Beko CLEARPOINT L 215 V, CLEARPOINT L 220 V, CLEARPOINT L 205 V, CLEARPOINT L 210 V, CLEARPOINT L 225 V Instructions For Installation And Operation Manual

...

EN - english

Instructions for installation and operation

Activated-carbon adsorber without dust filter

CLEARPOINT®L 205 – L295 V

Dear customer,

Thank you for deciding in favour of the CLEARPOINT®V activated-carbon adsorber. Please read these

installation and operating instructions carefully before mounting and starting up the CLEARPOINT®V

activated-carbon adsorber and follow our directions. Perfect functioning of the activated-carbon adsorber

can only be guaranteed when the provisions and notes stipulated here are strictly adhered to.

2 CLEARPOINT® L 205 – L295 V

Type plate CLEARPOINT® V activated-carbon adsorber

Year of construction

:

Type:

Max.

volume flow at the INLET

1 Type plate CLEARPOINT®V activated-carbon adsorber

Manufacturer:

BEKO TECHNOLOGIES GMBH

41468 Neuss, Germany

Phone: +49 2131 988-0

www.beko.de

Serial no.:

Max. permissible operating pressure

PS:

Working pressure:

Min./max. permissible temperature TS:

Compressed-air inlet temperature:

Weight approx.:

Please enter the data from the type plate of the activated-carbon adsorber here!

CLEARPOINT® L 205 – L295 V 3

Contents 2 Contents

1 Type plate CLEARPOINT®V activated-carbon adsorber.................................................................3

2 Contents............................................................................................................................................4

3 General advice ..................................................................................................................................6

4 Safety instructions.............................................................................................................................7

4.1 Safety labelling..................................................................................................................................7

4.1.1 Safety pictograms in accordance with DIN 4844...............................................................................7

4.1.2 Signal words in accordance with ANSI..............................................................................................8

4.2 General safety instructions................................................................................................................9

4.3 Special advice for plants under pressure in accordance with the 97/23/EC Pressure Equipment

Directive...........................................................................................................................................13

5 Residual risk....................................................................................................................................14

6 Field of application and proper use of the CLEARPOINT®V activated-carbon adsorber ...............14

7 Applied EU directives and harmonised standards...........................................................................15

8 General description of the CLEARPOINT®V activated-carbon adsorber .......................................16

9 Operating principle ..........................................................................................................................17

10 Technical data.................................................................................................................................18

10.1 Technical data CLEARPOINT®L 205-295 V...................................................................................18

10.2 Availableoptions..............................................................................................................................20

10.3 Filter selection table.........................................................................................................................21

11 Description of the components........................................................................................................22

12 Transport and set-up .......................................................................................................................24

12.1 Safety during transport and set-up ..................................................................................................24

12.2 Transport.........................................................................................................................................24

12.3 Set-up..............................................................................................................................................25

13 Installation .......................................................................................................................................26

13.1 Safety during the installation............................................................................................................26

13.2 Minimum requirements....................................................................................................................28

13.2.1 Filtration of the compressed air.......................................................................................................28

13.2.2 Water content of the compressed air ..............................................................................................28

13.2.3 Inlet temperature of the compressed air..........................................................................................28

13.3 Installation examples.......................................................................................................................29

13.3.1 Installation diagram CLEARPOINT®V with a refrigeration dryer ....................................................29

13.3.2 Installation diagram CLEARPOINT®V with an adsorption dryer.....................................................30

13.4 Work steps during the installation ...................................................................................................31

14 Start-up............................................................................................................................................32

14.1 Safety during the start-up ................................................................................................................32

14.2 Check prior to the start-up...............................................................................................................33

4 CLEARPOINT® L 205 – L295 V

Contents

14.3 Initial start-up...................................................................................................................................34

14.4 Restart.............................................................................................................................................35

14.5 Removal from service......................................................................................................................35

15 Troubleshooting and fault elimination..............................................................................................36

15.1 Safety during troubleshooting and fault elimination.........................................................................36

15.2 Status and alarm indications ...........................................................................................................38

16 Maintenance....................................................................................................................................40

16.1 Safety during maintenance..............................................................................................................40

16.2 Maintenance in general...................................................................................................................42

16.3 Maintenance of the CLEARPOINT®V activated-carbon adsorber..................................................42

16.3.1 Replacement of the activated carbon..............................................................................................43

16.4 Periodic inspections.........................................................................................................................45

17 Dismantling and disposal ................................................................................................................46

18 List of spare parts............................................................................................................................47

19 EC Declaration of Conformity..........................................................................................................47

CLEARPOINT® L 205 – L295 V 5

General advice

3 General advice

Prior to starting up the CLEARPOINT®V activated carbon adsorber, it must be ensured that

the operating staff are instructed and skilled according to these instructions for installation and

operation with regard to the set-up, monitoring, operation and maintenance of the plant, as well

as to the safety measures to be observed.

The operating instructions must be accessible at all times at the place of application of the

device.

Non-observance of the installation and operating instructions involves risks for persons and

systems.

If you have any queries regarding these instructions, please contact BEKO TECHNOLOGIES

GMBH.

6 CLEARPOINT® L 205 – L295 V

Safety instructions

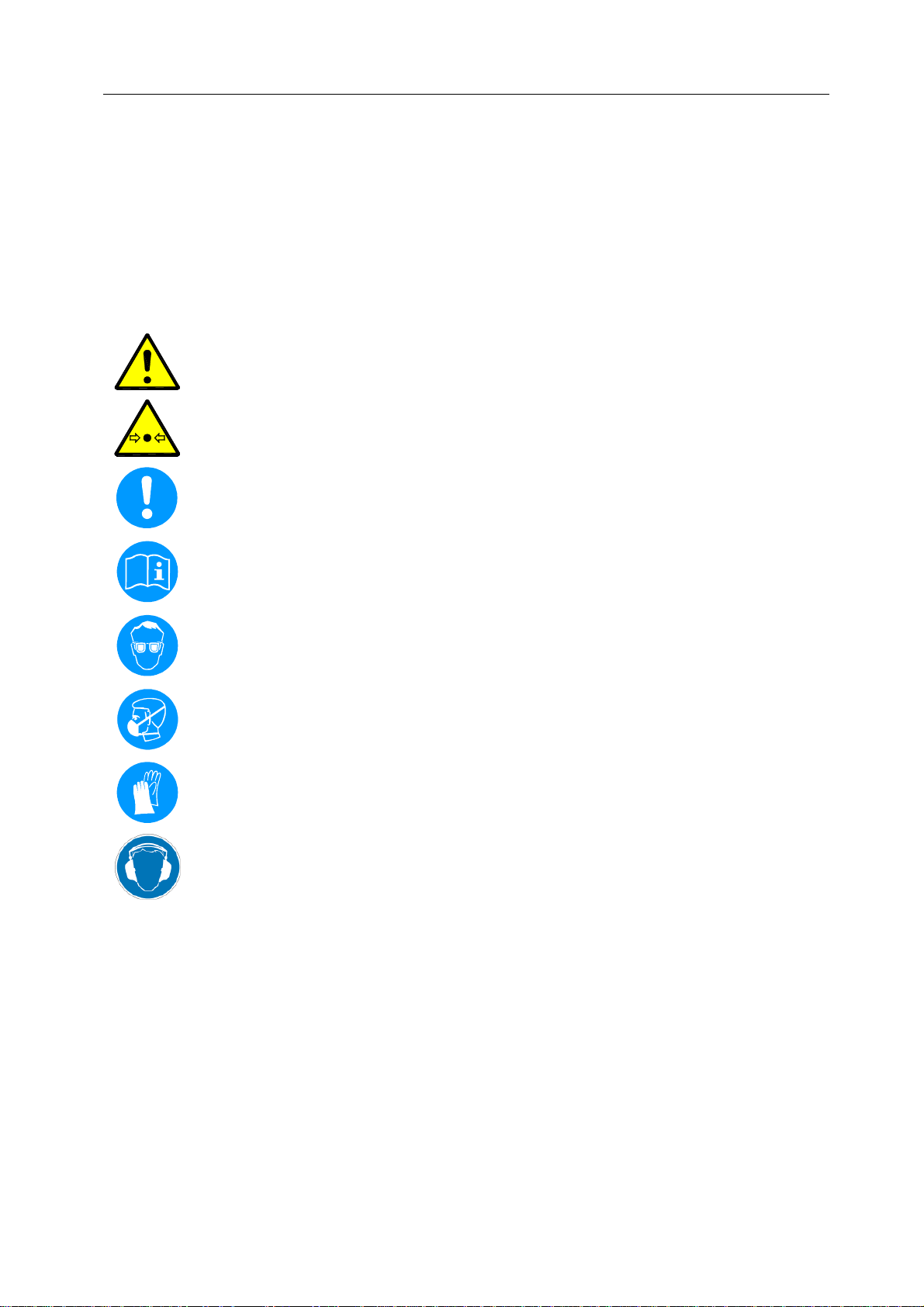

4 Safety instructions

4.1 Safety labelling

Safety instructions whose non-observance represents a threat to life and physical condition or can lead to

property damage are labelled in accordance with DIN 4844 and ANSI Z535.

4.1.1 Safety pictograms in accordance with DIN 4844

General danger symbol

Quickly escaping compressed air

Note

Observe operating instructions

Use eye protection

Wear light breathing protection

Use protective gloves

Wear ear protectors

CLEARPOINT® L 205 – L295 V 7

Safety instructions

4.1.2 Signal words in accordance with ANSI

Danger!

Warning!

Caution!

Notice!

Important!

Imminent hazard

Consequences of non-observance: serious injury or death

Potential hazard

Consequences of non-observance: possible serious injury or death

Imminent hazard

Consequences of non-observance: possibly injury or property damage

Potential hazard

Consequences of non-observance: possibly injury or property damage

Additional advice, info, hints

Consequences of non-observance: disadvantages during operation and maintenance, no

danger

8 CLEARPOINT® L 205 – L295 V

4.2 General safety instructions

Installation works must exclusively be carried out by authorised and qualified skilled

personnel. Prior to undertaking any measures on the CLEARPOINT®V, the skilled personnel

shall read up on the device by carefully studying the operating instructions. The operator is

responsible for the adherence to these provisions. The respective directives in force apply to

the qualification and expertise of the skilled personnel.

For safe operation, the device must only be installed and operated in accordance with the

indications in the operating instructions. In addition, the national and operational statutory

provisions and safety regulations, as well as the accident prevention regulations required for

the respective case of application, need to be observed during employment. This applies

accordingly when accessories are used.

Danger!

Compressed air!

Risk of serious injury or death through contact with quickly or suddenly escaping

compressed air or through bursting and/or unsecured plant components.

All types of installation, maintenance and repair works must only be carried out when the

CLEARPOINT®V is pressureless.

Safety instructions

It is the operator’s duty to ensure that the connected pressure generator is secured against

exceeding of the maximum operating overpressure and the temperature limits at the

CLEARPOINT®V.

Pressure relief valves used need to be arranged in such a manner that endangering of

persons is excluded. Where required, observe the manufacturer's additional advice. Suitable

and permissible arming devices need to be provided in accordance with the local regulations.

The max. permissible operating parameters, such as the operating overpressure,

temperature and volume flow must not be exceeded. The max. permissible operating

parameters are specified on the type plate and in the technical data (see "Technical data"

section).

Never make structural modifications to the plant!

Use suitable tools and genuine spare parts and accessories only!

Only use fittings and connecting elements that are approved for this application. It is of vital

importance to observe the specifications of the respective manufacturer. Ensure that the

connections are installed according to good professional practice.

Only use pipes, valves and fittings which are suitable for the pressure and temperature

range. It is of vital importance to observe the specifications of the manufacturer.

Sudden impact through pressure build-up can cause damage and escape of compressed air.

Avoid a sudden pressure build-up by operating the valves slowly.

Check all pipe connections subsequent to the installation and retighten them if necessary!

The general safety and accident prevention regulations apply!

Prior to the start-up, a leak test needs to be carried out. This test shall only be effected by

correspondingly qualified skilled personnel in compliance with the safety regulations.

Caution!

Unauthorised intervention!

Unauthorised interventions may endanger persons and plants and lead to

malfunction.

CLEARPOINT® L 205 – L295 V 9

Safety instructions

Unauthorised interventions, modification and abuse of the pressure device are prohibited.

Operators of the devices must observe the local and national pressure equipment

regulations in the country of installation.

Danger!

High pressure!

Subsequent to the start-up, components of the plant are under pressure.

Risk of serious injury or death through contact with quickly or suddenly escaping

compressed air or through bursting and/or unsecured plant components.

Any installation, repair and maintenance works must only be carried out when the plant is

disconnected, pressureless and de-energised.

Warning!

Improper use and application!

Improper use and application can lead to injury and damage to plants.

The following use is considered improper and is therefore prohibited:

Exceeding the max. permissible operating pressure

Exceeding the max. permissible operating temperature

Exceeding the max. permissible volume flow

All individual cases of application which are described as improper

Caution!

Improper transport!

Improper transport can lead to injury and damage to plants.

The CLEARPOINT®V must only be transported and installed by qualified and authorised

skilled personnel.

Only use suitable and technically unobjectionable lifting tools!

Only use lifting tools with a sufficient carrying capacity!

The respective national regulations and directives in force must be adhered to. Otherwise,

personal injuries may occur.

NOTE!

Damage through defective components!

Under no circumstances should you start up a damaged CLEARPOINT®V. Defective

components can impair the operational reliability and cause further damage.

Caution!

Incorrect installation!

Incorrect installation of the CLEARPOINT V®may endanger persons.

Ensure that the personnel in charge of the installation of the CLEARPOINT®V are sufficiently

instructed and competent for this task.

10 CLEARPOINT® L 205 – L295 V

Safety instructions

Danger!

Incorrect start-up!

The incorrect start-up of the CLEARPOINT®V may endanger persons.

Prior to starting up the CLEARPOINT®V, it must be ensured that the operating staff are

instructed according to these instructions for installation and operation with regard to the setup, monitoring, operation and maintenance of the plant, as well as to the safety measures to

be observed.

CAUTION!

Operational reliability at risk!

Overloading the CLEARPOINT®V can compromise the operational reliability!

Observe the permissible temperature range!

Do not exceed the permissible volume flow!

NOTE!

Operational reliability at risk!

Incorrect installation can compromise the operational reliability and affect service measures.

The clear diameter of the pipe joint must be at least as large as the mounting dimension of

the CLEARPOINT®V.

It is strongly recommended to install a shut-off valve both upstream and downstream of the

CLEARPOINT®V for the implementation of service measures.

To maintain the supply of compressed air during service failures, maintenance and repair

works on the CLEARPOINT®V, the installation of a bypass line around the CLEARPOINT®V

is advisable. This bypass line must have a shut-off valve.

Danger!

Mishandling!

Mishandling of the CLEARPOINT®V may endanger persons.

Prior to starting up the CLEARPOINT®V, it must be ensured that the operating staff are

instructed according to these instructions for installation and operation with regard to the setup, monitoring, operation and maintenance of the plant, as well as to the safety measures to

be observed.

CLEARPOINT® L 205 – L295 V 11

Safety instructions

Danger!

Incorrect maintenance!

The incorrect maintenance of the CLEARPOINT®V may endanger persons.

Ensure that the personnel in charge of the operation, monitoring and maintenance of the

CLEARPOINT®V are sufficiently instructed and competent for this task.

Caution!

Activated-carbon dust!

Eyes and respiration are endangered through quickly or suddenly escaping activated-

carbon dust.

Activated carbon can produce dust and wear debris!

Use eye protection!

During the start-up of the activated-carbon adsorber, compressed air might escape and

cause a very loud expansion noise. Wear silencing ear protectors.

Wear personal protective clothing!

Wear light breathing protection at strong dust development!

Caution!

Activated carbon produces dust and wear debris!

Endangering through dust explosion.

Use suitable tools and ex-protection-tested suction plants and accessories. Observe the

safety instructions.

12 CLEARPOINT® L 205 – L295 V

Safety instructions

4.3 Special advice for plants under pressure in accordance with the 97/23/EC Pressure Equipment Directive

The CLEARPOINT®V activated-carbon adsorber is a pressure device in the sense of the 97/23/EC

Pressure Equipment Directive. Therefore, the plant needs to be registered with the supervisory authority

in accordance with the local regulations, and requires the approval of the latter.

For the examination prior to the start-up and for periodic inspections, the national regulations need to be

observed, such as the industrial safety regulation in the Federal Republic of Germany. In countries

outside the EU, the respective regulations in force there need to be adhered to.

The proper use of pressure devices is the basic requirement for safe operation. As regards pressure

devices, the following needs to be observed:

The CLEARPOINT®V must only be employed within the pressure and temperature range limits

indicated by the manufacturer on the type plate.

No welding must be carried out on the pressure vessel of the device.

The CLEARPOINT®V must neither be installed in insufficiently ventilated rooms nor near heat

sources or inflammable substances.

To avoid fractures resulting from material fatigue, the CLEARPOINT®V should not be exposed

to vibrations during operation.

The maximum operating pressure indicated by the manufacturer on the type plate must not be

exceeded. It is the operator's responsibility to install the appropriate safety and control devices.

Prior to the start-up of the CLEARPOINT®V, the connected pressure generator (compressor

etc.) must be safeguarded against exceeding of the max. permissible operating pressure. The

integrated safeguard needs to be checked by an approved inspection agency.

The documents related to the CLEARPOINT®V (manual, operating instructions, manufacturer's

declaration etc.) must be kept safe for future reference.

No objects whatsoever must be installed or placed on the CLEARPOINT®V and the connecting

lines.

Installation of the plant in frost-free places only.

WARNING!

Unauthorised intervention!

Unauthorised interventions may endanger persons and plants and lead to malfunction.

Unauthorised interventions, modification and abuse of the pressure devices are prohibited.

Operators of the devices must observe the local and national pressure equipment

regulations in the country of installation.

Warning!

High pressure!

Subsequent of the start-up of the CLEARPOINT®V components of the plant are under

pressure. Serious injuries are possible.

Any installation, repair and maintenance works on the CLEARPOINT®V must only be carried

out when the plant is pressureless.

CLEARPOINT® L 205 – L295 V 13

Residual risk 5 Residual risk

The plant offers state-of-the-art technology. However, certain residual risks remain.

Risk through disregard of the safety instructions.

The safety instructions included in these operating instructions point to further residual risks. It is,

therefore, of vital importance to observe all safety instructions.

6 Field of application and proper use of the CLEARPOINT®V activated-carbon

adsorber

These operating instructions apply exclusively to the tank variants of the CLEARPOINT®L205 V to L295

V activated-carbon adsorbers from BEKO TECHNOLOGIES GMBH and refer to the device type without

dust filter and internal tubing.

The CLEARPOINT V®activated-carbon adsorber must only be applied under the conditions described in

this user manual, and only in connection with the components recommended or approved by the

manufacturer.

The field of application comprises the reduction of oil vapours and odorous substances from compressed

air or nitrogen. The system is intended for the use under industrial conditions inside buildings.

Any other use is considered improper. The manufacturer shall not be liable for problems occurring as a

consequence of improper use. The operator alone is responsible for any hazard resulting from that.

Please check, prior to reading the operating instructions, whether or not these instructions

correspond to the device.

Read these installation and operating instructions carefully prior to any intervention regarding

the CLEARPOINT®V.

The operating instructions must be accessible at all times at the place of application of the

device.

If you have any queries regarding these instructions, please contact BEKO TECHNOLOGIES

GMBH.

To ensure safe operation, the device must only be operated and maintained in accordance

with the indications in the operating instructions. In addition, the national and operational

statutory provisions and safety regulations, as well as the accident prevention regulations

required for the respective case of application, need to be observed during employment. This

applies accordingly when accessories are used.

Non-observance of the installation and operating instructions involves risks for persons and

systems.

Proper functioning and trouble-free operation of the activated-carbon adsorber is only ensured when the

transport, storage, set-up, installation, operation and maintenance are carried out in accordance with the

advice included in this user manual.

To handle the plant, the personnel must be trained to deal with devices of the compressed-air technology

and need to know the contents of this user manual as far as handling is concerned.

To start up and maintain the plant, the personnel must be familiar with the safety concepts of the

compressed-air technology. The personnel must be authorised and trained in such a manner that they

are capable of starting up and maintaining such facilities.

The proper employment and use of the CLEARPOINT®V according to the directions requires the exact

compliance with the installation instructions, in particular in respect of:

14 CLEARPOINT® L 205 – L295 V

Applied EU directives and harmonised standards

The place of installation, installation conditions

The pressure and temperature of the inlet air

The ambient temperature

The device is supplied as accepted in the factory. The operator only needs to establish the connections

with the compressed-air system, which is described in the following chapters.

WARNING!

Improper use!

The following is considered as improper use and is prohibited:

Exceeding the max. permissible operating pressure

Exceeding the max. permissible operating temperature

Exceeding the max. permissible volume flow

Employment of the CLEARPOINT®V in hazardous areas

All individual cases of application which are not described as proper us

7 Applied EU directives and harmonised standards

Applied EU directives:

97/23/EC Pressure Equipment Directive

Harmonised standards applied:

EN 10216-2: Seamless steel tubes for pressure purposes. Technical delivery conditions -

Part 2: Non-alloy and alloy steel tubes with specified elevated temperature

properties

EN 10028-2: Flat products made of steels for pressure purposes - Part 2: Non-alloy and alloy

steels with specified elevated temperature properties

EN 10242: Threaded pipe fitting in malleable cast iron

AD-2000 bulletins

CLEARPOINT® L 205 – L295 V 15

Loading...

Loading...