Page 1

BEI Sensors SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

PAUX

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@beisensors.com

www.beisensors.com

Web :

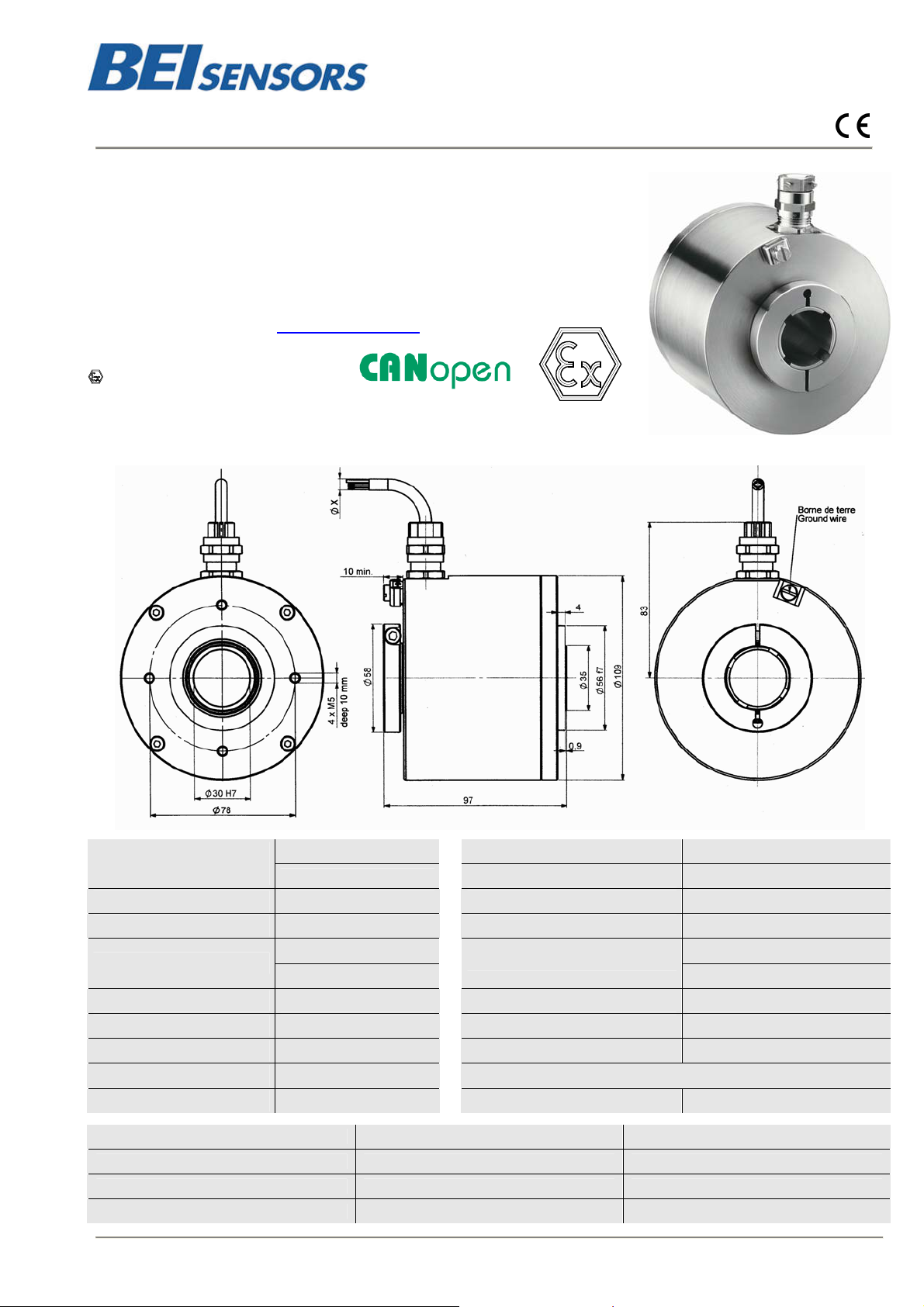

ATEX ABSOLUTE CANopen MULTI TURN ENCODER, PAUX RANGE

ATEX certified Explosion-proof encoders

according to Directive 94/9/CE

Explosion-proof rotary encoders for hazardous environments gas & dust

Robust design for heavy-duty applications

Hollow through shaft up to 30mm

Application fields: explosive atmospheres except for firedamp mines

EC type examination certificate

Download from our website www.beisensors.com

LCIE 03 ATEX 6407

CE0081

II 2 G/D

Ex d IIC T6, T5 or T4

Ex tD A21 IP6X T80°C T95°C T100°C

PAUX_30 connection B2R (radial cable)

DS 301 V4.02

DS 406 V3.1

Material

Stainless steel option

Cover: aluminium

Body: aluminium

Shaft Stainless steel

Bearings 6807 serie

Maximal load

Axial : 50 N

Radial : 80 N

Shaft Inertia 50.10-6 kg.m2

Torque 25.10-3 N.m

Permissible max. speed 4 500 min-1

Continuous max speed 3 000 min-1

Shaft seal Viton

T

Temperature class for gas atmosphere Temperature class for dust atmosphere

amb

-20°C ≤ Ta ≤ +40°C T6 T80°C

-20°C ≤ Ta ≤ +55°C T5 T95°C

-20°C ≤ Ta ≤ +60°C T4 T100°C

Shock (EN60068-2-27) 500 m.s-2 (during 6 ms)

Vibration (EN60068-2-6) 100 m.s

EMC EN 61000-6-4, EN 61000-6-2

Isolation 500 V (1 min.)

Weight

Operating temperature - 20... + 80 °C

Storage temperature - 20... + 80 °C

Protection(EN 60529) IP 65

Changes possible without further notice - Version 100105

Theoretical mechanical lifetime 109 turns (F

25 N / 40 N : 140 50 N / 80 N : 17

-2

(10 ... 2000 Hz)

2kg aluminium version

5kg satinless steel version

/ F

axial

radial

)

Page 2

PAUX

BEI Sensors SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@beisensors.com

www.beisensors.com

Web :

ATEX ABSOLUTE CANopen MULTI TURN ENCODER, PAUX RANGE

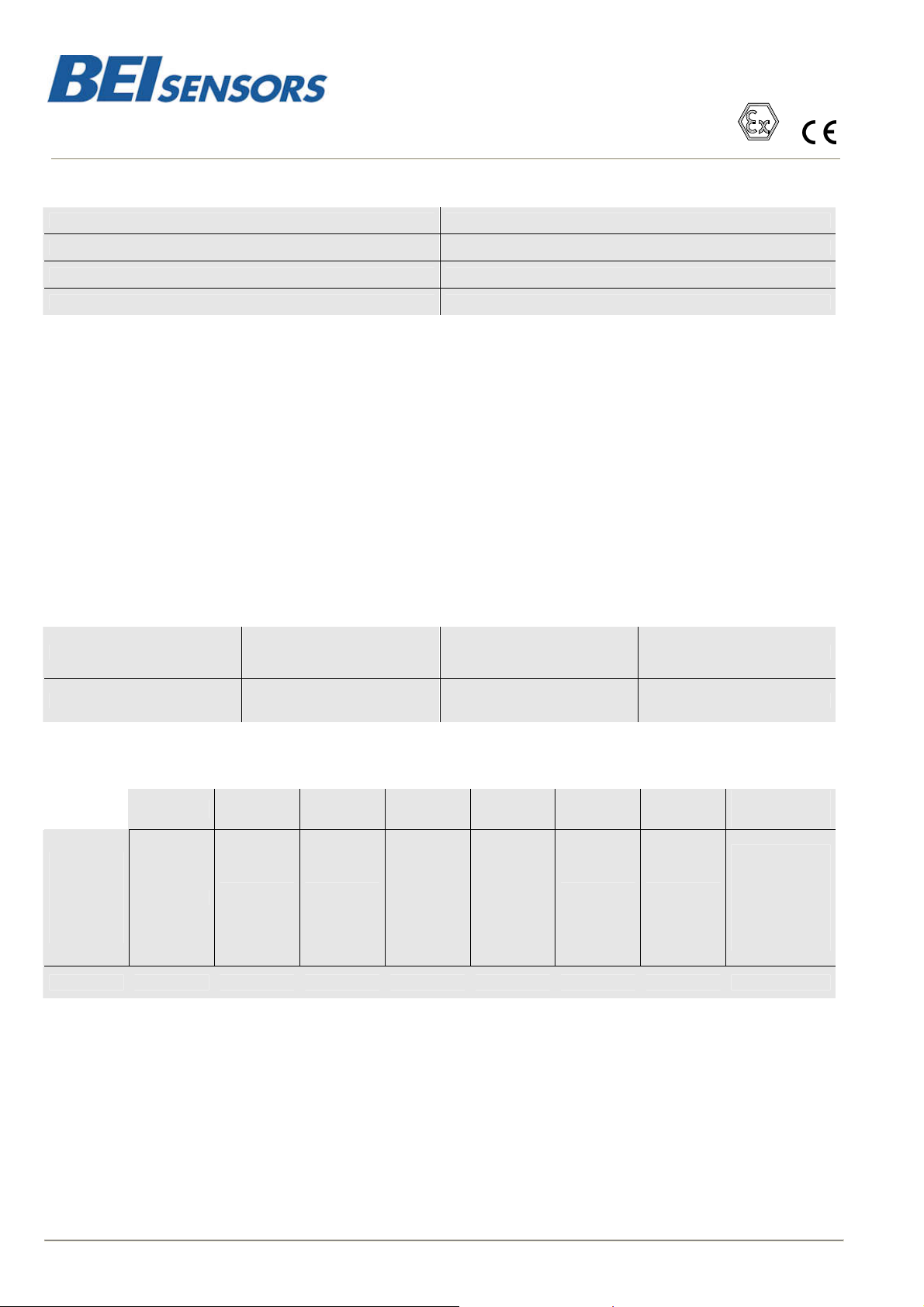

ELECTRICAL CHARACTERISTICS

Power supply 5 – 30Vdc

Introduction < 1 s

Consumption (without load) < 50mA (at 24Vdc)

Accuracy ± ½ LSB (13 bits)

Programmable parameters

Resolution: defines the resolution per revolution (0 to 8 192),

Global resolution : total amount of codes for the encoder (2

to 536 870 912),

Transmission speed : programmable from 10kBaud (1000m)

to 1 Mbaud (40 m) ; value per default: 20 Kbaud,

Address: define the software address of the encoder on the

bus (1 to 127, value by default: id = 1),

Direction : define the direction of count of the encoder ,

RAX : defines the value of its preset position (non turning

shaft),

CAM: Low and High Limits.

CANopen CONNECTION

Communication modes

3 modes are available to interrogate the encoder :

POLLING mode: (Response to a RTR message): The position

value is only given upon request (SDO mode),

CYCLIC mode: the encoder transmits its position in an

asynchronous manner. The frequency of the transmission is

defined by the programmable cyclical timer register from 0

to 65 535 ms,

SYNCHRO mode: the encoder transmits its position on a

synchronous demand by the master.

Blue Black White Red

CAN LOW 0V CAN HIGH 11/30Vdc

Nota : Refer to the bus standards for the maximal derivation length.

ORDERING REFERENCE

Shaft

Power

supply

PEUX

(stainless

steel)

30:30mm

P : 5 to

30Vdc

PAUX

(aluminium)

PEUX _ 30 // P BB B //

Output

stages

BB :

CANopen

Code Resolution Nb of turns Connection

B: Binary

13 : 8192

points per

turn (2

13 B16 //

13

)

B16 : 65 536

16

turns (2

)

B2: PUR

cable

B2 R050

Connection

orientation

Example :

R020 : 2m radial

cable

R050 : 5m radial

cable

ASSEMBLY CAUTION

NEVER OPEN THE ENCODER

NEVER CONNECT/DISCONNECT UNDER POWER SUPPLY/IN PRESENCE OF DUSTS ATMOSPHERE

The customer obliges to take up and to use our products, according to our specifications and to the manners of the profession. Our

company would not be responsible for any defect resulting from a defective or erroneous assembly. From a use superior to the

standard, or in abnormal conditions. The breakdowns resultant of shocks, bad electric supply, put in low capacity or overcapacity

of the product, the environment of bad conditions (humidity, projection, dust, etc) cannot be imputed to us. The converter doesn’t

require any maintenance. Any encoder presenting a dysfunction will have to be the object of immediate return for control in our

facilities. The encoder mustn’t be open in any case (cable gland and/or cover).

An earth situated on the cover must be linked with the ground of the installation.

Made in FRANCE

Changes possible without further notice - Version 100105

Page 3

PAUX PAUX

BEI Sensors SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél : +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail : info@beisensors.com

www.beisensors.com

Web :

ATEX ABSOLUTE CANopen MULTI TURN ENCODER, PAUX RANGE ATEX ABSOLUTE CANopen MULTI TURN ENCODER, PAUX RANGE

1) Déclaration de conformité CE

2) Nous, société BEI Sensors, certifions que ce matériel :

capteurs antidéflagrants, type

GAUX, CAUX, PAUX, GEUX, CEUX, PEUX

3) Avec les inscriptions suivantes :

1) Declaration of conformity EC

2) We, BEI Sensors, certify that this material : sensor

explosion-proof standard

GAUX, CAUX, PAUX, GEUX, CEUX, PEUX

3) With the following inscriptions :

CE 0081 II 2 G/D, Ex d II C T6, T5 ou T4

Ex tD A21 IP6X T80°C T95°C T100°C

A été conçu et fabriqué conformément à la directive

applicable suivante :

ATEX directive 94/9/CE

Directive CEM 89/336/CEE

4) La certification a été obtenu grâce à l’application

des normes suivantes :

EN 60079-0 (2006), EN 60079-1 (2004), EN 61241-0 (2004)

et EN 61241-1 (2004)

5) Une attestation d’examen CE de type a été obtenu :

LCIE 03 ATEX 6407

et une notification :

LCIE 03 ATEX Q8060

6) L’application des normes suivantes a participé à

l’obtention de la certification :

EN 60-529, NFC 23-520, NFC 23-539, EN 50081-1, EN 55022

classe B, EN 55014, EN 61000-6-2, CEI 61000-4-2, CEI

61000-4-3, CEI61000-4-4, CEI 61000-4-5, CEI 61000-4-6, CEI

61000-4-8, CEI 61000-4-11

7) L’organisme notifié responsable du suivi de la

directive ATEX est le

LCIE,B.P.8, F92260 Fontenay-aux-Roses

Numéro d’identification : 0081

8) La société chargée de la certification CEM est

nommée ci-après :

GRME, Cellule CEM, B.P.8, 68840 Pulversheim

9) Nous certifions que nos produits désignés ci-dessus

sont conformes à la directive et aux normes spécifiées

CE 0081 II 2 G/D, Ex d II C T6, T5 or T4

Ex tD A21 IP6X T80°C T95°C T100°C

Conceived and manufactured has the directive

applicable following :

ATEX directive 94/9/CE

Directive CEM 89/336/CEE

4) Certification to summer obtained thanks to the

application of the standards :

EN 60079-0 (2006), EN 60079-1 (2004), EN 61241-0 (2004)

and EN 61241-1 (2004)

5) EC type examination certificate was obtained :

LCIE 03 ATEX 6407

and a notification :

LCIE 03 ATEX Q8060

6) The application of the following standards took part in

obtaining certication :

EN 60-529, NFC 23-520, NFC 23-539, EN 50081-1, EN 55022

classe B, EN 55014, EN 61000-6-2, CEI 61000-4-2, CEI

61000-4-3, CEI61000-4-4, CEI 61000-4-5, CEI 61000-4-6, CEI

61000-4-8, CEI 61000-4-11

7) The notified organization responsible for the follow-up

of the directive ATEX is the

LCIE,B.P.8, F92260 Fontenay-aux-Roses

Identification number : 0081

8) The company in charge of certification CEM is

named :

GRME, Cellule CEM, B.P.8, 68840 Pulversheim

9) We certify that our indicated products so above are in

conformity with the directive and the specified standards

Date : ATEX Certified Product Approved Person

Changes possible without further notice - Version 100105

Loading...

Loading...