Beko FLMSF53LL220, FLMSF53DL220, FLMSF53LL400, FLMSF53DL400 Installation And Operating Manual

METPOINT® FLM SF53

FLMSF53LL220 | FLMSF53DL220 | FLMSF53LL400 | FLMSF53DL400

Thermal ow meter

Installation and operating manual

EN - English

10-221

Installation and operating manual EN

2 METPOINT® SF53

Content

1. Safety information .......................................................................................................................................... 4

1.1. Pictograms and symbols .......................................................................................................................... 4

1.1.1. In this documentation ........................................................................................................................................................4

1.1.2. On the device .......................................................................................................................................................................4

1.2. Signal words according to ISO 3864 and ANSI Z.535 ................................................................................ 4

1.3. Safety instructions .................................................................................................................................. 5

1.4. Transport and storage ............................................................................................................................. 6

1.5. Intended use ........................................................................................................................................... 7

1.6. Warranty and liability ............................................................................................................................. 7

2. Product information ....................................................................................................................................... 8

2.1. Scope of delivery .................................................................................................................................... 8

2.2. Type plate ............................................................................................................................................... 8

2.3. Product overview and description ........................................................................................................... 9

2.3.1. Identication based on product code.............................................................................................................................9

2.3.2. Product description .........................................................................................................................................................10

2.3.3. Operating principle .......................................................................................................................................................... 10

2.4. Control and display elements ................................................................................................................ 11

2.4.1. Version with display .........................................................................................................................................................11

2.4.2. Version with LED .............................................................................................................................................................. 11

2.4.3. Direction of ow ............................................................................................................................................................... 12

2.5. Dimensions ........................................................................................................................................... 13

2.6. Technical data ....................................................................................................................................... 14

2.7. Measuring ranges ................................................................................................................................. 15

3. Installation ................................................................................................................................................... 17

3.1. Warning ................................................................................................................................................ 17

3.1.1. Requirements for piping ................................................................................................................................................. 17

3.1.2. Requirements for inlet/outlet sections ....................................................................................................................... 17

3.1.3. Turning housing ................................................................................................................................................................ 18

3.2. Installation ........................................................................................................................................... 19

4. Electrical installation .................................................................................................................................... 20

4.1. Pin assignment of plug-type connectors ................................................................................................ 20

4.2. Connection options ............................................................................................................................... 20

4.2.1. Bidirectional RS485 bus system .................................................................................................................................... 20

4.2.2. Current output 4 ... 20 mA, 3-wire .............................................................................................................................. 21

4.2.3. MBus....................................................................................................................................................................................21

4.2.4. Galvanically isolated pulse output ............................................................................................................................... 22

4.3. Connection of METPOINT® BDL ............................................................................................................. 23

4.3.1. Bidirectional RS485 bus system .................................................................................................................................... 23

4.3.2. Current output 4 ... 20 mA, 3-wire ............................................................................................................................... 24

4.3.3. Galvanically isolated pulse output ............................................................................................................................... 24

4.4. Connection to METPOINT® BDL compact ............................................................................................... 25

4.4.1. Bidirectional RS485 bus system .................................................................................................................................... 25

4.4.2. Current output 4 ... 20 mA, 3-wire ............................................................................................................................... 25

4.4.3. Galvanically isolated pulse output ............................................................................................................................... 26

4.5. Modbus termination ............................................................................................................................. 26

EN Installation and operating manual

3 METPOINT® SF53

5. Start-up ........................................................................................................................................................ 27

6. Conguration and operation ......................................................................................................................... 27

6.1. Display during operation ....................................................................................................................... 27

6.2. Setup menu .......................................................................................................................................... 28

6.3. Sensor Setup ......................................................................................................................................... 28

6.3.1. Entering pipe inside diameter ....................................................................................................................................... 29

6.3.2. Entering / changing consumption counter value ..................................................................................................... 29

6.3.3. Selecting units for consumption, ow, temperature and pressure ...................................................................... 30

6.3.4. Entering reference conditions ....................................................................................................................................... 31

6.3.5. Setting zero point for low-ow cut-o function ....................................................................................................... 32

6.4. Modbus setup ....................................................................................................................................... 33

6.4.1. Modbus settings (2001 ... 2005) ................................................................................................................................... 34

6.4.2. Values register (1001 …1500) ........................................................................................................................................34

6.5. Pulse / alarm ......................................................................................................................................... 35

6.5.1. Pulse output ...................................................................................................................................................................... 35

6.6. User Setup ............................................................................................................................................ 36

6.7. Advanced ............................................................................................................................................. 36

6.8. 4 ... 20 mA ............................................................................................................................................ 37

6.9. Info ...................................................................................................................................................... 38

6.10. MBus .................................................................................................................................................. 38

6.10.1. Default communication settings ................................................................................................................................ 38

6.10.2. Transferred values .......................................................................................................................................................... 38

7. Spare parts and accessories ........................................................................................................................... 39

8. Maintenance and servicing............................................................................................................................ 39

9. Cleaning sensor head .................................................................................................................................... 39

10. Calibration ................................................................................................................................................. 39

11. LED indicator .............................................................................................................................................. 39

12. Declaration of Conformity .......................................................................................................................... 40

Installation and operating manual EN

4 METPOINT® SF53

1. Safety information

1.1. Pictograms and symbols

1.1.1. In this documentation

General instructions

Observe installation and operating instructions

General hazard symbol (danger, warning, caution)

General hazard symbol (danger, warning, caution)

relating to mains voltage and powered machine parts

The packaging material is recyclable. Dispose of it according to the applicable statutory regulations.

1.1.2. On the device

General instructions

General hazard symbol (danger, warning, caution)

1.2. Signal words according to ISO 3864 and ANSI Z.535

DANGER

Imminent danger

Consequences of non-compliance: serious or even fatal injury

WARNING

Potential danger

Consequences of non-compliance: serious or even fatal injury

CAUTION

Imminent danger

Consequences of non-compliance: injury and/or damage to property

NOTICE

Additional notes, tips and hints

Consequences of non-compliance: inecient operation, extra maintenance;

no risk to persons

EN Installation and operating manual

5 METPOINT® SF53

1.3. Safety instructions

DANGER Escaping compressed gas

Risk of serious or even fatal injury from contact with escaping compressed gas or from unsecured plant

components.

• Before carrying out any assembly, installation or maintenance work, depressurise the system. All

above work must be carried out by authorised specialist technical personnel1.

• Use only pressure-resistant installation materials and suitable tools that are in proper working order.

• Before pressurising the system, check all unit parts and repair them, if necessary. Open valves slowly

to prevent pressure blows during operation.

• Make sure that no persons can be injured or objects can be damaged by condensate or escaping

compressed gas.

• Protect the device parts against vibration and impact.

DANGER Mains voltage

Risk of serious or even fatal injury from electric shock when coming into contact with non-insulated,

powered components.

• For the electrical installation of the device, adhere to all applicable regulations (e.g. VDE 0100 / IEC

60364).

• Before carrying out any maintenance work, de-energize the system.

• All electrical work must be carried out by authorised specialist technical personnel1.

• The permissible operating voltage is printed on the type plate and must be strictly adhered to.

• All components of the electrical installation on site must be approved and/or bear the CE mark.

• A reliably accessible circuit breaker (e.g. power plug or switch) that shuts o all conductors must be

installed close to the unit.

WARNING Operation of device outside limit range

If the specied limits are exceeded, there is a risk of device malfunction, potentially resulting in injury

and/or damage to property.

• The device must only be operated for the intended purpose and within the permissible limits

specied on the type plate and in the technical data.

• From 10 bar, install a high-pressure protection element for safe installation and removal of the device.

• Do not operate the device in connection with ammable gases.

• Strictly adhere to the prescribed operating times and maintenance intervals.

• Observe the prescribed storage and transport conditions.

• Prevent condensation on the sensor element. Ensure that the air fed through the device is free of

droplets.

1

Specialist technical personnel

Specialist technical personnel are persons who, due to their professional qualication and knowledge in the eld of measuring,

control and pneumatic technology, and their knowledge of the applicable statutory regulations, guidelines and standards are in a

position to foresee potential dangers in relation to the use of the device and are qualied to perform the tasks described in this

manual. Special operating conditions (e.g. aggressive media) require additional knowledge.

Installation and operating manual EN

6 METPOINT® SF53

1.4. Transport and storage

Despite our best eorts regarding packaging, etc., the device might be damaged during transport. Upon receipt, please remove all

packaging material and inspect the product for visible damage. If you detect such damage, immediately notify the carrier company

and BEKO TECHNOLOGIES GMBH or one of its agents.

CAUTION Damage caused during transport or storage

Incorrect transport or storage, or the use of unsuitable lifting equipment might cause damage to the

device.

• The device must only be transported and stored by authorised and suitably trained technical

personnel.

• If you detect any damage, do not start the device.

• Adhere to the permissible storage and transport temperatures (see technical data).

• Protect the device against direct sunlight and heat radiation.

The device must be stored in the original

packaging. Seal the packaging and store it in a

dry and frost-free room. Ensure that the storage

temperature does not exceed the limits specied

on the type plate.

Even when packaged, take suitable measures to

protect the device against the elements.

While in storage, secure the device so that it

cannot topple over or fall, and protect it against

vibration.

NOTICE Recycling of packaging material

• The packaging material is recyclable. Dispose of the packaging material according to the applicable

statutory regulations.

EN Installation and operating manual

7 METPOINT® SF53

1.5. Intended use

The METPOINT® FLM is a thermal ow meter for the measurement of volume ow, consumption and ow velocity. By default, the

device is congured for the measurement of volume ow in m³/h, consumption in m³ and velocity in m/s.

• The METPOINT® FLM is primarily used in compressed air systems. On request, the sensor can be programmed by BEKO

TECHNOLOGIES GmbH for the measurement of other gases: nitrogen, argon, helium, carbon dioxide

• The device is not suitable for operation in potentially explosive or aggressive atmospheres.

• Protect the device against direct sunlight and heat radiation.

Operate the METPOINT® FLM only for the intended purpose and within the limit range specied in the technical data. Do not

operate the device with any media (uids, gas/vapour mixtures) other than those listed above. Any other use of the device is

deemed improper and poses a risk to persons, property and the environment.

1.6. Warranty and liability

All warranty shall be voided, if the METPOINT® FLM is used improperly, for a purpose other than the intended or is operated

outside the limits specified in the technical data. In such cases, the manufacturer shall also reject any liability for damages.

Improper operation includes:

• Incorrect installation, commissioning or operation; insucient maintenance

• Operation with defective components

• Non-compliance with the instructions in this document, in particular the safety instructions

• Modication of the device

• Non-compliance with the prescribed maintenance intervals

• Use of third-party spare parts that have not been approved by the manufacturer

Installation and operating manual EN

8 METPOINT® SF53

2. Product information

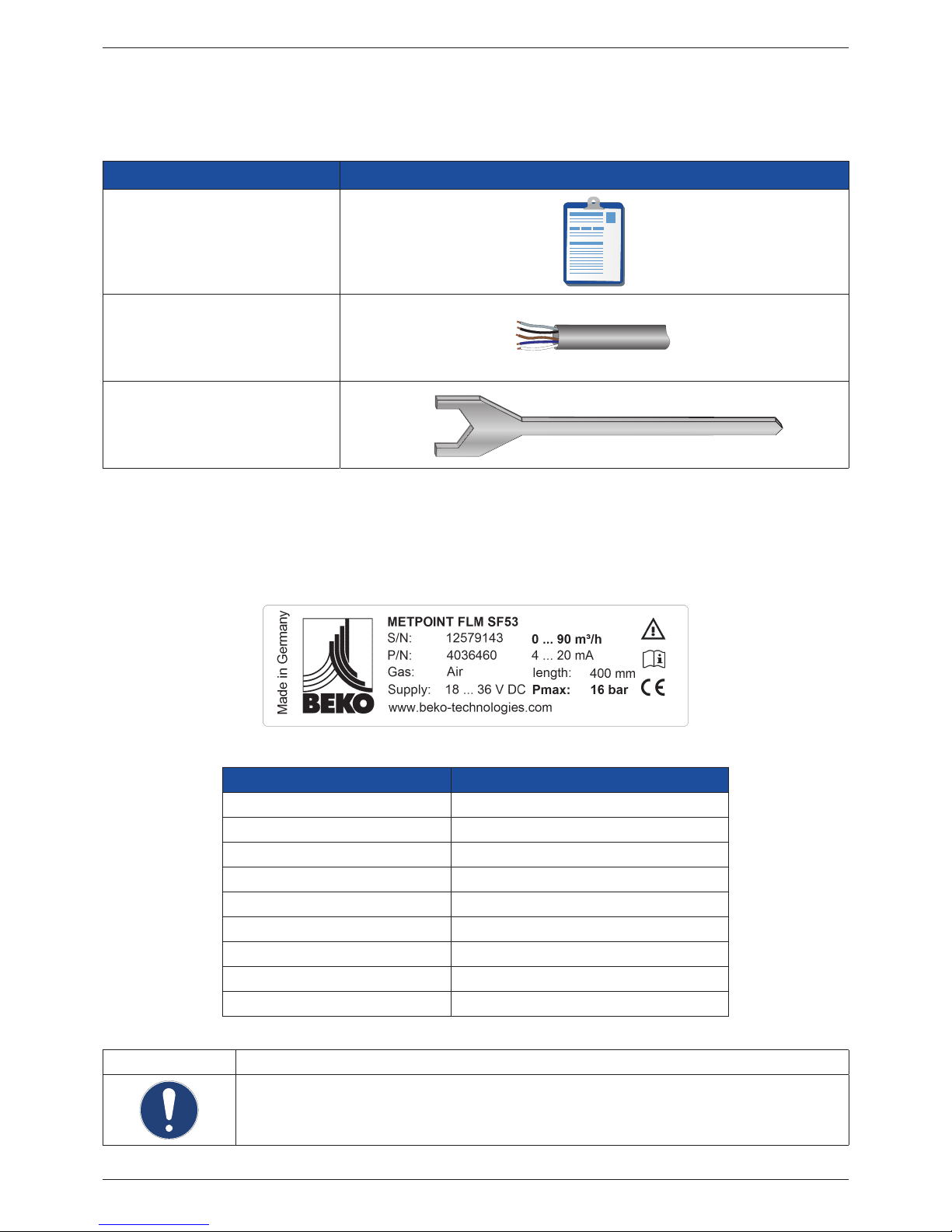

2.1. Scope of delivery

The table below shows the scope of delivery of the METPOINT® FLM.

Designation Picture

Calibration certicate

Connecting cable (5-wire)

Aligning aid

2.2. Type plate

The type plate is attached to the device housing. It contains all relevant technical data of the METPOINT® FLM. Please have these

details to hand when contacting the manufacturer or supplier:

Designation Description

METPOINT® FLM SF53 Type designation

S/N: 12579143 Serial number

P/N: 4036460 Product number

Gas: air Medium

Supply: 18 ... 36 V DC Power supply rating

0 ... 90 m³/h Min./max. measuring range

4 ... 20 mA Min./max. analog output current

Length: 400 mm Length of sensor tube

Pmax: 16 bar Max. permissible operating pressure

NOTICE Handling of type plate

Do not remove or cover the type plate, and protect it against damage.

For more information regarding the symbols printed on the type plate, see „Pictograms and symbols“

auf Seite 4.

EN Installation and operating manual

9 METPOINT® SF53

2.3. Product overview and description

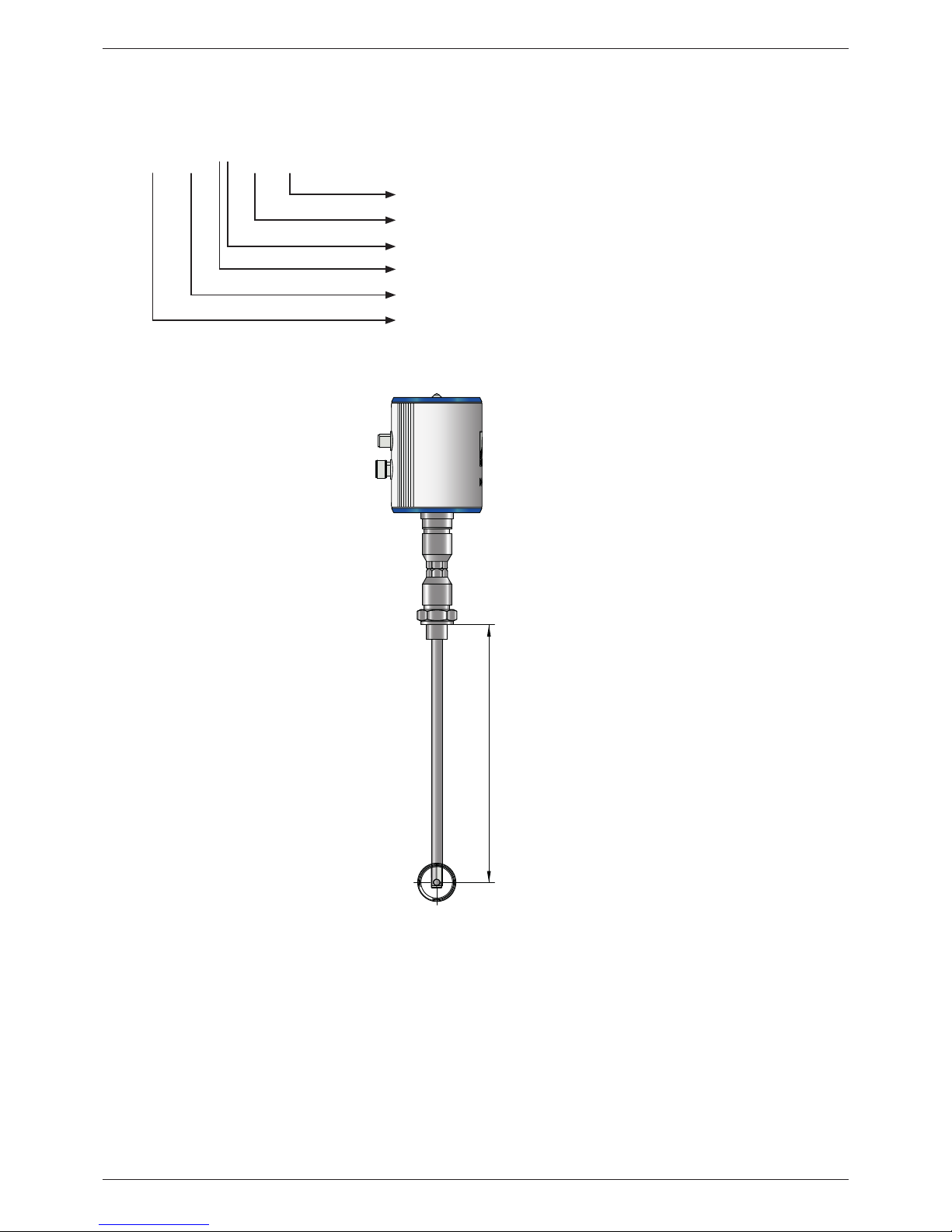

2.3.1. Identication based on product code

FLM

Sensor length (L)

Version with display

Interface: RS485

Operating pressure: 50 bar

SensorFlow (model designation)

FlowMeasurement (product designation)

SF 53

D

L220

L

Installation and operating manual EN

10 METPOINT® SF53

2.3.2. Product description

The METPOINT® FLM thermal ow meter measures the volume ow, which forms the basis for intelligent energy management.

It can be used to identify potential savings, overloads and weak points in a system to improve its eciency. By measuring the

actual ow to the various production units, operators are in a position to make decisions based on facts. The METPOINT® FLM

also indicates whether there are any leaks in their system. The METPOINT® FLM thus provides all the information operators need

to correctly dimension and congure their system and system components for improved eciency. The device is equipped with a

Modbus RTU(RS485) interface, a 4 ... 20 mA current output, a galvanically isolated pulse output and an optional MBus interface.

2.3.3. Operating principle

Two temperature sensors are installed in series in the direction of ow. The rst temperature sensor measures the current process

temperature, while the second sensor is electrically heated to a temperature that is exactly 40 K above the temperature measured

by the rst sensor. As the volume ow increases, the sensors would normally cool, but the electric heater of the second sensor

prevents such a temperature drop.

The electric energy required to maintain the temperature dierence is directly proportional to the volume ow. This energy

consumption of the heater is converted into the relevant ow measurements. Taking into account the inside diameter of the pipe,

the METPOINT® FLM determines the exact mass ow.

EN Installation and operating manual

11 METPOINT® SF53

2.4. Control and display elements

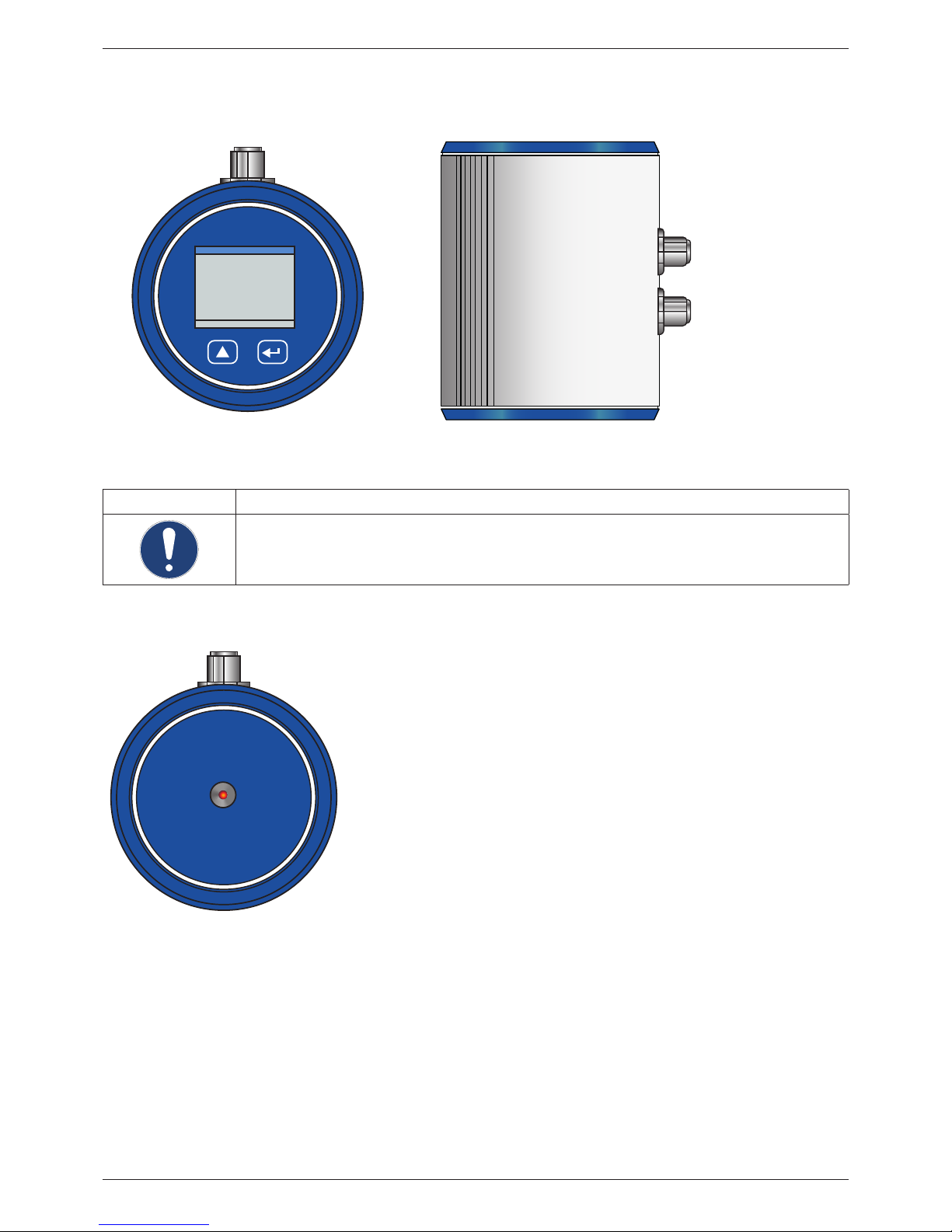

2.4.1. Version with display

NOTICE Additional information

For more information regarding the operation of the device, see „Conguration and operation“ auf Seite

27.

2.4.2. Version with LED

The METPOINT® FLM features a LED calibration indicator mounted at the top of the housing. After 15 months, the LED begins to

ash, indicating that the device needs to be calibrated. The ashing LED does not have any eect on the measuring process, and

the device continues to provide accurate measuring signals.

On request, the calibration interval can be adjusted at the factory.

ME TPOINT® F LM

FLOW MEASURING

HW:1.00 SW:1.00

AIR

395,38

160515

m3/h

m

3

Plug-type connector A

Plug-type connector B

METPOINT® FLM

C

A

L

I

B

R

A

T

I

O

N

Installation and operating manual EN

12 METPOINT® SF53

2.4.3. Direction of ow

The direction of ow is indicated by the arrows (1) on the housing of the METPOINT® FLM and on the sensor tube.

1

NOTICE Additional information

If necessary, turn the housing (e.g. to change the direction of ow through the device). For more

information, see „Turning housing“ auf Seite 18.

EN Installation and operating manual

13 METPOINT® SF53

2.5. Dimensions

Dimensions

Version with display Version with LED

A G ½" (ISO 228/1)

B (mm) 415 (Standard) 418.5 (Standard)

C (mm) 80

D (mm) Ø 11.7

E (mm) 220 (standard), optional: 400

F (mm) 94

G (mm) 102 105.5

F

E

D

C

A

B

G

F

F

E

D

E

D

C

A

B

G

A

B

G

C

Installation and operating manual EN

14 METPOINT® SF53

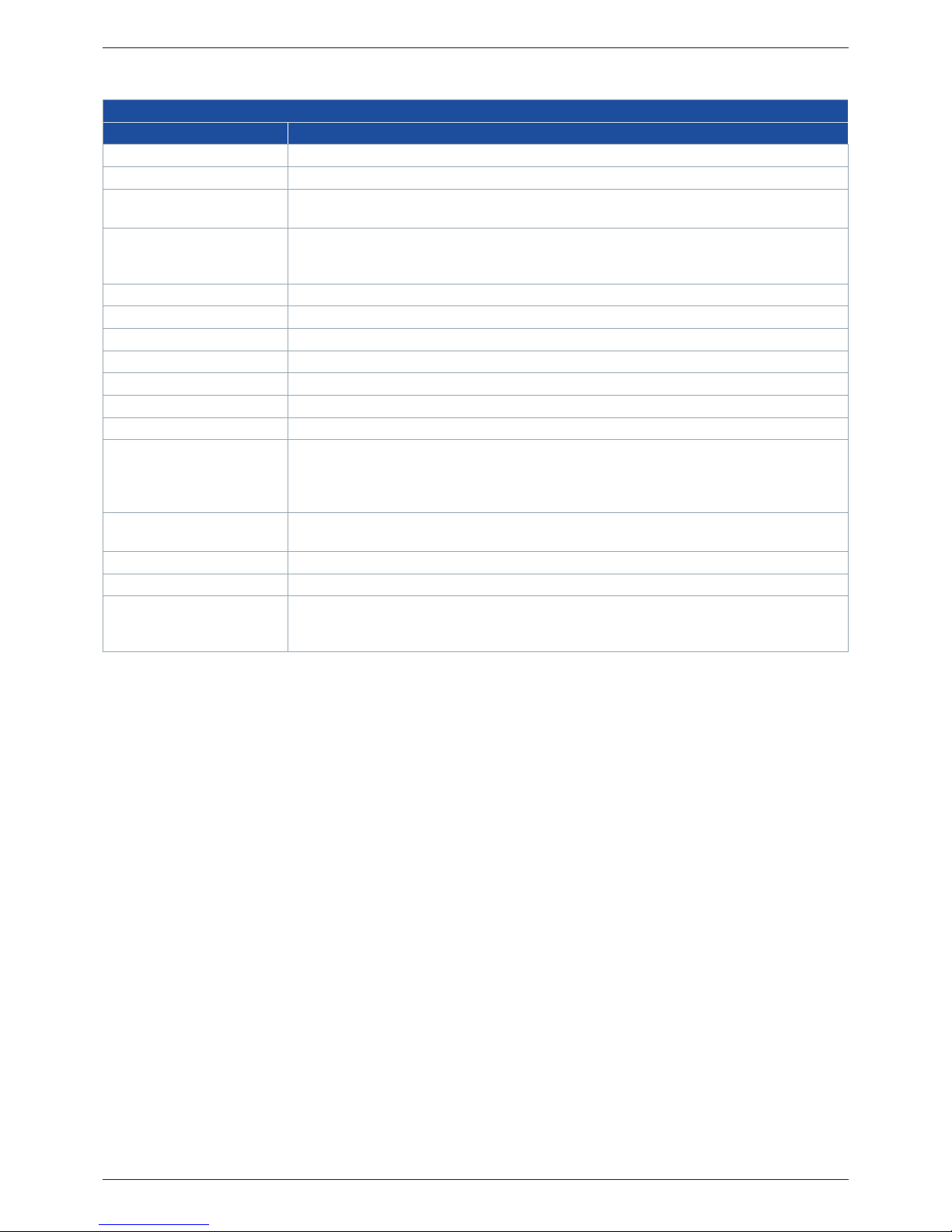

2.6. Technical data

Technical data

SF53

Max. operating pressure 16 bar, optional 50 bar

Measuring technique Calorimetric

Operating temperature Sensor tube and ttings: -30 ... +140 °C

Housing: -30 ... +80 °C

Measured parameters m³/h (factory settings)

On the display version, the following units can be chosen:

m³/min, l/min, l/s, ft/min, cfm, m/s, kg/min, kg/s

Sensor Pt45, Pt1000

Media nitrogen, argon, helium, carbon dioxide

Humidity of medium max. 90 % rH (no droplets)

Power supply 18 ... 36 VAC

Power consumption max. 5 W

Digital output RS485 (Modbus RTU)

Analog output 4 ... 20 mA (max. load < 500 Ω)

Pulse output Floating switch contact

Passive: max. 48 VDC 150 mA

1 pulse per m³ or per litre

Unit adjustable at display

Accuracy ± 1.5 % of measured value

± 0.3 % of nal value

Display/indicator Display: TFT 1.8" (resolution: 220 x 167) or service LED

Screw tting G½ (ISO 228/1)

Material Sensor tube and ttings: 1.4301 stainless steel

Housing: Powder-coated aluminium

Flange: 1.4404 (DIN EN 1092-1)

Loading...

Loading...