Page 1

Material

Macromelt OM638

Protection

IP 67

Encoder weight (approx.)

0,150 kg

Shocks (EN60068-2-27)

2000m.s-2 (during 6 ms)

Operating temperature

- 20... + 85 °C (encoder T°)

Vibrations (EN60068-2-6)

200m.s-2 (55 … 2 000 Hz)

Storage temperature

- 20... + 85 °C

BEI Sensors SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@beisensors.com

Web : www.beisensors.com

TCW4

PRELIMINARY - MAGNETIC CANopen ABSOLUTE MULTI TURN MODULAR SENSORS, TCW4 RANGE

With its modular design, the TCW4 CANopen absolute multi-turn sensor offers maximum flexibility

when installing it.

Application fields : agriculture, construction, forestry vehicles, medical, solar panels…

Robustness and excellent resistance to shocks / vibrations.

Standard IP 67 protection (IP69K option).

Operating temperature range: -20°C to 85°C.

Magnetic technology.

Universal supply 5 to 30Vdc – CANopen interface.

Available resolution up to 12 bits per revolution.

Turn counting up to 16 bits.

Also available : analog, PWM and SSI outputs.

Standard cable output with SUBD9 connector.

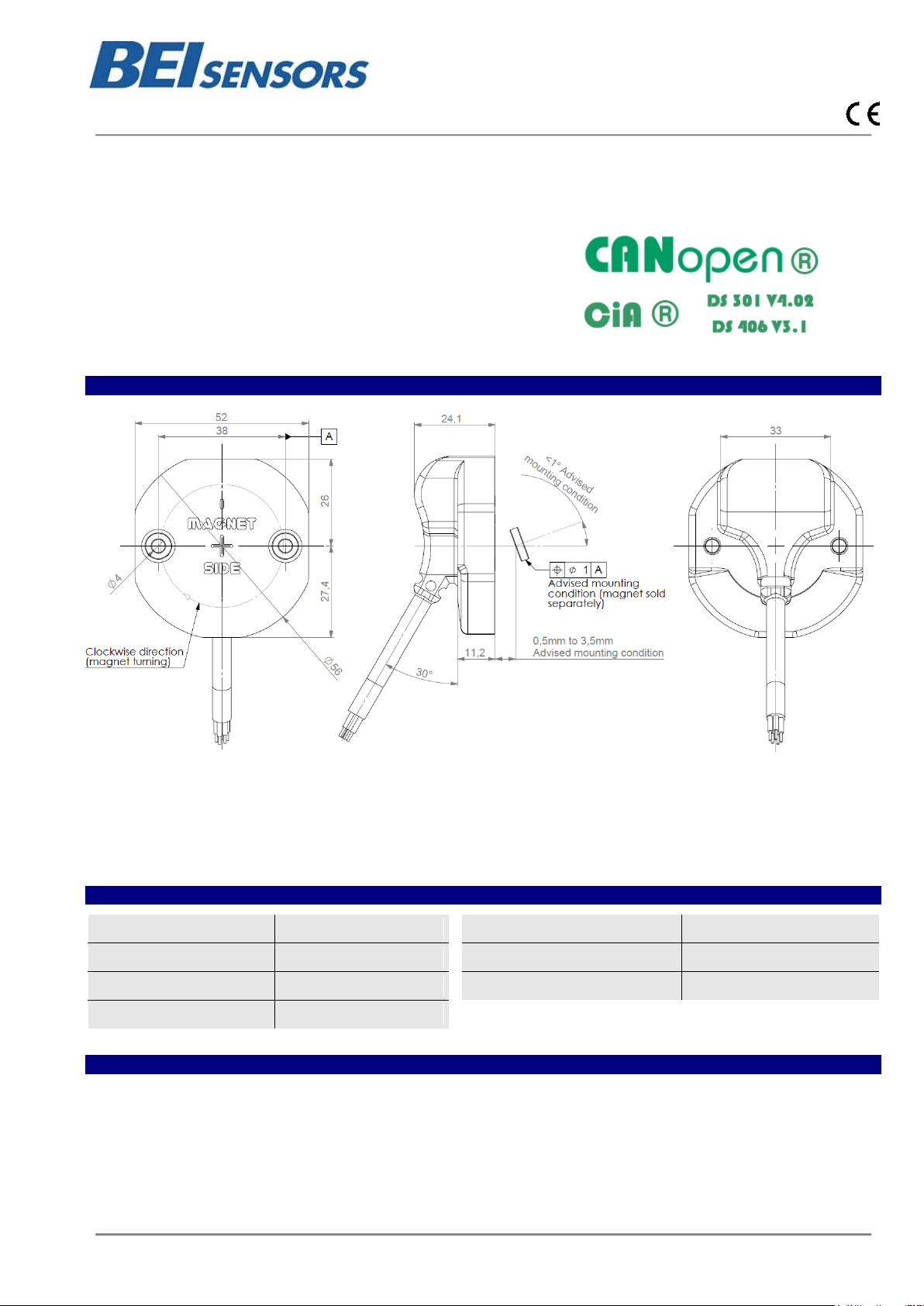

STANDARD TCW4 DIMENSION

Advised mechanical working conditions (for optimal performances) :

- recommanded air gap: 0,5mm to 3mm (between magnet's and sensor's faces),

- recommanded parallelism : +/-1° (between magnet and sensor),

- Misalignment tolerance : +/-0,5mm (between magnet's and sensor's centers).

Shaft system with magnet to be ordered separately (cf specific data-sheet M9105).

MECHANICAL DATA

ADAPTATION POSSIBILTY

BEI Sensors distinguishes itself by its flexible approach and ability to react to customers needs, with us no limit exists; we shall always

try to supply you the product offering the best solution to your specifications.

Modified mechanics: Precision prototypes units, small and medium size. Units that will match themselves exactly to your mechanical

configuration or to your dimensional constraints.

Specific shaft system: for example with integrated coupling.

Send us your subset: we can integrate our encoder into your subset and return you the complete assembly with the guarantee of

an optimal mounting.

Connection / Cable assemblies: On the whole range of our sensors a wide selection of electrical connections are possible.

Changes possible without further notic e 100716

Page 2

Power supply

5-30Vdc

Sampling rate*

1 kHz

Comsumption without load

< 40mA (at 24Vdc)

Accuracy

± 0.3 %

Resolution in the turn

12 bits

Repeatability

± 0.1 %

Nunmber of turns

16 bits max.

Introduction

< 1s

Total resolution

Up to 28 bits

Refresh rate

< 400µs

N.C.

CAN

LOW

CAN

GND /

0V

N.C.

N.C.

0V

CAN

HIGH

N.C.

5/30Vdc

Ground

BB

PVC Cable

+ DB9

1 2 3 4 5 6 7 8 9

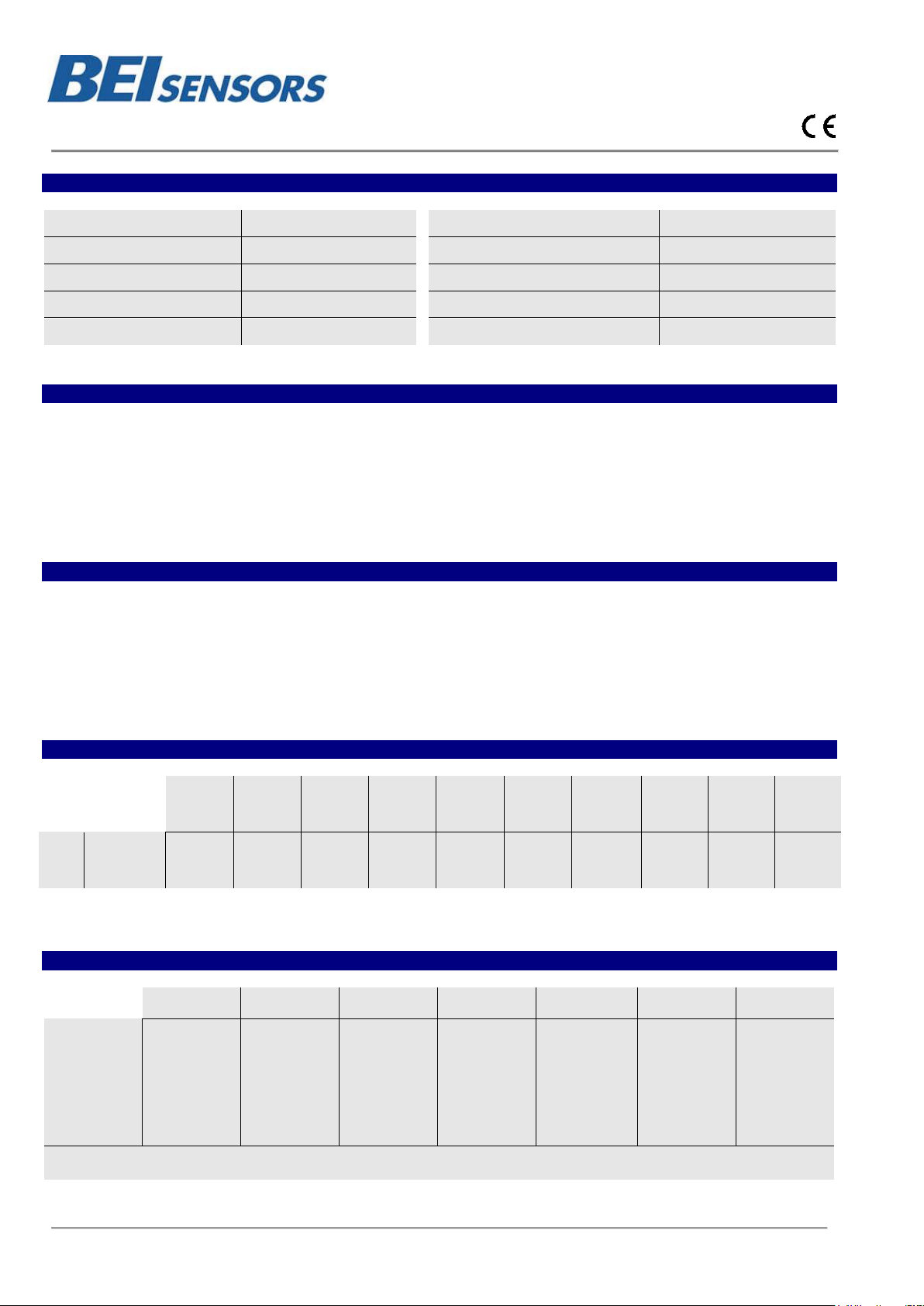

General

shielding

Mechanics

Supply

Output stage

Code

Resolution

Connection

Orientation

TCW4 :

Magnetic

Absolute

multi-turn

encoder

00 :

modular

P :

5 to 30Vdc

BB :

CANopen

B :

Binary

12B16 :

12 x 16 bits

BB :

PVC Cable +

DB9

CANopen

R005 :

Radial

0.5m cable

with SUBD9

Ex: TCW4_

00 //

P

BB

B //

12B16 //

BB

R005

BEI Sensors SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@beisensors.com

Web : www.beisensors.com

TCW4

PRELIMINARY - MAGNETIC CANopen ABSOLUTE MULTI TURN MODULAR SENSORS, TCW4 RANGE

ELECTRICAL DATA

* Nota : Internal data refresh rate

PROGRAMMABLE PARAMETERS

Resolution: defines the resolution per revolution (0 à 4 096).

Transmission speed : programmable from 10kBaud (1 000m) to 1 Mbaud (25 m) ; value per default : 20 Kbaud.

Address : defines the software address of the encoder on the bus (1 à 127, Value per default : id = 1).

Direction : defines the direction of count of the encoder.

RAX : define the value of the current position (stationnary shaft).

Cames : high and low limits.

COMMUNICATION MODES

Encoder configuration : Reading/Writing of the encoder objects dictionnary (SDO mode).

3 modes are available to interrogate the encoder position/speed :

CYCLIC mode : the encoder transmits its position in an asynchronous manner. The frequency of the transmission is defined by the

programmable cyclic timer register from 0 to 65 535 ms,

SYNCHRO mode : the encoder transmits its position on a synchronous demand by the master.

POOLING mode (Answer to a RTR signal) : the encoder only answers to a request.

CANOPEN CONNECTION, CABLE + DB9 CONNECTOR

Nota : Refer to the bus standards for the maximal derivation length.

TCW4 ORDERING REFERENCE (Contact the factory for special versions , ex : dimensions, connections…)

Made in France

Changes possible without further notice 100 716

Loading...

Loading...