Page 1

INCLINOMETER

RS232 – CURRENT

Main Features

- Two axis digital inclinometer

- Angle measurement range of +/-5°, +/-15°

and +/-30°, Resolution up to 0.001°

- Interface: RS232, Code: ASCII,

Current 4 to 20mA

- Housing: 70 mm

Programmable Parameters

- Transmission mode:

Polled Mode, Cyclic Mode

- Cycle Time

- Setting of zero point

- Baudrate 2.4 to 56 KBaud

Applications

- Structural engineering

- Leveling techniques

- Measuring techniques

- Inclinations

- Mechanical Structure

Electrical Features

- Linear and temperature compensated

characteristic line

- Microprocessor controlled

- Polarity inversion protection

- Over-voltage-peak protection

- Highly integrated circuit in

SMD-technology

Page 2

INCLINOMETER

RS232 – CURRENT

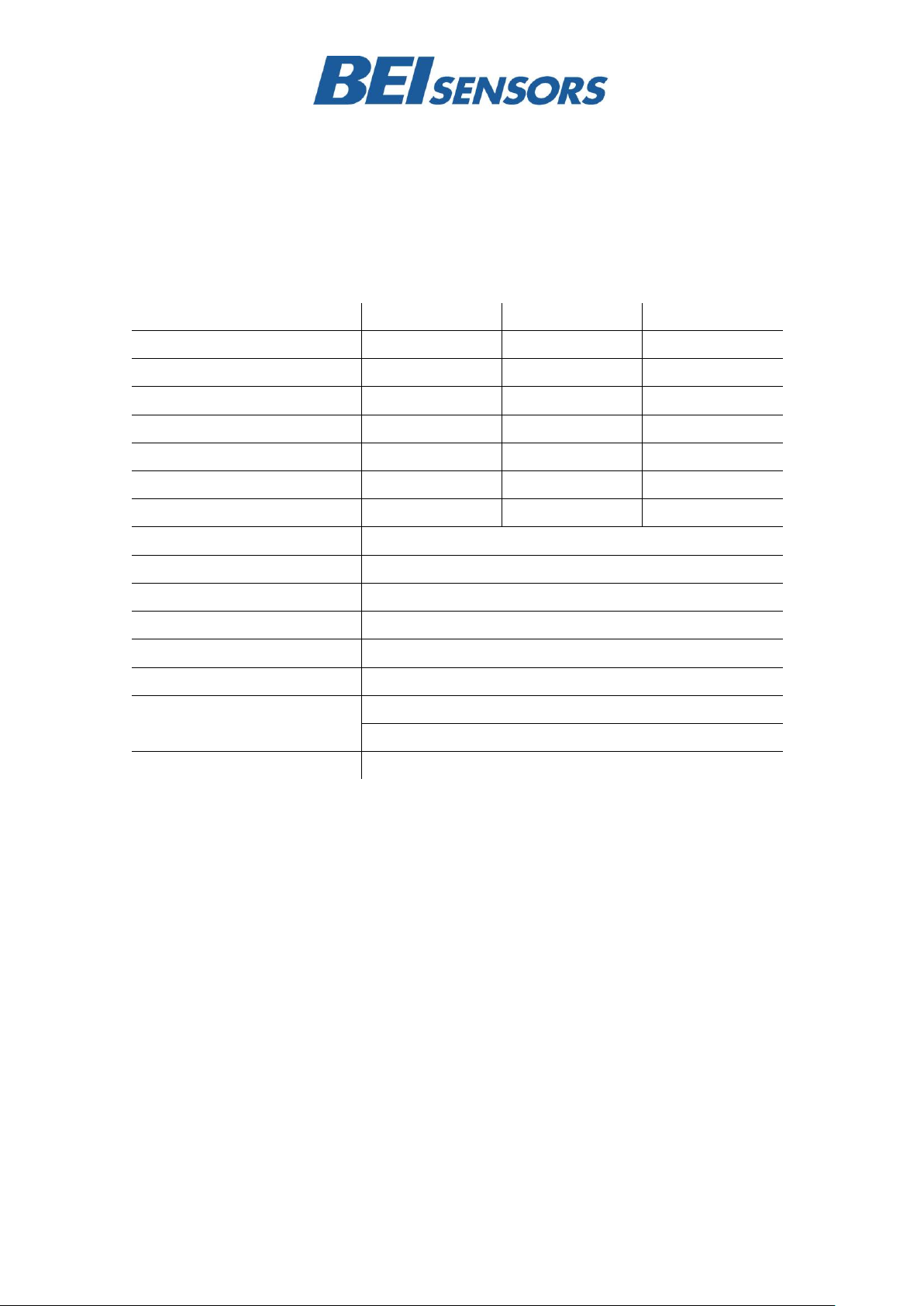

Model

INC 5

INC 15

INC 30

Measuring range

+/- 5°

+/- 15°

+/- 30°

Resolution digital

0.001°

0.001°

0.01°

Resolution analog

0,001°

0,005°

0,01°

Accuracy Digital1)

+/-0,01°

+/-0,01°

+/-0,02°

Accuracy Analog1)

+/-0,05°

+/-0,05°

+/-0,05°

Temperture Gradient2)

+0.001°/K

+0.002°/K

+0.003°/K

Inclination angle in x and y1)

+/-15°

+/-40°

+/-60°

Damping period 5° > 0°

Typical 1 s 10 %, 2 s 1 %, 3 s 0.1 %

Digital interface

RS232 format ASCII

Baud rate

Max. 56 k

Analog interface

4 to 20mA, 0°= 12mA, Load 300 Ohm

Supply voltage4)

10 to 30 V DC (absolute limits)

Current consumption

Typical 50 mA

EMC

Emitted interference: EN 61000-6-3

Noise immunity: EN 61000-6-2

Electrical lifetime

> 105 h

1 Technical Data

1.1 Electrical Data

1) T = +25°C, 90% total measurement range

2) e.g. temperature drift AGS005 (T= 0°C up to +55°C) = 55K * 0,001°/K = 0,055°

3) Supply voltage is applied.

4) Inclinometers should be connected only to subsequent electronics whose power supplies comply with EN 50178 (protective low

voltage)

Page 2 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 3

INCLINOMETER

RS232 – CURRENT

Housing

Aluminum

Lifetime

> 105 h

Shock

A=30g ; t= 11 ms, halfsine ; EN 60068-2-27

Vibration

10 to 150 Hz, 2,5 mm amplitude, 5 g const. Acceleration,

1 Octave /Minute ; EN 60068-2-6

Weight (standard version)

350 g

Operating/ Storage temperature

-40 to +85°C

Humidity

98 % (without liquid state)

Protection class

IP 67 (connected); EN 60529

1.2 Mechanical Data

1.3 Environmental Conditions

Page 3 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 4

INCLINOMETER

RS232 – CURRENT

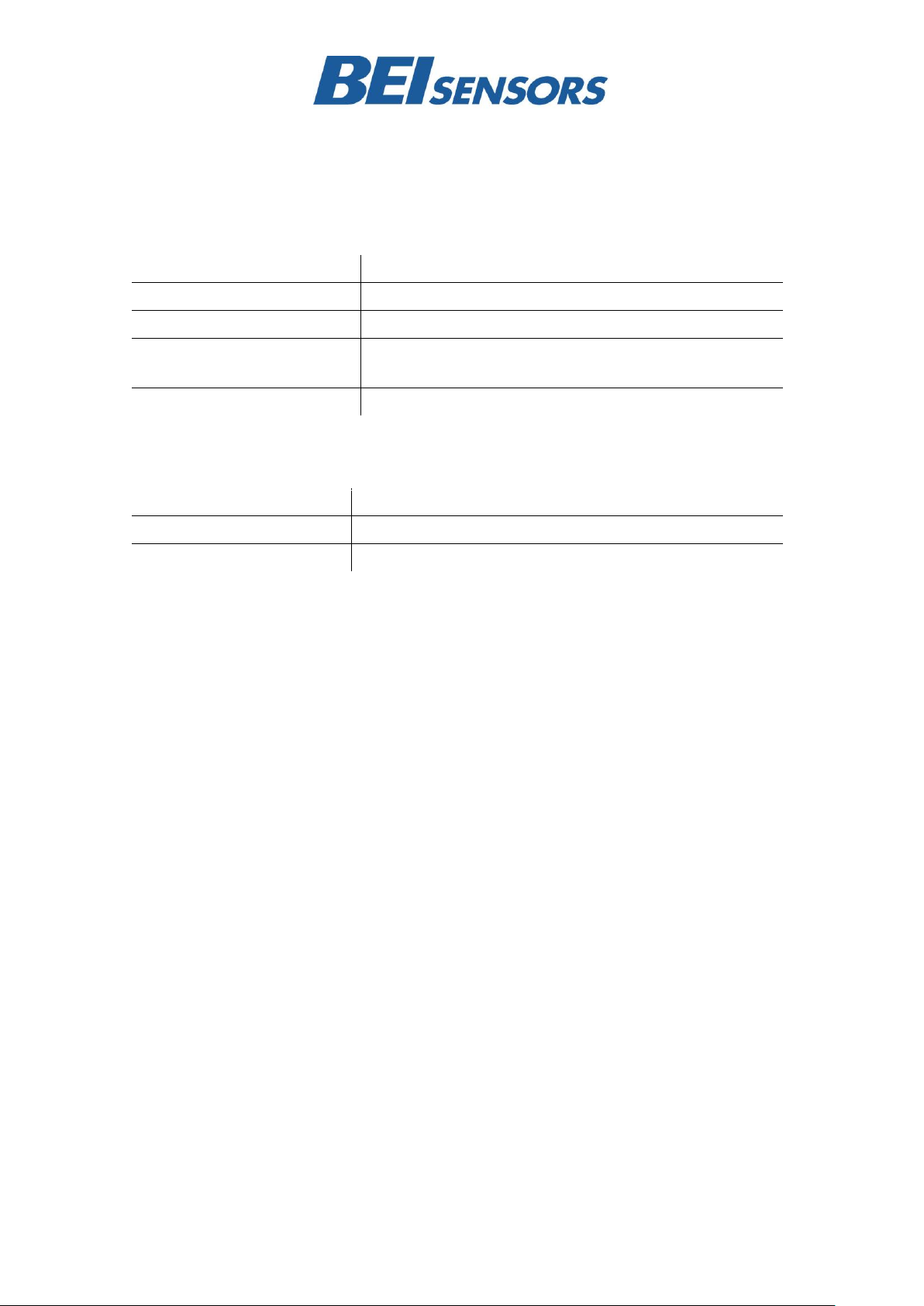

Pin

Description

P8F-Cable

CRW-Cable

1

+UB Supply voltage

white

white

2

RxD

brown

brown

3

TxD

green

green

4

Ground (Supply)

yellow

yellow

5

X-Output

grey

grey

6

S-Ground

pink

pink 7 Y-Output

blue

red 8 –

red

–

Front view of housing

Connector inclinometer

2 Installation

2.1 Electrical Connection

The inclinometer is connected via 8 pin round connector or a cable

2.2 Connector Assignment

Output signal (X, Y) analog current 4 to 20 mA (+x,y° to -x,y°)

Installation Instructions

Do not connect the inclinometer under power!

Do not stand on the inclinometer!

Avoid mechanical load!

Page 4 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 5

INCLINOMETER

RS232 – CURRENT

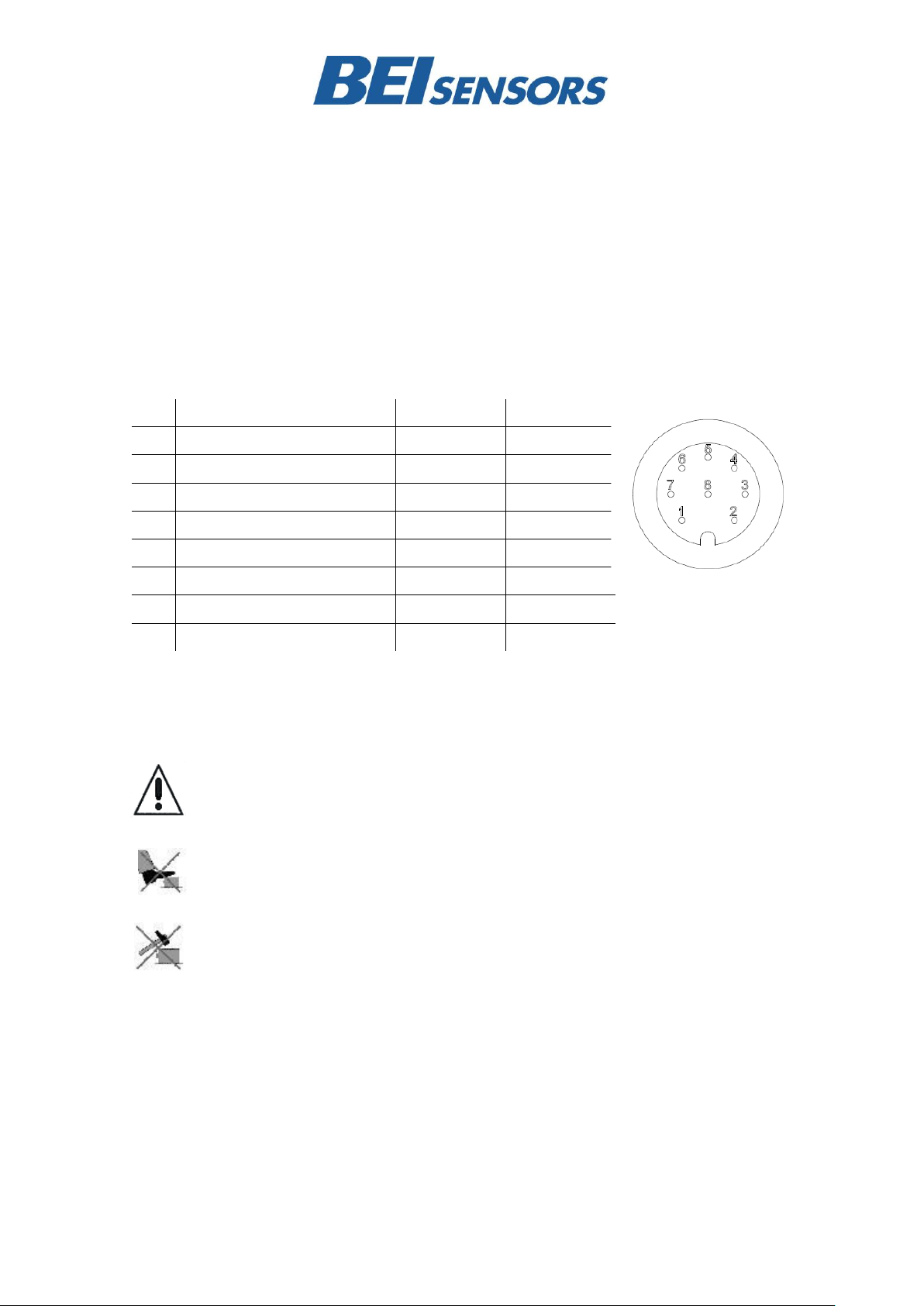

3 Mechanical Drawings

Dimension Housing (mm)

Page 5 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 6

INCLINOMETER

RS232 – CURRENT

Reference edge, base plate side

4 Reference Level

The inclinometer has a mounting reference angle

(black line) for an optimal mounting, which is

parallel to the x-axis. This reference angle must be

placed exactly parallel to the object to be

measured, to prevent or minimize any mechanical

offset/cross sensitivity.

Reference angle of the inclinometer, top view.

Page 6 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 7

INCLINOMETER

RS232 – CURRENT

+ y

- x

+ x

- y

Lateral axis

Longitudinal axis

5 Mounting and Installation Instruction

The inclinometer is designed for a horizontal

mounting, i.e. the base plate of the inclinometer

with the three mounting holes needs to be placed

on the horizontal plane of the object to be

measured. It can be mounted with M4 screw or

smaller.

5.1 Installation

Prior to installation, please check for all connection

and mounting instructions to be complied with.

Please also observe the general rules and

regulations on low voltage technical devices. Avoid

shock and vibration during installation, as these

5.2 Measurement

The measurement of the tilt angle of the single

measurement axis is carried out over the

respective longitudinal and lateral axis of the

View of male socket Side view

The mounting surface must be plane and free of

dust and grease. We recommend cheese head

screws with metrical thread M4 for the mounting.

Maximum fastening torque for the mounting screws

is 10 Nm.

could corrupt the measurement results. Inclination

sensors that base on a fluidic measurement

principle are optimal for static measurements and

suitable to only a limited extent of dynamic

measurement.

inclination sensor. Reference is always the

horizontal plane.

Page 7 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 8

INCLINOMETER

RS232 – CURRENT

Description

Type Key

Absolute Inclinometer

INC-

_ _ _

-2-S _ 1-H0-

_ _ _

Measuring range

005

015

030

Number of axis

RS232

without Interface

Volltage interface

Current interface

PWM

Switch

O

V

C

P

S

Version

Mounting

Dynamic

Horizontal

2 mPas

Connection

plug, 8 pins

1 m cable exit

P8M

CRW

Optionen

–

6 Models/Ordering Description

Page 8 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 9

INCLINOMETER

RS232 – CURRENT

7 Serial Interface RS 232

Communication with the sensor is done through a

standardized RS-232 interface. Data transmission

is effected in duplex mode. The baud rate is fixed

by 9600 baud. After Power On the sensor is

sending continuous the angle values in degrees

(°). In the setup level several settings can be

permanently modified. If the continuous mode was

permanently changed to the polling mode, the

sensor will send after Power On a start information

with actual parameters. On error no angle values

are sending and after Power On an error message

was add to the start information.

Page 9 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 10

INCLINOMETER

RS232 – CURRENT

…

X=+00.430

Y=-00.084

…

8 Programming Instructions

8.1 Basic Settings

After Power On, the sensor is in the user level. In

factory setting (=Free running mode) every 100ms

the current angle values are continuously supplied

with a baud rate of 9600 bd. In the Setup-level

several settings can be changed permanently such

as query or free running mode, output rate, baud

8.2 Interface parameter

- 9600 Baud , 8 data bits, parity even, 1 stop bit,

The baud rate can be adjusted to different values in the Setup-level.

Structure:

rate and angle offset. If query mode instead of free

running mode is selected, the sensor will send

start information with the current settings after

Power On. In case of errors no angle values will be

provided and after Power On an error message will

be added to the start information.

Baud rate: 9600 Baud (factory setting, changes in Setup-Mode possible)

Format ASCII, 8 data bits, 1 stop bit, parity even

Length: 22 byte

Display: <D0 ... D21>

D0 ... D10 = “X=±xx.xxx“, <CR>, <LF>

mit D2 = sign (+ or -)

mit D5 = point

D11 ... D21 = “Y=±xx.xxx“, <CR>, <LF>

with D13 = sign (+ or -)

with D16 = point

Display Example:

Page 10 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 11

INCLINOMETER

RS232 – CURRENT

Instruction

To the

sensor

Response sensor

Description

activate temporary polling

mode

„f“

„f“

the continuous sending of

angle values is stopped,

instructions can be sent to the

sensor

activate temporary continuous

mode

„F“

„X=vxx.xxx“, CR, LF,

„Y=vxx.xxx“, CR, LF,

„X= . . .

X angle in °

Y angle in °

with „±” = „+“ or „-“,

one string contains x and y

value

read angle values

at one-timeErreur ! Source

du renvoi introuvable.

„R“

„X=vxx.xxx“, CR, LF,

„Y=vxx.xxx“, CR, LF,

X angle in °

Y angle in ° with „±” = „+“ or „-“

switch to the setup level

3) 4)

”prog”

”P“

Sensor is at setup level

show active level

“*“

“Ux“ or

”Sx“

„U“ means Sensor is at User

level

„S“ means Setup-level is

active,

with „x“ Output-Mode of

Sensors „U“ / „I“ / „P“ / „S“

9 Commands in User Level

1) In free running mode measurement data is continuously displayed. In query mode measurement and display is only once on

command.

2) After reset or new Power On after an interruption of power supply, the sensor will be in user-level again with the original setup or with

the setup changed in the setup level.

3) Only possible in query mode (=free running mode deactivated).

4) The Input of „prog“ must take place within 20 sec.

Page 11 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 12

INCLINOMETER

RS232 – CURRENT

Instruction

To the sensor

Response sensor

Description

activate permanent

polling mode1)

“f“

“f“

the continuous sending of

angle values are

permanent stopped,

instructions can send to

the sensor

activate permanent

continuous mode1)

“F“

„X=±xx.xxx“, CR, LF,

”Y=±xx.xxx“, CR, LF,

”X= . . .

continuous sending of

X angle in °

Y angle in °

with „±” = „+“ or „-“

set rate of data

transmission for

continuous mode

2) 3) 4)

“O“

<Code transmission

rate>

“O”

<Code transmission

rate>

Echo,

Code transmission rate

or „E“ for Error, if the

code is outside defined

values

read angle values at

one-time2)

“R“ same as at user level

read version2)

“V“

“AGSxxx-2-Sx“, CR,

LF

”SN:xxxx-xxx“, CR,

LF

”HV:xx.x“ , CR, LF

”SV:xx.x“ , CR, LF

type of Sensor

serial number

HW Version internal

sensor

SW Version

offset adjust of the

specified axis

2) 3)

“n“

”x“ or ”y“

“n“

”OffsetX=±xx.xxx“ or

”OffsetY=±xx.xxx“

the actual angle of

specified axis is set to

zero, ±xx.xxx is the

internal offset in

degree

reset offset adjust

2) 3)

“N“

“N“

the offset adjust was

reset to the original value

Set Baud rate

2) 3) 6)

“B“

<Code Baud rate>

“B“

<Code Baud rate>

Echo, Code Baud rate or

„E“ for Error, if the code

is outside defined values

Filter deactivated

„M0“

„M0“

all filters are deactivated

Moving Average

Filter

10)

„M1“, “mm“

„M1mm“

Filter: Moving Average

Filter is activated

10 Setup Level

The Setup level is active until Power On or Reset.

All settings taken in the setup level are stored in

the EEPROM and permanent available also after

Power down.

Page 12 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 13

INCLINOMETER

RS232 – CURRENT

Exponential Filter

10)

„M2“, „tt“

„M2tt“

Filter: Exponential Filter

is activated

Set switch angle for

one axis

2) 3) 7) 8)

“Sx“

<switch angle> or “Sy“

<switch angle>

“Sx“ or “Sy”

<switch angle>

Echo, switch angle or „E“

for Error, if the angle is

outside admissible range

Set hysteresis for

switching point in both

axis

2) 3) 7) 9)

“Sh“

<hysteresis>

“Sh“

<hysteresis>

Echo, hysteresis or „E“

for Error, if the angle is

outside admissible range

show active level2)

“*“ same as at user level

Reset2)

“q“

“q“

Software-Reset will be

executed

1) in the continuous mode the sensor is sending continuous angle values, in the polling mode the sensor is sending one answer after

an instruction

2) only possible at polling mode.

3) for activating a reset or power fail restart is necessary

4) for Code transmission rate see

5) Table 1 <Code transmission rate>

6) for Code baud rate see Erreur ! Source du renvoi introuvable.

Attention! A reset of the baud rate to a default value is not possible. If the user forgets the adjusted baud rate, the new value must

be detected by testing.

7) this instruction is only effectual at sensors with switch output,

8) <switch angle>: three digits from “001” until “300” for the angle in tenths of a degree, max working range of the sensor. Default value

is 025 == 2,5°

9) <hysterese>: two digits from “01” until “99” for the stitching hysterese in tenths of a degree, max working range of the sensor, Default

value is 01 = 0,1°

10) Formulas for Filter :

- Moving Average Filter „M1“, „mm“ (possible values mm = 02 to 40, with mm = 00 is moving average filter deactivated): Output

value = Average over last mm values.

- Exponential Filter „M2“, „tt“ (first order low pass filter, possible values tt = 02 to 40, with tt = 00 is exponential filter deactivated):

Output value = ( old output value * (tt-1) / tt ) + (value / tt )

Page 13 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 14

INCLINOMETER

RS232 – CURRENT

<Code transmission rate>

Strings per second, 1 string contains x and y-value

“0“

reserved

“1“

25 Strings/s1)

“2“

10 Strings/s, Default value2)

“3“

5 Strings/s

“4“

2 Strings/s

“5“

1 Strings/s

“6“

0,2 Strings/s

“7“

0,1 Strings/s

“8“, “9”

not defined

<Code Baud Rate>

Baud rate

“0“

2400 Baud

“1“

4800 Baud

“2“

9600 Baud, Default value

“3“

19200 Baud

“4“

38400 Baud

“5“

57600 Baud

“6“, “7“, ”8“, ”9“

not defined

<Code transmission rate>

1) only allowed with baud rate of at least 9600 Bd

2) only allowed with baud rate of at least 4800 Bd

<Code Baud Rate>

Page 14 Inclinometer RS232 – Current Datasheet Version: 20130503

Page 15

INCLINOMETER

RS232 – CURRENT

Instruction

To the sensor

Response sensor

Description

„X=±xx.xxx“, CR, LF,

”Y=±xx.xxx“, CR, LF,

”X= . . .

continuous sending of

angles

activate temporary

polling mode

”f”

“f“

the continuous sending

of angle values are

stopped, instructions

can send to the sensor

switch to the setup

level

”prog”

”P“

Sensor is at setup level

set rate of data

transmission for

continuous mode

“O5“

“O5”

Code transmission rate

is set to 1Strings/s

Reset

“q“

“q“

Software-Reset will be

executed, the new

settings are guilty

„X=±xx.xxx“, CR, LF,

”Y=±xx.xxx“, CR, LF,

”X= . . .

continuous sending of

angles at

1 Strings/s

Example for Setting the Output Rate

We do not assume responsibility for technical inaccuracies or

omissions. Specifications are subject to change without notice.

Page 15 Inclinometer RS232 – Current Datasheet Version: 20130503

Loading...

Loading...