Page 1

HS20 Incremental Optical Encoder

Model HS20 is a

compact, rugged

hollow-shaft encoder

designed with harsh

environments in mind.

This optical encoder

can be used where

lighter duty encoders

are not suitable or cost

effective. The compact

design makes it easy

to incorporate into tight

installations and is

well-sealed to stand up to dust, dirt, and splashing liquids.

Other features include dual preloaded bearings for longevity and stability, differential line driver outputs for noise immunity and a standard, Euro-style 8-pin

(M12 x1) sealed connector for easy connectivity. A specially designed, nonmarring shaft clamp allows for easy installation and eliminates shaft damage

should you need to reinstall or reposition the encoder on the shaft. Model HS20

is ideal for small motor applications and a number of harsh applications including

off-highway agriculture and construction equipment.

Special Models of the HS20 Incremental Encoder are available with one or more of the

following certifications. Consult factory for details.

EN 55011

and EN 61000-6-2

UL 12.0035X

UL 12.0082X

U.S. Standards Class I, Group A,B,C & D;

Class II Group E, F & G

Canadian Standards

C

Class I, Zone 0, Group IIC

Mechanical Specifications

Shaft Bore: 5/8”, 1/2”, 1/4”, metric available

Allowable Misalignment: 0.005 TIR, 0.010

Axial using R2 Tether

Bore Runout: 0.001 TIR

Starting Torque at 25°C: 3.5 in-oz (max)

Bearings: 52100 dual preloaded bearings

Shaft Material: Aluminum

Bearing Housing:

Aluminum with protective finish Cover: Aluminum with protective finish

Bearing Life: 7.5 X 10

Maximum RPM: 6000 (see frequency response)

Moment of Inertia: 3.4 X 10

Weight: 8 ounces, maximum

9

revs

-4

oz-in-sec

2

Electrical Specifications

Code: Incremental output format; 2 channels in quadrature,

with complements; 1/2 cycle index gated with negative B channel

Cycles Per Shaft Turn: 2 through 1024

Supply Voltage: 5–28 VDC ± 5%

Current Requirements: 100mA typical + output load, 250mA (max)

Voltage/Output:

28V/V: Line Driver, 5–28 VDC in, V

28V/5: Line Driver, 5–28 VDC in, V

28V/OC: Open Collector, 5–28 VDC in, OC

(

Higher frequency response may be available.

Please consult with the factory.

Protection Level: Overvoltage, reverse voltage.

Outputs short-circuit protected (1 minute max)

Frequency Response: 100kHz

Output Termination Pinouts: see Table 1, back page

(see note 5)

)

= Vin

out

= 5 VDC

out

out

(see note 5)

Environmental Specifications

Enclosure Rating: IP64

Temperature: 0–70° Standard

Shock: 50 g’s for 11 msec duration

Vibration: 5– 2000 Hz @ 20 g’s

Humidity: 98% RH non-condensing

CENELEC

II 1 G Ex ia IIB/IIC T4

II 3 G Ex nA IIB T3 Gc

II 3 G Ex nA IIB T4 Gc

Class I, Div 2, Group A,B,C & D;

Class II, Div 2, Group F & G

NOTES AND TABLES: All notes and tables referred to in the text

can be found on the back page.

HS20 Incremental Ordering Options FOR ASSISTANCE CALL 800-350-2727

Use this diagram, working from left to right to construct your model number (example: HS20-50-R2-SS-1024-ABZC-28V/V-K8).

HS20

TYPE:

Hollow Shaft,

2.0” Diameter

These commodities, technology or software if exported from the United States must be in accordance with the Bureau of Industry, and Security, Export Administration regulations. Diversion contrary to U.S law is prohibited.

BORE SIZE

62 = .625”

37 = .375”

50 = .500”

25 = .250”

TETHER:

R2 = Tetherarm

R3 = Flexmount

SHAFT SEAL:

SS =Through Shaft

Rubber Seals

BS = Blind Shaft Rubber Seal

FS = Through Shaft Felt Seals

BFS = Blind Shaft Felt Seal

See Note 2

Tel: 805-968-0782 /800-350-2727 | Fax: 805-968-3154 / 800-960-2726

7230 Hollister Ave., Goleta, CA 93117-2807 | www.beisensors.com

CYCLES PER TURN:

2 to 1024, See table 2,

back page

CHANNELS:

ABZC

VOLTAGE/OUTPUT:

28V/V = 5–28V

28V/5 = 5–28V

28V/OC = 5–28V

in/out

in/5Vout

Connector:

K8 = M12 X 1, 8 Pin (Euro style)

CS18 = 18” pigtail with cable gland

in/OCout

HAZARDOUS

AREA RATINGS:

Blank = None

EX = Intrinsically Safe

NI = Non-Incendive

Contact factory for

voltage options

Specification No. 02082-001 Rev. 08-13

SPECIAL

FEATURES:

S = Special

features specified

on purchase order.

(Consult factory)

See note 6

Page 2

HS20 Incremental Optical Encoder

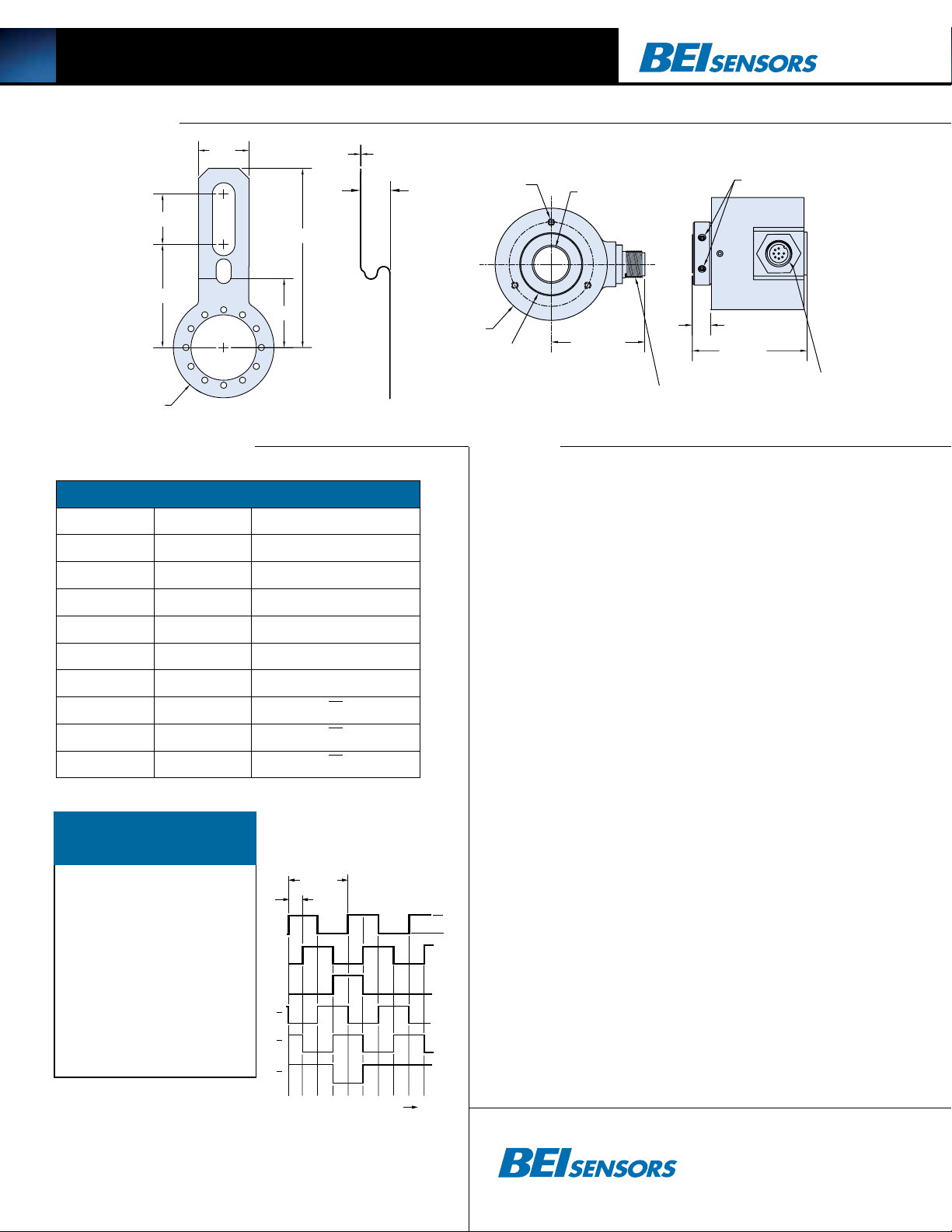

2.05±0.03

0.33

Ø 2.00

1.67 MAX

M12X1 CONN.

(2) #6 SET SCREW

NOTE: CONN. KEY

POSITION VARIES

HS20 Outline

Ø(BORE +0.0005)

+0.001/-0.000 THRU

0.60

0.02

3X #4-40 UNC-2B

X .25 DP. MIN

EQL SP ON

A Ø1.50 BC

2.05±0.03

0.33

Ø 2.00

1.67 MAX

M12X1 CONN.

(2) #6 SET SCREW

NOTE: CONN. KEY

POSITION VARIES

HS20 Outline

Ø(BORE +0.0005)

+0.001/-0.000 THRU

3X #4-40 UNC-2B

X .25 DP. MIN

EQL SP ON

A Ø1.50 BC

2.05±0.03

0.33

(2) #6 SET SCREW

NOTE: CONN. KEY

LO

Dimensions

R2 Tether Arm

1.00

2.05±0.03

1.00

3.56±0.03

1.37

0.60

0.02

HS20 Diagram

3X #4-40 UNC-2B

X .25 DP. MIN

EQL SP ON

A Ø1.50 BC

Ø 2.00

Ø 1.13

Ø(BORE +0.0005)

+0.001/-0.000 THRU

1.67 MAX

(2) #6 SET SCREW

0.33

2.05±0.03

Ø 2.00

Tables and Figures Notes

1. The typical hollow shaft product is supported by, and clamped to, the driving shaft. A flexible tether is used to

Table 1-Output Termination Pinouts

Pin (K8) Wire Function

1 YEL A

4 BLU B

6 ORN Z

2 RED +V (SUPPLY)

7 BLK OV (CIRCUIT COMMON)

N/C GRN CASE GROUND

3 W/YEL A

5 W/BLU B

8 W/ORN Z

Table 2–HS20

Disc Resolutions

1* 2 3 5 6 8 10 11

12 24 25 30 32 40

50 60 64 75 80 95

100 105 115 120 125

150 192 200 240 250

256 300 336 360 400

500 510 512 600 625

635 720 785 1000 1024

1200**

Resolutions Shown in RED are not available as

Express Encoders

*No index. For interpolation please specify the

multiplied output (up to 4,096 for HS20) in the

model number, i.e. 4,096-T4.

**Consult factory for this resolution

Figure 1

Output Waveform

A

B

Z

A

B

Z

CCW Rotation Viewing Face

1 CYCLE

90 Deg.

HI

keep the housing from rotating.

2. The rubber shaft seal is recommended in virtually all installations. The most common exceptions are

applications requiring a very low starting torque or those requiring operation at both high temperature and

high speed. For these exceptions, a felt shaft seal is recommended. Felt seals require very low starting torque and can virtually eliminate frictional heat. Encoders ordered with felt shaft seals will have an

enclosure rating of IP50 and will have less than 1/10th the Starting Torque specified under Mechanical

Configurations.

3. Non-standard index widths and multiple indices are available by special order. Consult factory.

4. Complementary outputs are recommended for use with line driver type (source/sink) outputs. When used

with differential receivers, this combination provides a high degree of noise immunity.

5. Output IC’s: Output IC’s are available as either Line Driver (LD) or NPN Open Collector (OC) types.

Open Collectors require pull-up resistors, resulting in higher output source impedance (sink impedance is

similar to that of line drivers). In general, use of a Line Driver style output is recommended. Line Drivers

source or sink current and their lower impedance mean better noise immunity and faster switching times.

Warning: Do not connect any line driver outputs directly to circuit common/OV, which may damage the

driver. Unused outputs should be isolated and left floating. Our applications specialists would be pleased

to discuss your system requirements and the compatibility of your receiving electronics with Line Driver

type outputs.

28V/V: Multi-voltage Line Driver (7272*): 100 mA source/sink. Input voltage 5 to 28 VDC +/- 5% standard

(Note: V

against overvoltage to 60 volts and reverse voltage. Outputs are short circuit protected for one minute.

Supply current is 120 mA typical (plus load current). This is the recommended replacement for 3904R and

7406R open collector outputs with internal pullup resistors. It is also a direct replacement for any 4469,

88C30, 8830 or 26LS31 line driver

28V/5: Multi-voltage Line Driver (7272*): 100 mA source/sink. Input voltage 5 to 28 VDC +/- 5% standard, internally regulated with 5V (TTL compatible) logic out. Supply lines are protected against overvoltage

to 60 volts and reverse voltage. Outputs are short circuit protected for one minute. Supply current is 90

mA typical (plus load current).

28V/OC: NPN Open Collector (3904*, 7273*). Current sink of 80 mA max. Current sourced by external

pull- up resistor. Output can be pulled up to voltage other than supply voltage (30 V max). Input voltage 5

to 28 VDC

3904, 7406, 3302, 681 and 689.

5V/OCR, 15V/OCR, 24V/OCR: Open Collector (3904R*, 7406R*, 7273R*): Current sink of 70 mA

max. Includes internal pull-ups sized at approximately 100 ohms/volt. Max current source is 10 mA.

Supply current is 100 mA typical, 120 mA with internal pull-ups. The 5V/OCR, 15V/OCR and 24V/OCR

are often replaced by the 28V/V in system upgrades.

5V/V. 5V/OC, 5V/OCR and 9V/OC can be intrinsically safe line driver and open collector outputs available on certain model variations. They are intrinsically safe only when installed per the controldrawing

noted on the certification label affixed to the encoder body.

6. Special –S at the end of the model number is used to define a variety of non-standard features such as

special shaft lengths, voltage options, or special testing. Please consult the factory to discuss your special

requirements.

7. Higher frequency response may be available. Please consult with the factory.

8. Extended temperature ratings are available in the following ranges:

-40 to 70°C, -40 to 85°C, –20 to 105°C and –40 to 105°C depending on the particular model. Some

models can operate down to

-55°C. Extended temperature ranges can affect other performance factors. Consult with factory for more

specific information.

9. Mating plug receptacles and mating cable assemblies may be ordered from the factory.

M12X1 CONN.

= Vin). This driver is TTL compatible when used with 5 volt supply. Supply lines are protected

out

+

/- 5% standard. Supply current is 120 mA typical. This replaces prior IC’s with designations of

Tel: 805-968-0782 /800-350-2727

Fax: 805-968-3154 / 800-960-2726

7230 Hollister Ave., Goleta, CA 93117-2807

NOTE: CONN. KEY

POSITION VARIES

www.beisensors.com

Loading...

Loading...