Page 1

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

SERVICE HANDBOOK NO:1

B13 B7S-B7SLED CONTROL SYSTEM

WASHING MACHINE

SERVICE HANDBOOK

Page 2

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

1. DOOR

2. Contents

1. DOOR………………………………………….………..………………………………..1

1. DOOR ...................................................................................................................................................... 2

2. CONTENTS ............................................................................................................................................... 2

3. SECURITY WARNINGS .............................................................................................................................. 5

3.1. GENERAL SECURITY ................................................................................................................................... 5

3.1.1. Electrical safety ............................................................................................................................... 5

3.1.2. Product safety ................................................................................................................................. 5

3.2. INTENDED USE ......................................................................................................................................... 6

3.3. CHILD SAFETY ........................................................................................................................................... 6

3.4. COMPLIANCE TO ROHS DIRECTIVE ............................................................................................................... 6

3.5. PACKAGING INFORMATION .......................................................................................................................... 7

3.6. DISPOSAL OF WASTE PRODUCT ..................................................................................................................... 7

3.7. POINTS TO CONSIDER DURING SERVICE .......................................................................................................... 7

4. PRODUCT INSTALLATION / INSTALLATION RULES / SETTINGS ................................................................. 9

4.1. CORRECT PLACE FOR INSTALLATION .............................................................................................................. 9

4.2. REMOVING THE PACKAGE SUPPORT ............................................................................................................ 10

4.3. REMOVING THE TRANSPORT SAFETY BOLTS .................................................................................................. 10

4.4. CONNECTION TO THE SUPPLY WATER.......................................................................................................... 11

4.5. CONNECTION TO THE WATER DRAIN ............................................................................................................ 12

4.6. ADJUSTMENT OF LEGS .............................................................................................................................. 13

4.7. ELECTRICAL CONNECTION .......................................................................................................................... 14

4.8. TRANSPORTATION OF THE PRODUCT............................................................................................................ 14

5. USE OF PRODUCT AND BYPRODUCTS .................................................................................................... 16

5.1. PREPARATION......................................................................................................................................... 16

5.1.1. Sorting the Laundry ....................................................................................................................... 16

5.1.2. Preparation of the garments to be washed ................................................................................... 17

5.1.3. Things to do for energy saving ...................................................................................................... 18

5.1.4. Correct load capacity ..................................................................................................................... 18

5.1.5. Laundry loading ............................................................................................................................. 19

5.1.6. Use of detergent and softener....................................................................................................... 19

5.1.7. First Use ......................................................................................................................................... 22

5.2. CONTROL PANEL ..................................................................................................................................... 23

5.3. PREPARING THE MACHINE ........................................................................................................................ 24

5.4. PROGRAM SELECTION AND TIPS FOR CORRECT WASHING ................................................................................. 25

5.5. MAIN PROGRAMS ................................................................................................................................... 26

5.6. ADDITIONAL PROGRAMS ........................................................................................................................... 26

5.7. SPECIAL PROGRAMS ................................................................................................................................. 27

5.8. TEMPERATURE SELECTION ......................................................................................................................... 27

5.9. AUXILIARY FUNCTION SELECTION ................................................................................................................ 28

5.10. STARTING THE PROGRAM .......................................................................................................................... 30

5.11. CHILD LOCK ........................................................................................................................................... 30

5.12. PROGRESS OF THE PROGRAM .................................................................................................................... 31

5.13. LOCK OF THE LOADING DOOR ..................................................................................................................... 31

5.14. CHANGING THE SELECTIONS AFTER THE PROGRAM STARTED ............................................................................. 31

5.15. CANCELLATION OF PROGRAM .................................................................................................................... 32

5.16. PROGRAM END ....................................................................................................................................... 32

5.17. THERE IS A “STANDBY MODE” IN YOUR MACHINE .......................................................................................... 32

6. MAINTENANCE AND CLEANING ............................................................................................................. 33

2

Page 3

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

6.1. CLEANING THE DETERGENT DISPENSER ......................................................................................................... 33

6.2. CLEANING THE LOADING DOOR AND THE DRUM ............................................................................................ 34

6.3. CLEANING THE BODY AND CONTROL PANEL ................................................................................................... 34

6.4. CLEANING THE WATER INLET FILTERS ........................................................................................................... 35

6.5. DRAINING THE REMAINING WATER AND CLEANING THE PUMP FILTER ................................................................. 35

7. . GENERAL OPERATING PRINCIPLE ......................................................................................................... 39

7.1. WATER INTAKE PROFİLE ........................................................................................................................... 39

7.2. HEATİNG PROFİLE ................................................................................................................................... 41

7.3. ANTİ-FOAMİNG PROFİLE ........................................................................................................................... 41

7.4. FOAM DETECTİNG AND EXTİNGUİSHİNG ALGORİTHM ..................................................................................... 42

7.5. PROGRAMME FLOWS ............................................................................................................................... 43

8. COMPONENT WORKING PRINCIPLES ..................................................................................................... 48

8.1. ELECTRONİC CONTROL AND VİSUAL CARD .................................................................................................... 48

8.2. SAFETY SWITCH (DOOR LOCK) ................................................................................................................... 49

8.3. MOTOR................................................................................................................................................. 49

8.4. HEATER ................................................................................................................................................. 50

8.5. VALVE ................................................................................................................................................... 50

8.6. DRAIN PUMP ......................................................................................................................................... 50

8.7. NTC ...................................................................................................................................................... 51

8.8. WATER LEVEL SENSOR ............................................................................................................................. 51

9. SERVICE FUNCTION TEST ....................................................................................................................... 53

10. B13 B7S B7SLED FAILURE FLOW DIAGRAM ............................................................................................ 57

11. LIST OF EQUIPMENT/APPARATUS TO BE USED IN COMPONENT ASSEMBLY / DISASSEMBLY ................ 80

11.1. SHOCK ABSORBER PIN PUNCHING APPARATUS ............................................................................................. 80

12. COMPONENT ASSEMBLY / DISASSEMBLY .............................................................................................. 83

12.1. UPPER TABLE ASSEMBLY / DISASSEMBLY ..................................................................................................... 83

12.2. FRONT DOOR GROUP ASSEMBLY/DISASSEMBLY ............................................................................................ 84

12.2.1. Exterior Door............................................................................................................................. 85

12.2.2. Hinge ........................................................................................................................................ 86

12.2.3. Handle cover ............................................................................................................................. 86

12.2.4. Handle ...................................................................................................................................... 87

12.2.5. Lock Hook- Spring ..................................................................................................................... 87

12.2.6. Decorative cover ....................................................................................................................... 88

12.2.7. Glass ......................................................................................................................................... 88

12.3. PUMP COVER ASSEMBLY/DISASSEMBLY ........................................................................................................ 88

12.4. FRONT WALL DISASSEMBLY/ASSEMBLY ....................................................................................................... 89

12.5. DISPENSER PANEL .................................................................................................................................... 90

12.6. PANEL ................................................................................................................................................... 91

12.7. PROTECTIVE FOIL .................................................................................................................................... 92

12.8. REFLECTOR ............................................................................................................................................ 93

12.9. PROGRAM CONTROL CARD ....................................................................................................................... 93

12.10. PARASITE FILTER ................................................................................................................................ 94

12.11. DETERGENT COMPARTMENT CONNECTION GROUP .................................................................................. 95

12.12. SINGLE VALVE .................................................................................................................................... 95

12.13. TWO-WAY VALVE ............................................................................................................................... 95

12.14. SAFETY SWITCH ................................................................................................................................. 96

12.15. HEATER ............................................................................................................................................ 96

12.16. PUMP .............................................................................................................................................. 97

12.17. DRUM BELLOWS ................................................................................................................................ 98

12.18. DRUM BELLOWS ASSEMBLY ................................................................................................................. 98

12.19. WATER INLET HOSE ............................................................................................................................ 98

3

Page 4

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

12.20. POLY V BELT ..................................................................................................................................... 99

12.21. PULLEY ............................................................................................................................................. 99

12.22. MOTOR ............................................................................................................................................ 99

12.23. POWER CABLE ................................................................................................................................. 100

12.24. UPPER COUNTERWEIGHT ................................................................................................................... 100

12.25. LOWER COUNTERWEIGHT .................................................................................................................. 100

12.26. DISCHARGE HOSE ............................................................................................................................. 101

13. POWER CIRCUIT DIAGRAM .................................................................................................................. 102

14. PRODUCTS WITH BUILT-IN DRAINING SIPHON SHUT-OFF SYSTEM ...................................................... 103

15. EXPLODED DRAWINGS ........................................................................................................................ 105

15.1. BODY GROUP ....................................................................................................................................... 105

15.2. CONTROL GROUP .................................................................................................................................. 105

15.3. WATER SYSTEM .................................................................................................................................... 106

15.4. VISUAL GROUP ..................................................................................................................................... 106

15.5. FRONT WALL GROUP ............................................................................................................................. 107

15.6. FRONT DOOR........................................................................................................................................ 107

15.7. DRIVING GROUP ................................................................................................................................... 108

15.8. 16.6. ISOLATION GROUP ........................................................................................................................ 108

16. PART LIST ............................................................................................................................................ 109

17. LIST OF FIGURES AND PICTURES .......................................................................................................... 109

18. TABLE LIST ........................................................................................................................................... 111

4

Page 5

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

3. Security Warnings

This section includes security instructions which may help prevent the injuries and

material damage risks. All kinds of warranties shall be invalid if these instructions are

not observed.

3.1. General Security

This product can be used by the children who are at the age of 8 and over and

the people whose physical, sensory or mental skills are not fully developed or who

do not have necessary required experience and knowledge as long as they are

supervised or trained about the safe use of the product and its risks. Children

should not play with the device. Cleaning and user maintenance procedures

should not be performed by the children unless they are supervised by a person.

Do not place the machine onto a floor covered with a carpet. Electrical parts will

get overheated since air cannot circulate from under the device. This may lead to

failures in machine.

If the product is faulty, it should not be operated before it is repaired by the

authorized service! Risk of electric shock!

3.1.1. Electrical safety

This product is designed to resume operation when power is on again after a

power cut. If you want to cancel a program, see the section titled “Cancelling a

Program”.

Plug the product into a grounded outlet protected by a 16-ampere fuse. Be sure to

make a qualified electrician arrange the grounding installation. If the machine is

used without grounding which conform to the local regulations, our company will

not be liable for any damages which may arise.

3.1.2. Product safety

Water mains and drain hose should be fixed securely and undamaged.

Otherwise, water leak may occur.

While there is still water inside the product, never open the loading door or

remove the filter. Probable injuries will take place due to flood or hot water.

Do not force open the locked loading door. Door can be opened a few minutes

after the washing cycle ends. If you force the loading door to open it, door and

lock mechanism may be damaged.

Unplug the product if it is not in use.

Do not wash the product by spraying or pouring water onto it! Risk of electric

shock!

Never touch the plug with wet hands! Do not grab the power cord to unplug the

machine, always unplug it by holding its plug.

Use only the detergents, softeners and additives intended for washing machines.

Observe the instructions on the label of textiles and the detergent package.

Product should be unplugged during installation, maintenance, cleaning and

repair procedures.

5

Page 6

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Always make the

Manufacturer cannot be held responsible for any damages which might arise due

to the operations performed by unauthorized persons.

If the power cord is damaged, it should be replaced by the manufacturer, after-

sale service or a similarly qualified, certified person (preferably an electrician) or a

person to be designated by the importer, in order to prevent the risk.

3.2. Intended Use

This product is for domestic use only. It is not suitable for commercial use and it

must not be used out of its intended use.

The product must only be used for washing and rinsing of laundry that are marked

accordingly.

The manufacturer waives any responsibility arisen from incorrect usage or

transportation.

Service life of the product you purchased is 10 years. This is the period of time

when the spare parts are made available in order for the product to operate as

specified.

Authorized Service

perform installation and repair procedures.

3.3. Child Safety

Packaging materials may be dangerous for the children. Keep the packaging

materials out of the reach of the children.

Electric products are dangerous for children. Keep the children away from the

product when it is in use. Do not allow them to play with the product. Activate child

lock to prevent the children to tamper with it.

Do not forget to close the loading door when leaving the room where the product

it located.

Keep all detergents and additives in a safe place out of the reach of the children

with their lids or packages are closed.

3.4. Compliance to RoHS Directive

This product does not contain the harmful and prohibited substances which are

specified in Directive “Restriction of the Use of Certain Hazardous Substances in

Electrical and Electronic Equipments” (Turkey RoHS) issued by the Ministry of

Environment and Forestry of Republic of Turkey.

Complies with the EEE Directive.

6

Page 7

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

3.5. Packaging information

Packaging materials of the product are manufactured from recyclable materials in

accordance with our National Environment Regulations.

Do not dispose of the packaging materials together with the domestic or other

wastes. Take them to the packaging material collection points designated by the local

authorities.

3.6. Disposal of waste product

This product has been manufactured with high quality parts and materials which can

be reused and are suitable for recycling.

For this reason, do not discard this product with the domestic products and other

wastes at the end of its service life. Take the product to a collection point for the

recycling of the electric and electronic equipments. Ask these collection points to the

local administration in your region. Help contribute to the protection of environment

and conservation of the natural resources by delivering the used products to the

recycling points. Before disposing the product, cut its power cord and break the lock

mechanism of the loading door and make it inoperable for the safety of children.

3.7. Points to consider during service

During panel installation, make sure that the cables to be mounted onto the

electronic card are not pinched between the bracket sheets. It should be ensured

that all the sockets on the electronic card are seated well.

Is should be ensured that cable in the installation of cable group is not damaged.

Stripped or damaged cables should not be installed.

Cable route should be taken into account during installation; cable’s coming into

contact with sharp surfaces should be avoided and it should not be pinched.

It should be ensured that the sockets of all components which are serviced are

seated well. Arc may occur in case of inadequate contact.

It should be checked that the serviced product is connected to a grounded outlet

which is protected by a fuse with suitable current. Connection should not be made

with extension cable or multiple outlet. Moreover, no extension should be made to

the power cord or internal cables.

Put the serviced product onto a firm ground; do not put it on a carpet with high pile

or other similar surfaces. Electrical parts may get overheated since air cannot

circulate from under the device.

Do not put the serviced product onto its power cord or another cable.

If you have to unplug the serviced product from the mains, never grab it from its

power cord, always unplug it by holding its plug only.

7

Page 8

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Check the power cord and plug of the serviced product. If its power cord or plug is

faulty, replace the power cord group completely with a new group. Please make

sure that the cables are not shortened, snapped, stripped, hardened and plug

ends are not broken, cracked, oxidized or loosened.

Check the outlet which the serviced product is plugged in. Product should not be

plugged in the outlets which are loosened, dislocated from its housing, broken, in

contact with water, dusty, dirty, oiled.

Along the route of the power cord from the outlet to the machine, make sure that

the cord does not come under heating sources, cupboards, devices, etc. which

may damage the product.

During service, do not perform hot works on the machine, such as soldering,

welding, etc. Do not leave these devices on the machine.

During service, do not wipe the machine with flammable and combustible

substances such as thinner, alcohol, etc.

After the machine is serviced, do not forget any paper-based materials inside the

machine such as service slip, brochure, etc.

IMPORTANT:

When the machine is required to be serviced by being tilted to the front, its transport

safety bolts should be installed.

This is required for the front components of the machine not to be damaged.

8

Page 9

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Customer is liable to prepare the place of installation for the product,

electricity, clean water and waste water installations.

Installation and electrical connections of the product should be performed

by Authorized Service. Manufacturer cannot be held responsible for any

damages which might arise due to the operations performed by

unauthorized persons.

WARNING:

Before use, check whether there is any damage on the

product. If the product is damaged, do not have it installed. Damaged

products pose a risk for your safety.

Make sure that the water inlet and drain hoses and the power cord of the

machine are not folded, pinched or broken during when the product is

pushed into its place after the installation or cleaning works.

4. Product Installation / Installation Rules / Settings

Apply to the nearest Authorized Service agent for the installation of your product. In

order to make your machine ready for use, before calling the authorized service,

make sure that electrical installation, clean water installation and water drain are

appropriate by checking the user manual. If this is not the case, call for a qualified

electrician and technician and take necessary actions.

4.1. Correct Place for Installation

Place the product on a hard floor. Do not put it onto a carpet with high pile or

other similar surfaces.

When the washing machine and drier are placed on top of each other, their total

weight –when loaded– amounts to 180 kilograms. Place the product onto a sound

and flat surface having an adequate load bearing capacity!

Do not place the product on the power cable.

Do not install the product in the environments where the temperature falls below 0

ºC.

Leave a minimum space of 1 cm between the machine and the furniture.

9

Page 10

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

WARNING:

Do not remove the transport safety bolts before removing the

packaging support.

WARNING:

Before operating the washing machine, remove the transport

safety bolts! Otherwise, the product will be damaged.

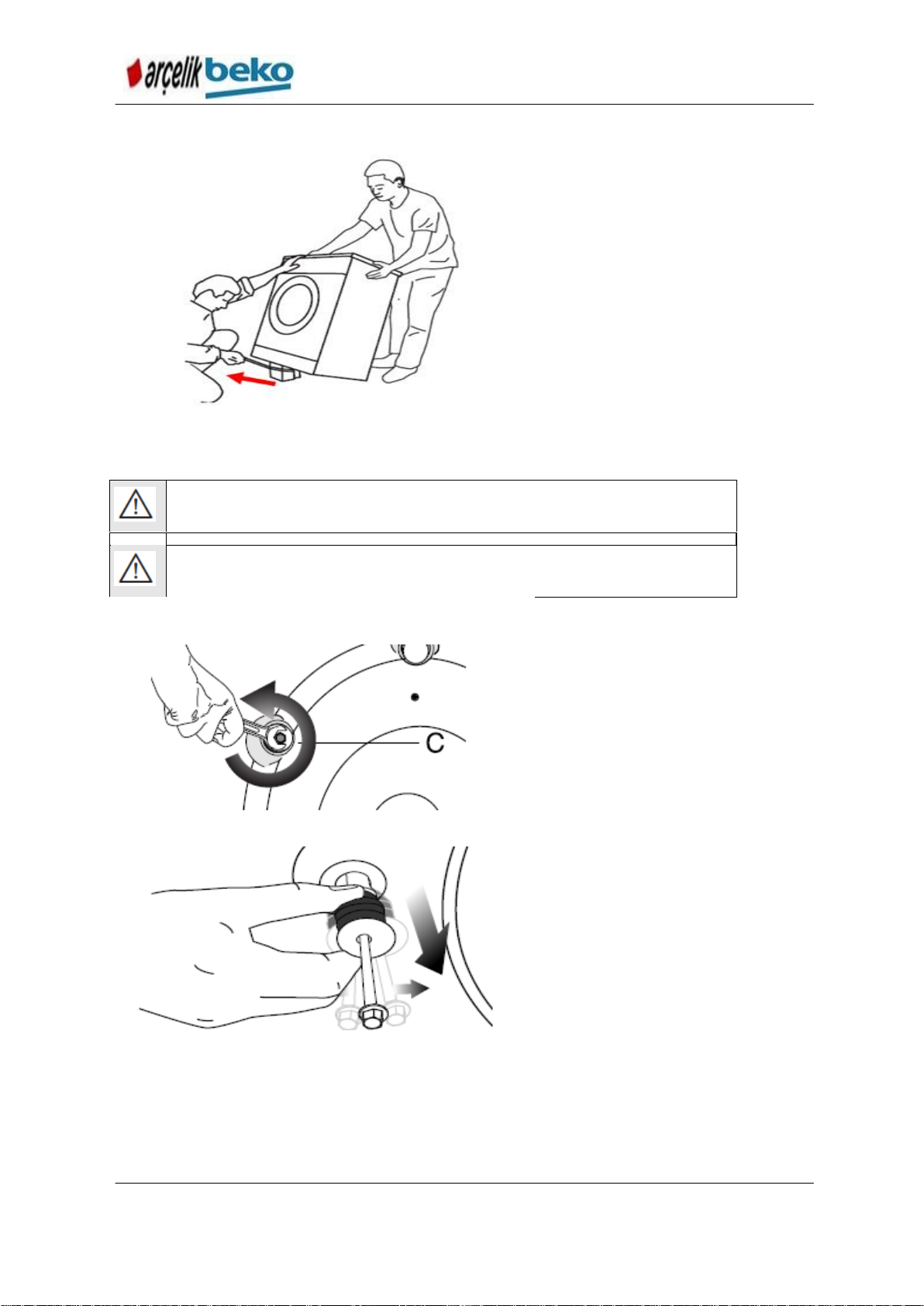

Tilt the machine backwards in

order to remove the package

support. Remove the

packaging reinforcement by

1. Loose all bolts with an

appropriate key until

they turn freely (C).

2. Remove transportation

safety bolts by turning

them gently.

4.2. Removing the Package Support

Figure 4.1

4.3. Removing the Transport Safety Bolts

Figure 4.2

Figure 4.3

10

Page 11

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Keep the transportation safety bolts in a safe place to reuse when the

washing machine needs to be moved again in the future.

Never transport the machine unless its transport safety bolts are installed!

Required water pressure is between 1-10 bar (0.1-1 MPa) for the proper

operation of the machine. For the healthy operation of the machine, 10 – 80

liters of water per minute should be supplied from a fully opened tap. If the

water pressure is higher, attach a pressure decrease valve.

If you will use the double water inlet product as a single water inlet

(cold)

,

before operating the product, make sure you insert the plug supplied with

the product to the hot water inlet. (It applies to the products with which blind

plug group is supplied.)

WARNING:

Single water inlet models should not be be connected to the hot

water tap. Laundry may be damaged or product may not operate according

to the protection status.

WARNING:

Do not use the old or used water inlet hoses for the new

product. It may leave stains on your laundry.

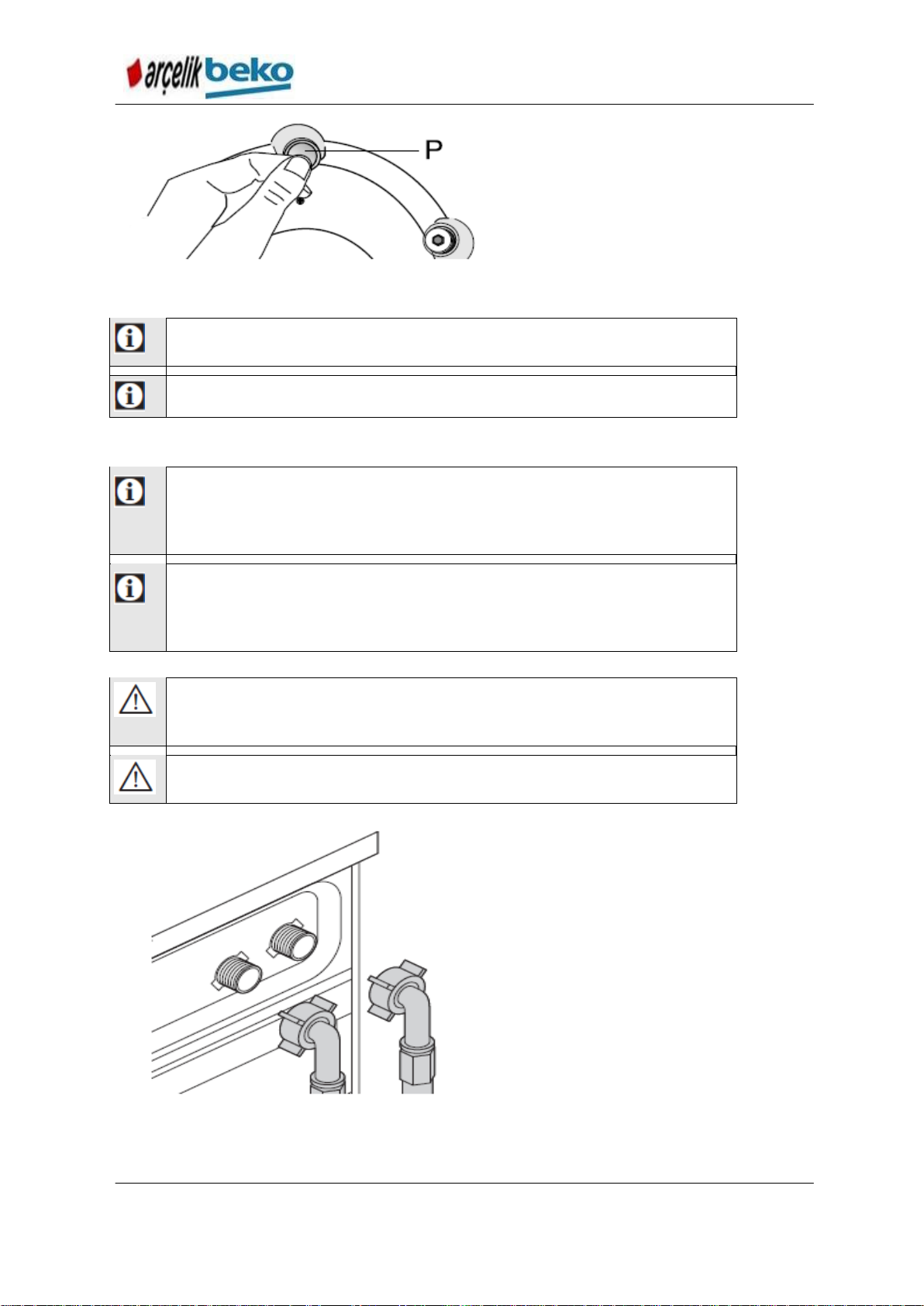

3. Attach the plastic covers

supplied in the User Manual

bag into the holes on the

rear panel. (P)

1. Connect the special hoses

supplied with the product to

the water inlets on the

product. Hose with red

inscriptions (left) (Max. 90

ºC) is for hot water inlet,

hose with blue inscriptions

(right) (Max. 25 ºC) is for

cold water inlet.

Figure 4.4

4.4. Connection to the Supply Water

Figure 4.5

11

Page 12

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

WARNING:

Make sure that the hot and cold water taps are

connected correctly when the product is being installed. Your laundry

may come out hot at the end of the washing cycle and wear out.

WARNING:

If the hose is dislocated during water draining, it will flood

your house. Also, there is risk of burning by hot water due to washing at

high temperatures. In order to prevent such situations and make sure

that the machine performs water intake and discharge processes

without any problem, fix the drain hose securely.

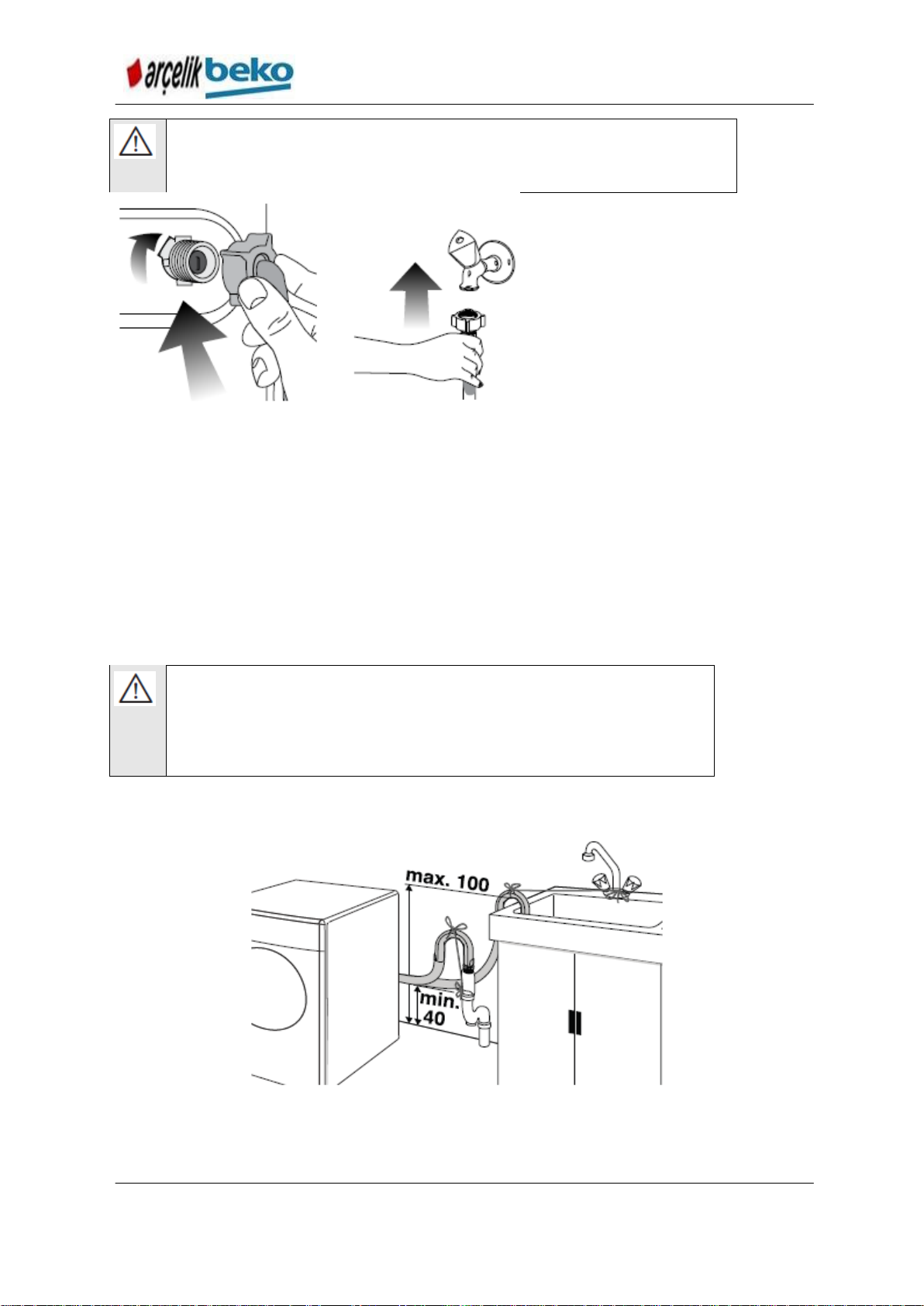

2. Tighten the nuts of the

hose by hand. Never

use a tool when

tightening the nuts.

Figure 4.6

3. When hose connection is completed, check whether there is leak problems at

the connection points by opening the taps fully. In case of any leakage, close

the tap and remove the nut. Check the seal and tighten the nut again carefully.

In order to prevent the water leaks and resultant damages, keep the taps

closed when you do not use the product.

4.5. Connection to the water drain

End of the drain hose should be attached directly to waste water drain, lavatory or

bathtub.

The hose should be attached to a height of at least 40 cm, and 100 cm at most.

Figure 4.7

12

Page 13

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

WARNING:

Product should stand on its legs stable and in a

balanced way in order for it to operate silently and without vibration.

Ensure balance by setting its legs. Otherwise, the product may move

from its place and cause crushing and vibration problems.

If the hose is placed at floor level or near to floor (less than 40 cm) and heightened

later on, water drain becomes difficult and laundry may come out extremely wet.

Therefore, follow the heights described in the figure.

To prevent the waste water to go back into the machine again and to ensure easy

drainage, do not immerse the end of the hose into the waste water or do not insert

it into the drain for more than 15 cm. Shorten it if it is longer than enough.

End of the hose should not be bent, it should be stepped on and Hose should not

be folded between the drain and the machine.

If the hose is not long enough, add the original extension hose to be supplied and

use it in this way. Hose cannot be longer than 3.2 m. In order to prevent water

leaks, fasten the extension hose and the drain hose of the product securely with a

clips to prevent any leak.

4.6. Adjustment of legs

Figure 4.8

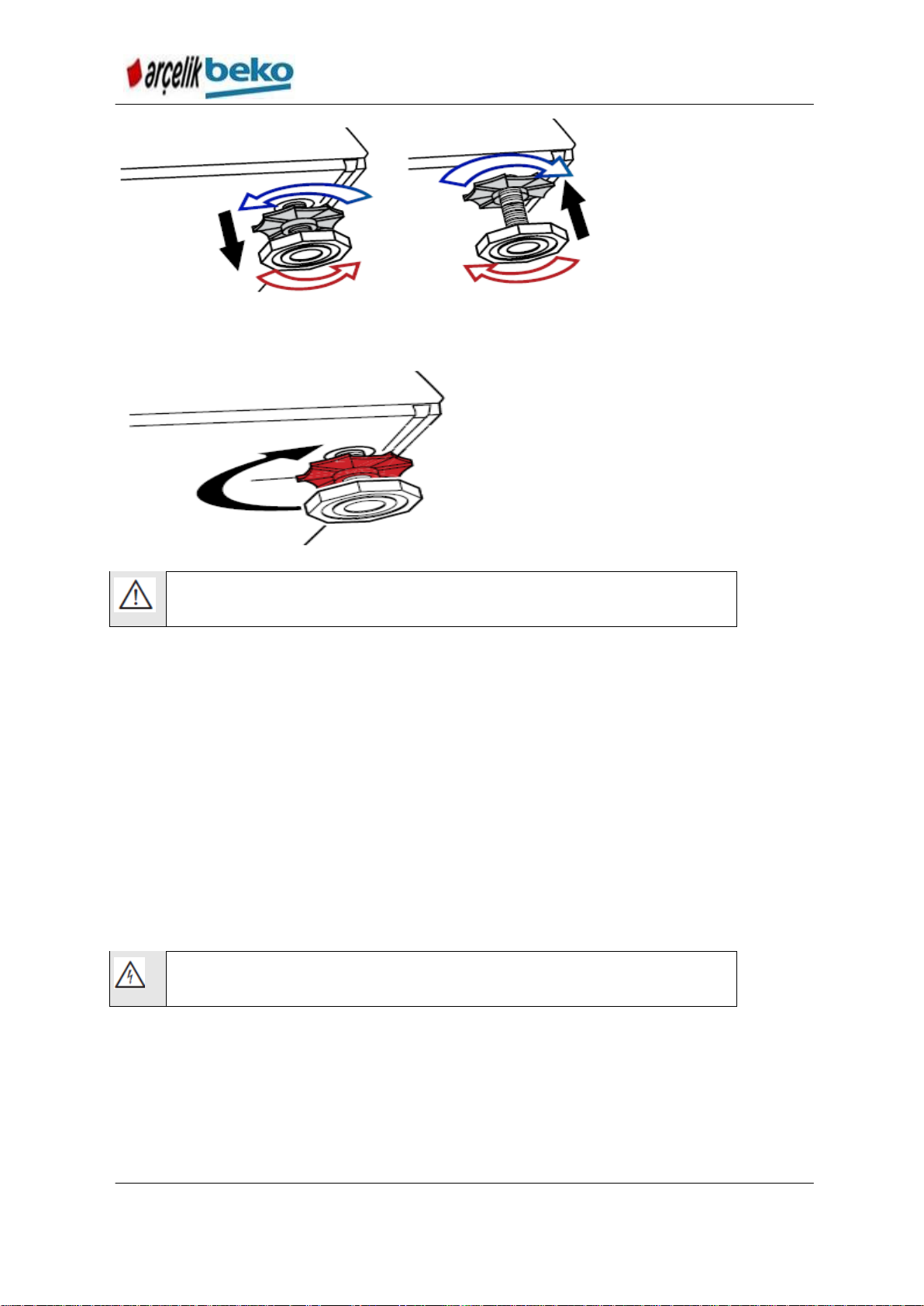

1. Loosen the lock nuts on the feet by hand.

Figure 4.9

2. Adjust the legs until the product stands in a stable and balanced way.

13

Page 14

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

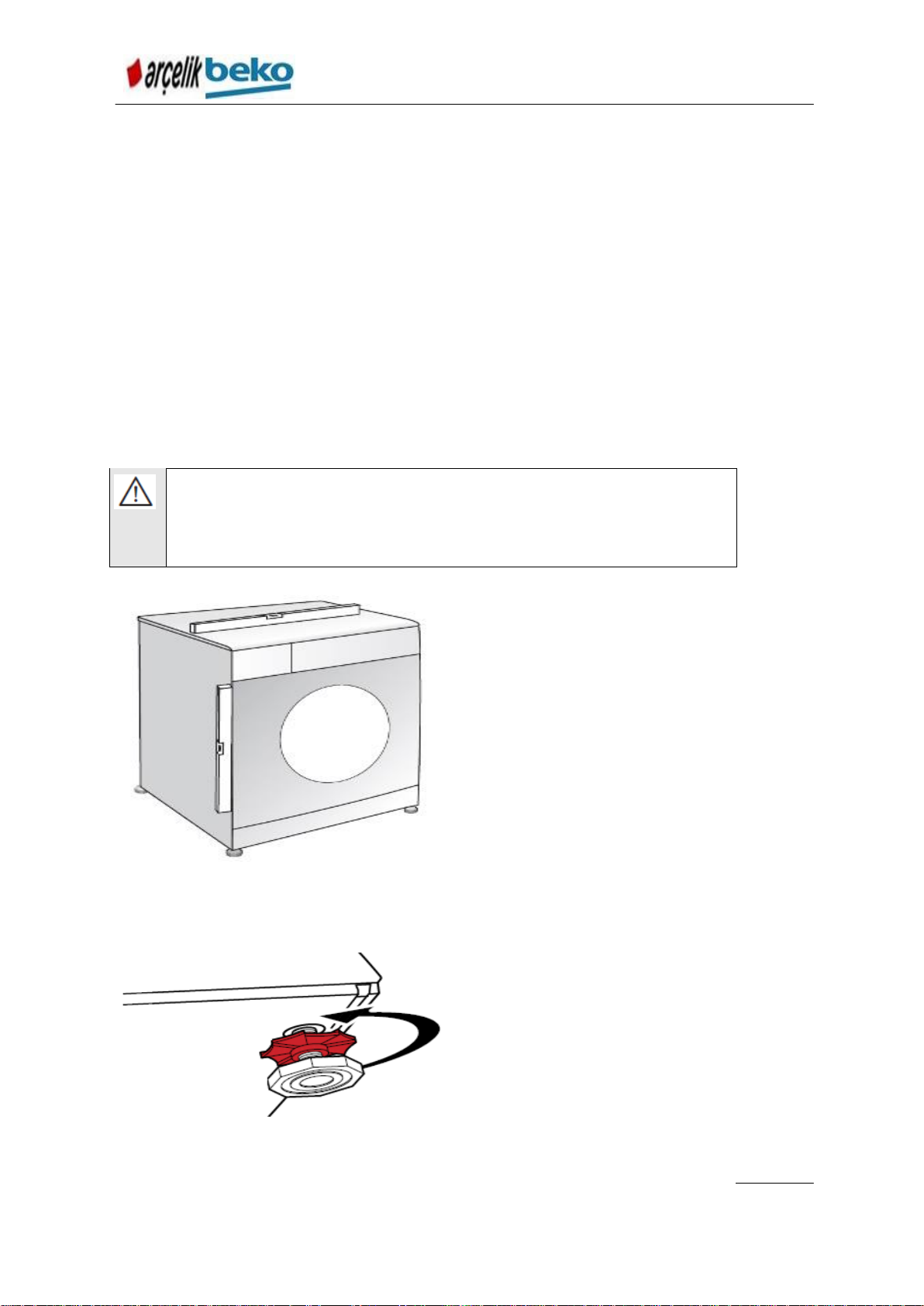

WARNING:

Do not use any appliance or tool to loose the lock nuts.

Otherwise, they may be damaged.

WARNING:

Damaged power cables should be replaced by the

Authorized Service.

Figure 4.10

3. Tighten all lock nuts by hand again.

Figure 4.11

4.7. Electrical connection

Plug the product into a grounded outlet protected by a 16-ampere fuse. If the

machine is used without grounding which conform to the local regulations, our

company will not be liable for any damages which may arise.

Connection should comply with the national regulations.

Power cable's plug should be easily accessible after installation.

If the current value of your fuse is below 16 amperes, make a qualified electrician

connect a 16-ampere fuse.

Voltage specified in the “Technical specifications” section should match the mains

voltage.

Do not connect to the extension cables or multiple outlets.

4.8. Transportation of the product

1.

Before transporting the product, unplug it from the mains.

2. Remove the connections of water drain and water mains.

3. Discharge the entire amount of water left inside the product.

4. Install the transport safety bolts in reverse order of the disassembly procedure.

14

Page 15

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Never transport the machine unless its transport safety bolts are

installed!

WARNING:

Packaging materials may be dangerous for the children.

Keep the packaging materials out of the reach of the children.

15

Page 16

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

5. Use of Product and Byproducts

5.1. Preparation

5.1.1. Sorting the Laundry

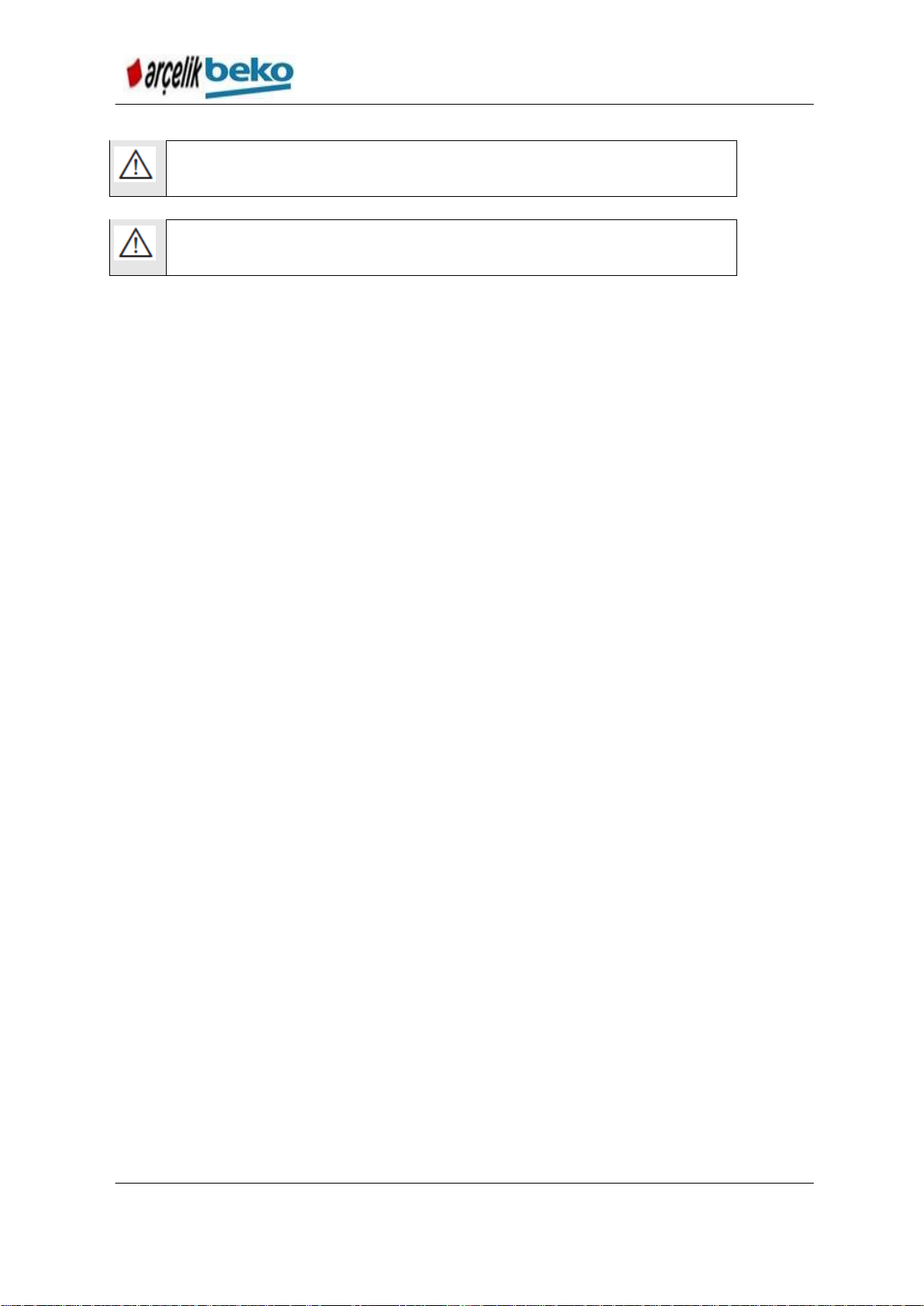

Sort laundry according to type of fabric, color, and degree of soiling and allowable

water temperature.

Always obey the instructions given on the garment tags.

Figure 5.1 Washing Symbols

16

Page 17

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

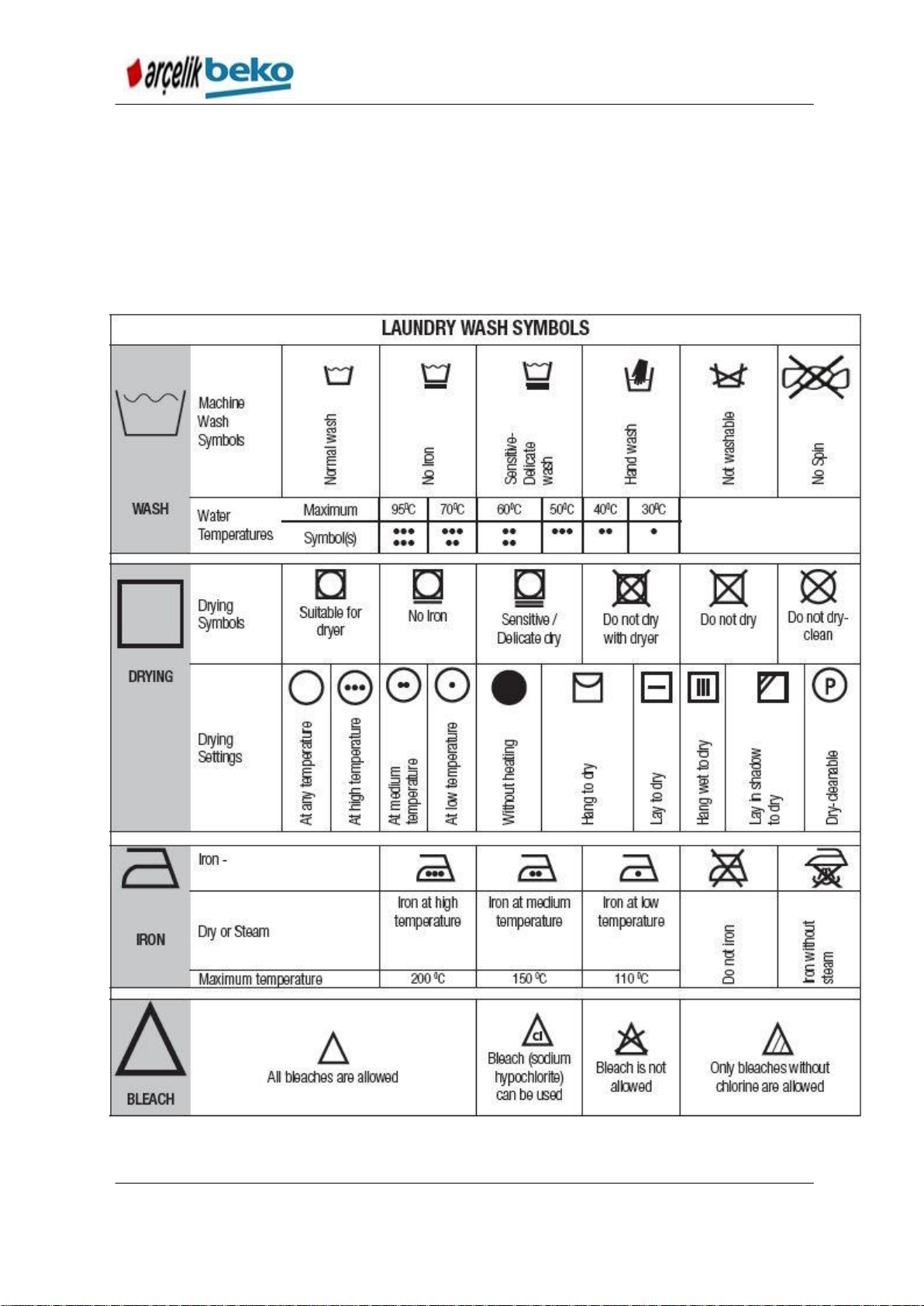

5.1.2. Preparation of the garments to be washed

Laundry items which contain accessories such as support wire, buckle or metal

button may damage the washing machine. Remove the metallic parts or wash the

laundry by putting them into a bag or pillow case.

Figure 5.2

Remove all objects such as coins, pens, paper clips, etc. and reverse the pockets

and brush them. Such objects may damage the product or lead to sound problem.

Put the small size laundry items such as children socks or nylon socks into a

laundry bag or pillow case.

Place the curtains without squeezing them. Remove the curtain fittings.

Close the zips, sew the loose buttons, repair the tears and rips.

Wash the items at appropriate programs according to “Machine Wash” or “Hand

Wash” labels.

Do not wash the colored items with whites. New, dark color cotton garments may

release much dye. Wash them separately.

Tenacious stains should be handled appropriately before wash. If you are not

sure, check it with a dry cleaner.

Only use the dyes / color changers and descaling agents which are appropriate to

machine wash. Read the instructions on the packaging.

Wash the pants and delicates by reversing them.

Before washing the garments made of angora wool, wait them in the freezer

compartment of the refrigerator for a few hours. Thus, the tuft amount which may

be created will lessen.

Before putting the laundry items which are frequently exposed to substances such

as flour, lime powder, milk powder, etc., shake them well. Such dusts and

powders on the laundry may build up on the inner parts of the machine in time

and can cause damage.

17

Page 18

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

WARNING:

Observe the information written in the "Program and

consumption table”. When it is overloaded, washing performance of the

machine will be decreased. Also, sound and vibration problems may occur.

Laundry type

Weight (g)

Bathrobe

1200

Napkin

100

Quilt cover

700

Bed sheet

500

Pillow case

200

Table cover

250

Towel

200

Hand towel

100

Night dress

200

Underwear

100

Men’s smock

600

Men’s shirt

200

Men’s pajamas

500

Blouse

100

5.1.3. Things to do for energy saving

Following information will help you use the product in an ecological and energy-

efficient manner.

Operate the machine with the highest capacity permitted by the program you

selected and do not over load it. See “Program and consumption table”.

Observe the temperature recommendations given on the detergent package.

Wash your slightly soiled laundry at low temperatures.

Prefer short programs for the slightly soiled and small amounts of laundry.

Do not use pre-wash and high temperatures for your laundry which are not

heavily soiled and stained.

If you will dry your laundry in a drier, select the highest spin speed which is

recommended for your washing program.

Do not use detergent in excess of the amount recommended on the detergent

package.

5.1.4. Correct load capacity

The maximum load capacity depends on the type of laundry, the degree of soiling

and the washing programme desired.

Machine automatically adjusts the water amount according to the weight of the

laundry put inside it.

Figure 5.3 Laundry weights

18

Page 19

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Loading door gets locked when operating. Door lock opens soon after the

program finishes.

WARNING:

If the laundry is placed wrongly, sound and vibration problems

may occur in the machine.

When using detergent, softener, starch, fabric dye, bleach or lime scale

remover; read the manufacturer's instructions on the package carefully and

follow the suggested dosage values. Use measuring cup if available.

5.1.5. Laundry loading

1. Open the laundry cover.

2. Put the garments into the machine in a loose manner.

3. Push and close the loading cover until you hear the locking sound. Make sure

that the garments do not get pinched between the door.

5.1.6. Use of detergent and softener

DETERGENT DISPENSER

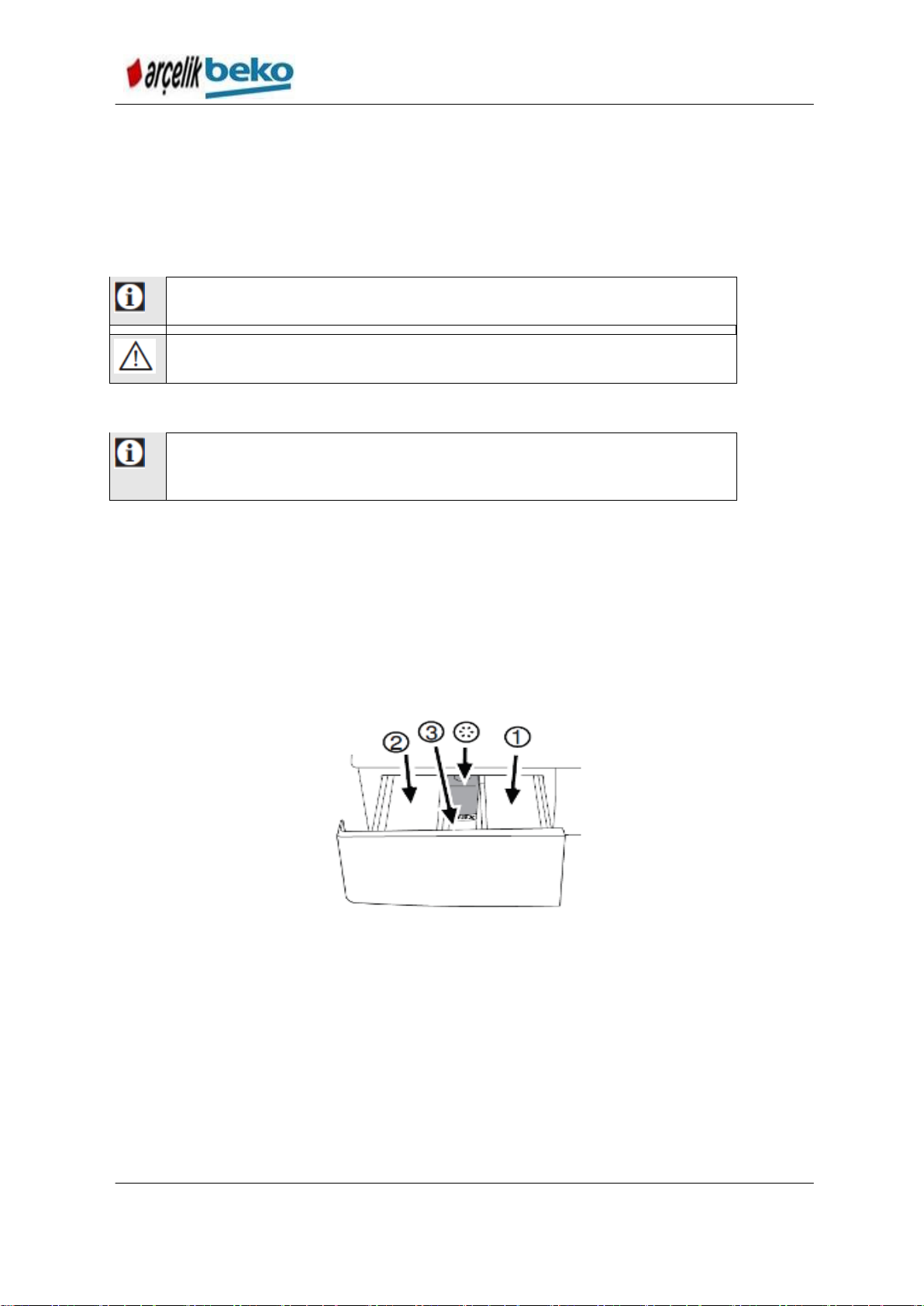

Detergent dispenser consists of three compartments:

– (1) For prewash

– (2) For main wash

– (3) For softener

– (*) Moreover, there is a siphon part in the softener compartment.

Figure 5.4 Compartments of the detergent dispenser

DETERGENT, SOFTENER AND OTHER CLEANING AGENTS

Before starting the wash program, add detergent and softener.

While the washing cycle is in progress, do not leave the detergent dispenser

open!

If you are using a program without prewash, do not add detergent into the

prewash compartment (compartment number “1”).

In a prewash program, do not add liquid detergent into the prewash compartment

(compartment number “1”).

19

Page 20

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

WARNING:

Only use the detergents which are intended and manufactured

for the washing machines.

WARNING:

Do not use soap powder.

If you are using detergent bag or dosage ball, do not select a prewash program.

Place the detergent bag or dosage ball directly among the garments in the

machine.

If you are using liquid detergent, do not forget to place the liquid detergent

container into the main wash compartment (compartment number “2”).

DETERGENT SELECTION

Detergent type to be used depends on the fabric type and color.

Use separate detergents for color and white laundry items.

Wash your delicate garments only with the special detergents which are used for

delicates (liquid detergent, wool shampoo, etc.).

You are recommended to use liquid detergent when washing dark color garments

or quilts.

Only wash the woolens with the special detergent used for woolens.

ADJUSTMENT OF DETERGENT AMOUNT

Amount of detergent to be used depends on the laundry amount, soil degree and

hardness of water.

Do not exceed the dosages which are recommended on the detergent package in

order to prevent the excessive foam and bad rinse results, to save detergent and

to protect the environment.

Use lower amounts of detergent for a small amount of laundry or slightly soiled

items.

USE OF SOFTENER

Put the softener into the softener compartment of the detergent dispenser.

Do not exceed the (>max<) level sign on the softener compartment.

If the softener lost its fluidity, dilute it with water before putting it into the

compartment.

USE OF LIQUID DETERGENTS

If the product has a liquid detergent container

Make sure that you place the liquid detergent container into the compartment

number “2”.

If the liquid detergent lost its fluidity, dilute it with water before putting it into the

detergent container.

20

Page 21

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Tablet detergents may leave a residue in the detergent compartment. If you

encounter such a problem, place the tablet detergent among the laundry

items at the bottom of the drum.

Use the tablet or gel detergent without selecting the prewash function.

Figure 4.5 Use of liquid detergent container

If the product does not have a liquid detergent container

In a prewash program, do not use liquid detergent for prewash.

Liquid detergent leaves stains on your items when delayed start function is used.

Do not use liquid detergent if you will use Delayed Start feature.

Use of gel and tablet detergent

Apply the following actions when using tablet, gel detergents, etc.

If the gel detergent is fluid and if your machine does not have a special liquid

detergent container, put the gel detergent into the main wash detergent

compartment during first intake of water. If your machine has a liquid detergent

container, fill the detergent into this container before starting the program.

If the gel detergent is not fluid or it is a capsule liquid tablet, put it directly into the

rum before starting the washing cycle.

Put the tablet detergents into the main wash compartment (number “2”) or directly

into the drum before starting the washing cycle.

Use of Soda

Put the liquid soda, powder soda or the fabric dye into the softener compartment.

In a wash program, do not put softener and soda at the same time.

After using soda, wipe the inside of the machine with a damp and clean cloth.

Use of bleach and decolorant

Add the bleach at the beginning of the washing cycle by selecting a prewash

program. Do not put detergent into the prewash compartment. As an alternative

application, add the bleach while the machine is taking water from the detergent

compartment in the first rinse step by selecting a program with additional rinse.

Do not use bleach by mixing it with detergent.

21

Page 22

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Use an anti-limescale suitable for the washing machines.

There might be a little amount of water left inside the product due to

the quality control procedures during manufacturing. It is not harmful

for the product.

Use a small amount of bleach (1/2 tea glass-approx. 50 ml) and rinse the laundry

well since bleach will cause skin irritation. Do not pour the bleach onto the laundry

and do not use it with the colored items.

When using oxygen-based decolorant, select a program which washes the

laundry at a low temperature.

Oxygen-based decolorant can be used with the detergent; however, if it is not at

the same consistence, first put detergent in the compartment number “2” in the

detergent dispenser and wait for the machine to flush the detergent when taking

in water. While the machine continues taking in water, add decolorant in the same

compartment.

Use of descaling agent

When it is necessary, only use the descaling agents which are intended and

manufactured for the washing machines.

5.1.7. First Use

Before starting to use the product make sure that the preparations are made which

are in line with the “Important Safety Instructions” and the instructions in the

“Installation” section.

In order to make the machine ready to wash laundry, perform the first washing cycle

with the Drum Cleaning program. If your machine does not have a Cauldron Cleaning

program. In order to make the machine ready to wash laundry, perform the first

washing cycle in line with the method which is described under the heading Cleaning

the Loading Door and Drum in section .

Figure 5.6 Cleaning the bellows

22

Page 23

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

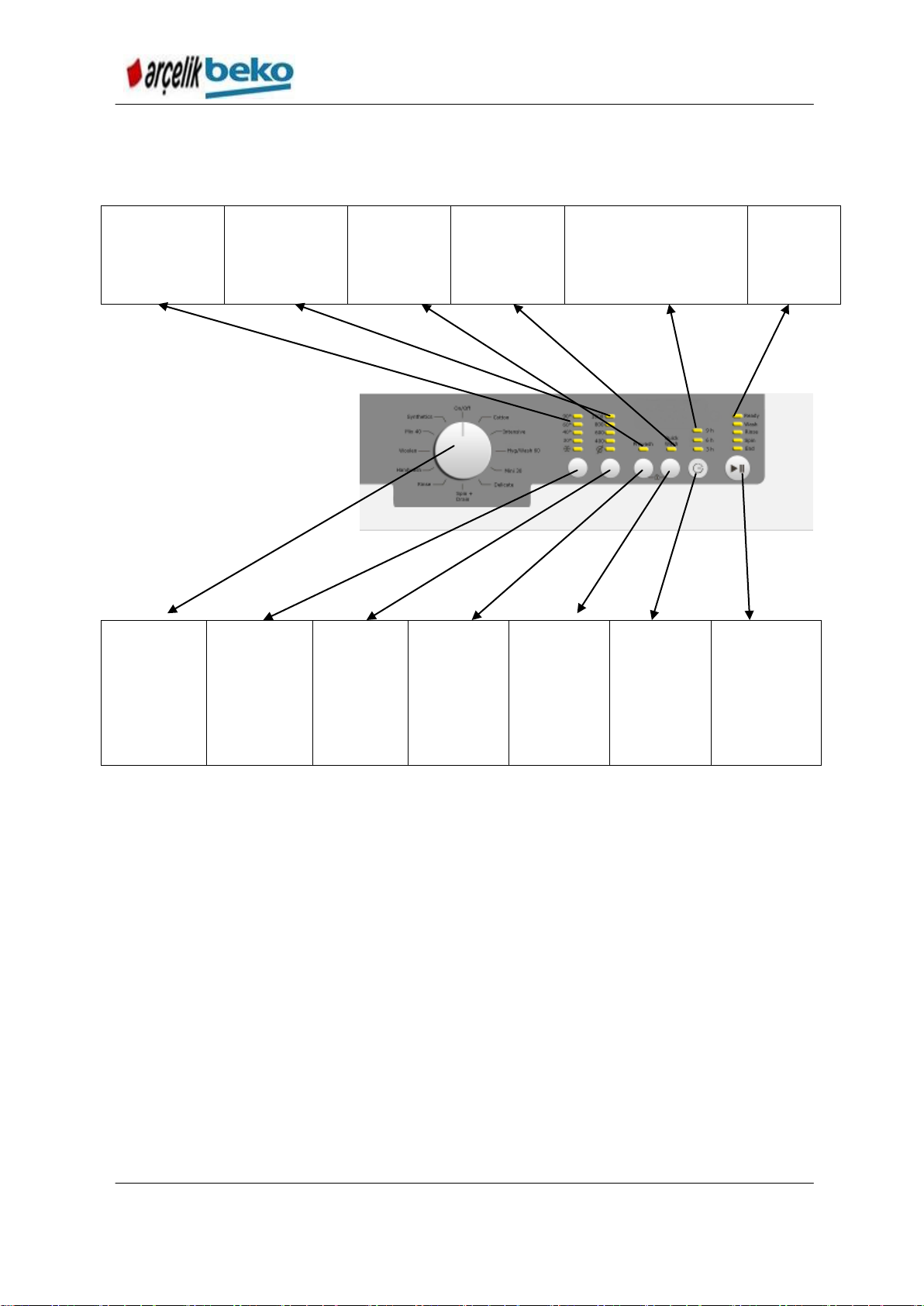

Speed Level

LEDs

Auxiliary

Function_1

LED i

Auxiliary

Function_2

LED i

Time Delay LEDs (3

LEDs as 3, 6, 9 hours)

or Auxiliary Function_3

LED i (1 LED)

2 or

16-position

(temperature

integrated)

Program

Selection

Switch

Temperature

Setting

Button (It

may not be

available in

Auxiliary

Function_1

Button

Auxiliary

Function_2

Button

Time Delay

Button or

Auxiliary

Function_3

Button

Start/Standby

button

5.2. Control panel

B13 B7S Introduction of LED Control System

Figure 5.7 Control panel

1 - Program Selection knob (Uppermost position On / Off)

2 - Screen

3 - Delayed Start Indicator

4 - Program Follow-up indicator

5 - Start / Pause button

6 - Auxiliary Function buttons

7 - Spin Speed Adjustment button

8 - Temperature Adjustment button

23

Page 24

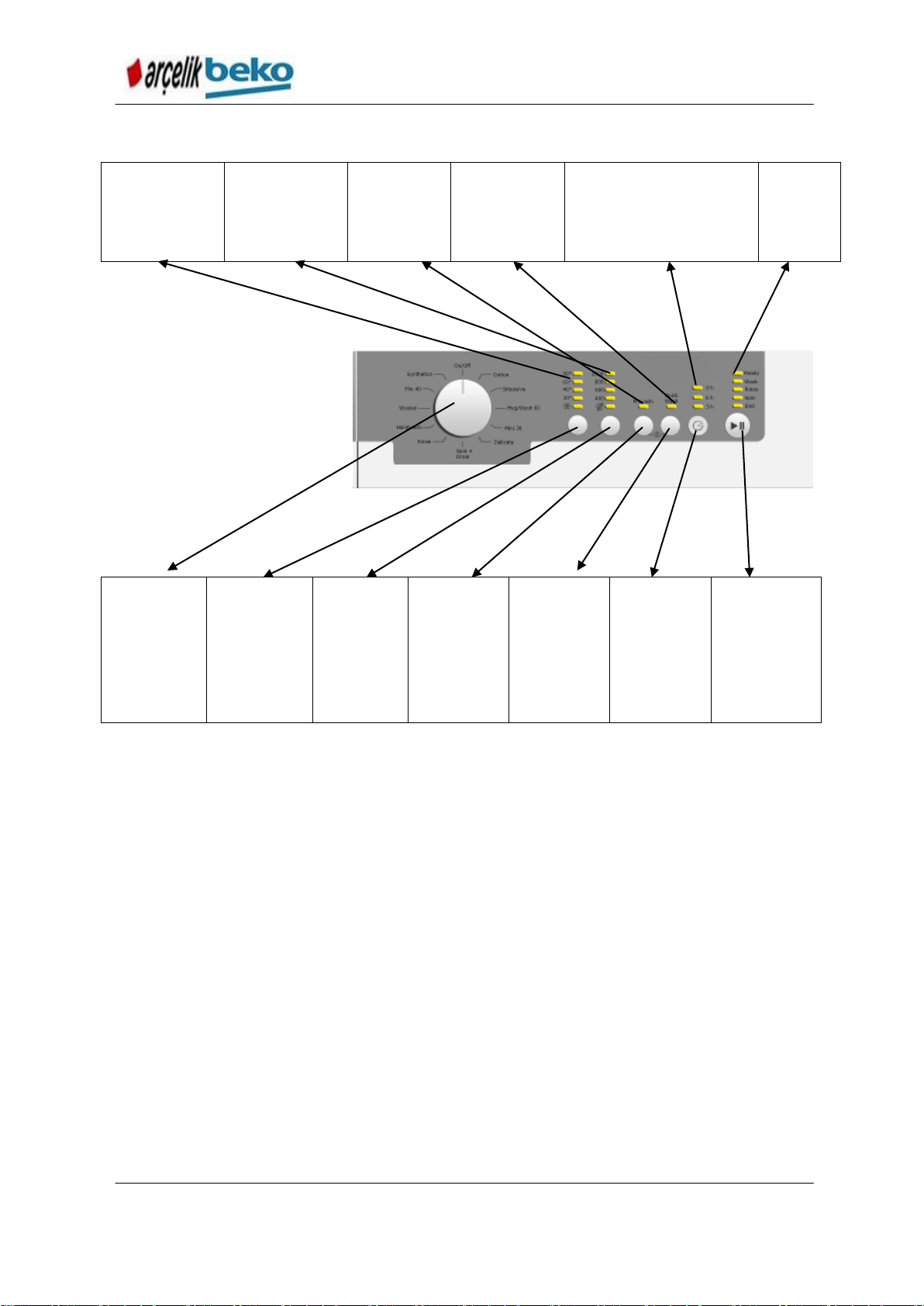

B13

Speed Level

LEDs

Auxiliary

Function_1

LED i

Auxiliary

Function_2

LED i

Time Delay LEDs (3

LEDs as 3, 6, 9 hours) or

Auxiliary Function_3

LED i (1 LED)

2 or

16-position

(temperature

integrated)

Program

Selection

Switch

Temperature

Setting

Button (It

may not be

available in

Auxiliary

Function_1

Button

Auxiliary

Function_2

Button

Time Delay

Button or

Auxiliary

Function_3

Button

Start/Standby

button

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Introduction of LED Control System

B7S

Figure 5.8 Control panel

5.3. Preparing the Machine

1. Make sure that the hoses are secured tightly.

2. Plug in the machine.

3. Open the water tap fully.

4. Place the laundry inside the machine.

5. Add detergent and softener.

24

Page 25

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

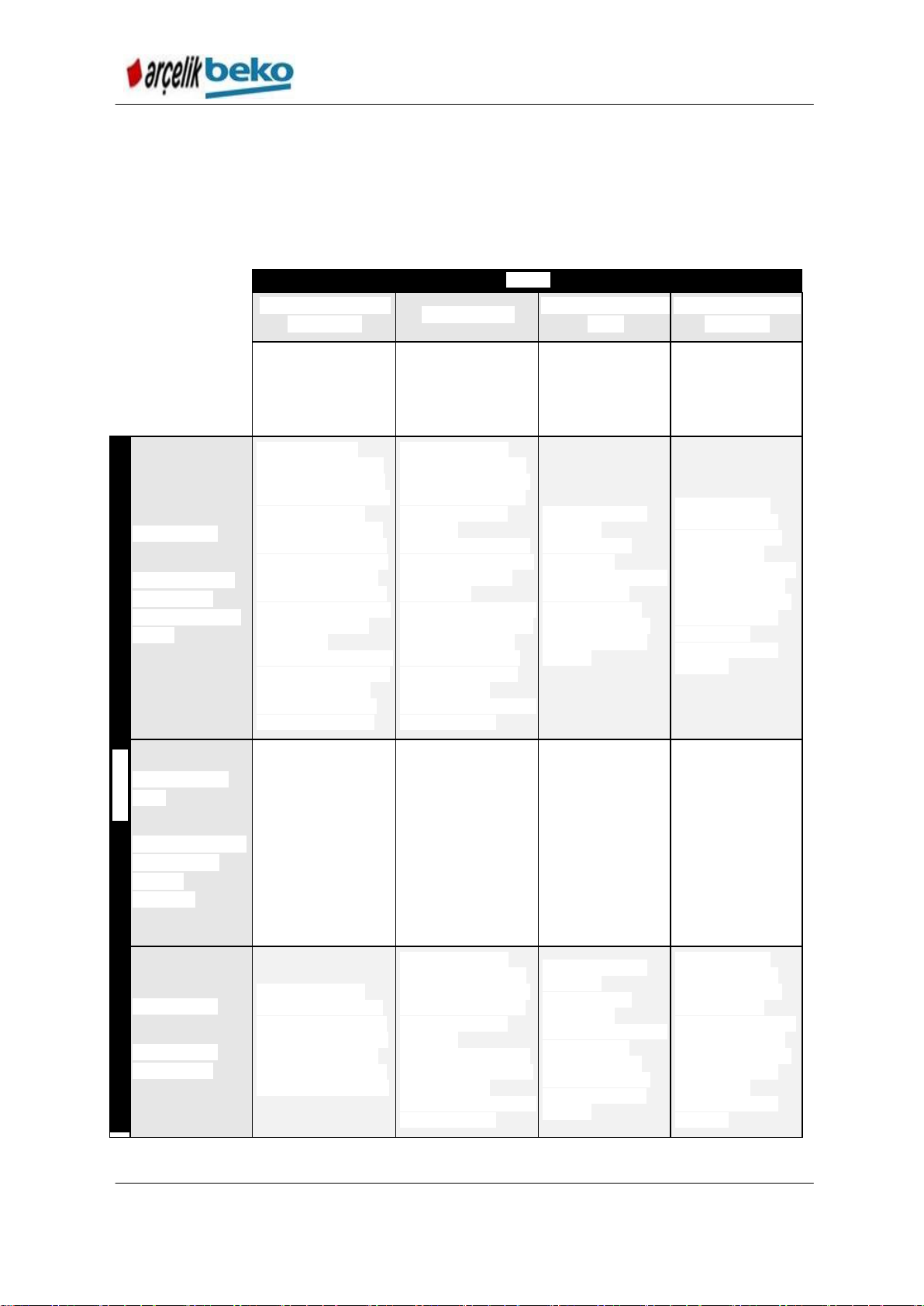

Clothes

Light Colored Items

and Whites

Colored Items

Black/Dark Colored

Items

Delicates/Woolens/

Silk Items

(Washing temperature

range recommended

for the soil amount:

40-90C)

(Washing temperature

range recommended

for the soil amount:

cold-40C)

(Washing

temperature range

recommended for

the soil amount:

cold-40C)

(Washing

temperature range

recommended for

the soil amount:

cold-30C)

Soil Amount

Heavily Soiled

(Tenacious stains

such as grass,

coffee, fruit, blood

stains.)

Prewash may be

necessary in order to

perform a preliminary

process for the stains.

Powder and liquid

detergents which are

recommended for the

whites can be used at

the doses which are

recommended for the

heavily soiled laundry.

It is recommended

that powder

detergents are used to

clean the stains which

are sensitive to the

decolorants and the

clay and soil stains.

Powder and liquid

detergents which are

recommended for the

colored items can be

used at the doses

which are

recommended for the

heavily soiled laundry.

It is recommended

that powder

detergents are used to

clean the stains which

are sensitive to the

decolorants and the

clay and soil stains.

Detergents not

containing decolorants

should be used.

Liquid detergents

which are

appropriate for

colored and

black/dark items can

be used at the

doses which are

recommended for

the heavily soiled

laundry.

Prefer the liquid

detergents which

are manufactured

for the delicate

laundry. Woolens or

silk clothes should

be washed with the

detergents which

are specially

manufactured for

woolens.

Normally Soiled

Items

(Body dirt stains at

the collars and

cuffs are

examples.)

Powder and liquid

detergents which are

recommended for the

whites can be used at

the doses which are

recommended for the

normally soiled

laundry.

Powder and liquid

detergents which are

recommended for the

colored items can be

used at the doses

which are

recommended for the

normally soiled

laundry. Detergents

not containing

decolorants should be

used.

Liquid detergents

which are

appropriate for

colored and

black/dark items can

be used at the

doses which are

recommended for

the normally soiled

laundry.

Prefer the liquid

detergents which

are manufactured

for the delicate

laundry. Woolens or

silk clothes should

be washed with the

detergents which

are specially

manufactured for

woolens.

Slightly Soiled

(There are not

visual stains.)

Powder and liquid

detergents which are

recommended for the

whites can be used at

the doses which are

recommended for the

slightly soiled laundry.

Powder and liquid

detergents which are

recommended for the

colored items can be

used at the doses

which are

recommended for the

slightly soiled laundry.

Detergents not

containing decolorants

should be used.

Liquid detergents

which are

appropriate for

colored and

black/dark items can

be used at the

doses which are

recommended for

the slightly soiled

laundry.

Prefer the liquid

detergents which

are manufactured

for the delicate

laundry. Woolens or

silk clothes should

be washed with the

detergents which

are specially

manufactured for

woolens.

5.4. Program selection and tips for correct washing

1. Select the programme suitable for the type, quantity and soiling degree of the

laundry in accordance with the "Programme and consumption table" and the

temperature table below.

2. Select any program you want to use by using Program Selection switch.

Table 5.1 Recommendations for correct washing

25

Page 26

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

differ according to the model

of the machine.

5.5. Main Programs

Depending on the type of fabric, use the following main programs.

Cottons

Use this programme for your cotton laundry (such as bed sheets, duvet and

pillowcase sets, towels, bathrobes, underwear, etc.). Your laundry will be washed

with vigorous washing action for a longer washing cycle.

Synthetics

Use this programme to wash your synthetic clothes (shirts, blouses, synthetic/cotton

blends, etc.). Your laundry is washed with a softer washing movement and in a

shorter period of time.

You are recommended to use Synthetics 40˚C program for your curtains and tulle

curtains by selecting the prewash and crease reduction functions. Wash tulles by

putting a small amount of detergent into the main wash compartment since tulle

creates too much foam due to its porous structure. Do not put detergent into the

prewash compartment.

Woolens

You can wash your machine-washable woolen laundry at this program. Wash

your laundry by selecting an appropriate temperature written on its label. It is

recommended that you use appropriate detergent for woolens.

5.6. Additional programs

For special cases, additional programmes are available in the machine.

Cottons Eco

By washing normally soiled cotton and linen laundry in this programme, you can

ensure higher energy and water efficiency than other cotton programmes do. Actual

water temperature may be different from the stated wash temperature. When you

load the machine with less laundry (e.g. ½ capacity or less), programme time may

automatically get shorter in the later stages. In this case, energy and water

consumption will reduce for a more economic wash. This feature is provided in the

models with the remaining time indicator.

Delicate

Use it to wash your delicate laundry. It washes with a gentler action without any

interim spins compared to the Synthetics program. It should be used for laundry for

which sensitive wash is recommended.

Hand wash

Use this programme to wash your woolen/delicate clothes that bear “not machine-

washable” tags and for which hand wash is recommended. It washes laundry with a

very gentle washing action to not to damage clothes.

26

Page 27

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Use lower spin speeds for delicate laundries.

If the programme has not reached the heating step yet, you can

change the temperature without switching the machine to Pause

mode.

Mini

Use this programme to wash your lightly soiled cotton clothes in a short time.

Quick 14

Use this programme to wash your little amount of lightly soiled cotton clothes in a

short time. Your clothes will be washed at 30 ˚C in a short time like 14 minutes.

Dark colored items

Use this programme to wash your dark colored laundry or the laundry that you do not

want it get faded. Washing is performed by a low mechanical movement and at a low

temperature. Liquid detergent or wool shampoo are recommended for colored items.

Mix

Use this programme to wash your cotton and synthetic clothes together without

sorting them.

Shirts

Use this programme to wash the shirts made of cotton, synthetic and synthetic

blended fabrics together.

Sports

Use this programme to wash your garments that are worn for a short time such as

sportswear. It is suitable to wash little amount of cotton / synthetic blended garments.

5.7. Special programs

For specific applications, select any of the following programmes.

• Rinse

Use this programme when you want to rinse or starch separately.

• Spin+Pump

Use this programme to apply an additional spin cycle for your laundry or to drain the

water in the machine.

Before selecting this programme, select the desired spin speed and press Start /

Pause button. First, the machine will drain the water inside of it. Then, it will spin the

laundry with the set spin speed and drain the water coming out of them.

If you wish to drain only the water without spinning your laundry, select the

Pump+Spin programme and then select the No Spin function with the help of Spin

Speed Adjustment button. Press Start / Pause button.

5.8. Temperature selection

Whenever a new programme is selected, the maximum temperature for the selected

programme appears on the temperature indicator.

To decrease the temperature, press the Temperature Adjustment button.

Temperature will decrease gradually.

27

Page 28

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Some functions cannot b selected at the same time. For example,

Prewash and Quick Wash.

If an auxiliary function which is incompatible with the first selected

auxiliary function before the machine is operated, first selected

function will be cancelled and the last selected auxiliary function will

remain selected. For instance, if Prewash is selected first and then

Quick Wash is wanted to be selected, prewash becomes cancelled,

quick wash remains valid.

Auxiliary functions which are not compatible with the program

cannot be selected. (See “Program and consumption table”)

Auxiliary function buttons may vary according to the model of the

machine.

Prewash without detergent is recommended for tulle and curtains.

When you select this function, load laundry which is just the half of

the maximum laundry load specified in the program table.

When you select this function, load laundry which is just the half of

the maximum laundry load specified in the program table.

5.9. Auxiliary function selection

Select the auxiliary functions before starting the program. Furthermore, you may also

select or cancel auxiliary functions that are suitable to the running programme without

pressing the Start / Pause button when the machine is operating. For this, the

machine must be in a step before the auxiliary function you are going to select or

cancel.

If the auxiliary function cannot be selected or canceled, light of the relevant auxiliary

function will blink 3 times to warn the user.

Prewash

Prewash is necessary for heavily soiled laundry only. If you do not use a prewash

cycle, you save energy, water, detergent and time.

Quick

This function can be used for Cottons and Synthetics programs. If makes it possible

to shorten the wash time of the not very soiled laundry and decreases the rinse

number.

Extra rinse

This function will make sure that the machine performs an extra rinse in addition to

the rinse applied after the main program. Therefore, you can avoid the risk of

affecting the sensitive skins (baby skins, allergic skins, etc.) by the small amount of

leftovers on the laundry.

Extra water

This function makes sure that you wash and rinse your laundry at Cottons,

Synthetics, Delicates and Woolens programs with plenty of water. Use this function

for the delicate laundry which are easily creased.

28

Page 29

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

CAUTION: Never wash your pets in the washing machine.

Do not use liquid detergents when you set Delayed Start! There is

risk of staining the laundry.

Additional laundry may be loaded during the delayed start period.

Crease reduction

This function ensures that the laundry is creased less when being washed. Drum

rotation movements are lessened and spinning speed is limited in order to reduce the

crease level. In addition to them, wash is performed at a high water level.

Rinse Hold

If you are not going to unload your clothes immediately after the programme

completes, you can use rinse hold function to keep your laundry in the final rinsing

water in order to prevent them from getting wrinkled when there is no water in the

machine. Press Start / Pause button after this process if you want to drain the water

without spinning your laundry. Programme will resume and complete after draining

the water.

If you want to spin the laundry held in water, adjust the Spin Speed and press Start /

Pause button.

Program will continue. Water is drained, laundry is spun and the programme is

completed.

Pet hair removal

This function helps to remove pet hair that remain on your garments more effectively.

When you select this function, Prewash and Extra Rinse steps are added to the

normal programme. Thus, washing is performed with more water (30%) and the pet

hair is removed more effectively.

Delayed Start

With the Delayed Start function the startup of the program may be delayed up to 19

hours. Delayed start time can be increased by increments of 1 hour.

1. Open the loading door, load the laundry and fill in detergent, etc.

2. Select the wash program, temperature, spinning speed and the auxiliary functions

if necessary.

3. Set the desired time by pressing the Delayed Start button.

4. Press Start / Pause button. The delayed start time you have set is displayed.

Delayed start countdown starts. “_” symbol next to the delayed start time moves up

and down on the display.

5. At the end of the countdown, duration of the selected programme will be displayed.

“_” symbol will disappear and the selected programme will start.

Changing the delayed start period

If you want to change the time during countdown:

1. Press Delayed Start button. Time will increase by 1 hour each time you press the

button.

2. If you want to decrease the delayed start time, press Delayed Start button

repeatedly until the desired delayed start time appears on the display.

29

Page 30

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

If no programme is started or no key is pressed within 1 minute during

programme selection process, the machine will switch to Pause mode

and the illumination level of the temperature, speed and loading door

indicator lights will decrease. Other indicator lights and indicators will

turn off. Once the Programme Selection knob is rotated or any button is

pressed, indicator lights and indicators will turn on again.

If the Programme Selection knob is turned when the Child Lock is

active, "Con" appears on the display. The Child Lock does not allow

any change in the programmes and the selected temperature,

speed and auxiliary functions.

Even if another programme is selected with the Programme

Selection knob while the Child Lock is active, previously selected

programme

will continue running.

Canceling the Delayed Start function

If you want to cancel the delayed start countdown and start the programme

immediately:

1. Set the Delayed Start period to zero or turn the Programme Selection knob to

any programme. Thus, Delayed Start function will be canceled. The End/Cancel

light flashes continuously.

2. Then, select the programme you want to run again.

3. Press Start / Pause button to start the programme.

5.10. Starting the program

1. Press Start / Pause button to start the programme.

2. Programme follow-up light showing the startup of the programme will turn on.

5.11. Child Lock

You can prevent the children to play with the machine by means of the child lock

function. You can prevent any change to be effected for any program in progress by

activating this function.

To activate the Child Lock:

1st and 2nd Press the Auxiliary Function buttons for 3 seconds. The lights on the 1st

and 2nd Auxiliary Function buttons will flash while you keep the buttons pressed for

3 seconds, and "C03", "C02", "C01" will appear on the display respectively. Then,

"Con" will appear on the display indicating that the Child Lock is activated. If you

press any button or turn the Programme Selection knob when the Child Lock is

active, same phrase will appear on the display. The lights on the 1st and 2nd

auxiliary function buttons that are used to deactivate the Child Lock will blink 3 times.

To deactivate the Child Lock:

While any programme is running 1st and 2nd Press the Auxiliary Function buttons for

3 seconds. The lights on the 1st and 2nd Auxiliary Function buttons will flash while

you keep the buttons pressed for 3 seconds, and "C03", "C02", "C01" will appear on

the display respectively. Then, "COF" will appear on the display indicating that the

Child Lock is deactivated.

30

Page 31

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

In addition to the method above, to deactivate the Child Lock,

switch the Programme Selection knob to On / Off position when no

programme is running, and select another programme.

Child Lock is not deactivated after power failures or when the

machine is unplugged.

If the machine does not pass to the spinning step, Rinse Hold function

might be active or the automatic unbalanced load detection system might

be activated due to the unbalanced distribution of the laundry in the achine.

If no change is allowed, the relevant light will flash for 3 times.

5.12. Progress of the Program

Progress of a running programme can be followed from the Programme Follow-up

indicator. At the beginning of every programme step, the relevant indicator light will

turn on and light of the completed step will turn off.

You can change the auxiliary functions, speed and temperature settings without

stopping the programme flow while the programme is running. To do this, the change

you are going to make must be in a step after the running programme step. If the

change is not compatible, relevant lights will flash for 3 times.

5.13. Lock of the loading door

There is a locking system on the loading door of the machine that prevents opening

of the door in cases when the water level is unsuitable.

Loading door light will start flashing when the machine is switched to Pause mode.

Machine checks the level of the water inside. If the level is suitable, Loading Door

light illuminates steadily within 1-2 minutes and the loading door can be opened.

If the level is unsuitable, Loading Door light turns off and the loading door cannot be

opened. If you are obliged to open the loading door while the Loading Door light is

off, you must cancel the current programme. See "Cancelling a Program".

5.14. Changing the selections after the program started

Switching the machine to pause mode

Press the Start / Pause button to switch the machine to pause mode while a

programme is running. The light of the step which the machine is in starts flashing in

the Programme Follow-up indicator to show that the machine has been switched to

the pause mode.

Also, when the loading door is ready to be opened, Loading Door light will also

illuminate continuously in addition to the programme step light.

Changing the auxiliary function, speed and temperature

Depending on the step the programme has reached, you can cancel or activate the

auxiliary functions. See "Auxiliary function selection".

Moreover, you can also change the speed and temperature settings. See “Speed

Selection” and “Temperature Selection”

Addition or removal of laundry

31

Page 32

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Depending on the step where the programme was canceled in, you

may have to put detergent and softener again for the programme

you have selected anew.

1. Press Start / Pause button to switch the machine to pause mode. The programme

follow-up light of the relevant step during which the machine was switched into the

pause mode will flash.

2. Wait until the Loading Door can be opened.

3. Open the Loading Door and add or take out the laundry.

4. Close the Loading Door.

5. Make changes in auxiliary functions, temperature and speed settings if necessary.

6. Press Start / Pause button to start the machine.

5.15. Cancellation of program

To cancel the programme, turn the Programme Selection knob to select another

programme. Previous programme will be cancelled. End / Cancel light will flash

continuously to notify that the programme has been canceled.

Pump function is activated for 1-2 minutes regardless of the programme step, and

whether there is water in the machine or not. After this period, your machine will be

ready to start with the first step of the new programme.

5.16. Program end

“End” appears on the display at the end of the programme.

1. Wait until the loading door light illuminates steadily.

2. Press On / Off button to switch off the machine.

3. Take out your laundry and close the loading door. Your machine is ready for the

next washing cycle.

5.17. There is a “Standby Mode” in your machine

After you switch on your machine with On-Off button, if no program is started or no

other procedure is performed at the selection step or no action is taken within approx.

2 minutes after the your selected program ends, your machine will switch to the

energy saving mode automatically. Brightness level of the indicator LEDs will be

decreased. Moreover, if there is a display on your product showing the program

duration, this display will turn off completely. If you turn the program switch or touch

any other button, LEDs and display will get back its original settings. Selections which

made while exiting the energy saving mode may change. Before you start the

program, check the accuracy of your selections. If necessary, repeat them. This is

not an error.

32

Page 33

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

If water and softener more than a normal amount start to stay on the

softener compartment, siphon cleaning should also be performed.

6. MAINTENANCE AND CLEANING

Service life of product extends and frequently experienced problems will be reduced

if it is cleaned at regular intervals.

6.1. Cleaning the detergent dispenser

Clean the detergent drawer at regular intervals (every 4-5 washing cycles) as shown

below in order to prevent accumulation of powder detergent in time.

Figure 6.1 Cleaning the detergent compartment

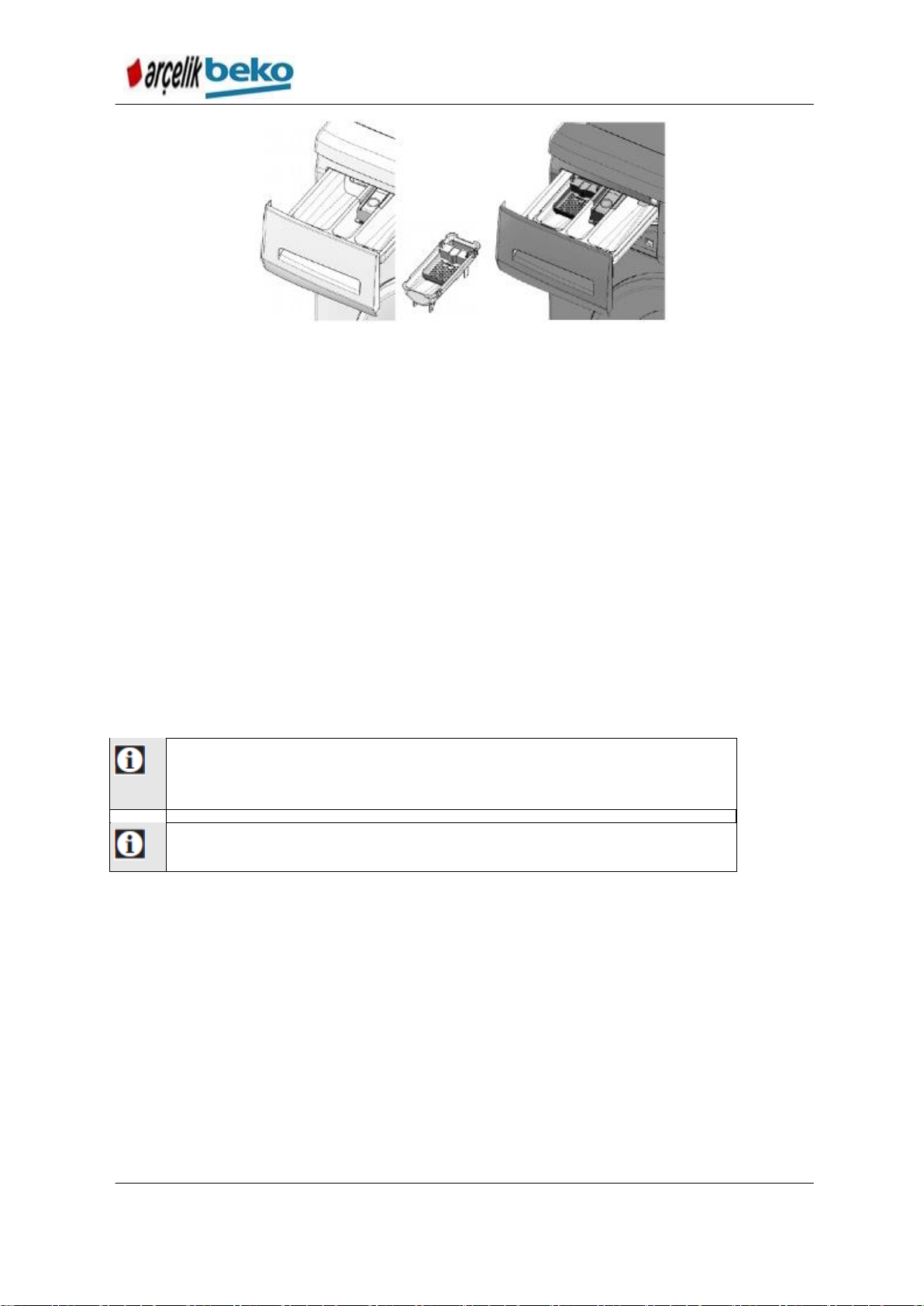

1. Pull the detergent compartment towards yourself and remove it out by pushing

onto the marked point of the siphon on the softener compartment.

33

Page 34

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

Repeat the drum cleaning work at every 2 months.

Use a descaling agent which is appropriate for the washing machines.

Rust stains may form inside the drum due to the metal objects. Clean the stains on

the surface of the boiler with stainless steel cleaning agents. Never use steel wool or

wire wool.

WARNING:

Never use sponge or scrub materials. These will damage the painted and

plastic surfaces.

2. Wash the dispenser and the siphon in the lavatory with an ample amount of

lukewarm water. In order to prevent the residues to contact your skin, clean it with

an appropriate brush by wearing a pair of gloves.

3. After the cleaning, replace the dispenser in order to make sure that the siphon is

seated into its place well .

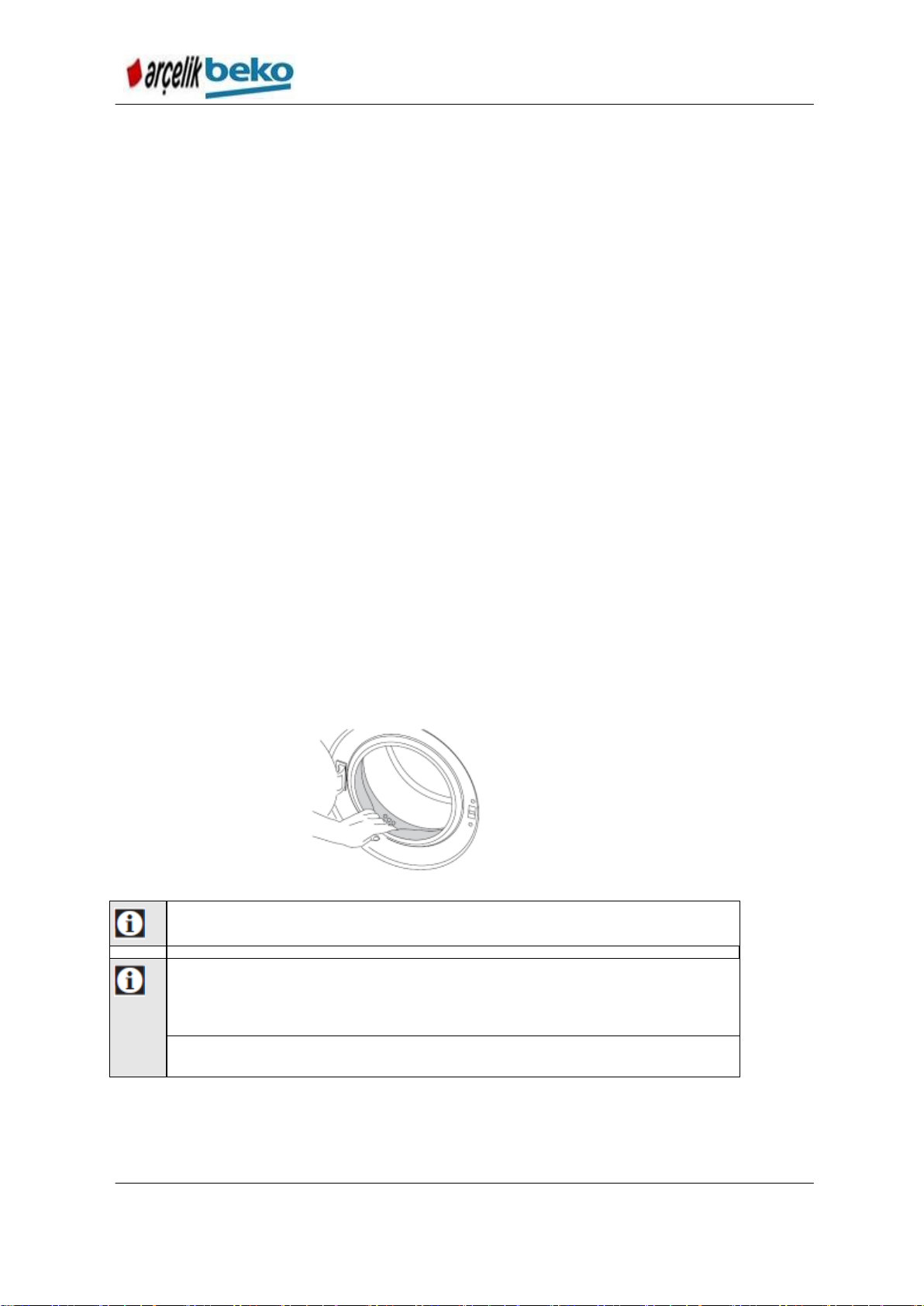

6.2. Cleaning the Loading Door and the Drum

Softener, detergent and dirt residues may accumulate in your machine in the course

of the time and lead to complaints of odor and bad wash results. To prevent this, use

Drum Cleaning

program. If your machine does not have

use the Cottons-90 program by selecting the Extra

Water

Drum Cleaning

or

Extra Rinse

program,

auxiliary

function. Run these processes definitely without any laundry and when the machine

is empty. Before starting the program, put one teaspoon (max. 100 g) powder

descaling agent into the main wash detergent compartment (number 2). If the

descaling agent is a tablet, put one tablet into the compartment number 2. After the

program finishes, wipe dry the inside of the bellows with clean cloth.

Make sure that there is not any foreign bodies left inside the drum after each wash.

Figure 6.2 Cleaning the bellows

If the holes in the bellows shown in the Figure are clogged, open the holes by means

of a toothpick.

6.3. Cleaning the body and control panel

Wipe the body of the machine with soapy water or non-corrosive mild gel detergents

as necessary, and dry with a soft cloth.

34

Page 35

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

WARNING:

Foreign objects which stay inside the pump filter may damage your

machine or cause noise problem.

WARNING:

If the product is not being used, tap should be shut, mains pipe should be

removed and the water inside the machine should be emptied against any likely

freezing.

WARNING:

Shut the tap which the mains pipe of the product is connected to after

each use.

Use only a soft and damp cloth to clean the control panel.

6.4. Cleaning the water inlet filters

There is a filter at the end of each water intake valve at the rear of the machine and

also at the end of each water intake hose where they are connected to the tap.

These filters prevent the foreign substances and dirt in the supply water to enter into

the machine. Filters should be cleaned when they become dirty.

Figure 6.3

1. Shut the taps.

2. Remove the nuts of the water inlet hoses and clean the sediments on the filters of

the water inlet valves with an appropriate brush. If the filters are too dirty, remove

them from their places with a pliers and clean in this way.

3. Remove the filters on the flat end of the water inlet hoses along with their seals

and wash them under running water well.

4. Replace the seals and filters carefully and tighten their nuts by hand.

6.5. Draining the remaining water and cleaning the pump filter

The filter system in your machine prevents solid items such as buttons, coins and

fabric fibers clogging the pump impeller during discharge of washing water. Therefore

the waste water is discharged without any problems and the service life of the pump

is increased.

If the machine does not drain the water, pump filter may have been clogged. Filter

should be cleaned when clogged or once in 3 months. In order to clean the pump

filter, first the water should be drained.

Also, before transporting the machine (for example when moving to new house) and

when the water has the risk of freezing, water may have to be fully drained.

35

Page 36

B13 B7S B7SLED WASHING MACHINE SERVICE HAND BOOK

WARNING:

Temperature of the water inside the machine may rise up to 90 ºC. In