Belkin DLA-HD2KU, DLA-HD2KE User Manual

PA019200410

SERVICE MANUAL

HOME THEATER PROJECTOR

DLA-HD2KU, DLA-HD2KE

¨

ON

OFF

OPERATE

FOCUS

TEST

LIGHT

MENU EXIT

ENTER

PRESET

HIDE

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.PA019

2004/10

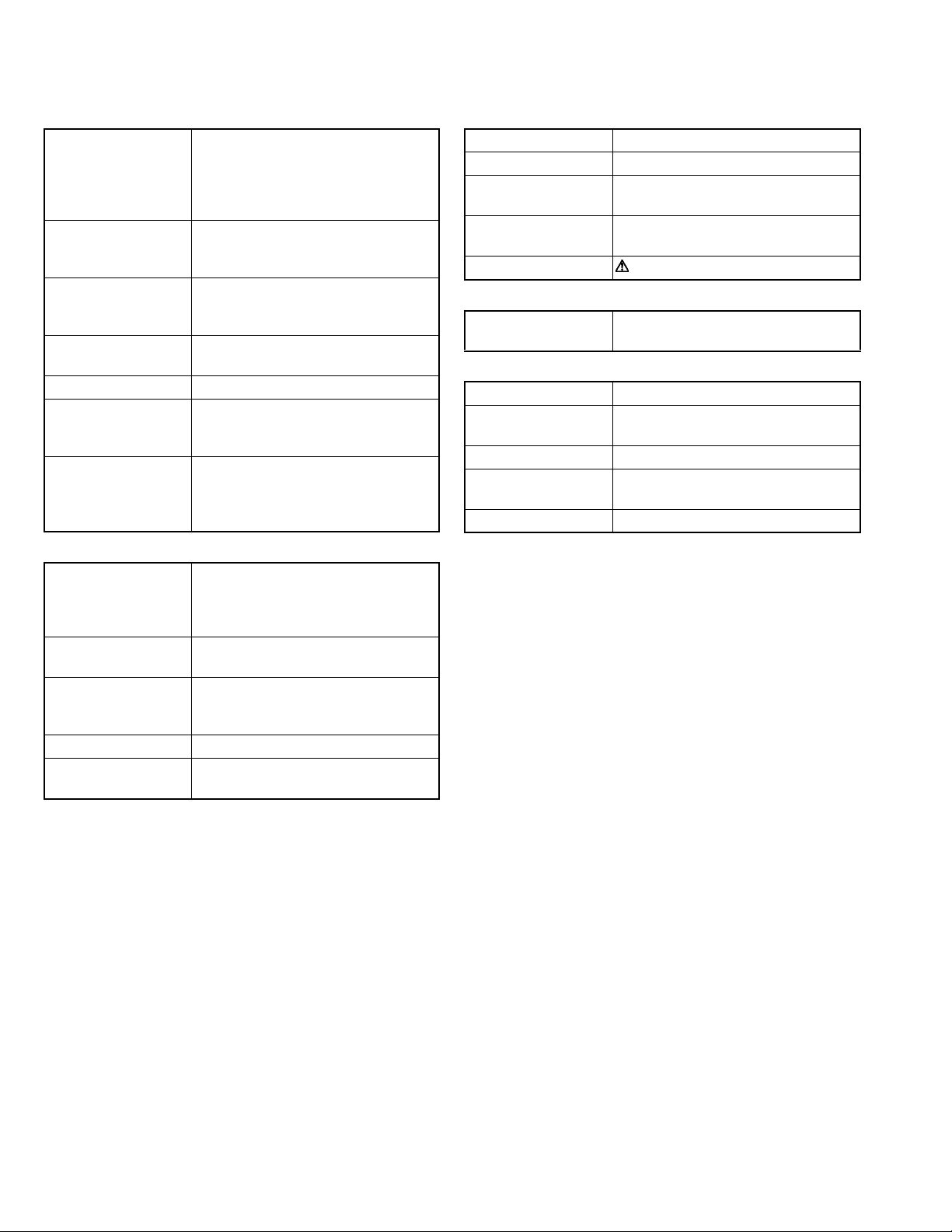

SPECIFICATION

GENERAL

Type

Dimensions

(W × H ×D)

Mass

Power requirements

Power Consumption

Operating temperature

Operating humidity

Storage temperature

Projection angle

(Adjustable Foot)

Remote control unit RM-MH2KG

operation

Accessories Remote control unit (RM-MH2K) × 1

OPTIC

Projection system

D-ILA device

Projection lens 1.3times (1.8 : 1-2.35 : 1) manual ZOOM

Screen size 40" (101.6cm) [tele : min]-200" (508cm)

Projection distance approx 1.5m (4.92ft)-12m(39.36ft)

Light lamp BHL5006-S

D-ILA HOME THEATER PROJECTOR

Approx. 298 mm × 134 mm × 360 mm

(Approx. 11-7/8" × 5-3/10" × 14-1/5")

(Excluding handle, lens and protrusions)

Approx. 6.2kg (Approx.13.7lbs)

AC 100-240V 50Hz/60Hz

3.5A (100VAC)~1.4A (240VAC)

+5°~+35°[41°F~95°F]

20%~80% (no-condensation)

-10°C~+60°C[14°F~140°F]

Vertical : max. +6° upper

Horizontal : max. 3° (±1.5°)

Distance : 7m

Angle: Horizontal =±30° Vertical =±20°

Mass

100g (includes dry cell battery)

Dry cell battery (size : UM-4/AAA/R02) × 2

DVI Cable (5m) × 1

Power code (2.5m) × 1

D-ILA(reflective activematrix principle)system

0.82-inch(2.1cm) measured diagonally

[H:1920 pixels × V:1080 pixels] × 3

< Total : 6,220,000 pixels >

lens [50% fix shift]

< recommended >

*measured diagonally with aspect 16:9

UHP(Ultra High-Pressue mercury) lamp

ELECTRIC

Input signal 1080 / 60p signal, 1080 / 50p signal

Resolution 1920 × 1080 dots

Scanning frequency Horizontal : 56.25kHz,67.43kHz,67.5kHz

Vertical : 50Hz,59.94Hz,60Hz

Keystone distortion

correction

Fuse QMF51D2-6R3-J1(6.3A)

OUTPUT TERMINAL

CONTROL SYNC OUT × 1

INPUT CONNECTORS

VIDEO IN

CONTROL Using external computer control

RS-232C RS-232C protocol

SERVICE stereo mini-jack × 1 (For Service)

Top-bottom tilt:

Horizontal=about 25°, Vertical=about 5°

stereo mini-jack (For Service)

DVI DVI-D (single-24pin) terminal

HDCP-compatible

D-sub 9-pin × 1

1-2 (No.PA019)

SECTION 1

r

e

PRECAUTION

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

•Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

Consequently, when servicing these products, replace the

cathode ray tubes and other parts with only the specified

parts. Under no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray

tube.

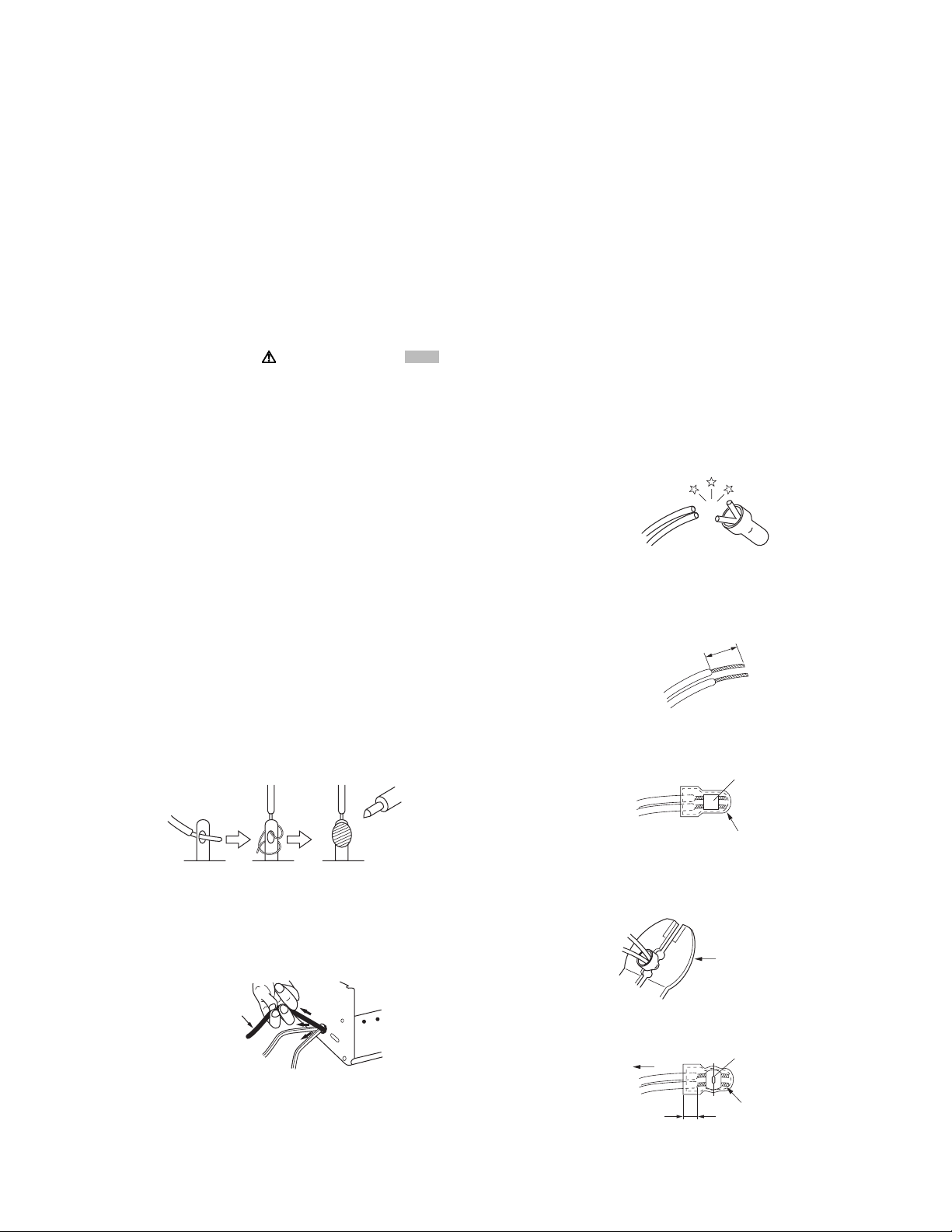

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections between the power cord and power trans former primary lead

wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely according to the

following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. In-

sert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2

.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleev

Conductors extended

Fig.1-1-7

(No.PA019)1-3

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

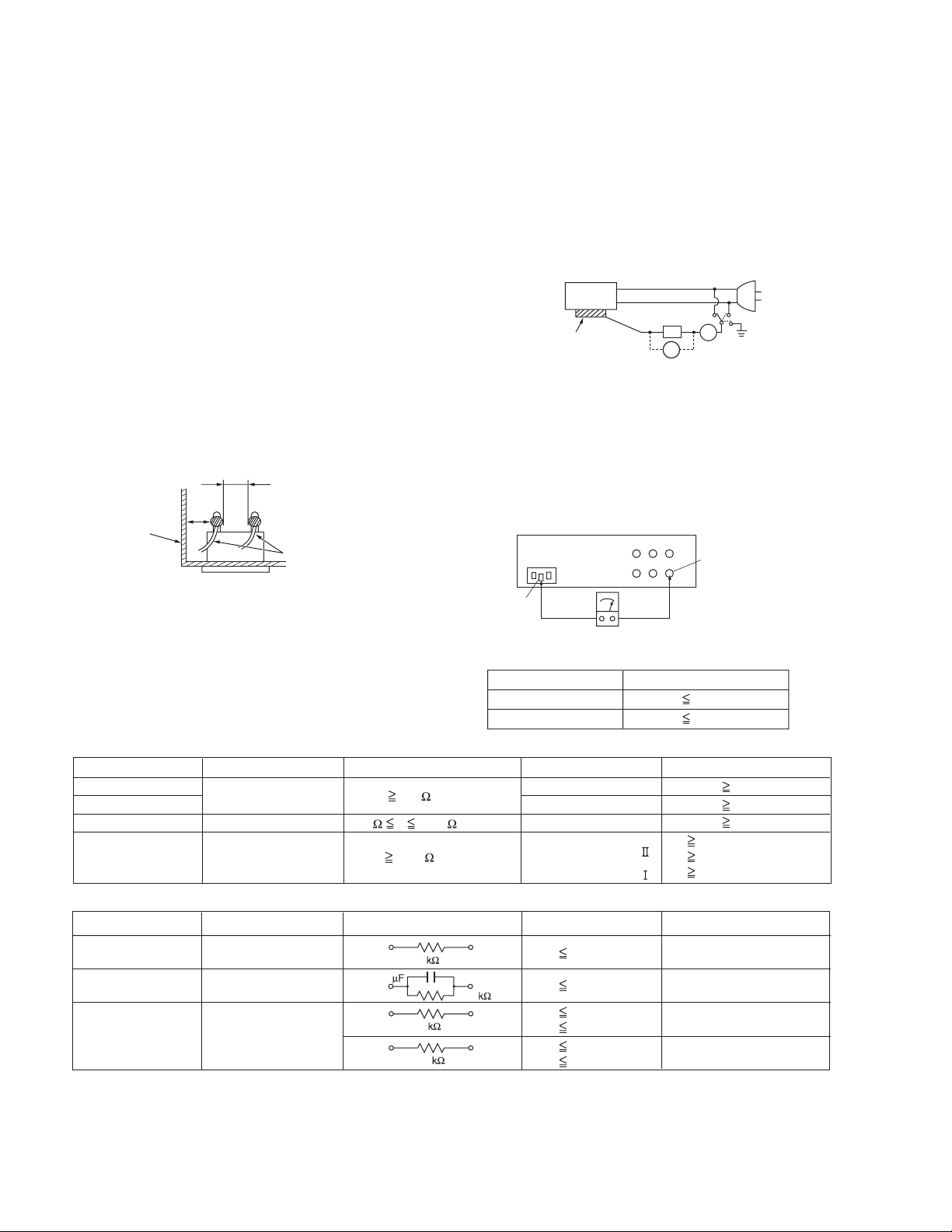

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure

across both terminals of load Z. See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.PA019)

1.1.3 Warning and caution labels

• Labels advising of warning and caution are affixed on and in various locations of the product.

• Take careful notice of these during service and inspection.

WARNING Risk of lethal or otherwise serious personal injury.

CAUTION Risk of personal injury and damage to the product.

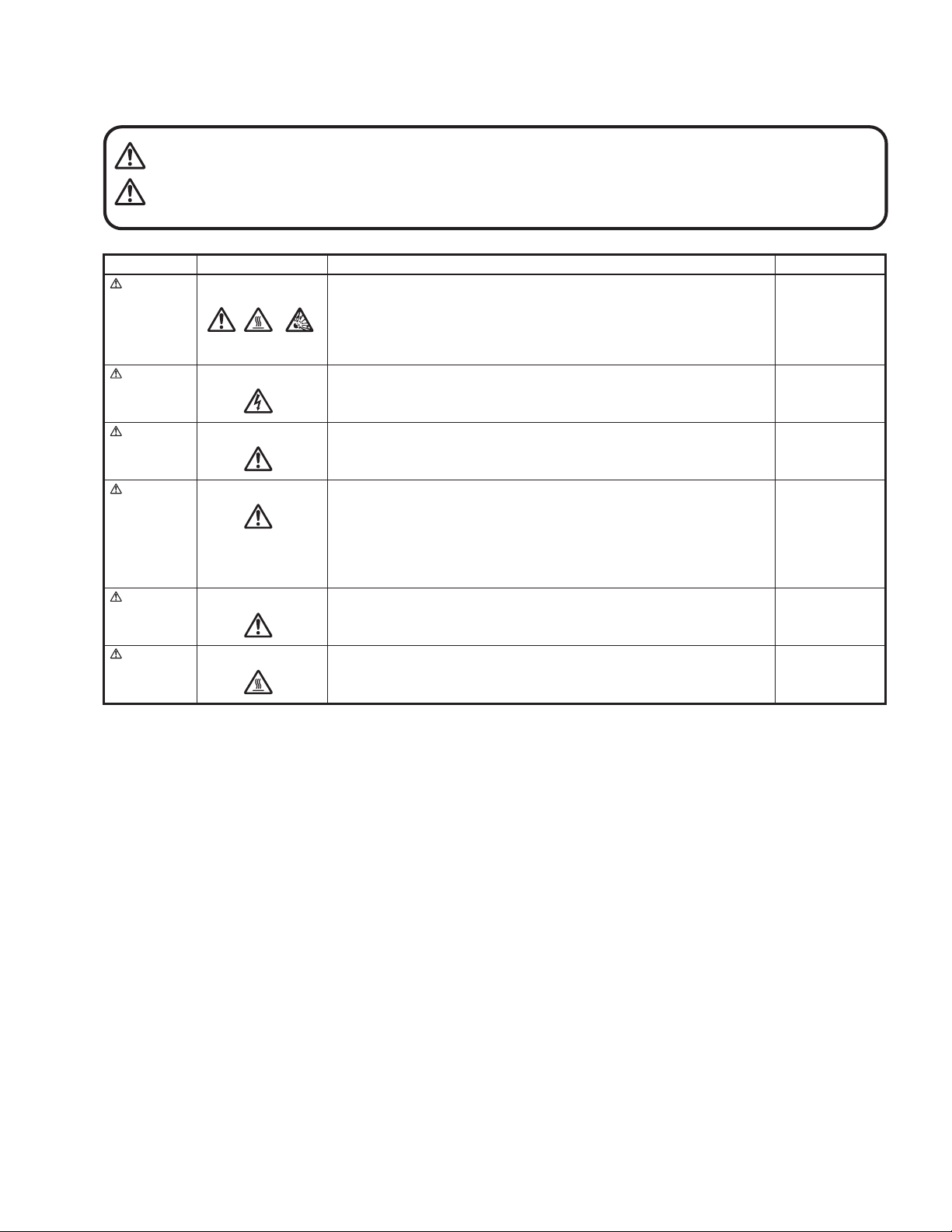

Class Pictorial Label advisory Location

WARNING

WARNING

Hot, breakable This projector lamp emits high heat and contains high-pressure during use.

If touched, the lamp (bulb) may rupture and burns may result. Before

attempting to replace the lamp, remove the power cord plug from the outlet and

wait for the lamp (bulb) to cool (at least one hour). Then proceed to replace the

lamp.

High voltage Never open any cover on the projector except the lamp and filter covers.

Dangerous electrical voltage inside the projector.

Bottom chassis

Bottom chassis

WARNING

CAUTION

CAUTION

CAUTION

High brightness Never look into the lens while the projector is on.

There is danger of eye damage.

Hot, shock hazard

High voltage

Hot Caution, high temperature Lamp unit

Do not insert foreign objects into the ventilation holes as this can result in fire or

electrical hazards.

Do not block the ventilation holes as this may cause the internal temperature to

rise and possibly result fire.

When the inside of the unit requires cleaning, consult your nearest JVC dealer

or service center.

Turn off before opening this lamp cover. See user's manual for replacing the

lamp. Replace with the same type (BHL5006-S) lamp rated 250W.

Top cover

Bottom chassis

Bottom chassis

1.1.4 Additional cautionary items

• High voltage is applied for lighting the lamp. During adjustments and other work with the cover removed, extreme care is needed to

avoid electric shock.

• Use care to avoid touching the fan or safety switch terminals during work with the cover removed.

• Select a stable, horizontal work site to prevent dropping the product and components.

• Use the power cord and interface cable supplied with the product.

Before starting work, be sure to also check the safety notices contained in the instruction manual.

(No.PA019)1-5

1.2 INSTALLATIONS

1.2.1 Installation method

The D-ILA system (reflecting type active matrix liquid crystal system) does not require convergence adjustment. Note the following

when placed on a floor (refer to OPERATING INSTRUCTIONS for actual operating method).

(1) Place the projector at the position needed for the required image size observe the projector is not tilted horizontally.

[The image size is 40 to 200(wide side) inches diagonal (16:9), requiring a projection distance of 1.58m to 8.03m (wide side).]

(2) Adjust the placement site and screen tilt so that the projection angle is perpendicular to the screen.

(3) Adjust the placement site and screen position (height) so that the projection lens center is at the lower edge of the screen.

(4) Project an image on the screen. (Connect video equipment and power source, switch power on and select the input.)

(5) Fine adjust the projected image position and angle. If adjusting the placement site and screen cannot correct the projected po-

sition (too low) or angle (lower part of image widened), adjust the front foot.

(6) Turn the lens ZOOM ring by hand and adjust for suitable image size.

(7) Turn the lens FOCUS ring by hand and adjust to correct image blur.

1.2.2 Installation site and status

• The projector contains a fan for cooling. Obstruction of the ventilation openings can lead to internal overheating, abnormal operation

and failure. Also observe there is plenty of free space between the projector and adjacent walls, ceiling and other equipment.

Note that excess heat can cause failure and damage to both the projector and nearby equipment.

Required spacing :

Front = 15cm / left and right sides = 30cm / rear = 50cm (When the unit is enclosed with block according to the required spacing

on the left side, provide the unit with adequate ventilation so that the temperature inside of the enclosed area is kept at the same

temperature in the open space in the room.)

• Avoid locations that are wobbly or inclined. If the setting site floor has protrusions or horizontal cannot be maintained, there is risk

the projector may drop, fall over, etc. If located in a site where left to right tilt is greater than ±5° and front to rear tilt greater than

±20°, particularly the optical system components can be severely affected and there is risk basic performance and quality of the

projector cannot be maintained.

• Observe the site can stably bear the weight (approx. 6.2kg) of the projector over a long period of time.

• If mounted on a stand with casters, observe the casters are securely braked to prevent movement.

• Avoid suspending in a location subject to vibration. Both the projector and mounting fixture can be damaged.

• Do not place in the following types of locations.

Especially, Avoid locations subject to dust, grit, smoke or other airborne contaminants. Use adequate caution when providing external ventilation, filters and dust protection.

Near water or in humid sites Near heaters or heat generating equipment

Dust or grit Direct sunlight

Oily or tobacco smokes Very high or very low temperature

1-6 (No.PA019)

SPECIFIC SERVICE INSTRUCTIONS

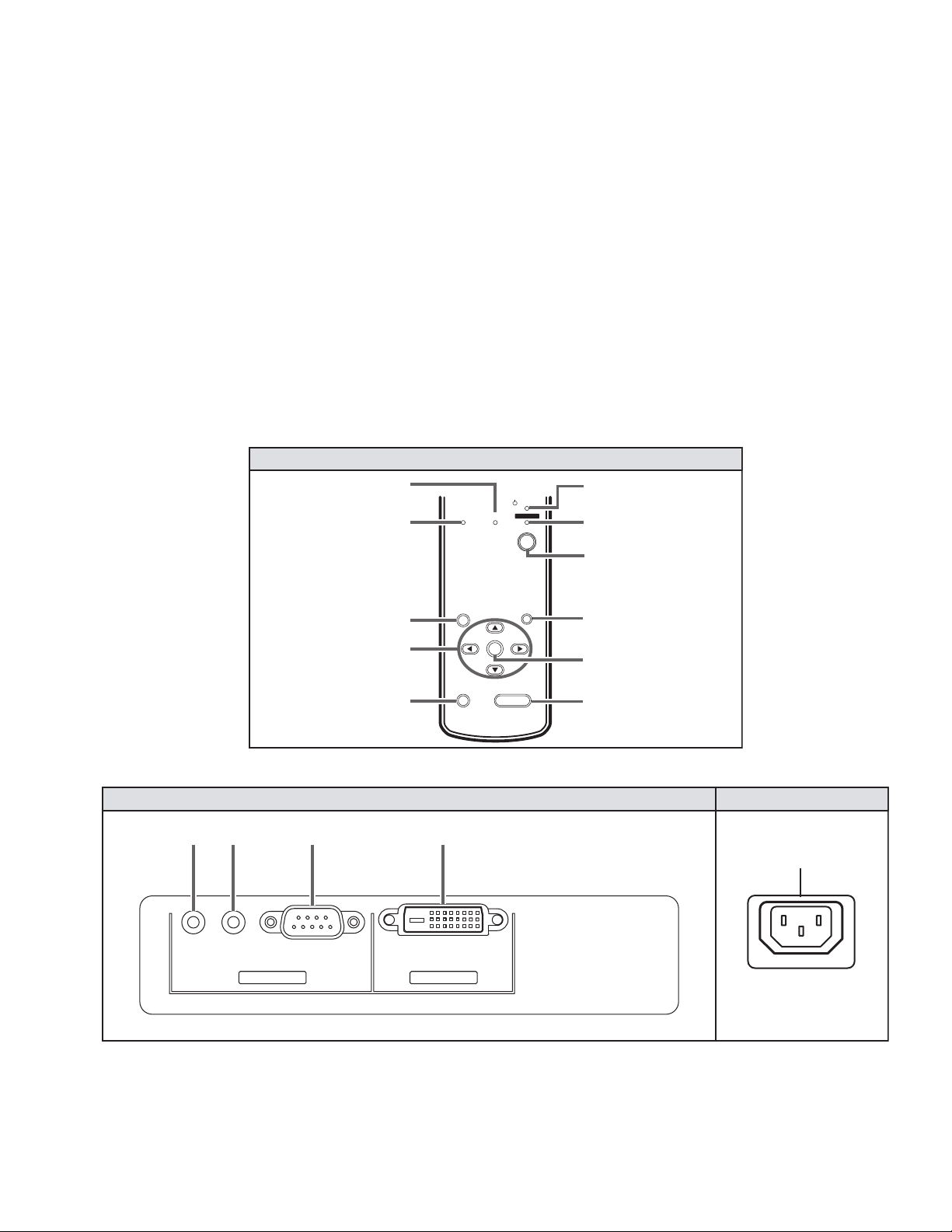

TOP VIEW (Operation Panel)

2.1 FUNCTIONS

2.1.1 LED indications

The LED operations are as follows.

OPERATE LED

Lighted : Power on mode in progress.

Extinguished : Mode other than above.

STAND-BY LED

Lighted : Stand-by mode in progress.

Flashing : Cool down mode in progress.

Extinguished : Mode other than above.

TEMP LED

Flashing : Internal temperature abnormally high

(shift to emergency mode) .

Extinguished : Internal temperature normal.

2.1.2 Operation button & LED location

TOP VIEW (Operation Panel)

TEMP LED

LAMP LED

SECTION 2

LAMP LED

Lighted : Lamp replacement time near (used approx.1900

Flashing : Lamp end of life (approx. 2000 hours), power

Extinguished : Mode other than above

NOTE :

Please refer to troubleshooting about the warning display by

LED.

LAMP TEMP

STAND BY

OPERA TE

hours) At power on, message appears by the onscreen display for advising to "LAMP REPLACE".

on inhibited.

(lamp abnormally absent) .

STAND BY LED

OPERATE LED

MENU BUTTON

CURSOR BUTTON

PRESET BUTTON

2.1.3 Input / output terminal location

SYNC OUT RS-232CSERVICE DVI INPUT

SYNC

OUT

SERVICE

RS-232C

CONTROL

RIGHT SIDE

MENU

PRESET

DVI

VIDEO IN

OPERATE BUTTON

EXIT

ENTER

HIDE

EXIT BUTTON

ENTER BUTTON

HIDE BUTTON

LEFT SIDE

POWER INPUT

(No.PA019)1-7

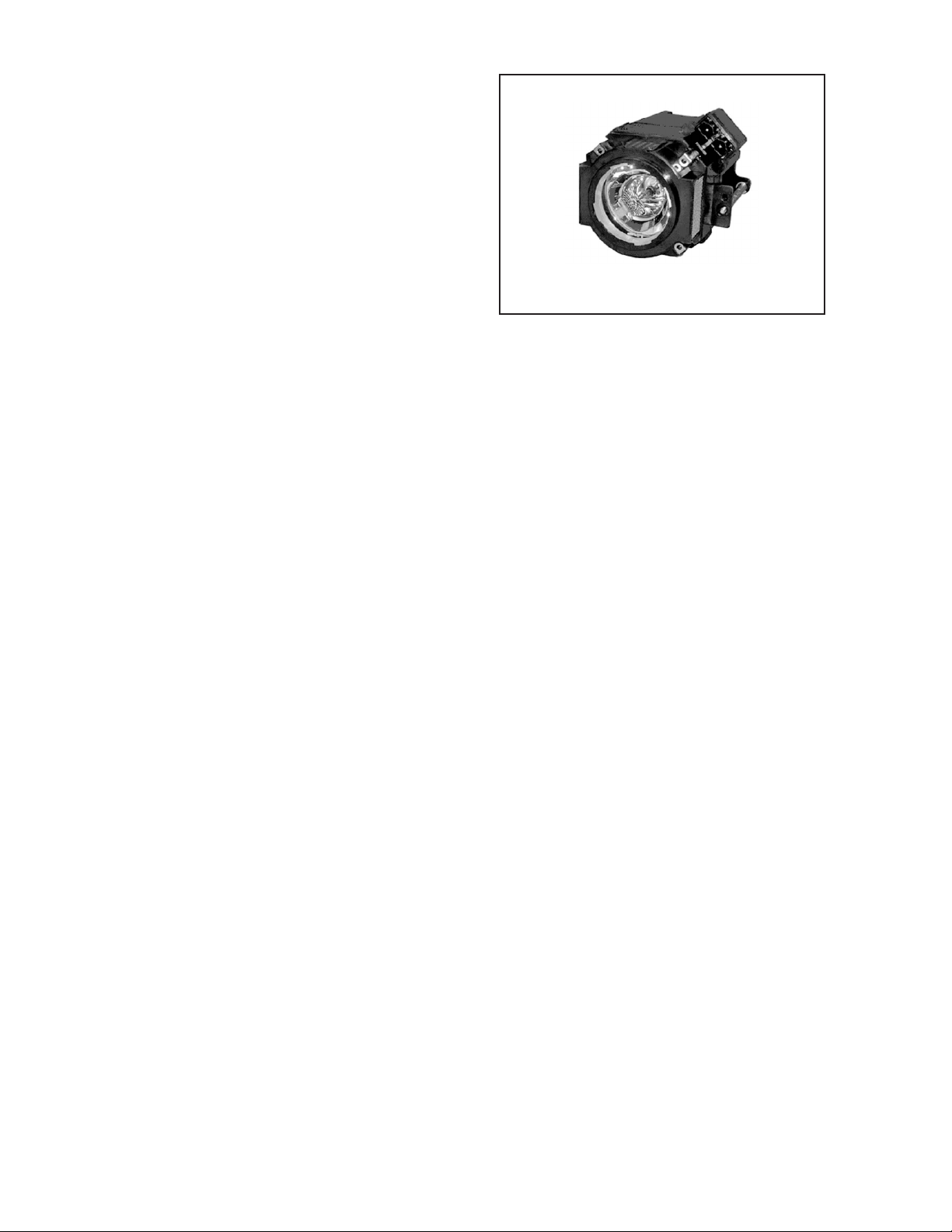

2.2 LAMP UNIT INSTRUCTIONS

Refer to the OPERATING INSTRUCTIONS for a detailed operating description.

2.2.1 Lamp life

Life of the projector lamp (time to reach 1/2 average brightness)

is about 2000 hours.

∗ Lamp use time can be checked at the menu < Information > -

[Lamp time].

LAMP UNIT : BHL5006-S

2.2.2 Operation when lamp use time exceeds 1900 hours

z 1900 to 2000 HOURS

• Power on : LAMP LED lights.

• Operation : "Lamp replacement" message appears on

screen (∗press any button to extinguish).

z 2000 to 2010 HOURS

• Power on : LAMP LED flashes.

• Operation : "Warning" and "Lamp replacement" messages

appear on screen, and "Warning" flashes.

∗Press [EXIT] button to extinguish the display. But after 1

hour, "Warning" and "Lamp replacement" again appear.

NOTE:

At power off, the stand-by mode is produced and further operation is prevented.

∗To again use the projector, replace the lamp unit and reset

the lamp use time indication.

z AFTER 2010 HOURS

• Power on : Power is cut and cool-down mode entered,

LAMP and OPERATE LEDs flash.

2.2.3 Handling cautions

• Use a cross-head screwdriver to take out and reinstall the lamp

cover (2 screws) and lamp unit (2 screws). Refer to the OPERATING INSTRUCTIONS.

• Observe the following cautions.

- Be sure to disconnect the power cord from the AC power

source.

- The lamp remains quite hot after power off. Be sure to allow

plenty of time (30 minutes to 1 hour) to cool before proceeding.

- The lamp can break if dropped or subjected to physical

shock.

- Use care not to directly touch or soil the lamp projecting

(glass) face.

• When installing the lamp unit, observe the interior projections

of the lamp cover are securely inserted into the holes of the

projector. Since the lamp cover projections engage the interlock switch part of the protector circuit (normal operating state),

be sure the cover is properly positioned and secure with

screws.

• The replaced old lamp (depleted lamp unit) can be discarded

in the same manner as a fluorescent lamp. Check local ordinances and dispose of the used lamp as prescribed.

2.2.4 Lamp use time reset

• Be sure to reset the Lamp use time after replacing the lamp

unit. Unless reset, the projector will cease operation (lamp will

not light) when 2000 hours are reached.

∗Conversely, reset the use time only after replacing the lamp.

• RESETTING

(1) Set for stand-by mode.

(2) In sequence, press the [EXIT], [HIDE] and [PRESET]

buttons.

(3) Press the [] button for more than 2 seconds.

∗The STAND-BY and OPERATE LEDs alternately flash

for about 3 seconds, then only the STAND-BY LED

lights steadily.

• RESET AFTER REPLACING MAIN PWB ASS'Y

The lamp use time data are stored in memory on the MAIN

PWB ASS'Y and need to be reentered after replacing the

MAIN PWB ASS'Y. Use the special software and a personal

computer to reenter the data. Afterwards, confirm the mode

has been returned to that prior to board replacement.

1-8 (No.PA019)

2.3 PROJECTION SPECIFICATIONS AND NOTES

2.3.1 Projection distance

• The usable projection distance (focus obtainable) is tele side :

approx. 2.07m to 10.45m / wide side : approx. 1.58m to 8.03m.

The picture size (16:9) is 40 to 200 inches.

• Use the wide side for sizes bigger than 200 inches.

• If picture edge distortion occurs at the minimum distance

(1.6m), increase the distance slightly.

• The guaranteed projection distance range is from 2m to 10m.

2.3.2 Projection image and image size

• The projection distances and image size relationship given in

the operation manual is approximate for general reference.

The actual values may vary due to lens tolerance and other

factors.

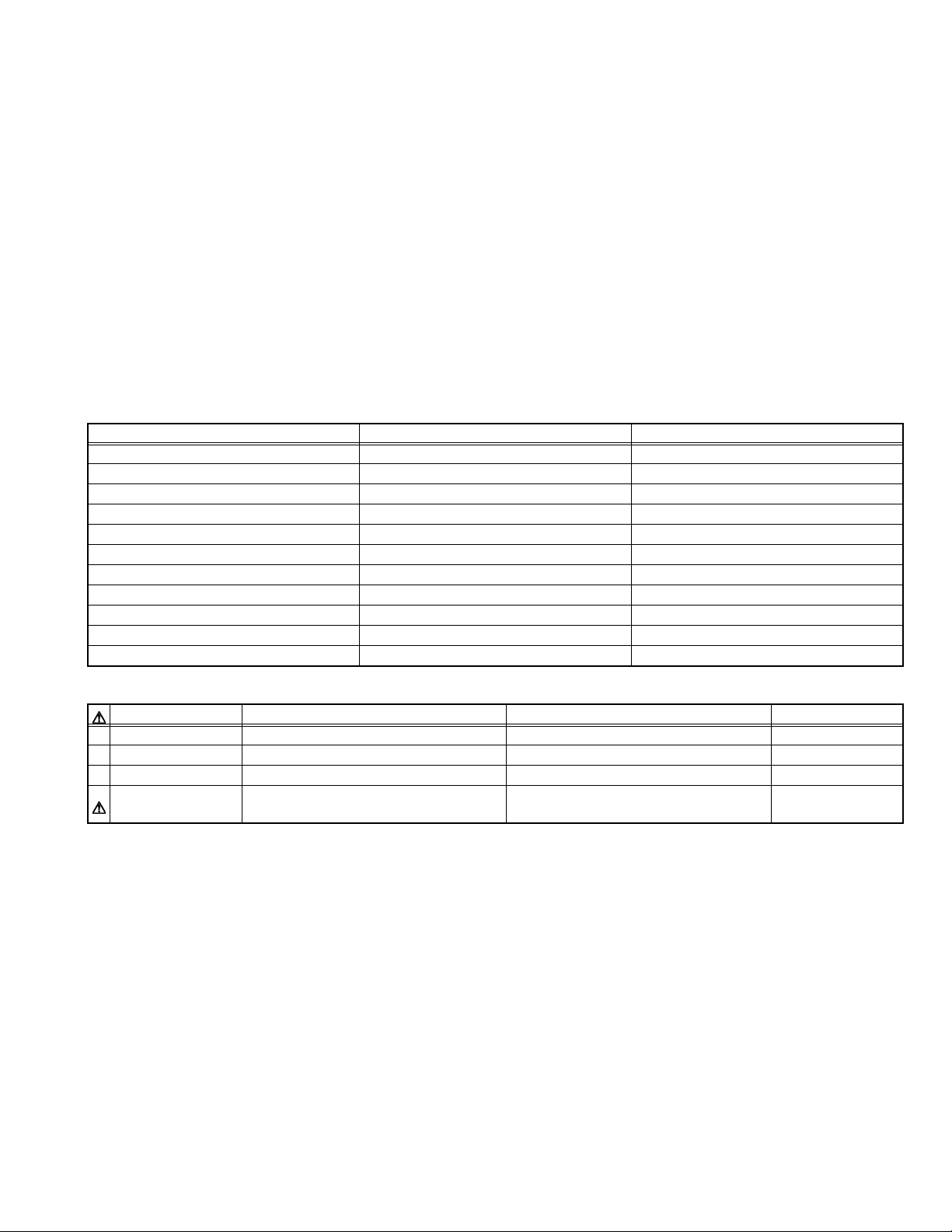

2.5 SERVICE POLICY

The following service policy is being utilized.

Item Parts number Service method

MAIN PWB ASS'Y LCA90233-01B Replace PWB (Some parts are excluded)

DD SUB1 PWB ASS'Y LCA90234-01B Replace PWB (Some parts are excluded)

DD SUB2 PWB ASS'Y LCA90235-01B Replace PWB (Some parts are excluded)

POWER PWB ASS'Y LCA10383-01A Replace parts

IR1 PWB ASS'Y LCA90271-01B Replace parts

IR2 PWB ASS'Y LCA90236-01B Replace parts

CONT. & 3.3V PWB ASS'Y SXG-0P002A Replace parts

OPERATION PWB ASS'Y LCA90272-01B Replace parts

OPTICAL BLOCK ASS'Y HD2KOP-S Replace (module)

LAMP BALLAST UNIT QAL0435-002 Replace (module)

LAMP UNIT BHL5006-S Replace (module)

2.3.3 Other cautions

• Use care not to directly touch the lens. Clear soiling from the

lens with optical lens paper or a photographer's blower.

• Check the lens cap is removed before projecting. If left installed the projector can overheat and the lens cap can be deformed.

• Sunlight or other illumination can render the image difficult to

see. Use a curtain or other means to shield the screen from

stray light.

2.4 CONNECTION AND OPERATION CAUTIONS

• The projector can function with fH 56.25kHz, 67.43kHz,

67.5kHz, fV 50Hz, 59.94Hz, 60Hz signal input, but even within

this range, partial picture loss, fold-over at the top and bottom

picture edges and other effects can occur according to signal

type and conditions to prevent a normal projected image (see

"Input Sync Frequency" of the OPERATING INSTRUCTION).

2.6 MAIN DIFFERENCE LIST

Part name DLA-HD2KU DLA-HD2KE Remark

PACKING CASE LC21468-005A LC21468-008A

POLY BAG QPA01503005 -------- For Warranty card

WARRANTY CARD BT-51030-3 -------- Accessory

POWER CORD QMPE240-250-R

QMPL280-200-R (for EU)

QMPP220-200-R (for UK)

Accessory

(No.PA019)1-9

2.7 SERVICE MENU

options

software version

software version

options

The service menu contains items not ordinarily needed by the user. Use these as necessary during service.

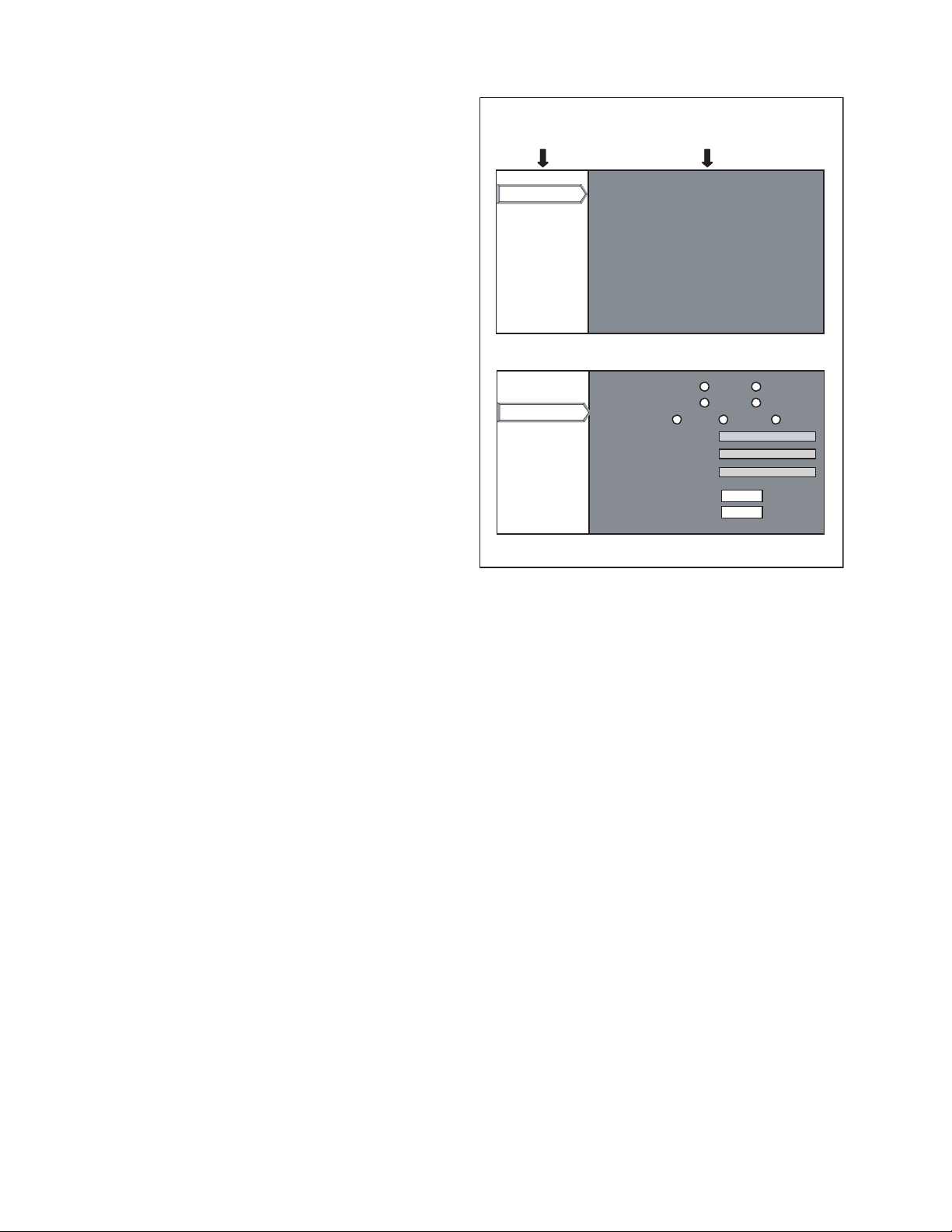

2.7.1 Enter

(1) No menu shown.

(2) Press the [] button.

(3) Within press the [] button.

(4) Within press the [] button.

(5) Within press the [] button.

(6) Within press the [ENTER] button to display the service

menu.

NOTE:

When the Service Menu Screen is not displayed, go back to

the beginning. It is recommended that you press the buttons a

little earlier and steadily.

2.7.2 Release

Press the [MENU] button to exit the menu indication.

2.7.3 Basic operation

Use the following buttons to operate the service menu.

(1) Choose the SETTING MENU with the [/] button.

(2) When the [] button is pressed after choosing the SET-

TING MENU, the cursor will shift to the SETTING / ADJUSTMENT ITEMS of each SETTING MENU.

(3) When the cursor is shifted, choose the SETTING / AD-

JUSTMENT ITEMS with the [/] button.

(4) Using the [/] button, change the setup values and ad-

justment values, respectively.

(5) When the [EXIT] button is pressed, the cursor will return to

the SETTING MENU.

(6) When the [MENU] button is pressed, the SERVICE MENU

will go out of the screen.

NOTE:

The SERVICE MENU will go out of the screen automatically

after 10 seconds if you do not press the [MENU] button.

SERVICE MENU

SETTING NENU SETTING / ADJUSTMENT ITEM

software version

࠰ࡈ࠰ࡈ࠻ࡃ࠻ࡃ࡚ࠫࠫࡦ

options

software version

options

PRG : 014

OSD : 011

DLA-HD2K

Software version SCREEN

Back Color Black

Auto shut off Off

Color temp.

RED

GREEN

BLUE

Factory reset

Adjust pattern

Option SCREEN

Blue

On

USER1 D65 USER2

0

0

0

ENTER

ENTER

1-10 (No.PA019)

2.7.4 Setting items

software version

options

Item Initial value

Adjustment

range

Description

Setting

object

Software version

Software version ------ ------ Information of PROGRAM -----Option

Back color Blue [Select 2 items] "Sets no signal background color to blue or black.

Common

[Blue] : Blue color [Black] :Black color"

Auto shutdown ON [Select 2 items] If POWER OFF is selected, no warning will be displayed on and

Common

after 1900 hours of the lamp operating time. However, POWER

ON is also available after 2000 hours of the lamp operating time.

Color temp D65 Select 3 items Setting of [D65]:6500K, USER1, USER2 Common

R 0 -255~0 Setting color temp of red Common

G 0 -255~0 Setting color temp of green Common

B 0 -255~0 Setting color temp of blue Common

Factory reset ------ ------ Press [ENTER] then all reset. Common

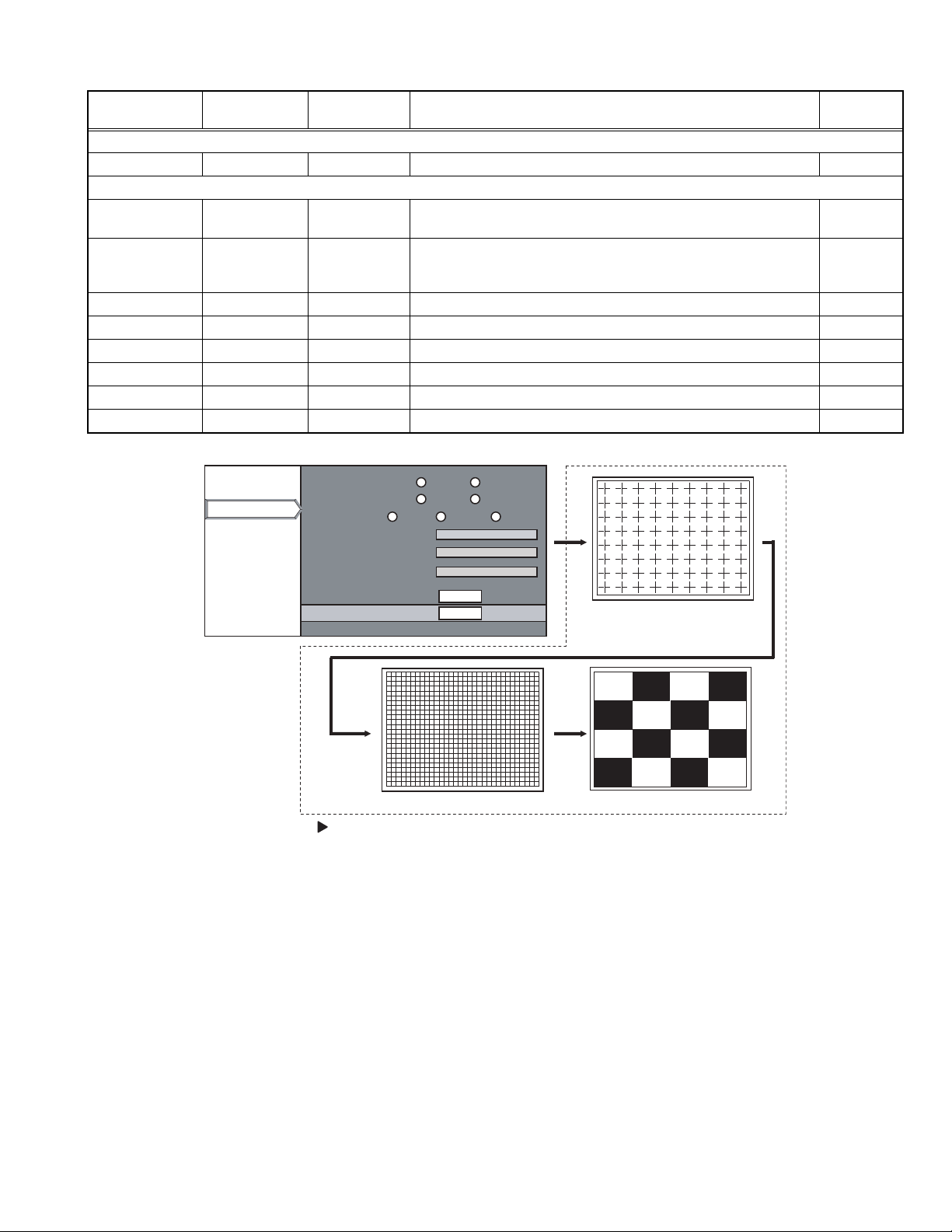

Adjust pattern ------ [Select 5 items] Press [ENTER] then Test pattern appear. (Refer to following Fig.1) Common

Test patter Screen

convergence

software version

options

SERVICE MENU Screen

Back Color Black

Auto shut off Off

Color temp.

RED

GREEN

BLUE

Factory reset

Adjust pattern

Blue

On

USER1 D65 USER2

0

0

0

ENTER

ENTER

checkercross-hatch

(When the key is pressed, the screen is changed one after the other as shown in the above.)

(No.PA019)1-11

Loading...

Loading...