Page 1

H25X Absolute Optical Encoder

The H25X series single turn encoder is

designed for those applications that

require 14 or 15 bits of resolution

in a compact, easy-to-integrate

package. Gray Code and Natural

Binary outputs are available for

installations using a parallel input

with the controller. For simplic-

ity of data transmission, ease of

cabling and better noise immu-

nity, an SSI (Serial Synchronous

Interface) is also offered. This

encoder works with the BEI Serial-to-

Parallel converter, allowing for system

upgrades from parallel output to SSI.

The H25X is built to the exacting mechanical standards used with the H25 design,

including: dual preloaded ABEC 7 bearings; matched thermal coefficients on critical

components and electronically centered code disks for high accuracy and stability over

a range of environments. Specify the H25X when you need high pointing accuracy and

ruggedness in a 14 or 15 bit absolute encoder for your telescope, antenna, robotics,

material handling or general industrial automation.

The H25 Absolute Encoder is avail able with the following certification:

EN 55011 and EN 61000-6-2

Mechanical Specifications

Shaft Diameter: 3/8”

Shaft Loading: Up to 25 pounds axial and radial

Shaft Runout: 0.0005 T.I.R. at midpoint regardless of shaft diameter

Starting Torque at 25°C: With shaft seal 2.5 in-oz

Bearings: Class ABEC 7 standard, ABEC 5 for 1/2” shaft

Shaft Material: 416 stainless steel

Bearing Housing: Die cast aluminum with iridite finish

Cover: Die cast aluminum

Bearing Life: 2 X 108 revs (1300 hrs at 2500 RPM) at rated load

1 X 1010 revs (67,000 hrs at 2500 RPM) at 10% of rated load

Maximum RPM: 12,000 RPM mechanical,

Moment of Inertia: 4.1 X 10-4 oz-in-sec

Weight: 13 oz typical

Connector: MS3112E14-19P, 19–pin connector on encoder body,

mates to MS3116J14-19S (or equivalent)

2

Electrical Specifications

Code: 14 or 15 bits NB or GC

Counts Per Shaft Turn: 16,384 or 32,768

Count Transition Accuracy: ± 1/2 bit maximum

Supply Voltage: 5–28 VDC

Current Requirements: 120 mA typical

Output Formats:

Parallel: Gray Code, Natural Binary

Serial: Serial Synchronous Interface (SSI) compatible

Voltage/Output: (see note 4)

28V/V: Line Driver, 5–28 VDC in, V

28V/5: Line Driver, 5–28 VDC in, V

28V/OC: Open Collector, 5–28 VDC in, OC

SSI: 5–28 VDC IN/5V

Protection Level: Reverse, overvoltage and output short circuit

protection (see note 3)

Frequency Response: 500kHz

Output Termination Pinouts: see Table 1, back page

(see back page)

out

= Vin

out

= 5 VDC

out

out

Environmental Specifications

Enclosure Rating: NEMA 4 & 13 (IP 66) when ordered with shaft seal (on

units with an MS connector) or a cable gland (on units with cable termination).

Temperature: Operating, 0º to 70º C; extended temperature

testing available (see note 7); Storage, -25º to 90º C unless extended

temperature option called out.

Shock: 50 g’s for 11 msec duration

Vibration: 5 to 2000 Hz @ 20 g’s

Humidity: 98% RH without condensation

NOTES & TABLES: All notes and tables referred to in the text can be

found on the back of this page.

H25X Absolute Encoder Ordering Options FOR ASSISTANCE CALL 800-350-2727

Use this diagram, working from left to right to construct your model number (example: H25XD-F4-SS-14GC-28V/V-CW-SM14/19).

All notes and tables referred to can be found on the back of this page.

H25X

TYPE:

Heavy Duty

2.5 inch Dia.

X = Extended

Resolution

HOUSING :

D = Square Flange

E = 2.5 inch dia.

servo mount

These commodities, technology or software if exported from the United States must be in accordance with the Bureau of Industry, and Security, Export Administration regulations. Diversion contrary to U.S law is prohibited.

FACE MOUNTS:

F4 = 6–32 holes,

3 places equally

spaced on

2.00 inch bolt circle

See note 1

SHAFT SEAL

CONFIGURATION:

SS = Shaft Seal

See note 2

NUMBER OF BITS:

14 = 14-Bits, 16,384 counts per turn

15 = 15-Bits, 32,768 counts per turn

Tel: 805-968-0782 /800-350-2727 | Fax: 805-968-3154 / 800-960-2726

7230 Hollister Ave., Goleta, CA 93117-2807 | www.beisensors.com

CODE TYPE:

GC = Gray Code

NB = Natural Binary

VOLTAGE/OUTPUT

28V/V = 5–28V

28V/5 = 5–28V

28V/OC = 5–28V

S3 = Serial Synchronous

Interface (See note 4)

DIRECTION OF COUNT:

CW = Clockwise increasing count

CCW = Counter clockwise

increasing count

in/out

in/5Vout

in/OCout

TERMINATION

LOCATION:

TERMINATION TYPE:

M14/19 = 19 pin connector

CS = Cable with gland seal

Cable length specified in inches

(i.e. C18 = pigtail 18” long)

M18 = MS3102R18-1P

(S3 output only)

OUTPUT

E = End

S = Side

Specification No. 02085-001 Rev.08-11

FEATURES:

S = Special features

specified on purchase

order (consult factory)

See note 5

SPECIAL

Page 2

Serial Synchronous Interface (SSI)

1.38

Ø 2.500

0.100

.100 MIN

Ø 2.275

1.2500

1.2495

0.300

NOTE: SHAFT SEAL NOT

AVAILABLE ON H25 G

2.500

2.498

Ø 2.625

0.125

0.125

Ø

Ø

MS STYLE

1.30 (SM 14/19)

1.38

Ø 2.500

0.100

.100 MIN

Ø 2.275

1.2500

1.2495

0.300

EM CONNECTOR

POSITION

SM CONNECTOR

POSITION

2.50

0.255

0.30

1.2500

1.2495

NOTE: SHAFT SEAL NOT

AVAILABLE ON H25 G

0.3747

0.3745

0.88 ± 0.03

0.34

2.500

2.498

Ø 2.625

0.125

0.125

6-32 UNC-2B

0.250 Min. Deep

3 places equally spaced

on a Ø 2.00 bolt circle.

F4

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a

Ø 1.875 bolt circle.

F1

Ø

Ø

Ø

30° 30°

Ø 2.500

0.100

Ø 2.275

1.2500

1.2495

0.300

NOTE: SHAFT SEAL NOT

AVAILABLE ON H25 G

2.500

2.498

Ø 2.625

0.125

0.125

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

F1

Ø

Ø

30°

NOTE: SHAFT SEAL NOT

AVAILABLE ON H25 G

2.500

2.498

Ø 2.625

0.125

0.125

Ø

CONNECTOR*

DATA+A

FUNCTION

YEL

CABLE

1

H40

TERM BOARD

DATA-H

WHT/YEL

7

CLOCK+ B

BLU

2

CLOCK- I

WHT/BLU

8

DIRECTION CONTROL C

ORN

3

ENABLE (OPTIONAL) J

WHT/ORN

9

SUPPLY VOLTAGE (+V)D

RED

4

CIRCUIT COMMON (0V) F

BLK

5

CASE GROUND G

GRN

6

Max. Frequency (KHz)

Cable Length (feet) 50

1800

100

900 500

200

300

300

200

500

100

1000

4

2

1

3

9

6

8

7

5

H38

(XX = cable length in feet, ie. 10 = 10 feet)

Pin C must be pulled to LO (0V)

ONE REVOLUTION

CW Increasing Count Viewing Shaft

ETC. THRU LSB (GO)

SSI output provides effective synchronization

in a closed-loop control system. A clock pulse

train from a controller is used to clock out sensor data: one bit of position data is transmitted

to the controller per one clock pulse received

by the sensor. The use of a differential driver

permits reliable transmission of data over long

distances in environments that may be electrically noisy. The encoder utilizes a clock signal,

provided by the user interface, to time the

data transmission. Receiving electronics must

include an appropriate receiver as well as line

terminating resistors.

Features :

• Synchronous transmission

• Transmission lengths to 1000 feet

• Accepts clock rates from 100 KHz to 1.8 MHz

Data Transmission Sequence

1. Output driver of the encoder is a MAX 491 transceiver in transmit mode. The recommended receiver is

a MAX 491 transceiver in receive mode.

2. Controller provides a series of pulses (or differential pulse pairs) on the CLOCK input lines.

3. On the first HIGH-to-LOW CLOCK transition, the

encoder latches its data at the current position and

prepares to transmit.

4. Controller reads data on the falling edge of the

next 15 clock cycles.

5. The first bit is a START bit and is always HIGH.

6. Next comes 13 data bits beginning with the

most significant bit (MSB) and ending with the parity bit. On 12 bit encoders, bit 13 is LOW. When

parity is not ordered, parity is LOW.

7. After the last CLOCK HIGH-to-LOW transition,

a minimum of 40 microseconds must pass before

the beginning of the next CLOCK series.

Interfacing Long Data Lines

Cable impedance can create a transmission

delay, in effect, shifting the phase relationship

between the clock pulse and the data. If this

phase shift exceeds 180°, then the wrong bit

position will be sampled by the receiver. As a

result, the maximum allowable clock frequency

is a function of the cable length. For 24 AWG,

stranded, 3 pair cable (BEI part number 37048003 or equivalent) the group delay is 1.36ns/ft.

The table below shows the maximum transmission rate allowable as a function of cable length

to ensure a phase shift of less than 90°.

CLOCK, Maximum (kHz) =

92,000 / Cable Length (ft)CW

Cable Length (ft) 50 100 200 300 500 1000

Max Freq (kHz) 1800 900 500 300 200 100

Figures

Figure 1

Gray Code

Figure 2

Natural Binary

H25X Absolute Optical Encoder

2

M14/19

and the compatibility of your receiving electronics with

Line Driver type outputs.

28V/V: Multi-voltage Line Driver (7272*): 100 mA

source/sink. Input voltage 5 to 28 VDC +/- 5% standard

(Note: V

= Vin). This driver is TTL compatible when

out

used with 5 volt supply. Supply lines are protected

against overvoltage to 60 volts and reverse voltage.

Outputs are short circuit protected for one minute.

Supply current is 120 mA typical (plus load current). This

is the recommended replacement for 3904R and 7406R

open collector outputs with internal pullup resistors. It is

also a direct replacement for any 4469, 88C30, 8830 or

26LS31 line driver.

28V/5: Multi-voltage Line Driver (7272*): 100 mA

source/sink. Input voltage 5 to 28 VDC +/- 5% standard, internally regulated with 5V (TTL compatible) logic

out. Supply lines are protected against overvoltage to

60 volts and reverse voltage. Outputs are short circuit

protected for one minute. Supply current is 90 mA typical (plus load current). Note: Limit encoder load to 2.5W

max at ambient. Example at 12 VDC: 2.5W/(+12VDC

minus +5VDC) = 357 mA total allowed current. Consult

factory for your specific requirements.

28V/OC: NPN Open Collector (3904*, 7273*). Current

EM CONNECTOR

POSITION

SM CONNECTOR

POSITION

2.50

0.255

0.30

0.88 ± 0.03

ETC. THRU LSB (GO)

ETC. THRU LSB (20)

CW Increasing Count Viewing Shaft

CW Increasing Count Viewing Shaft

ONE REVOLUTION

ONE REVOLUTION

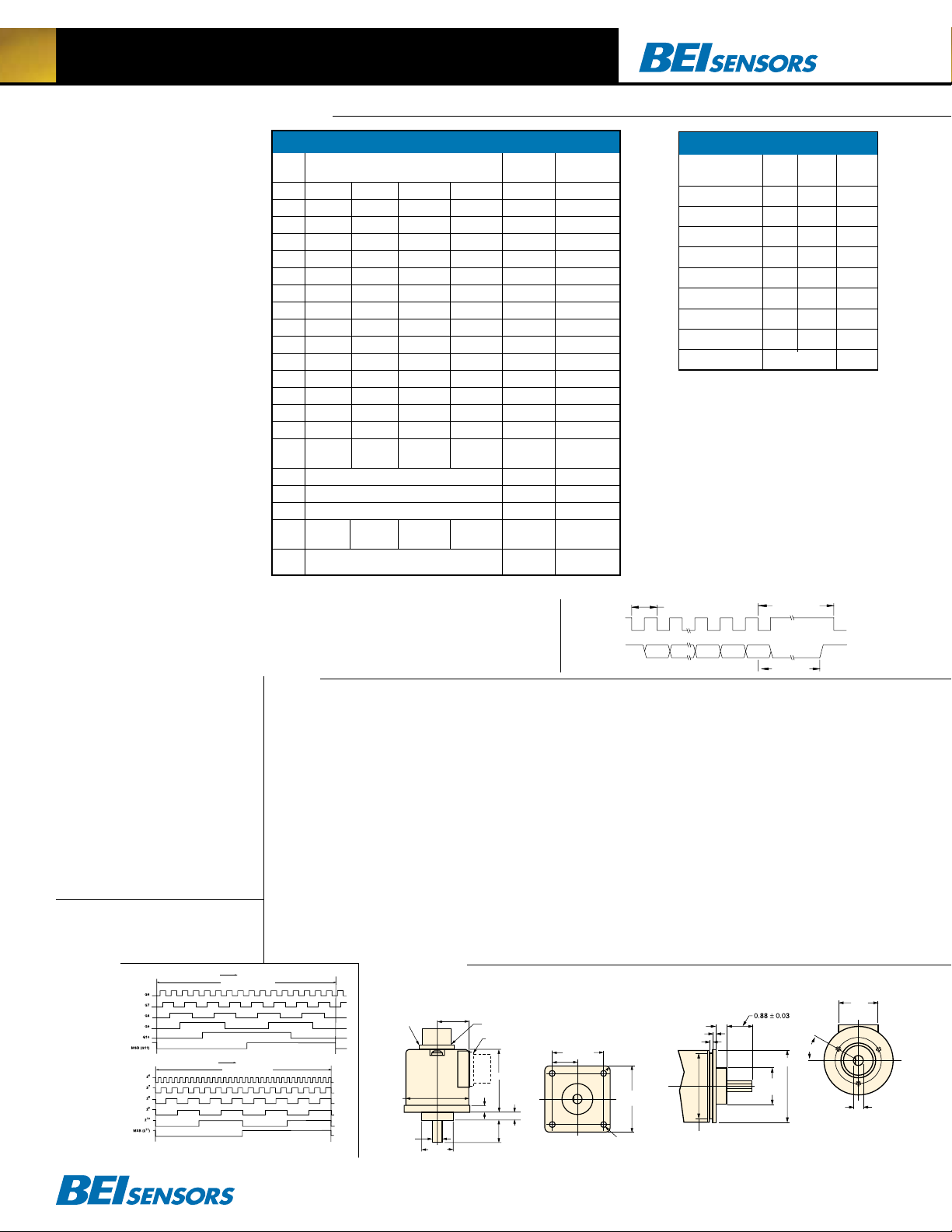

Gray Code Natural Binary Connector Cable

14 BIT 15 Bit 14 BIT 15 Bit

MSB G

G

G

G

G

G

G

G

G

G

G

G

G

LSB14 G

LSB15 DIR G

CONTROL CONTROL

G14 213 214 A WHT/BLK

13

G13 212 213 B WHT/BRN

12

G12 211 212 C WHT/RED

11

G11 210 211 D WHT/ORN

10

G10 29 210 E WHT/YEL

9

G9 28 29 F WHT/GRN

8

G8 27 28 G WHT/BLU

7

G7 26 27 H WHT/VIO

6

G6 25 26 J WHT/GRY

5

G5 24 25 K WHT

4

G4 23 24 L GRY/BLK

3

G3 22 23 M GRY/BRN

2

G2 21 22 N GRY/RED

1

G1 20 21 P GRY/ORN

0

DIR 20 R *

0

CASE GROUND S GRN

OV (CIRCUIT COMMON) T BLK

LATCH DIR/LATCH LATCH DIR/LATCH U *

+V (SUPPLY +V (SUPPLY +V (SUPPLY +V (SUPPLY V RED

VOLTAGE) VOLTAGE) VOLTAGE) VOLTAGE)

SHIELD DRAIN — BARE

* DIR Control - ORN, LATCH - YEL, 15 bit LSB-GRY/YEL

2

Units Manufactured before April 2007 are LSB Justified

Ordering SSI :

HOW TO SPECIFY SSI OUTPUT IN THE ENCODER MODEL

NUMBER: Use the designation, S3 between the Code Format designation

and the Connector designation. Example: H25D-SS-12GC-S3-CW-SM18

Notes

1. Mounting is usually done either using the D-style square

flange mount, E- or G-style servo mounts, or one of the

standard face mounts, F1 for example. Consult factory for

additional face mount options.

2.The shaft seal is recommended in virtually all installations. The most common exceptions are applications

requiring a very low starting torque or those requiring

operation at both high temperature and high speed.

3. Complementary outputs are recommended for use

with line driver type (source/sink) outputs. When used

with differential receivers, this combination provides a

high degree of noise immunity.

4. Output IC’s: Output IC’s are available as either Line

Driver (LD) or NPN Open Collector (OC) types. Open

Collectors require pull-up resistors, resulting in higher

output source impedance (sink impedance is similar to

that of line drivers). In general, use of a Line Driver style

output is recommended. Line Drivers source or sink current and their lower impedance mean better noise immunity and faster switching times. Warning: Do not connect

any line driver outputs directly to circuit common/OV,

which may damage the driver. Unused outputs should

be isolated and left floating. Our applications specialists

would be pleased to discuss your system requirements

Parallel Code (14 & 15 Bit)

Tel: 805-968-0782 /800-350-2727 | Fax: 805-968-3154 / 800-960-2726 | 7230 Hollister Ave., Goleta, CA 93117-2807

www.beisensors.com

Dimensions

H25XD - Square Flange

1.30 (SM 14/19)

1.2500

Ø

1.2495

Ø 2.52

MAX

MS STYLE

CONNECTOR

0.3747

Ø

0.3745

2.064 TYP

1.032

Direction of Count: Standard is CW increasing when viewed from the

shaft end. Pin R is normally HI (or N/C) and is pulled up internally to +V.

To reverse the count direction, Pin R must be pulled LO (COMMON ).

Latch control: Encoder outputs are active and provide continuous

parallel position information when Pin U is HI (or N/C). Pin U is pulled up

internally to +V. When Pin U is LO (COMMON) the encoder outputs are

latched at the logic state that is present when the latch is applied and

will stay latched until Pin U is no longer grounded.

Dir/Latch on 15-Bit Encoders: Due to a limited number of connector

pins, either direction of count or latch is available on pin U. Direction

standard of latch specified as -S special.

M18 Connector is a MS3102R18-1P, 10-pin connector on the

encoder body and mates to an MS3106F18-1S connector or can be

used with a standard cable/connector assembly, BEI P/N 924-3118618XX (Where XX = 10, 20 30 or 50 for a 10, 20, 30, or 50 foot length).

This is the preferred connector for SSI output.

M14/19 Connector is a MS3112E14-19P, 19-pin connector on the

encoder body and mates to an MS3116J14-19S or equivalent.

SSI Timing

CLOCK+

DATA+

START

20us Max

1212 13 14 15

MSB MSB-1 LSB12 LSB13

BIT

H25XE - 2.50 Servo Mount

0.21 R

SQUARE

Ø 0.218 4 HOLES

(Ø 2.919 B.C. REF)

.100 MIN

2.650

SSI Output Termination Table

M18

M14/19

Cable

Conn

START OF

NEXT CLOCK

START

BIT

30°

F4

6-32 UNC-2B

0.250 Min. Deep

3 places equally spaced

on a Ø 2.00 bolt circle.

Conn

1.38

Conn

DATA + A A YEL

DATA- H B WHT/YEL

CLOCK+ B C BLU

CLOCK- I D WHT/BLU

DIR CONTROL C R ORN

CASE GROUND G S GRN

CIRCUIT COMMON F T BLK

+V SUPPLY VOLTAGE D V RED

SHIELD DRAIN — — BARE

40us Min

Parity

(Optional)

30us Min

sink of 80 mA max. Current sourced by external pullup resistor. Output can be pulled up to voltage other

than supply voltage (30 V max). Input voltage 5 to 28

+

VDC

/- 5% standard. Supply current is 120 mA typical. This replaces prior IC’s with designations of 3904,

7406, 3302, 681 and 689.

5. Special –S at the end of the model number is used to

define a variety of non-standard features such as special

shaft lengths, voltage options, or special testing. Please

consult the factory to discuss your special requirements.

6. Higher frequency response may be available. Please

consult with the factory.

7. Extended temperature ratings are available in the following ranges: -40 to 70°C, -40 to 85°C, –20 to 105°C and

–40 to 105°C depending on the particular model. Extended

temperature ranges can affect other performance factors.

Consult with factory for more specific information.

8. Mating straight plug receptacles may be ordered from

the factory: For M14/19 use MS3116J14-19S,

For M16 use MS3106F16S-1S

For standard pinouts, refer to the facing page.

* Products manufactured prior to April 2007 used the line driver IC number instead of voltage

output in model number.

0.300

0.100

Ø 2.500

1.2500

Ø

1.2495

Ø 2.275

0.34

Loading...

Loading...