Page 1

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

POSI+ CANOPEN USER MANUAL

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

ABSOLUTE ROTARY ENCODER WITH CAN-BUS INTERFACE

POSI+ RANGE

USER MANUAL

Page 2

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

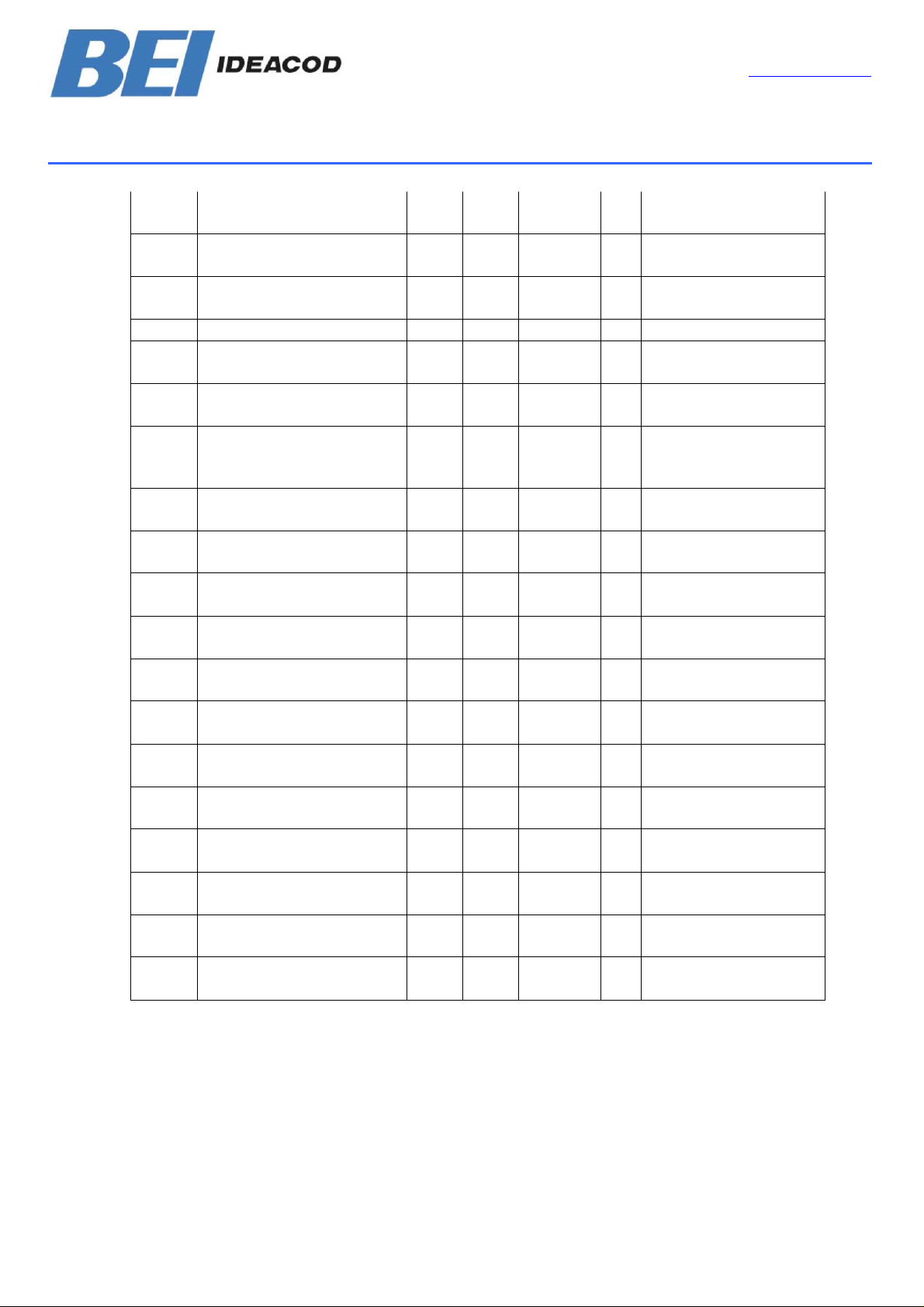

1. Introduction.............................................................................................................................................3

1.1 Absolute rotary encoder......................................................................................................................3

3

1.2 CANopen technology..........................................................................................................................3

1.3 CAN Communication Reference Model............................................................................................5

1.4 Definitions..............................................................................................................................................6

1.5 Troubleshooting ....................................................................................................................................7

2. Device Configuration.............................................................................................................................8

2.1. CANopen Data Transmission..............................................................................................................8

Data Transmission - COB-ID

2.2. Service data communication ............................................................................................................9

Request for parameter – Parameter to the encoder - Index / Sub-index - SDO examples:

Request of a value by the master from the slave

Writing of a value by the master into the slave

2.3 Process data communication........................................................................................................... 11

Synchronous- Cyclical (asynchronous) - Response to an RTR message -Transmission of the c urrent

position

3. Operational mode................................................................................................................................12

Init - Pre-operational mode - Operational m ode - Stopped mode - Reset of the absolute rotary

encoder

4.Communication objects 1000h to 1FFFh (DS 301)..............................................................................14

Object 1010h: Store parameters

Object 1011h: Restore Default parameters

Object 1800h: 1st Transmit PDO communication Parameter

Transmission mode

COB-ID Structure

Inhibit Time (Sub-index 3)

Event Timer (Sub-index 5)

Object 1801h: 2nd Transmit PDO communication Parameter

5. Manufacturer-specific Objects 2000h to 5FFFh.................................................................................20

Object 2002h: Speed

Object 2005h: PDO type

Object 2100h: Transmission Rate

Object 2101h: Node Number

6. Encoder-specific objects 6000h to 9FFFh (DS 406)............................................................................ 22

Object 6000h: Operating Parameters

Object 6001h: Measuring Units per revolution

Object 6002h: Total measuring range in measuring units

Object 6003h: Preset Value

Object 6004h: Position Value

Object 6200h: Cyclic Timer

Object 6500h: Operating Status

Object 6501h: Singleturn Resolution (Rotary)

Object 6502h: Number of Distinguishable Revolutions

Object 6503h: Alarms

Object 6504h: Supported Alarms

Object 6505h: Warnings

Object 6506h: Supported Warnings

Object 6507h: Profile and Software Version

Object 650Ah: Module identification

Object 650Bh: Serial Number

Appendix: Compatibility with with the old encoders SHM5/SHU9/CHU9/MHM5.............................. 31

CONTENTS

Page 2 Version 1.02

Page 3

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

1. Introduction

This manual describes the implementing and confi guration of an absolute rotary encoder with

CANopen interface. The device fullfills the requirements of a CANopen device regarding the

device specification DS406 of the CANopen user group.

1.1 Absolute rotary encoder

The basic principle of an absolute rotary encoder is the optical sampling of a transparent code

disc which is fixed with the driving shaft.

The absolute rotary encoder has a maximum resolution of 8192 steps per revolution (13 Bit). The

Multi-Turn version can detect up to 65536 revolutions (16Bit). Therefore the largest resulting

resolution is 29 Bit = 2

standard Multi-Turn version 29 Bit.

Open functions. The following modes can be programmed and ena bled or disabled:

- RTR Message (Polled mode)

- Cyclic Mode

- Sync Mode

The protocol supports the programming of the following addi tional functions:

- Code sequence (Complement)

- Resolution per revolution

- Total revolutions

- Preset value

- Two limit switches

- Baudrate

- Node number

The general use of absolute rotary encoders with CAN-Bus interface using the CAN Open

protocol is guaranteed.

1.2 CANopen technology

CAN stands for Controller Area Network and was developed by the company Bosch for

applications within the automobile are a. In the meantime CAN has become i ncreasi ngl y used for

industrial applications. CAN is a multi-masterable system, i.e. all users can access the bus at any

time as long as it is free. CAN doesn’t operate with addresses but with mess age identifiers. Access

to the bus is performed according to the CSMA /CA principle (carrier sense multipl e access with

collision avoidance), i.e. each user liste ns if the bus i s free, and i f so, is allowed to send messa ges.

If two users attempt to access the bus simultaneously, the one with the highest priority (lowest

identifier) receives the permi ssi on to send. Us ers with l ower pri ority interrupt their data tr ansfer and

will access the bus when it is free again. Messages can be received by every participant.

Controlled by an acceptance filter the participant accepts only messages that are intended for

it.

29

= 536.870.912 steps. The standard Single-Turn version has 13 Bit, the

Version 1.02 Page 3

Page 4

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

CANopen

Transmission Technology: Two-core cable

Baud rates: 10 kBaud up to 1 MBaud

Participants: maximum 127

Cable Length: 30 m for 1 MBaud

1000 m for 20 kBaud

The data communication is done via message telegram s. In general, telegrams can be spli t in a

COB-Identifier and up to 8 foll o wing byte s. Th e C OB-Identifier, which determines the priority of the

message, is made from the function code and the node number.

The node number is uniquely assi gned to each user. The function code vari es according to the

type of message transmitted:

- Administrative messages (LMT, NMT)

- Servi ce data objects (SDOs)

- Process da ta Objects (PDOs)

- pre-defined messages (synchronization, emergency messages)

PDOs (Process Data Objects) are needed for real time data exchange. Since this messages

possess a high priority, the function code and therefore the identi fier are low. SDOs (service data

objects) are necessary for the bus node configuration (e.g. transfer of device parameters).

Because these message telegrams are tranferred acyclicly (usually only while powering up the

network), the priority is low.

BEI IDEACOD rotary encoders with CANopen interface support all CANopen functions. The

following operating modes can be programmed:

- Response to a RTR message (Polled mode):

The position value is only given upon request

- Cyclic Mode:

The position value is written cyclicall y (interval adjustable) to the bus

- Sync mode:

After receiving a sync message by the host, the encoder answers with the current

process value. If a node is not requi red to ans wer after each sy nc message , a par ameter

sync counter can be programmed to skip a certain number of sync messages before

answering again

Further functions (direction of rotation, resolution,etc..) can be parameterized. BEI IDEACOD

rotary encoders correspond with the class 2 profile for encoder (

whereby the characteristics of rotary encoders with CANopen interface are defined. For

configuration and parameterization various sof tware tools are available from different prov iders.

With the help of the provided EDS file (electronic data shee t) si mpl e line-up and program mi ng ar e

possible.

DS 301 V4.0.2, DS 406 V3.1),

Page 4 Version 1.02

Page 5

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

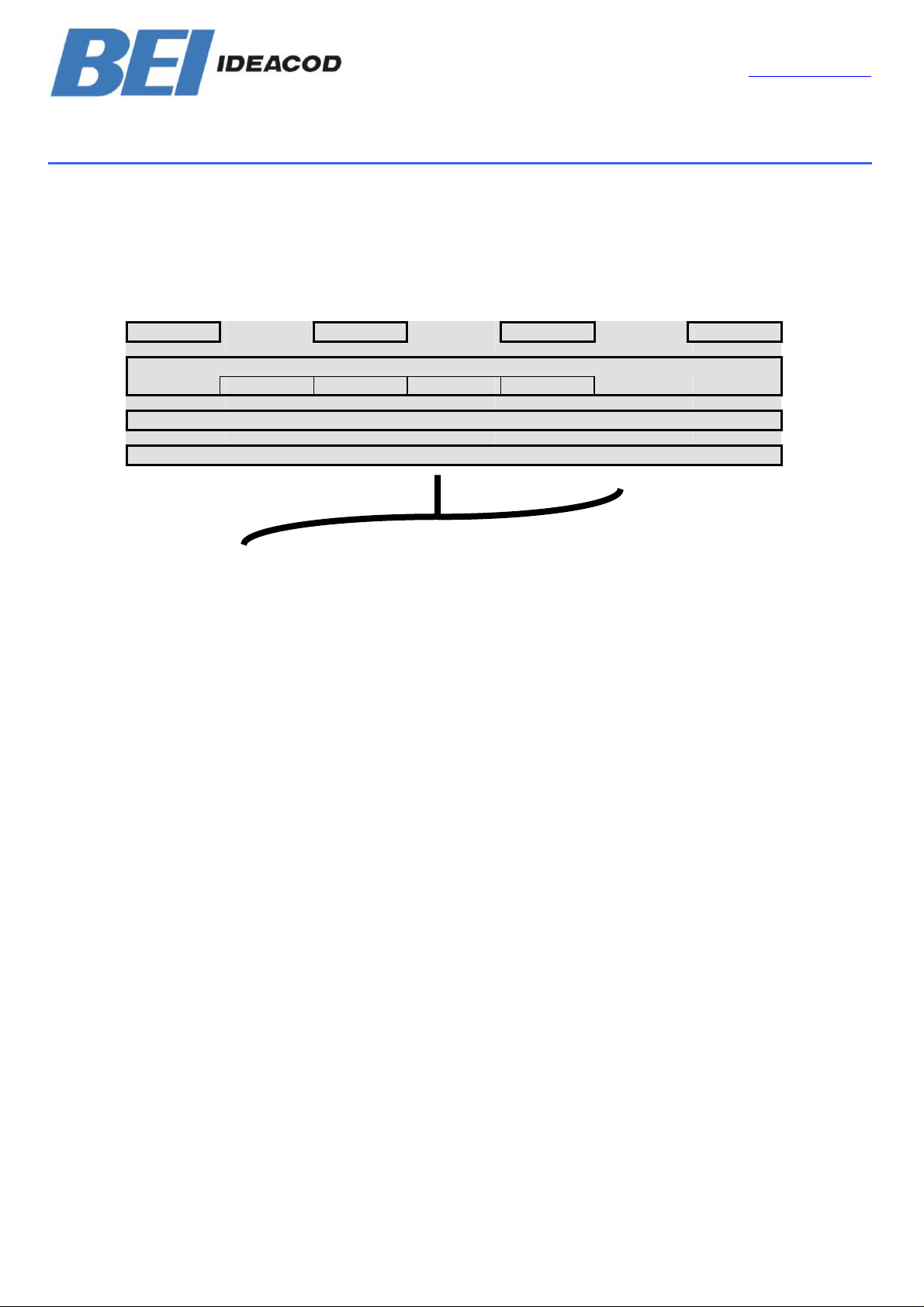

1.3 CAN Communication Reference Model

The communication concept can be descri bed similar to the ISO-OSI Reference Model:

Device A Device B Device C Device X

ISO/OSI Layer 7: CAL

NMT DBT LMT CMS

ISO/OSI Layer 2: Data Link Layer

ISO/OSI Layer 1: Physical Layer

CANbus

The communication model* supports s ynchronous and asynchronous messages. With respect to

the functionality four different message objects are provided:

Administrational Messages (LMT, NMT)

Service Data Messages (SDO)

Process Data Messages (PDO)

Pre-defined Messages (Synchronisation and Emergency Messages)

Further information is available at:

CAN in Automation (CiA) International Users and Manufac turers Group e.V.

Am Weichselgarten 26

D-91058 Erlangen

(*) Reference: CAN Application Layer for Industrial Applications

CiA Draft Standard 201 ... 207, Version 1.1

CAL-based Communication Profile for Industrial Systems

CiA Draft Standard 301

Version 1.02 Page 5

Page 6

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

1.4 Definitions

CAN Controller Area Network

CAL CAN Application Layer

CMS CAN Message Specification.

One of the service elements of the application layer in the CAN Reference Model.

COB Communication Object. (CAN message)

A unit of transportation in a CAN Network.

Data must be sent across a Network inside a COB.

COB-ID COB-Identfier. Identifies a COB uniquely in a Network. The i dentifier determines the

priority of that COB.

LMT Layer Management. One of the service elements of the application layer in the CAN

Reference Model. It serves to configure parameters of each layer in the CAN

Reference Model.

NMT Network Management. One of the service elements of the application layer in the CAN

Reference Model. It performs initialisation, configuration and error handling in a CAN

network.

SDO Service Data Object. A data object with low pri ority to configure a CAN node.

PDO Process Data Object. A data object with high priority to transmit data in synchron ous and

asynchronous modes.

Additionally, following abbreviations are used in the manual:

APV Absolute Position Value

CW Clockwise. Turning direction as seen on shaft.

CCW Counterclockwise. Turning direction as seen on shaft.

FC Function code. It determines the kind of message, which i s sent across the CAN

network.

NN Node number. It determines uniquely the CAN device.

PV Preset value

PCV Process value

Page 6 Version 1.02

Page 7

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

1.5 Troubleshooting

Malfunction of the position value during transmission

Problem:

During the transmission of the position value occasional malfunctions occurs.

Possible solution:

Check, if the last bus node has switched on the terminal resistor.

Too much ERROR-Frames

Problem:

The bus load is too high in case of too much error frames.

Possible solution:

Check if all bus node has the same baudrate. I f one node has another baudrate error frames

are produced automatically.

Installation hints

Both the cable shielding and the metal housi ngs of encoders and subse que nt el ectroni cs hav e a

shielding function. The housing must have the same potential and be connected to the main

signal ground over the machine chassi s or by means of a separate potenti al compensating line.

Potential compensating lines should have a minimum cross section of 6 mm2.

Do not lay signal cable in the di rect vicinity of interference sources (air clearance > 100 m m (4

in.).

A minimum spacing of 200 mm (8 in.) to inductors is usually required, for example in switch-mode

power supplies.

Configure the signal lines for minimum l ength and avoid the use of intermediate terminals.

In metal cable ducts, sufficient decoupling of signal lines from interference signal transmitting

cable can usually be achieved with a grounded partition.

Version 1.02 Page 7

Page 8

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

2. Device Configuration

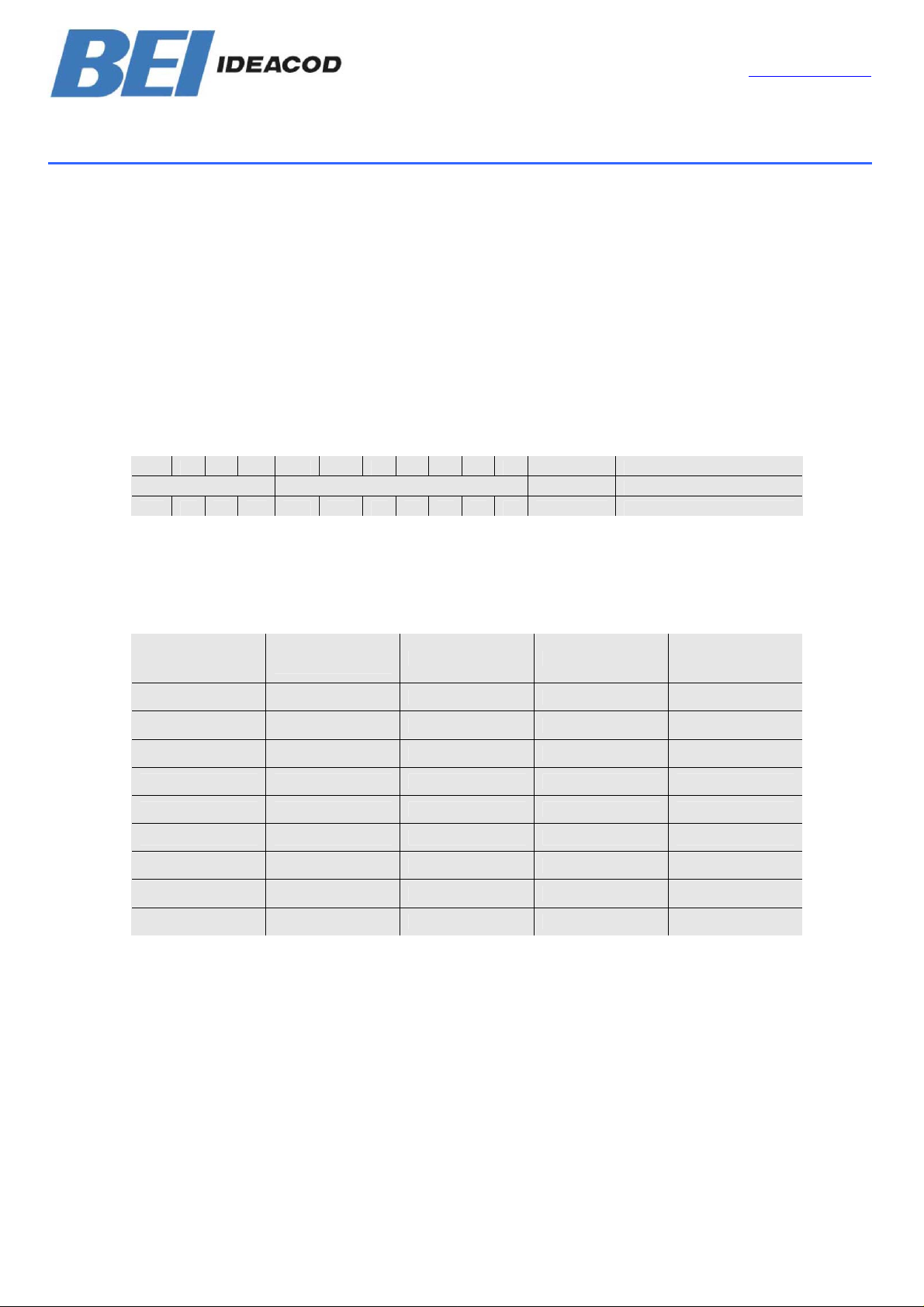

2.1. CANopen Data Transmission

Data Transmission

Data is transmitted in a CANopen network in the form of messages. These messages basically

consist of a COB-ID and 8 data bytes.

COB-ID The 11-bit COB-ID is made up as follows:

10 9 8 7 6 5 4 3 2 1 0

Function code Node number

X X X X X X X X X X X X free, to be selected

The COB-ID only determines the messag e object. It consists of a function code, which identi fies

the message class and the node number, which is the absolute encoder address. The node

number is fixed using the CAN interface.

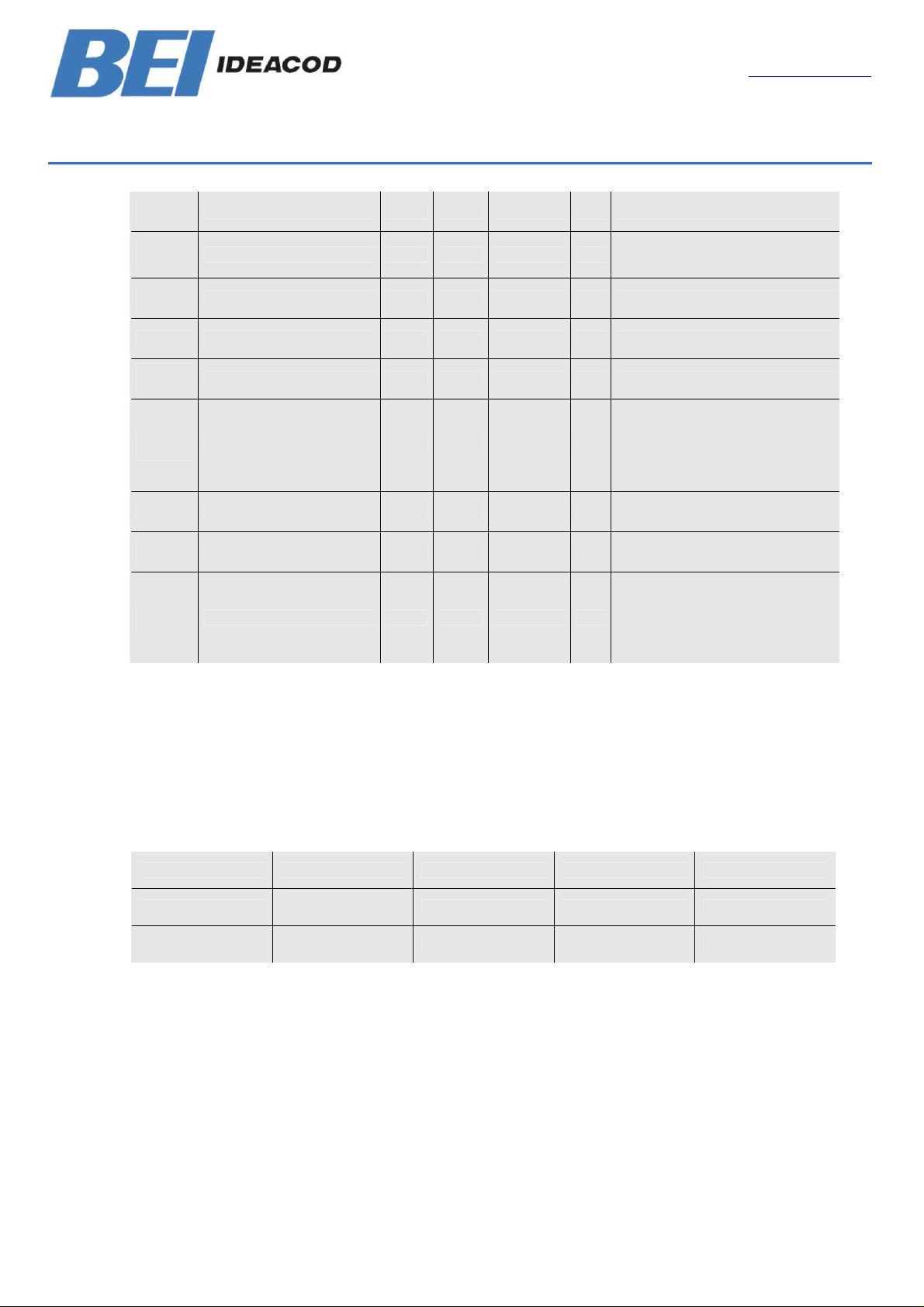

The following function codes are avail abl e (rx and tx as viewed by the master):

Object

Function code

(binary)

COB-ID result Hex. Priority class*

NMT 0000 0 0

SYNC 0001 128 80 0

Emergency 0010 129-255 81-FF 0,1

PDO (tx) 0011 385-511 181-1FF 1,2

PDO (rx) 0100 513-639 201-27F 2

PDO (tx) 0101 641-767 281-2FF 2,3

PDO (rx) 0110 769-895 301-37F 3,4

SDO (tx) 1011 1409-1535 581-5FF 6

SDO (rx) 1100 1537-1663 601-67F 6,7

* Priority: 0= maximum priority, 7=minimum priority

Page 8 Version 1.02

Page 9

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

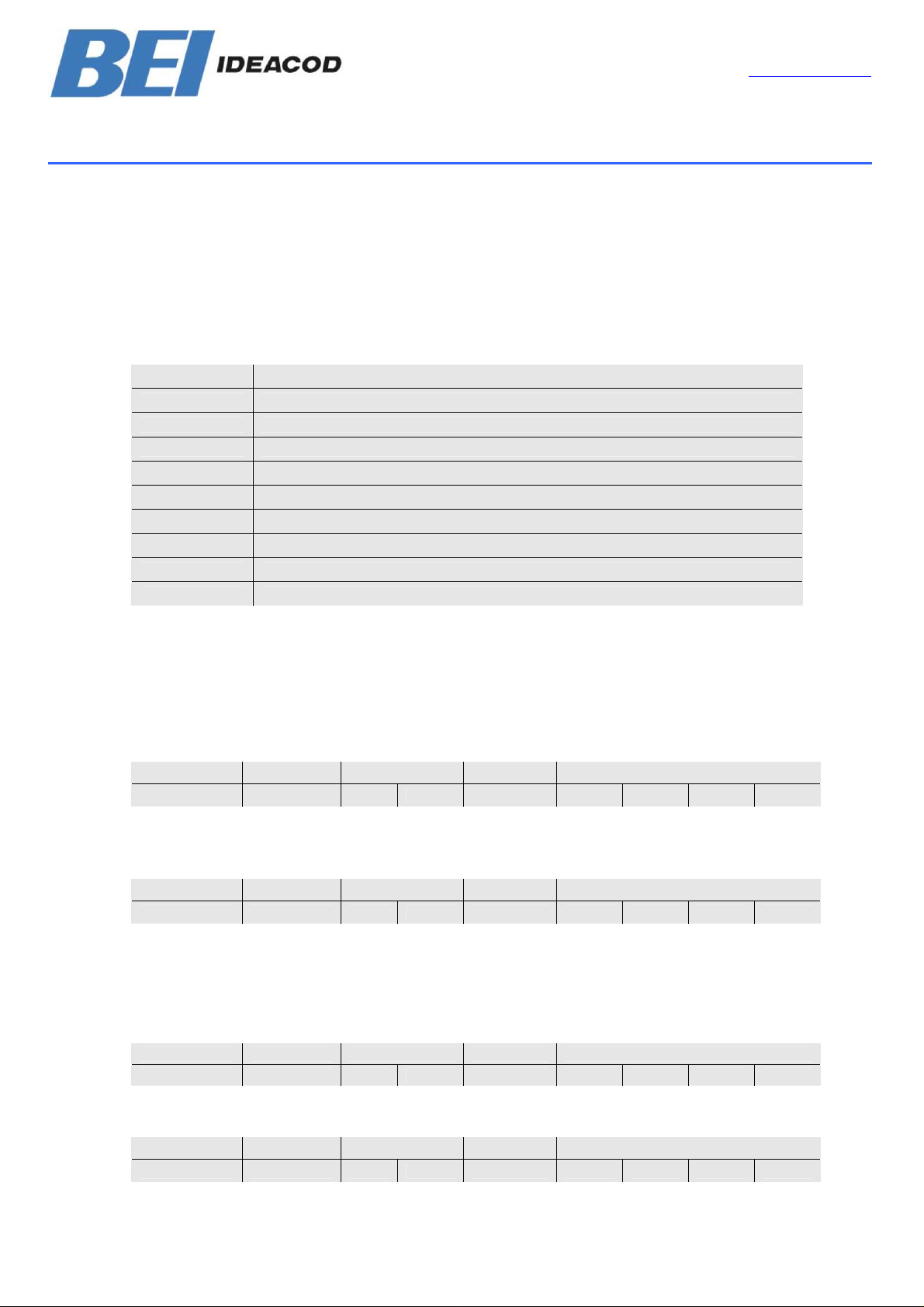

2.2. Service data communication

The service data objects correspond to the standards of the CiA. It is possible to access an objec t

via index and subindex. The data can be requested or where appli cabl e written into the object.

COB-ID Command Index Sub Index Service Data (Parameters)

11 bit Byte 0

Byte 1

(LSB)

Byte 2

(MSB)

Byte 3

Byte 4

(LSB)

Byte 5 Byte 6

Byte 7

(MSB)

COB-ID

An SDO-COB ID is composed as follows:

Master -> Encoder : 600h + Node ID

Encoder -> Master : 580h + Node ID

Request for parameter

Command Function Description

40h Master -> Encoder Request for parameter

43h Encoder -> Master Response 4 bytes (unsigned 32)

4Bh Encoder -> Master Response 2 bytes (unsigned 16)

4Fh Encoder -> Master Response 1 byte (unsigned 8)

80h Encoder -> Master Error

Parameter to the encoder

Command Function Description

23h Master -> Encoder Write 4 bytes (unsigned 32)

2Bh Master -> Encoder Write 2 bytes (unsigned 16)

2Fh Master -> Encoder Write 1 byte (unsigned 8)

60h Encoder -> Master Parameter received

80h Encoder -> Master Error

Version 1.02 Page 9

Page 10

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Index / Sub-index

Data is transmitted solely usi ng objects referenc ed by index. The o bjects are simpl e or composed

type. In this case, the index associated to the comp osed object will be subdivided into several

sub-index.The number of sub-index is specified into subindex 0, it can be from 1 to 254. Each

object is described into a object dictionary.

The organization of a standard object dictionary is shown in the following table:

Index (hex) Object

0000 Not used

0001-001F Static data types

0020-003F Complex data types

0040-005F Manufacturer specific data types

0060-0FFF Reserved

1000-1FFF Communication area (see Communication profile objects 1000h to 1FFFh (DS301)

2000-5FFF Manufacturer specific area (see Manufacturer-specific Zone Objects 2000h to 5FFFh)

6000-9FFF Device profile specific area (see Hardware Profile objects 6000h to 0FFFh (DS406)

A000-FFFF Reserved

SDO examples

Request of a value by the master from the slave

A frequent request will be a request for position Object 6004h

COB-ID Command Index Sub Index Service Data (Parameters)

600h+node ID 40h 04h 60h 00h X X X X

Response by the slave to the request for a value

The position is 4 bytes long, the precise values can be found under object 6004h.

COB-ID Command Index Sub Index Service Data (Parameters)

580h+node ID 43h 04h 60h 00h Pos0 Pos1 Pos2 Pos3

Writing of a value by the master into the slave

Position setting can be performed with preset. Object 6003h

COB-ID Command Index Sub Index Service Data (Parameters)

600h+node ID 22h 03h 60h 00h Pre0 Pre1 Pre2 Pre3

Slave’s response to the writing of a value

COB-ID Command Index Sub Index Service Data (Parameters)

580h+node ID 60h 03h 60h 00h 0 0 0 0

Page 10 Version 1.02

Page 11

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

2.3. Process data communication

Process data objects are used for real time data exchange for process data :position. PDOs can

be transmitted synchronously or cyclically (asynchronously). The encoder supports the PDO1

and the PDO2. Both PDOs supply the current position of the encoder and are defined in the

objects 1800h,1801h, 1A00h, 1A01.

Synchronous

In order to transmit the process data synchronously, a value bet ween 1 and F0h (=240) must be

written into the object 1800h / 1801h Subindex 2. If the value i s 3, the PDO is transmitted on ev ery

third sync telegram (if the value 1 is entered, transmission takes place on every sync tel egram)

In synchronous operation, the PDO is requested by the m aster via the Sync telegram (COB-ID =

80h).

Cyclical (asynchronous)

If you wish the PDOs to b e transmitted cyclically, the value FEh must be written i nto the object

1800h / 1801h Subindex 2. In addition, the cycle time in milliseconds must be entered in the same

object subindex 5. The entered time is rounded off to 1 ms. If the v al ue is stored for 0 ms, th e PDOs

are not transmitted. The function is switched off.

Response to an RTR message

by means of the remote frame = recessive RTR bit, precisely the message with the transferred

identifier will be requested

Transmission of the current position

The process value is sent on the CAN network with the following message:

COB-ID Process value

11 bits Byte 0 Byte 1 Byte 2 Byte 3

27 to 20 215 to 28 223 to 216 231 to 224

The COB-ID contains the node number and the correspondi ng PDO(tx). By default, the sended

process value use the COB-ID 0180h+Node-ID and, in response to the SYNC message, use the

COB-ID 0280h+Node ID.

The PDO COB-ID are defined in the object 1800h/1801h subindex 1.

Version 1.02 Page 11

Page 12

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

3. Operational mode

Principle The absolute rotary encoder accesse s the CA N network less one s econd af ter poweru p

in pre-operational mode.

Init

Following initalization, the encoder logs on to the CAN bus with a BootUp message. The enc oder

then goes automatically to the pre-opera tional mode status.

The COB ID of the BootUp message is made up of 700h and the node ID.

COB-ID Byte 0

700h+Node ID 00

Pre-operational mode

In the pre-operational mode, SDOs can be read and written.

Operational mode

In the operational mode, the encoder transm its the requested PDOs. In addition, SDOs can be

read and written.

Stopped mode

In the stopped mode, only NMT communication is possible. No SDO parameters can be read or

set.

Reset of the absolute rotary encoder

If a node is not operating correctly, it is advisable to carry out a Reset.

COB-ID

00h 81h 00h NMT Reset Remote Node, all Node

Command

(Byte 0)

Node Number

(Byte 1)

Description

00h 81h 01h..7Fh NMT Reset Remote Node node number

After Reset, the absolute rotary encoder accesses the bus in pre-op erational mode.

Page 12 Version 1.02

Page 13

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

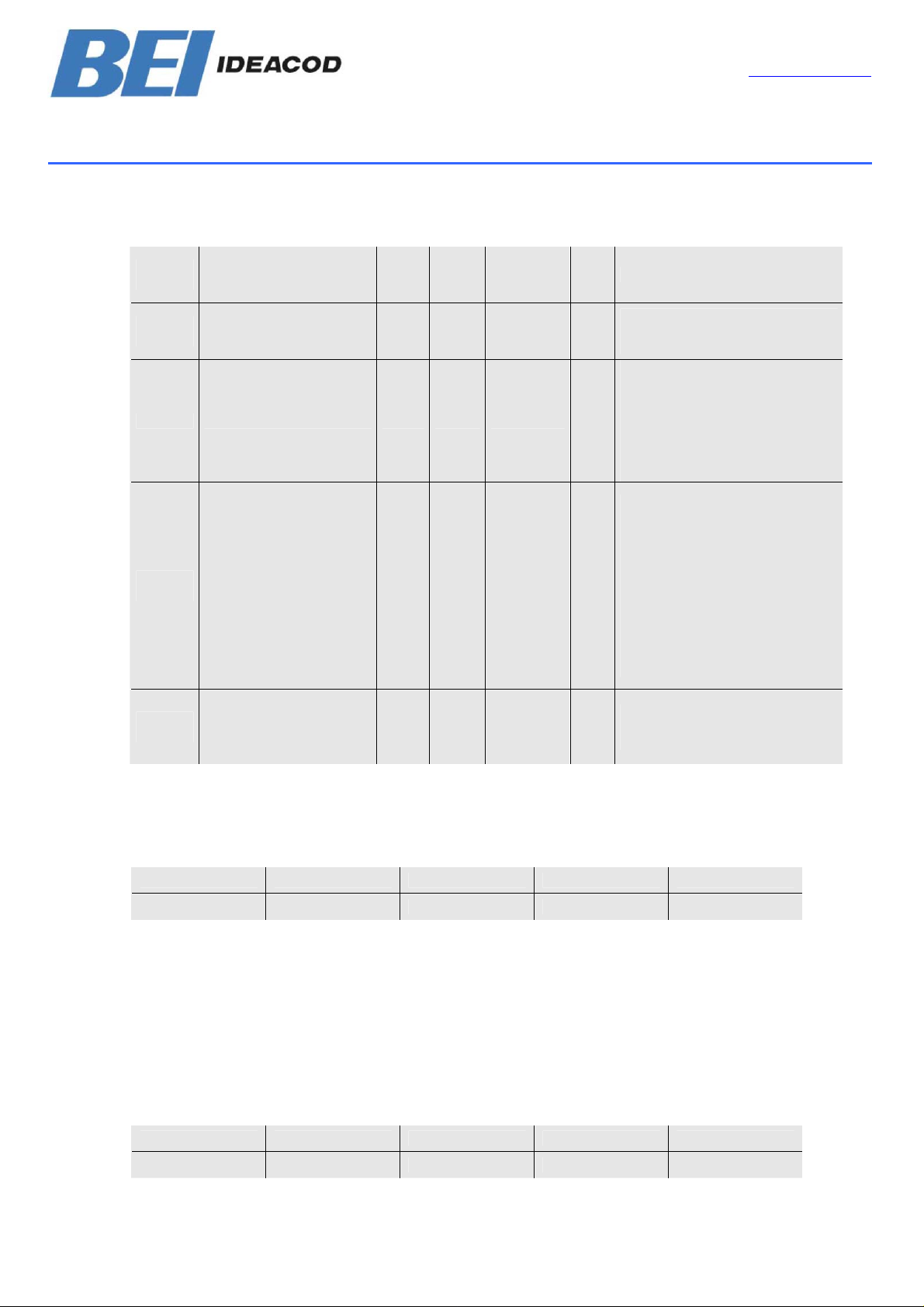

Mode: Preoperational

To set a node to pre-operational mode, the master must send the following message:

COB-ID

00h 80h 00h NMT Preoperational, all Node

00h 80h 01h..7Fh NMT Preoperational node number

Mode: Start

For 1 or all the nodes to switch to operational mode, the master sends the fol lowing message:

COB-ID

00h 01h 00h NMT Start, all Node

Command

(Byte 0)

Command

(Byte 0)

Node Number

(Byte 1)

Node Number

(Byte 1)

Description

Description

00h 01h 01h..7Fh NMT Start node number

Mode: STOP

For 1 or all the nodes to switch off operational mode, the master sends the fol lowing message:

COB-ID

00h 02h 00h NMT Stop, all Node

00h 02h 01h..7Fh NMT Stop node number

Command

(Byte 0)

Node Number

(Byte 1)

Description

Version 1.02 Page 13

Page 14

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

4. Communication objects 1000h to 1FFFh (DS 301)

Introduction This section li sts the objects relating to the communication. Each object, with all its

technical characteristics, is described according to th e CANopen standard.

EDS File : PHM5V102.EDS Standard Encoder, Device Name (1008h) = POSI+

(EDS File : PHM5SFV102.EDS for the compatibility with old encoder SHM 5,SHU9 ,MHM5

Device Name = POSI+SF, not for new designs, objects description i n Appendix)

Format:

U8 : Unsi g ned 8 bi ts

U16 : Unsigned 16 bits

U32 : Unsigned 32 bits

Access:

RO : Read Only

RW : Read Write

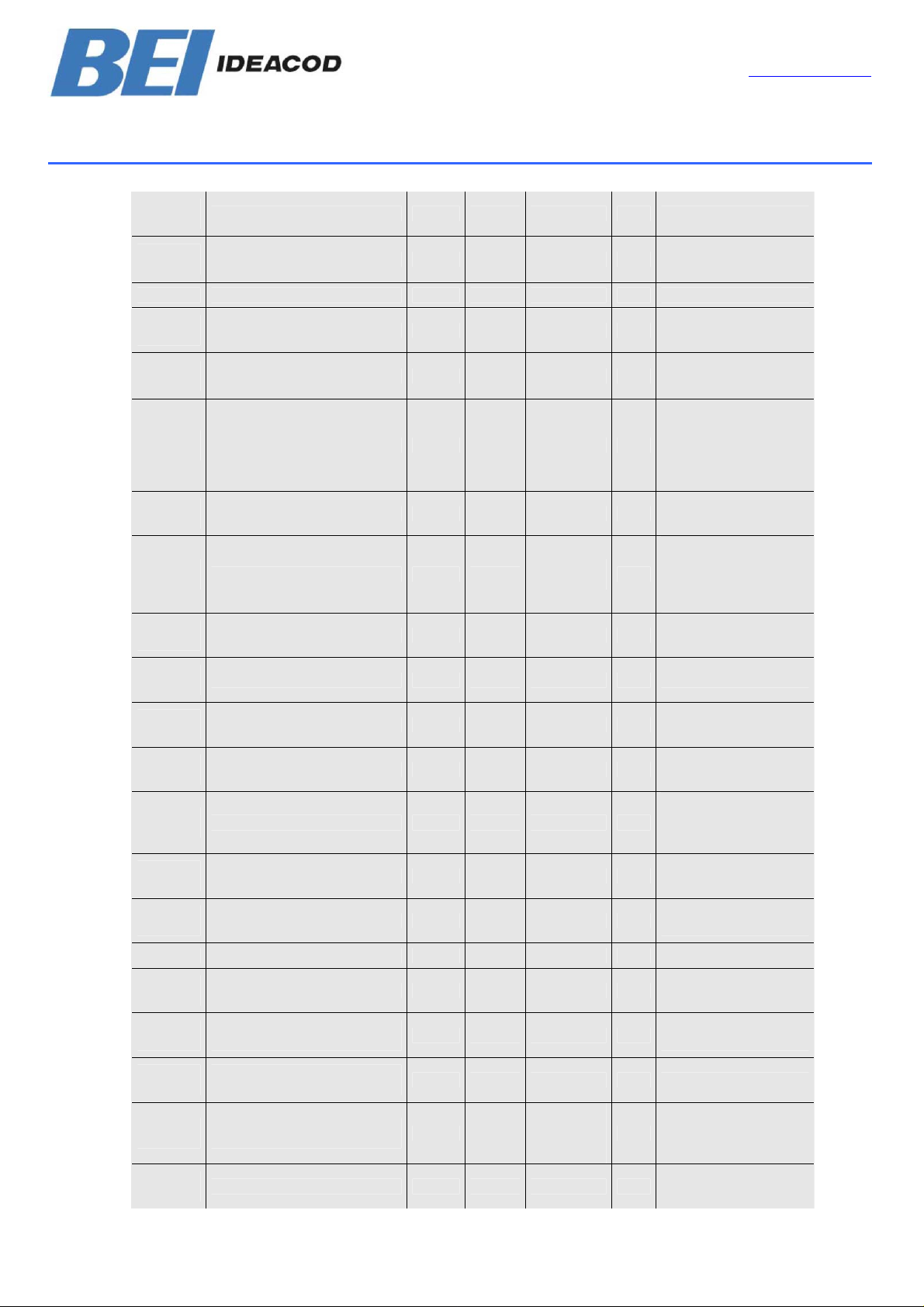

Object

SubIndex

1000

0

1001

0

Name Format Access Default Save Description

multiturn

DeviceType U32 RO

ErrorRegister U8 RO 00h

00020196h

monoturn

00010196h

Encoder type: Bytes 0,1

0001:Monoturn 0002:Multiturn Profil

Bytes 2,3: 0196h=406

Bit0 = Generic error

Bit4 = Communication error

1003 pre-defined error field Contains the last error

1003

0

1003

1

1005

0

1008

0

100C

0

100D

0

1010 StoreParameters Save parameters to encoder

1010

0

1010

1

1011 RestoreDefaultParameters

1011

0

Number of actual errors U8 RW 00h

New, actual error U32 RO ########

COB-ID SYNC Message U32 RW 00000080h Yes COB ID of the sync object

DeviceName STR CONST POSI+

GuardTime U16 RW 0000h Yes Timer for nodeguarding

LifeTimeFactor U8 RW 00h Yes Multiplication of Guard time

LargestSupportedSubindex U8 RO 01h No. of save possibilities 1

SaveAllParameters U32 RW 00000001h ="evas " (0x65766173) to save

LargestSupportedSubindex U8 RO 01h No. of restore possibilities = 1

Number of stored messages 0 or 1

Write 0 to reset the counter

Last Error

1000h Generic error

8130h Life Guard error or Heartbeat

error

Name : POSI+ (standard)

Name : POSI+ SF for compatibility

with SHM5/MHM5 see Appendix

Restore default parameters from

the encoder

Page 14 Version 1.02

Page 15

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

POSI+ CANOPEN USER MANUAL

1011

1014

1016 Consumer Heartbeat Time

RestoreAllDefaultParameters U32 RW 00000001h ="daol" (0x64616F6C) to load

1

0

COB-ID EMCY U32 RO 00000081h

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

COB ID of the emergency object

80h + Node ID

1016

0

1016

1

1017

0

1018 Identity Object

1018

0

1018

1

1018

2

1018

3

1018

4

1200 Server SDO Parameter 0

1200

0

1200

1

1200

2

1800

1800

0

1800

1

1800

2

1800

3

1800

5

1801

1801

0

1801

1

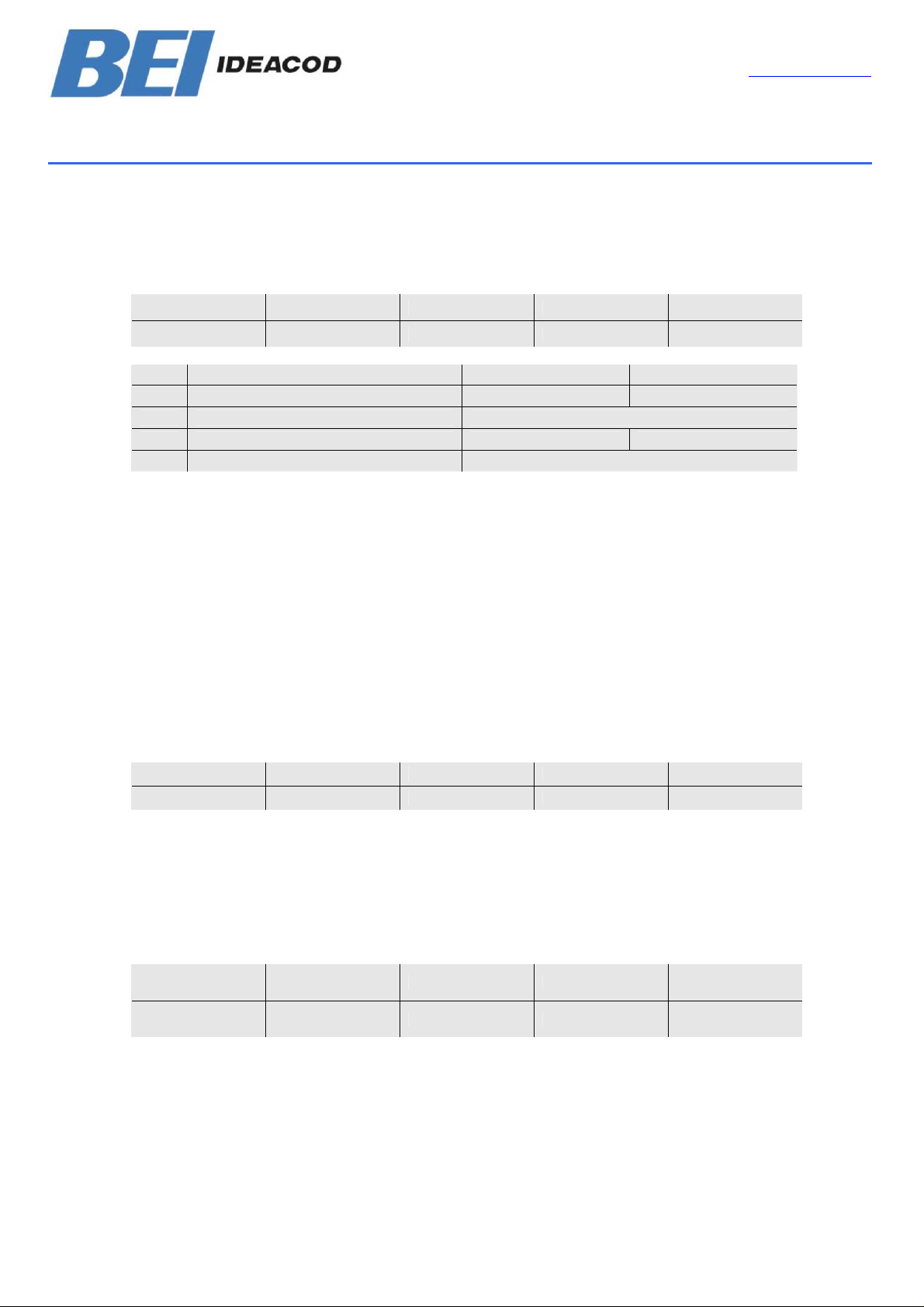

Number of entries U8 RO 01h

Consumer Heartbeat Time 1 U32 RW 00000000h Yes

Producer HeartBeat Time U16 RW 0000h Yes Producer heartbeat time in ms

LargestSupportedSubindex U8 RO 04h

Vendor ID U32 RO 00000184h Vendor no. issued by CiA

Product code U32 RO 354D4850h

Revision number U32 RO 00010000h Current revision number

Serial number U32 RO xxxxxxxxh Unique consecutive serial number

Number of entries U8 RO 02h

COB-ID Client -> Server U32 RO 00000601h 600h+Node ID

COB-ID Server -> Client U32 RO 00000581h 580h+Node ID

Transmit PDO1

Communication Parameter

NrOfEntries U8 RO 05h

COB-ID U32 RW 00000181h Yes PDO ID = 180h + node ID

TransmissionType U8 RW FEh Yes FEh=User defined, cyclical

InhibitTime U16 RW 0000h Yes

Event Time r U16 RW 0000h Yes Cycle time in ms

Transmit PDO2

Communication Parameter

NrOfEntries U8 RO 05h

COB-ID U32 RW 00000281h Yes PDO ID = 280h + node ID

Bit0..15 Consumer heartbeat in ms

Bit16..23 Node-ID

minimum interval for PDO

transmission

multiple of 100µs.

Version 1.02 Page 15

Page 16

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

1801

2

1801

3

1801

5

1A00 Transmit PDO1 Mapping

TransmissionType U8 RW 01h Yes 01h= synchronous operation

minimum interval for PDO

InhibitTime U16 RW 0000h Yes

Event Time r U16 RW 0000h Yes Cycle time in ms

transmission

multiple of 100µs.

1A00

0

1A00

1

1A01 Transmit PDO2 Mapping

1A01

0

1A01

1

NrOfEntries U8 RO 01h

mapping for th e PDO1 the device is

Mapped Object U32 RO 60040020h

NrOfEntries U8 RO 01h

mapping for th e PDO2 the device is

Mapped Object U32 RO 60040020h

able to transmit

b0..b7 : object length

20h = Unsigned32

b8..b15 : sub-index (00h)

b16..b31 : Index (6004h)

able to transmit

b0..b7 : object length

20h = Unsigned32

b8..b15 : sub-index (00h)

b16..b31 : Index (6004h)

Object 1010h: Store parameters

Description This object supports the saving of parameters in non volatile memory.

In order to avoid storage of parameters by mistake, storage i s only executed when the specific

signature “save” is written to the S u b-Index

Characteristics The characteristics of this object are outlined in the following table:

Sub-index Desciption Dtat type Default value Access

0

1 Store all parameters UNSIGNED32 - rw

Number of subindexes

UNSIGNED8 1 Ro

Operation To save the parameters, the "save" character string (6576 6173h) must be written

in the corresponding index:

Information on storage functionality is read from a sub-index. The result obtained, 0000 0001h,

indicates that the module saves parameters only when it receives the command to do so.

Page 16 Version 1.02

Page 17

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Object 1011h: Restore Default parameters

Description This object is used to restore the encoder default parameters.

In order to avoid the restoring of default parameters by mistake, restori ng is only executed when

the specific signature “load“ (6461 6F6Ch) is written to the appropriate sub-index.

Characteristics The characteristics of this object are outlined in the following table:

Sub-Index Description Data type Default value Access

0

1

Number of subindexes

Restore all default

parameters

Unsigned8 1 Ro

Unsigned32 - rw

Note: The restoration of parameters will only be taken into account after a power up or NMT Reset.

After the power on or the NMT Reset, the transmission Rate and the node number are the default

values

Operation To restore the parameters, the corresponding index must be written in the "load"

character string (6461 6F6Ch):

Most significant word Least Significant word

ISO 8859 (ASCII)

signature

d a o l

Hex value 64h 61h 6Fh 6Ch

Information on whether it is possible to restore the m odule's factory parameters is read from a

sub-index. The result obtained, 00000001h, indicates that the factory parameters can only be

restored when the module receives the command to do so.

Object 1800h: 1st Transmit PDO communication Parameter

Description This object contains the Transmit PD O comm unication parameter.

Characteristics The characteristics of this object are outlined in the following table:

Sub-Index Description Data type Default value Access

0

1 COB-ID Unsigned32 180h + Node ID rw

Number of subindexes

Unsigned8 5 ro

2 Transmission mode Unsigned8 FEh rw

3 Inhibit time Unsigned32 0 rw

4 Not available

5 Event timer Unsigned32 0 rw

Version 1.02 Page 17

Page 18

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

POSI+ CANOPEN USER MANUAL

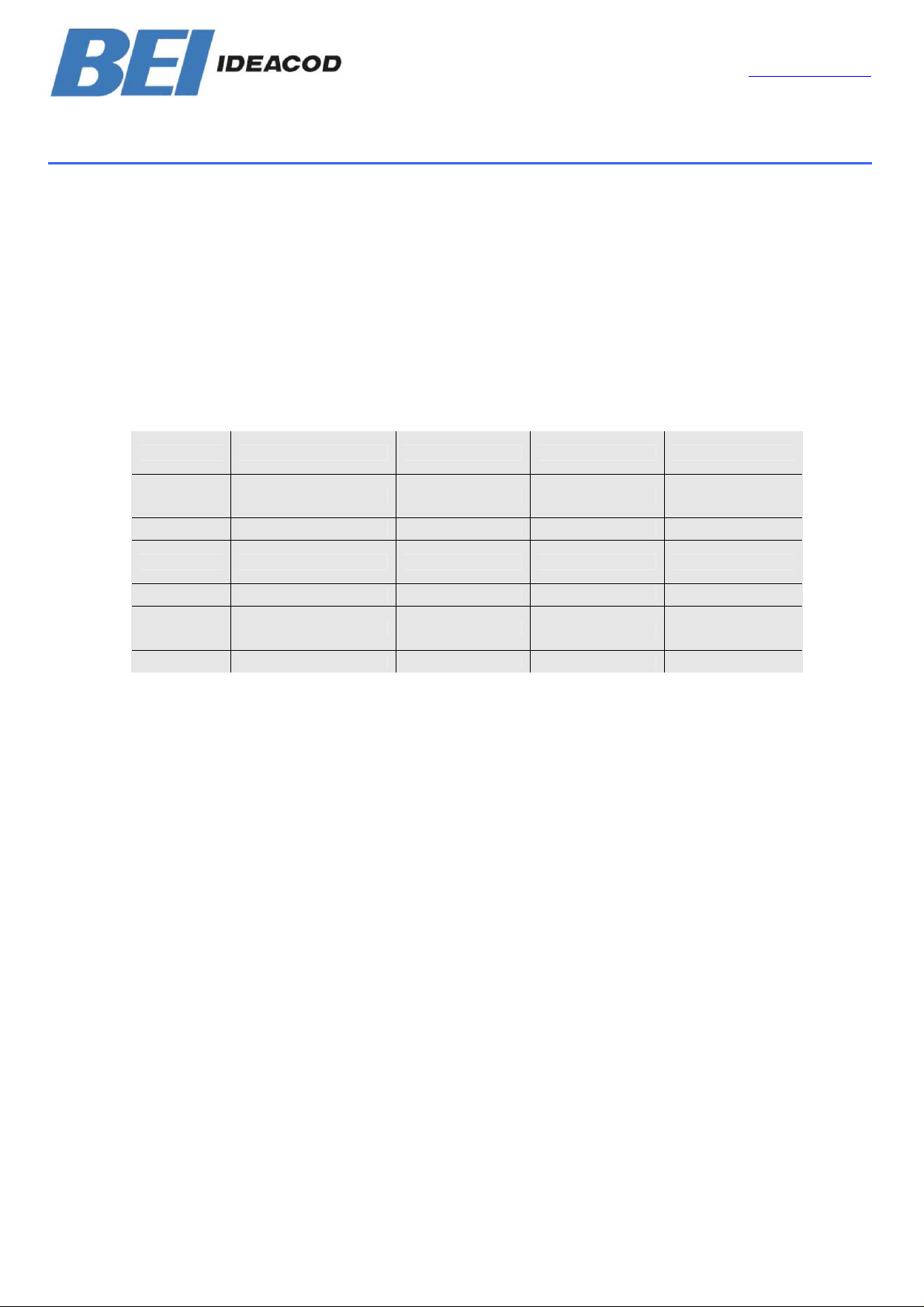

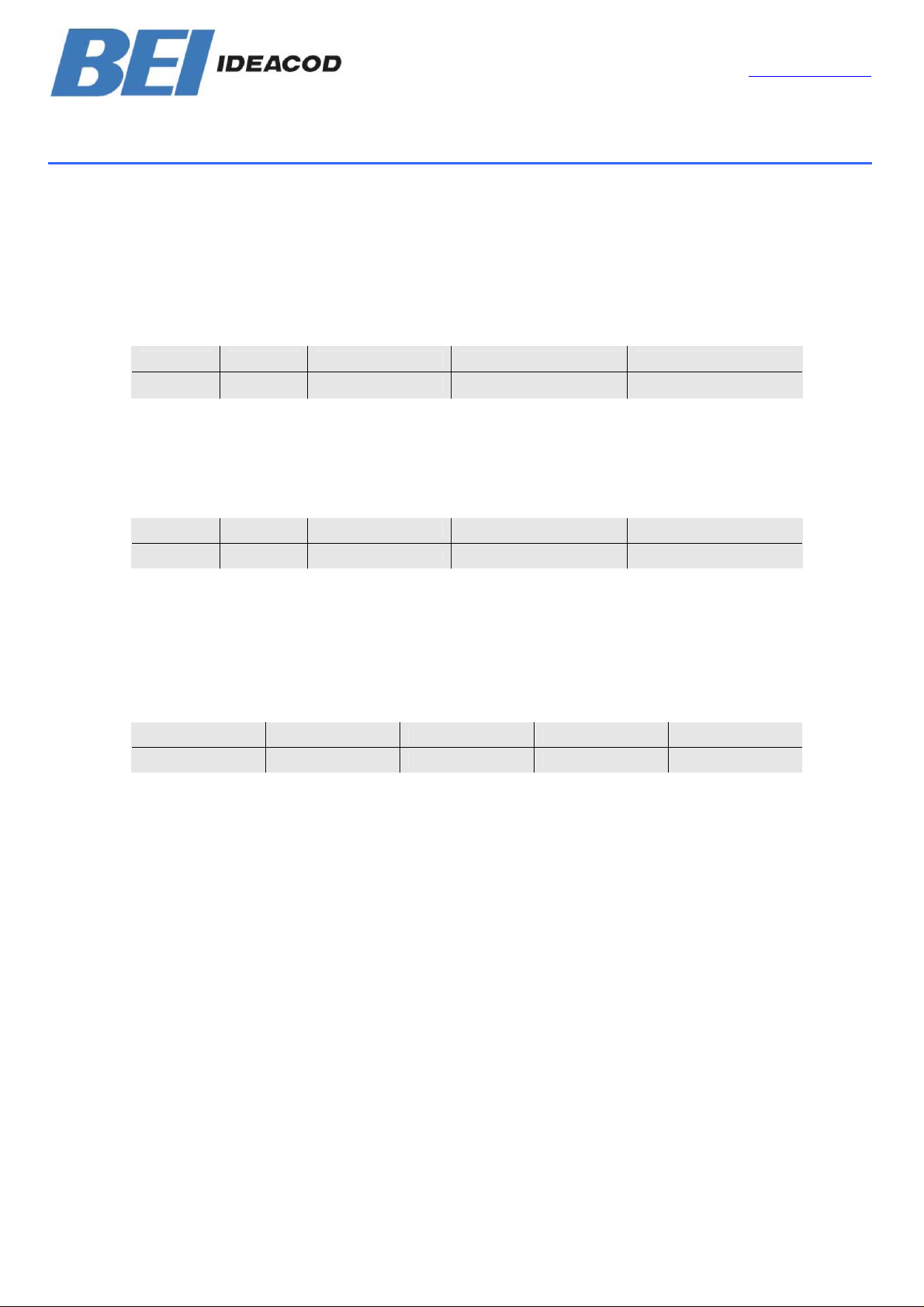

Transmission mode

The PDO transmission mode can be configured as desc ribed in the table below.

Tranfer

code

0 x x

1 to

240

241 to

251

252 x x

253 x x

Transmission code

Cyclic Acylic Synchronous Asynchronous RTR only

x x

Reserved -

Notes

Send PDO on first Sync

message following an event

Send PDO every n (n=0…240)

Sync messages

Update data immediately

after Remote request and

send PDO on next SYNC

message

Update data and send PDO

on Remote Request

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

254 x

255 x Send PDO on encoder -event

Send PDO on manufacturerevent

COB-ID Structure

The structure of a COB-ID for CAN2.0 is shown in the following table:

Bit No. Value Meaning

31 (MSB)

30

29 0 11-bit ID (CAN 2.0A)

28-11 0 If bit 29 = 0

10-0 (LSB) X Bit 10-0 of the identifier

0 The PDO object exists

1 The PDO object doesn’t exis t

0 RTR mechanism authorized

1 RTR mechanism unauthorized

Inhibit Time (Sub-index 3)

For "Transmit PDOs", the "inhibit time" for PDO transm issions can be entered in this 16 bit field. If

data is changed, the PDO sender checks whether an "inhibit time" has expired since the last

transmission. A new PDO transmission can only take place if the "inhibit time" has expired. The

"inhibit time" is useful for asynchronous transmission (transmission mode 254, 255), to avoid

overloads on the CAN bus. The "inhibit time" is a multiple of 100µs of object 1800sub03/1801sub03.

Page 18 Version 1.02

Page 19

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Event Timer (Sub-index 5)

In mode 254/255, if a value > 0 is written in thi s 16-bi t field, the TPDO is al ways sent after the "event

timer" expires. The value written i n 1800sub05 and 1801sub05 corresponds to the "event timer" in

ms.

Object 1801h: 2nd Transmit PDO communication Parameter

Description This object contains the Transmit PD O comm unication parameter.

Characteristics The characteristics of this object are outlined in the following table:

Sub-Index Description Data type Default value Access

0 Number of sub-indexes UNSIGNED8 5 Ro

1 COD-ID UNSIGNED32 280h+node ID Rw

2 Transmission mode UNSIGNED8 1 Rw

3 Inhibit time UNSIGNED16 0 Rw

4 Not available

5 Event timer UNSIGNED16 0 Rw

Version 1.02 Page 19

Page 20

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

POSI+ CANOPEN USER MANUAL

5 Manufacturer-specific objects 2000h to 5FFFh

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

Object

SubIndex

2002

0

2005 PDO-Type U8 RW 00h

2100

0

2101

0

Name Format Access Default Save Description

Speed I16 RO No

Transmission Rate U8 RW 01h Yes

Node Number U8 RW 01h Yes

Yes

(1.02)

Speed of the encoder shaft

Number of physical impulses with a

time period of 5 ms

Types for PDO1 and PDO2

Bit 3..0 = PDO1 Bit 7..4=PDO 2

0 (Default):Byte 0 .. Byte3 of PDO =

Value of position

2 (Type 2):Byte 0 .. Byte3 of PDO =

Value of position

Byte 4 .. 5 of PDO = Speed

Byte 6 .. 7 of PDO = 0x00 0x00

After setting the baud rate, the

EEPROM must be saved and

reinitialized

0=10 kBit/s

1=20 kBit/s (default)

2=50 kBit/s

3=100 kBit/s

4=125 kBit/s

5=250 kBit/s

6=500 kBit/s

7=800 kBit/s

8=1000 kBit/s

Node number 1..127 possible After

setting the baud rate, the EEPROM

must be saved and reinitialized.

Object 2002h: Speed

Only for standard encoder with software version >=1.01 : DeviceName (1008h) = « POSI+ » ,

Software Version (6507h) >= 0x0101

CMS Index Default value Value range Data length

SDO 2002h Signed 16

Description To measure the rotati onal speed of the encoder shaft, the difference betwee n two

physical (unscaled) values of position with a time period of 5 ms is calculated. The difference

between the two values will be read out as a signed 16 bits value (positive value = clockwise

direction of rotation ).

The output of the speed by means of PDO is made possible by setti ng the desired PDOs to typ e 2

(see object 2005h).

Object 2005h: PDO Type

Only for standard encoder with software version >=1.01 : DeviceName (1008h) = « POSI+ » ,

Software Version (6507h) >= 0x0101

CMS Index Default value Value range Data length

SDO 2005h 00h Unsigned 8

This object helps to determine the types for PDO1 and PDO2.

Page 20 Version 1.02

Page 21

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

The COB ID and the transfer type for the PDOs is determined in the objects 1800h and1802h.

With the software version = 1.01, this value cannot be stored in the EEPROM and has to be

transferred again after each activation (Reset or Power-On).

With the software version >=1.02, this value can be stored in the EEPROM.

Data Bit 7 .. 4 = PDO2 Bit 3 .. 0 = PDO1

00h Default Default

02h Default Type2

20h Type2 Default

22h Type2 Type2

Standard: PDO1 and PDO2 set to type Default (00h)

COB-ID Process data (PDO)

11 bit Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Default Value of position

Type 2 Value of position Speed 00h 00h

Object 2100h: Transmission Rate

Only for standard encoder : DeviceName (1008h) = « POSI+ »

Description This object contains the baud rate, see table above for the values.

Default = 20kbit/s

Object 2101h: Node Number

Only for standard encoder : DeviceName (1008h) = « POSI+ »

Description This object contains the Node Number.

Default = 1

Note: After setting the baud rate or the node number, the parameters must be saved in the

EEPROM with “StoreParameters” (Object 1010h) and the new values are set valid after the device

is reset (NMT reset node ) or power cycled.

Version 1.02 Page 21

Page 22

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

6. Encoder-specific objects 6000h to 9FFFh (DS 406)

Introduction This section lists the encoder-specific objects. Each object, with all its technical

characteristics, is described according to the CANopen standard.

Object

SubIndex

6000

0

6001

0

6002

0

6003

0

Operating Parameters U16 RW 0004h Yes

Measuring Units per Revolution U32 RW 00002000h Yes

Total Measuring Range U32 RW

Name Format Access Default Save Description

Bit0 = Position increasing

Bit2 = 0 Scaling function

revolution: 13 bits

Multi:

20000000h

Mono:

00002000h

Preset Value U32 RW 00000000h Yes Preset in increments

Yes

0 CW

1 CCW

disabled 1 Scaling

function enabled

Resolution in steps /

Overall measuring

range in increments

29Bit = multiturn

13Bit = singleturn

6004

0

6200

0

6300 Cam state register

6300

0

6300

1

6301 Cam enable

6301

0

6301

1

6302 Cam polarity

Position Value U32 RO 00000ECBh Position value

Cyclic timer U16 RW 0000h Yes

NrOfAvailableChannel U8 RO 01h only CAM1

Cam state channe l 1 U8 RO 00h

NrOfAvailableChannel U8 RO 01h only CAM1

Cam enable channel 1 U8 RW 00h Yes

In ms, identical object

1800h, subindex 5

status bit of the cam in

a cam channel

Bit0 = CAM1

0 = CAM Inactive

1 = CAM active

Bit0 = CAM1

0 = cam disable

1 = cam state

calculated by the

device

6302

0

6302

1

6310 Cam1 low limit

Page 22 Version 1.02

NrOfAvailableChannel U8 RO 01h

Bit0 = CAM1

Cam polarity channel 1 U8 RW 00h Yes

0 = cam state not

inverted

1 = cam state not

inverted

Page 23

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

6310

0

6310

1

6320 Cam1 high limit

NrOfAvailableChannel U8 RO 01h only CAM1

Cam1 low limit channel 1 U32 RW 00000000h Yes

switch point for the

lower limit setting for

CAM1

6320

0

6320

1

6500

0

6501

0

6502

0

6503

0

6504

0

6505

0

6506

0

6507

0

6508

0

NrOfAvailableChannel U8 RO 01h only CAM1

Cam1 high limit channel 1 U32 RW 00000000h Yes

Operating Status U16 RO 0004h

Single Turn Resolution U32 RO 00002000h

Number of Revolutions U16 RO

Alarms U16 RO 0000h Alarms

Supported Alarms U16 RO 0000h Supported Alarms

Warnings U16 RO 0000h Warnings

Supported Warnings U16 RO 0000h Supported Warnings

Profile & Software Version U32 RO 01020301h

Operating Time U32 RO FFFFFFFFh not used

Multi FFFFh

Mono 0001h

switch point for the

higher limit setting for

CAM1

Bit0 = Position increasing

Bit2 = 0 Scaling function

Max. Resolution in steps

/ revolution: 13 bits

Byte 0,1:Profile version

version = 1.02 = 0102h

0 CW

1 CCW

disabled 1 Scaling

function enabled

Number of

distinguishable

revolutions

Multiturn = FFFFh

Monoturn = 1

=3.1 = 0301h

Byte 2,3: Software

6509

0

650A Module Identification

650A

0

650A

1

650A

2

650A

3

650B

0

Version 1.02 Page 23

Calculated Offset Value INT32 RO

NrOfEntries U8 RO 03h

manufacturer_offset_value

Manufacturer_Min_Position_Val

ue

Manufacturer_Max_Position_Va

lue

Serial Number U32 RO

U32 RO 00000000h

U32 RO 00000000h Minimum position value

Multi:

U32 RO

1FFFFFFFh

Mono:

00001FFFh

Offset calculated from

preset 6003h

Manufacturer offset

value

Maximum position value

Linked with serial

number object 1018-4

Page 24

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Object 6000h: Operating Parameters

Presentation The code sequence (Complement) can be selected as the operating parameter.

CMS Index Default value Value range Data length

SDO 6000h 0h 0h-FFFFh Unsigned 16

Bit Function Bit = 0 Bit = 1

0 Code Sequence CW CCW

1 Commissionning Diagnostic control Not used

2 Scaling function control Disabled Enabled

3 Measuring direction Not used

CODE SEQUENCE: The code sequence defines whether i ncreasing or decreasing position values

are output when the encoder shaft rota tes clockwise or counterclockwise as seen on the shaft.

SCALING FUNCTION CONTROL: With the scaling function the encoder numerical value is

converted in software to change the physical resol ution of the e ncoder.

The measuring units per revolution object (6001h) and total measuring rang e in measuring units

object (6001h) are the scaling parameters. The scaling function bit is set in the operating

parameters. If the scaling function bit is set to zero, the scaling function is disabled.

Object 6001h: Measuring Units per revolution

Presentation The Measuring Units per revolution parameter is used to program the required

number of steps per revolution. Choose a value between 2 and 8192:

CMS Index Default value Value range Data length

SDO 6001h - 0h – 2000h Unsigned 16

Object 6002h: Total measuring range in measuring units

Presentation Thi s parameter is used to program the requi red number of measuring units from th e

global measuring range. This value mu st not exceed that of the total resolution of the absolute

rotary encoder

CMS Index Default value Value range Data length

SDO 6002h

2000 0000h 2 - 2000 0000h

Unsigned 32

Total measuring range (total resolution) = Number of revolutions x ·Measuring Units per resolution

Page 24 Version 1.02

Page 25

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Object 6003h: Preset Value

Presentation The preset value is the req uired position value to be reached at a certai n physical

location of the axis. The position value is fixed as being the process value required by the

presetting of the parameters.

To avoid execution time errors, the preset value must not exceed the total measuring range (total

resolution) -1 of the parameters.

CMS Index Default value Value range Data length

SDO 6003h - 0 – (total resolution-1) Unsigned 32

Object 6004h: Position Value

Description This object is used to define the position of the encoder.

CMS Index Default value Value range Data length

SDO 6004h - 0 – (total resolution-1) Unsigned 32

Object 6200h: Cyclic Timer

Cyclic mode The absolute rotary encoder transmits the current process value cyclically – without

being polled by the host. The cycle time can be programmed i n milliseconds for valu es between

1 ms and 65535 ms. (For example: 64h = 100 ms).

CMS Index Default value Value Range Data l ength

SDO 6200h 0h 0h – FFFFh Unsigned 16

This parameter is identical “Event Timer” of the transmit PDO1 Index 1800h, Sub Index 05h.

See description of the object “Transmit PDO1” (1800h) for the use of the cyclic timer.

If the value is 0, the cyclic timer is disabled and the position is never sent.

Note: After setting the encoder parameters, they must be saved in the EEPROM with

“StoreParameters” (Object 1010h). If the encoder parameters are not saved, the configuration will

be lost at the next power up.

Version 1.02 Page 25

Page 26

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Object 6500h: Operating Status

Description This object contai ns the operating status of the encoder. It provides informatio n on

the encoder internal parameters.

Values The values of this object are outlined in the fol lowing table:

Bit Function Value = 0 Value = 1

0 Code sequence CW CCW

1

2 Scaling function control Disabled Enabled

Commissionning

Diagnostic Control

Not supported Supported

3 Measuring direction Not used

4…11 Reserved

12

13

14

15

Manufacturer specific

alarm

Manufacturer specific

alarm

Manufacturer specific

alarm

Manufacturer specific

alarm

Not used

Not used

Not used

Not used

CMS Index

SDO 6500h 00h - - Unsigned 16 ro

Sub

Index

Default value Value range Data length Access

Object 6501h: Singleturn Resolution (Rotary)

Description This object indcates the number of s teps per revolution according to the position of

the encoder. The maximum encoder resolution is 8192.

CMS Index

SDO 6501h 00h 2000h - Unsigned 32 ro

Sub

Index

Default value Value range Data length Access

Object 6502h: Number of Distinguishable Revolutions

Description This obj ect indicates the number of revolutions that the encoder can execute. The

maximum number of revolutions of the encoder is 65536.

CMS Index

SDO 6502h 00h FFFFh - Unsigned 16 ro

Sub

Index

Default value Value range Data length Access

Page 26 Version 1.02

Page 27

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Object 6503h: Alarms

Description This object contains the various alarm messages. An alarm will be displayed if a

malfunction of the encoder cause a posi tion error. The al arm bit remains enabled unti l the alarm

is cleared and the encoder is able to provide a correct position value.

Values The values of this

Bit Function Value = 0 Value = 1

0 Position error No Yes

1

2…11 Reserved

12

13

14

15

Object 6504h: Supported Alarms

Description This object indicates the alarms suppor ted by the encoder.

Values The values of this object are outlined in the fol lowing table:

Bit Function Value = 0 Value = 1

object are outlined in the following table:

Commissionning

diagnostics

Manufacturer specific

alarm

Manufacturer specific

alarm

Manufacturer specific

alarm

Manufacturer specific

alarm

Not supported Supported

Disabled Enabled

Disabled Enabled

Disabled Enabled

Disabled Enabled

0 Position error No Yes

1

2…11 Reserved

12

13

14

15

Commissionning

diagnostics

Manufacturer specific

alarm

Manufacturer specific

alarm

Manufacturer specific

alarm

Manufacturer specific

alarm

No Yes

No Yes

No Yes

No Yes

No Yes

Version 1.02 Page 27

Page 28

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Object 6505h: Warnings

Description Thi s object indicates if the tolerances of certain encoder internal parameters have

been exceeded

Values The values of this object are outlined in the fol lowing table:

Bit Function Value = 0 Value = 1

0 Position error No Yes

1 Ligth control reverse Not reached Error

2 CPU watchdog status OK Reset

3

4 Battery charge OK Too slow

Operating time limit

warning

No Yes

5 Reference point Reached Not reached

6…11 Reserved

12

13

14

15

Manufacturer specific

warning

Manufacturer specific

warning

Manufacturer specific

warning

Manufacturer specific

warning

N/A N/A

N/A N/A

N/A N/A

N/A N/A

Object 6506h: Supported Warnings

Description This object indicates the warnings supported by the encoder.

Values The values of this object are outlined in the fol lowing table:

Bit Function Value = 0 Value = 1

0 Frequency exceed Not supported Supported

1 Light cont rol rev erse Not supported Supported

2 CPU watchdog status Not supported Supported

3

4 Battery charge Not supported Supported

Operating time limit

warning

Not supported Supported

5 Reference point Not supported Supported

6…11 Reserved Not supported Supported

12

13

14

15

Manufacturer-specific

warning

Manufacturer-specific

warning

Manufacturer-specific

warning

Manufacturer-specific

warning

Not supported Supported

Not supported Supported

Not supported Supported

Not supported Supported

Page 28 Version 1.02

Page 29

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Object 6507h: Profile and Software Version

Description This object indicates the encoder hardware profile versi on and software v ersi on.

Object 6508h: Operating Time

Description This object indicates the encoder operating time. The operating time i s recorded in

the EEPROM memory as long as the encoder is powered up.

This function is not available for this encoder. The delivered value is FFFFFFFFh.

Object 6509h: Offset Value

Description This object indicates the offset value. The offset value is calculated by the Preset

value function (see Object 6003h: Pres et Valu e, p. 83 ). It is then used by the encoder to offset the

position value.

The offset value is recorded and can be read in the encoder.

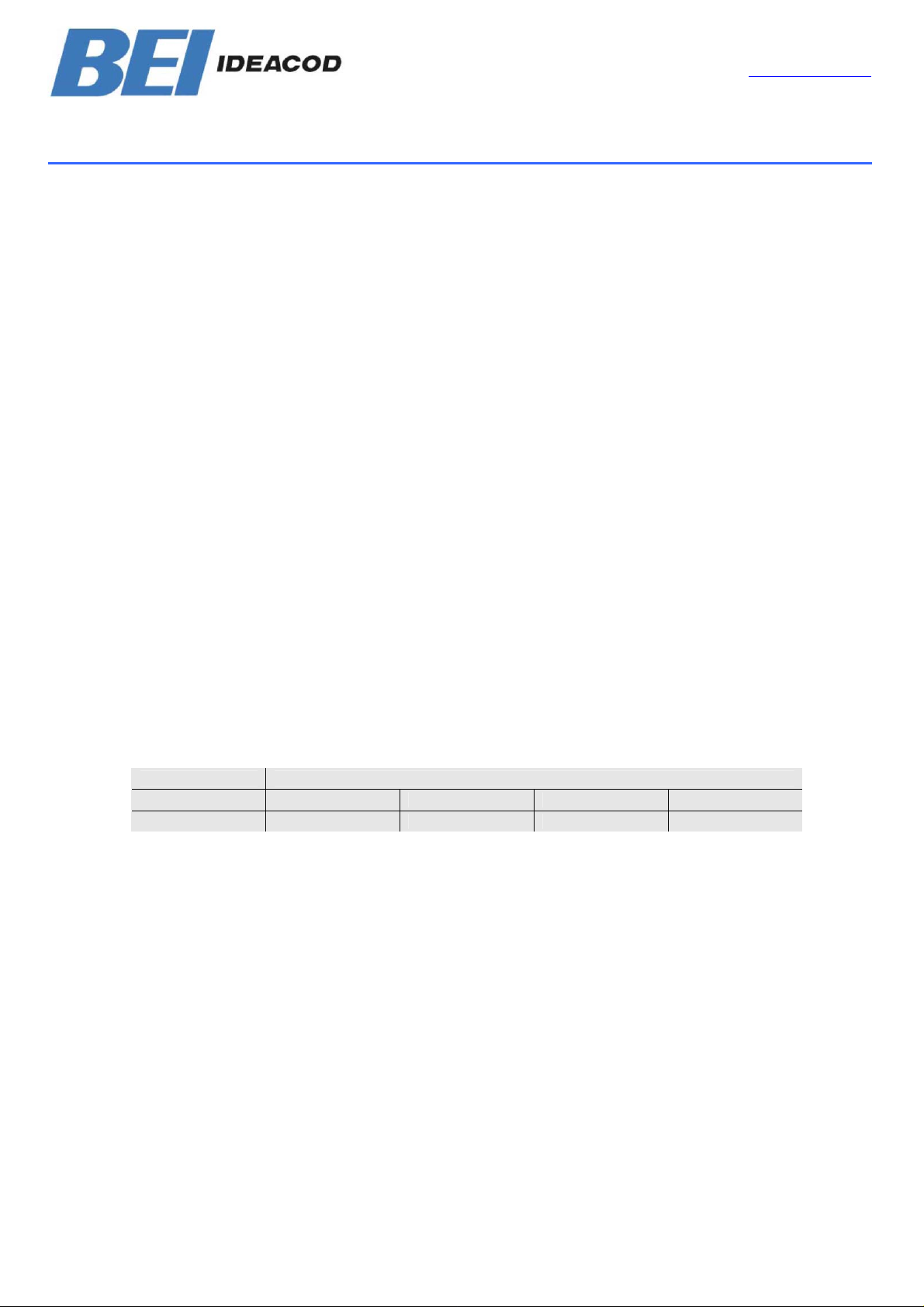

Object 650Ah: Module identification

Description This object indicates the manufacturer-speci fic offset value, as well as the minimum

and maximum position values.

The offset value is stored in sub-index 1.

The minimum and maximum position values are stored in sub-indices 2 and 3 respectively.

Characteristics The characteristics of this object are outlined in the following table:

Sub-Index Dscription Data type Default value Access

0 Number of inputs Unsigned 32 ro

1

2

3

Object 650Bh: Serial Number

Description This object indicates the encoder serial number.

Linked with serial number object 1018-4.

Manufacturer

offset value

Manufacturer

minimum value

Manufacturer

maximum position

value

Unsigned 32 Oh Ro

Unsigned 32 Ro

Unsigned 32 ro

Version 1.02 Page 29

Page 30

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

Encoder Cam1 :

Only for standard encoder : DeviceName (1008h) = « POSI+ »

Only one CAM is available.

Cam1 has parameters for the minimum switch point, the maximum switch point.

The encoder calculates the cam state if the bi t0 of the Object “Cam Enable” channel 1 (Index

6301h Sub Index 01h) is set to 1.

Low limit of CAM1 : Object “Cam1_low_limit_channel_1” (Index 6310h Sub Index 01h)

High limit of CAM1 : Object “Cam1_high_limit_channel_1” (Index 6320h Sub Index 01h)

Polarity of CAM1 : bit0 Index 6302h Sub Index 01h

If the polarity bit is set t o 1 , the c am s ta te of an a cti ve cam shall signal by setti ng the r el ated c am

state bit to zero. In the other case the cam state of the related cam shall not be inverted.

State of CAM1 : Object “Cam_state_channel_1” Index 6300h Sub Index 01h

The status bit set to 1 shall defi ne “cam activ e“. The sta tus bi t set to 0 shal l defi ne “cam i nacti ve“.

If the polarity bit of a cam is set (refer to index 6302h Sub Index01h) the actual cam state will be

inverted.

Cam state

register

(6300h -01h)

Cam state

register

(6300h -01h)

polarity bit is set to 1 ( 6302h -01 )

Nota: The ESD can be downloaded free of charge from our Homepage www.bei-ideacod.com.

We do not assume responsibility for technical inaccuracies or omissi ons. S pecifications are subject

to change without notice.

polarity bit is set to 0 ( 6302h -01 )

Page 30 Version 1.02

Page 31

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

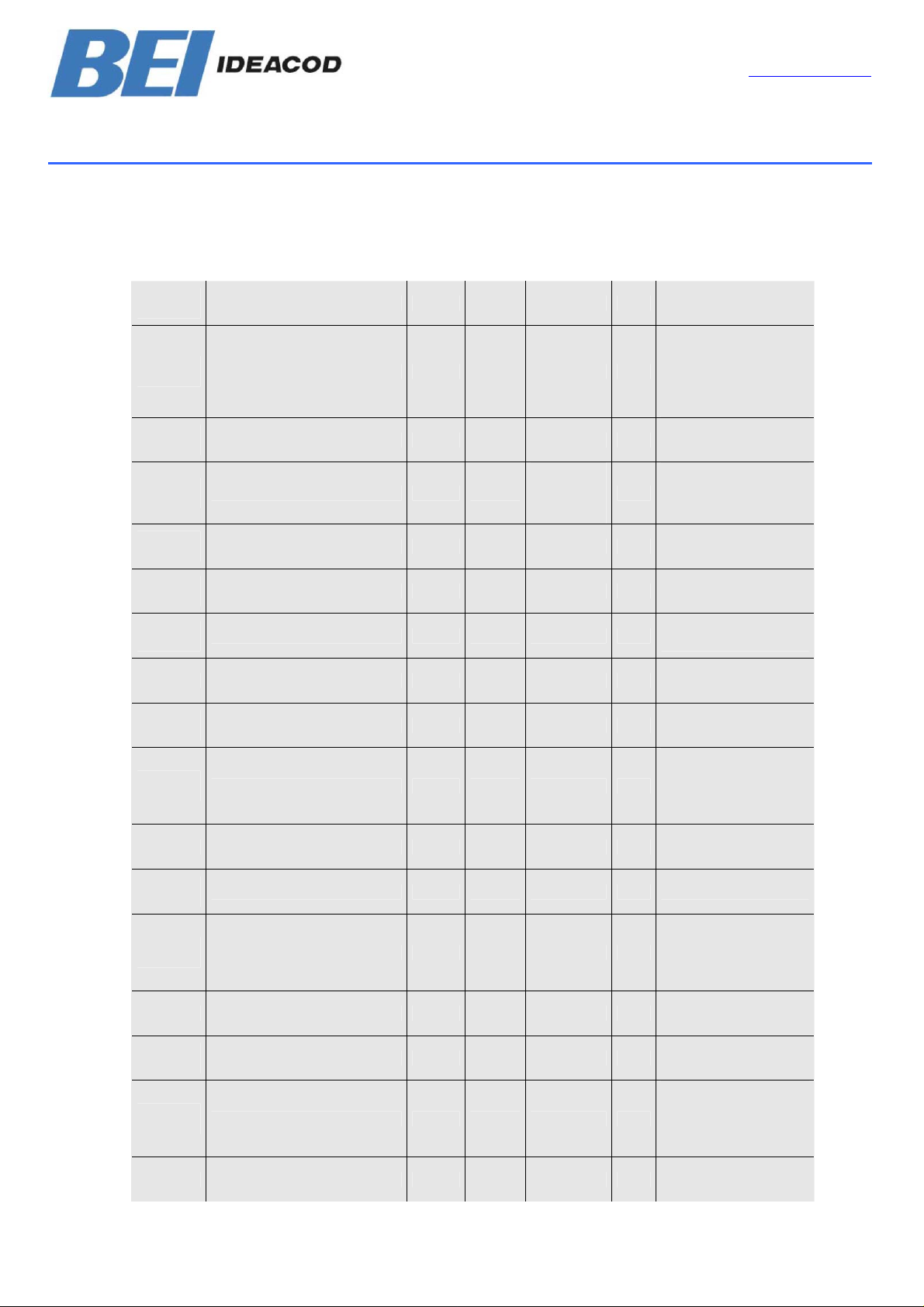

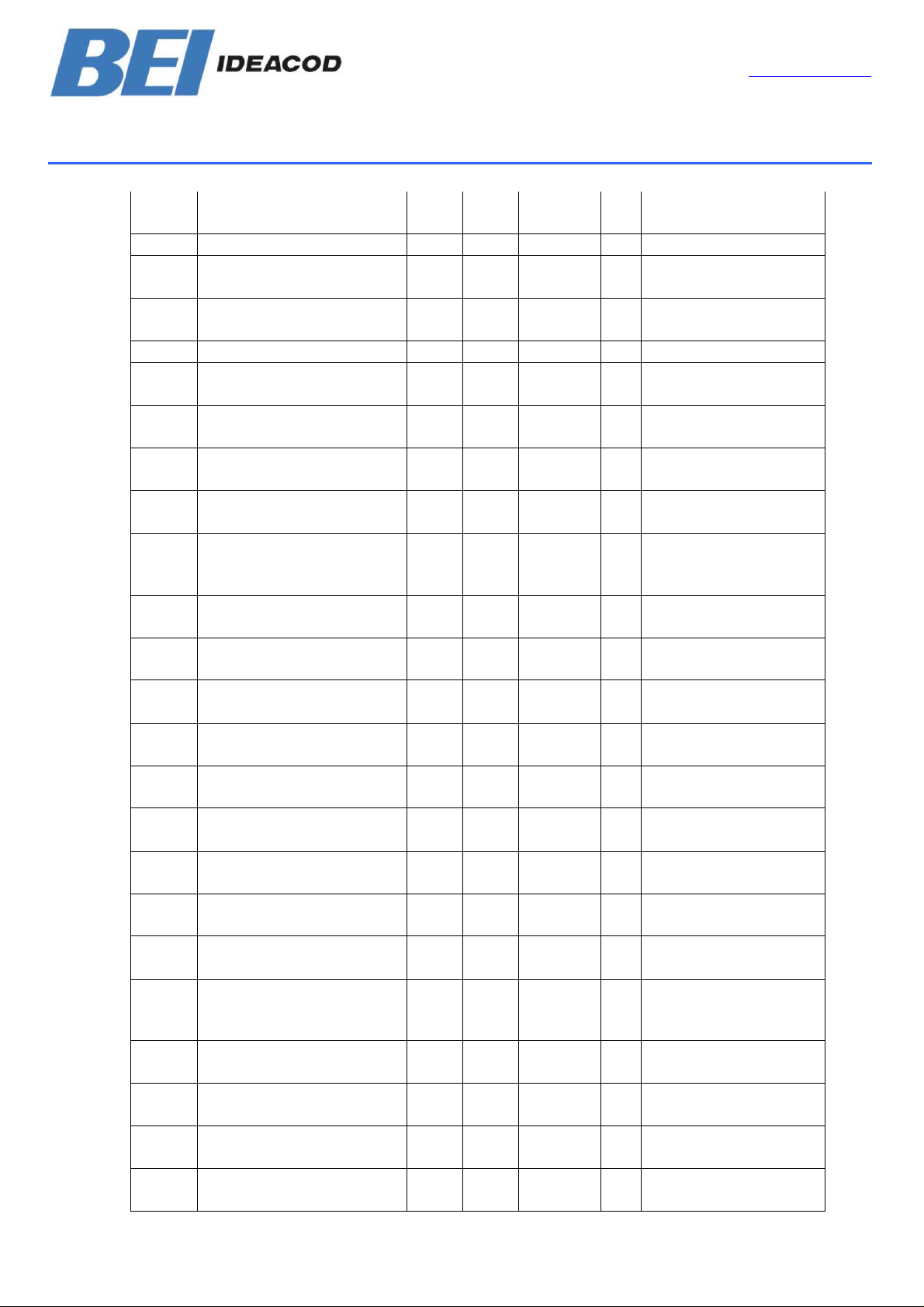

Appendix

Software for the compatibility with with the old encoders SHM5/ S HU9/CHU9/MHM5

Do not use this version for the new designs only to replace old encoders.

EDS File: PHM5SFV102.EDS

Device Name (0x1008) = “POSI+ SF” for this version and the following objects are supported

See the SHM5 / MHM5 Manual for the complete description of these objects.

Object

SubIndex

1000

0

1001

0

1018

1018

0

1018

1

1018

2

1018

3

1018

4

1003

1003

0

1003

1

1004

Name Format Access Default Save Description

multiturn

DeviceType U32 RO

ErrorRegister U8 RO 00h

Identity Object

LargestSupportedSubindex U8 RO 04h

Vendor ID U32 RO 00000184h

Product code U32 RO 354D4850h

Revision number U32 RO 00010000h

Serial number U32 RO xxxxxxxxh

pre-defined error field

Number of actual errors U8 RW 00h

New, actual error U32 RO ########

Number of PDOs supported

00020196h

monoturn

00010196h

1004

0

1004

1

1004

2

1005

0

1008

0

100C

0

100D

0

100F

0

Version 1.02 Page 31

Number of PDOs supported U32 RO 00000002h

Number of synchronous PDOs U32 RO 00000001h

Number of asynchronous PDOs U32 RO 00000001h

COB-ID SYNC Message U32 RW 00000080h Yes

DeviceName STR CONST POSI+ SF

GuardTime U16 RW 0000h Yes

LifeTimeFactor U8 RW 00h Yes

number of SDOs supported U32 RO 00000001h

Page 32

1010

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

POSI+ CANOPEN USER MANUAL

StoreParameters

1010

0

1010

1

1011

1011

0

1011

1

1014

0

1016

1016

0

1016

1

1017

0

1200

1200

0

1200

1

LargestSupportedSubindex U8 RO 01h

SaveAllParameters U32 RW 00000001h

RestoreDefaultParameters

LargestSupportedSubindex U8 RO 01h

RestoreAllDefaultParameters U32 RW 00000001h

COB-ID EMCY U32 RO 00000081h

Consumer Heartbeat Time

Number of entries U8 RO 01h

Consumer Heartbeat Time 1 U32 RW 00000000h Yes

Producer HeartBeat Time U16 RW 0000h Yes

Server SDO Parameter 0

Number of entries U8 RO 02h

COB-ID Client -> Server U32 RO 00000601h

1200

2

1800

1800

0

1800

1

1800

2

1800

3

1800

5

1801

1801

0

1801

1

1801

2

1801

3

COB-ID Server -> Client U32 RO 00000581h

Transmit PDO1 Communication

Parameter

NrOfEntries U8 RO 05h

COB-ID U32 RW 00000181h Yes

TransmissionType U8 RW FEh Yes

InhibitTime U16 RW 0000h Yes

Event Timer U16 RW 0000h Yes

Transmit PDO2 Communication

Parameter

NrOfEntries U8 RO 05h

COB-ID U32 RW 00000281h Yes

TransmissionType U8 RW 01h Yes

InhibitTime U16 RW 0000h Yes

Page 32 Version 1.02

Page 33

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

POSI+ CANOPEN USER MANUAL

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

1801

5

1A00

1A00

0

1A00

1

1A01

1A01

0

1A01

1

6000

0

6001

0

6002

0

6003

0

6004

0

Event Timer U16 RW 0000h Yes

Transmit PDO1 Mapping

NrOfEntries U8 RO 01h

Mapped Object U32 RO 60040020h

Transmit PDO2 Mapping

NrOfEntries U8 RO 01h

Mapped Object U32 RO 60040020h

Operating Parameters U16 RW 0004h Yes

Measuring Units per Revolution U32 RW 00002000h Yes

Multi:

Total Measuring Range U32 RW

Preset Value U32 RW 00000000h Yes

Position Value U32 RO 1FFFFDE6h

20000000h

Mono:

00002000h

Yes

6005

0

6006

0

6100

0

6101

0

6200

0

6500

0

6501

0

6502

0

6503

0

6504

0

6505

0

Limit Switch Min U32 RW 00000000h Yes

Limit Switch Max U32 RW 00000000h Yes

Transmission Rate U16 RW 0002h Yes

Node Number U16 RW 0001h Yes

Cyclic timer U16 RW 0000h Yes

Operating Status U16 RO 0004h

Single Turn Resolution U32 RO 00002000h

Multi

Number of Revolutions U16 RO

Alarms U16 RO 0000h

Supported Alarms U16 RO 0000h

Warnings U16 RO 0000h

FFFFh

Mono

0001h

6506

0

Version 1.02 Page 33

Supported Warnings U16 RO 0000h

Page 34

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

POSI+ CANOPEN USER MANUAL

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@bei-ideacod.com

Web : www.bei-ideacod.com

6507

0

6508

0

6509

0

650A

650A

0

650A

1

650A

2

650B

0

2000

0

2100

0

2101

0

Profile Version U32 RO 01020301h

Operating Time U32 RO FFFFFFFFh

Calculated Offset Value INT32 RO 00000000h

Module Identification

Manufacturer Offset Value INT32 RO 00000000h

Manufacturer Minimum Position

Value

Manufacturer Maximum Position

Value

Serial Number U32 RO 12345678h

Process Value U32 RO 1FFFFDE6h

Operating Parameter U16 RW 0000h Yes

Resolution per Revolution U16 RW 2000h Yes

INT32 RO 00000000h

Multi:

INT32 RO

1FFFFFFFh

Mono:

00001FFFh

2102

0

2103

0

2104

0

2105

0

2200

0

2300

0

3000

0

3001

0

Total Resolution U32 RW 20000000h Yes

Preset Value U32 RW 00000000h Yes

Limit Switch Min U32 RW 00000000h Yes

Limit Switch Max U32 RW 00000000h Yes

Cyclic Time U16 RW 0000h Yes

Save Parameter U32 WO ########

C5 Node number U8 RW 01h Yes

C5 Baud Rate U8 RW 00h Yes

Page 34 Version 1.02

Loading...

Loading...