load Hang-Up due to Too Small of a Load Ring or Multiple Load Rings

Load rings that are too small or multiple load rings will

hang on the load beam when the load is released. Only

correctly sized load rings must be used. See example below.

Figure 3

Page 11

Document Number

121-044-00

Page

11 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

2. NORMAL PROCEDURES, continued

Un-Commanded Release Due to Nylon Type Straps

Nylon type straps (or similar material) must not be used

directly on the cargo hook load beam as they have a

tendency to creep under the keeper and fall free. If nylon

straps must be used they should first be attached to a

correctly sized primary ring. Only the primary ring should

be in contact with the cargo hook load beam. See example

below.

Figure 4

Page 12

Document Number

121-044-00

Page

12 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

2. NORMAL PROCEDURES, continued

Un-Commanded Release Due to Cable or Rope Type Straps

Cable or rope type straps must not be used directly on the

cargo hook load beam. Their braided eyes will work around

the end of the load beam and fall free. If cable or rope is

used they should first be attached to a correctly sized

primary ring. Only the primary ring should be in contact

with the cargo hook load beam. See example below.

Figure 5

Page 13

Document Number

121-044-00

Page

13 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

2. NORMAL PROCEDURES, continued

The suspension system is designed to

accommodate loads through an angle of up to

55° from vertical —both forward and aft.

However, when loads exceed 55°, the travel

stops on the Pillow Blocks prevent the

Suspension Beam from further rotation and

cause bending stresses to be carried by the

Load Cell. Care should be taken to avoid this

flight regime.

The situation is most likely to occur when

flying at high speeds with light loads, which

have large aerodynamic drag, for example - an

empty fire or fertilizer bucket or an empty long

line. Figure 6 illustrates the adverse loading

situation.

Page 14

Document Number

121-044-00

Page

14 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

2. NORMAL PROCEDURES, continued

Figure 6

Page 15

Document Number

121-044-00

Page

15 of 15

Rev. 0

Bell 206L/407 Cargo Hook Kit

Rotorcraft Flight

Manual Supplement

FAA Approved

3. EMERGENCY PROCEDURES

Consult the Rotorcraft Flight Manual Supplement – Cargo Hook

issued by Bell Helicopter for emergency procedures during

external load operations.

4. PERFORMANCE

The Rotorcraft Flight Manual Supplement – Cargo Hook issued by

Bell Helicopter remains applicable.

When an Onboard Systems 200-196-00 Cargo Hook Suspension

System with Load Weigh is installed the following applies. The

Load Weigh System is designed and installed as a means of

MONITORING the load (weight) suspended from the cargo hook.

Functional and performance characteristics have not been

determined on the basis of the load cell indication or display.

Therefore, this instrument shall NOT be used as a primary

indication of performance and flight operation must NOT be

predicated on its use.

Loading...

Loading...