Page 1

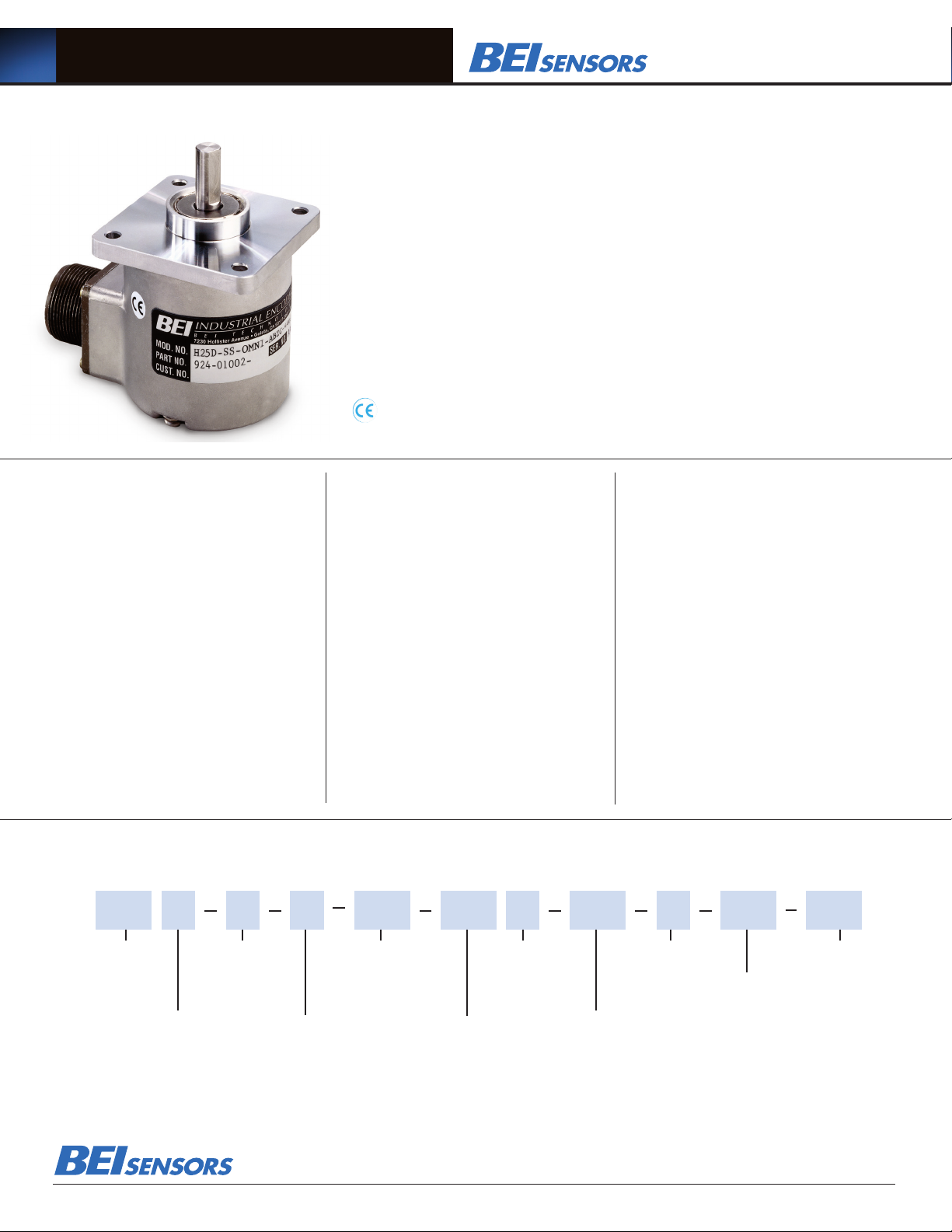

Omnicoder® Model H25®

The Omnicoder features a patented dynamic encoder resolution capability that allows users to easily

program the encoder resolution to any value between 1 and 10,000 counts per turn. Packaged in

BEI’s flagship Model H25® incremental encoder, the Omnicoder allows for virtually unlimited resolution

variations.

Using the simple programming interface software and USB interface cable, users can program

the encoder resolution on site as needed. In the software, type the encoder resolution and click

‘Program’. A new resolution is now programmed. It’s that easy!

With the Omnicoder, resolution can be programmed and reprogrammed at any time by the user.

For users with multiple resolution requirements, Omnicoders can be kept in stock and programmed

as needed.

The Omnicoder Model H25 Incremental Encoder is available with the following certification:

EN 55011 and EN 61000-6-2

Mechanical Specifications

Shaft Diameter: 3/8” (1/2”as special feature)

Flat On Shaft: 3/8” Shaft: 0.80 long X 0.03” deep;

1/2” Shaft: 0.80 long X 0.04” deep

Shaft Loading: 3/8” shaft: Up to 40 pounds axial and 35

pounds radial; 1/2” shaft: Up to 90 pounds axial and 80 pounds

radial

Shaft Runout: 0.0005 T.I.R. at midpoint regardless of

shaft diameter

Starting Torque at 25°C: Without shaft seal 1.0 in-oz (max);

With shaft seal 2.5 in-oz (max); 1/2” shaft with shaft seal:

3.5 in-oz (max)

Bearings: Class ABEC 7 standard, ABEC 5 for 1/2” shaft

Shaft Material: 416 stainless steel

Bearing Housing: Die cast aluminum with protective finish;

stainless steel (special feature)

Cover: Die cast aluminum; stainless steel (special feature)

Bearing Life: 2 X 108 revs (1300 hrs at 2500 RPM)

at rated load 1 X 1010 revs (67,000 hrs at 2500 RPM) at

10% of rated load

Maximum RPM: 12,000 RPM nominal, 8000 RPM with

1/2” shaft (see Frequency Response, below) 30,000 RPM

available on units with 3/8” shaft— consult with factory

Moment of Inertia: 4.1 X 10-4 oz-in-sec2; 5.2 X 10-4

oz-in-sec2 with 1/2” shaft

Weight: 13 oz typical, 14.5 oz typical with 1/2” shaft

Electrical Specifications

Code: Incremental

Output Format: 2 channels in quadrature, 1/2 cycle index

gated with negative B channel

Cycles Per Shaft Turn: 1 to 10,000 reprogrammable

resolutions. Place “OMNI” in resolution option box.

Supply Voltage: 5 to 28 VDC available

Current Requirements: 140 mA typical + output load, 290 mA

(max).

Voltage/Output: (see note 5)

28V/V: Line Driver, 5–28 VDC in, V

Protection Level: Reverse, overvoltage and output short circuit

(see note 5)

out

= V

in

Frequency Response: Max RPM of 3,000.

Output Terminations: M18

Note: Consult factory for other electrical options

Environmental Specifications

Enclosure Rating: NEMA 4 & 13 (IP 66) when ordered with

shaft seal (on units with an MS connector) or a cable gland

(on units with cable termination).

Temperature: Operating, 0º to 70º C; extended temperature

testing available (see note 8); Storage, -25º to 90º C unless

extended temperature option called out.

Shock: 50 g’s for 11 msec duration

Vibration: 5 to 2000 Hz @ 20 g’s

Humidity: 98% RH without condensation

NOTES & TABLES: All notes and tables referred to in the text

can be found on the back of this page.

Omnicoder Model H25 Ordering Options for assistance call 800-350-2727

Use this diagram, working from left to right to construct your model number (example: H25D-SS-OMNI-ABZC-28V/V-SM18).

H25

All notes and tables referred to in the text

can be found on the back of this page.

TYPE:

H = Heavy Duty

25 = 2.500” Dia.

HOUSING CONFIG.

LETTER:

D=Square Flange

E=2.50 Dia. Servo Mount

G=2.62 Dia. Servo Mount

See dimensions

These commodities, technology or software if exported from the United States must be in accordance with the Bureau of Industry, and Security, Export Administration regulations. Diversion contrary to U.S law is prohibited.

OPTIONAL

FACE MOUNTS

F1, F2, F3, or F4

Blank = None

See note 1

SHAFT SEAL

CONFIGURATION:

SS = Shaft Seal

(Not avail. on H25G)

Blank = Shielded Bearing

See note 2

Tel: 805-968-0782 /800-350-2727 | Fax: 805-968-3154 / 800-960-2726

7230 Hollister Ave., Goleta, CA 93117-2807 | www.beisensors.com

CYCLES PER TURN:

OMNI = Omnicoder

reprogrammable resolution,

select 1 to 10,000 integer CPT

NO. OF CHANNELS:

ABZ = Dual with Index

COMPLEMENTS

C = Complementary

Outputs

VOLTAGE/OUTPUT:

28V/V = 5–28V

OUTPUT TERMINATION

in/out

See note 3

LOCATION:

S = Side

OUTPUT

TERMINATION:

M18 =MS3102R18-1P

See table 1 & note 6

Specification No.02126-001 Rev. 02-14

SPECIAL

FEATURES:

S = Special

specified on

purchase

features

order

(consult

factory)

See

note 4

Page 2

Omnicoder® Model H25®

30°

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 2.00 bolt circle.

F1

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

45°

F2

F3

For Reference: Old Color of Drawings:

30°

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

F1

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

45°

F2

For Reference: Old Color of Drawings:

For Reference: Old Color of Drawings:

1.38

0.34

30°

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 2.00 bolt circle.

45°

F1

F2 (H25G Only)

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

45°

F2

F3

For Reference: Old Color of Drawings:

0.88 ± 0.03

1.38

Ø 2.500

0.100

.100 MIN

Ø 2.275

1.2500

1.2495

0.300

NOTE: SHAFT SEAL NOT

AVAILABLE ON H25G

0.34

30°

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 2.00 bolt circle.

45°

F1

F2 (H25G Only)

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

45°

F2

F3

Ø

For Reference: Old Color of Drawings:

30°

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

45°

F1

45°

For Reference: Old Color of Drawings:

0.88 ± 0.03

1.38

Ø 2.500

0.100

.100 MIN

Ø 2.275

1.2500

1.2495

0.300

0.34

30°

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

4-40 UNC-2B

0.250 Min. Deep

45°

F1

F2 (H25G Only)

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

45°

F2

Ø

For Reference: Old Color of Drawings:

0.88 ± 0.03

1.38

Ø 2.500

0.100

.100 MIN

Ø 2.275

1.2500

1.2495

0.300

NOTE: SHAFT SEAL NOT

AVAILABLE ON H25G

0.34

2.500

2.498

Ø 2.625

0.125

0.125

0.88 ± 0.03

30°

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 2.00 bolt circle.

45°

F1

F2 (H25G Only)

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

45°

F2

F3

MS STYLE

CONNECTOR

1.30 (SM16)

1.65 (SM 18)

EM CONNECTOR

POSITION

SM CONNECTOR

POSITION

2.50

0.255

0.30

Ø 2.52

MAX

1.2500

1.2495

0.3747

0.3745

0.88 ± 0.03

Ø

Ø

Ø

Ø

For Reference: Old Color of Drawings:

0.88 ± 0.03

1.38

Ø 2.500

0.100

.100 MIN

Ø 2.275

1.2500

1.2495

0.300

0.34

0.88 ± 0.03

30°

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

45°

F1

F2 (H25G Only)

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

45°

F2

1.30 (SM16)

1.65 (SM 18)

SM CONNECTOR

POSITION

2.50

0.255

0.30

Ø 2.52

MAX

1.2500

1.2495

0.3747

0.3745

0.88 ± 0.03

Ø

Ø

Ø

For Reference: Old Color of Drawings

:

30°

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

F1

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

45°

F2

For Reference: Old Color of Drawings:

Dimensions

H25D - Square Flange H25E - 2.50 Servo Mount

H25G - 2.62 Dia Servo Mount

0.88 ± 0.03

2.064 TYP

1.032

0.21 R

SQUARE

Ø 0.218 4 HOLES

(Ø 2.919 B.C. REF)

2.625

TOLERANCES: .XX = ± 0.01, .XXX = ±0.005

0.125

0.125

2.500

Ø

2.498

Ø 2.625

NOTE: SHAFT SEAL NOT

AVAILABLE ON H25G

Optional Face Mounts

0.34

30°

F1

10-32 UNF-2B

0.188 Min. Deep

3 places equally spaced

on a Ø 1.875 bolt circle.

45°

F2 (H25G Only)

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 1.272 bolt circle.

(0.900 square, Ref.)

F3

4-40 UNC-2B

0.250 Min. Deep

4 places equally spaced

on a Ø 2.00 bolt circle.

30°

F4

6-32 UNC-2B

0.250 Min. Deep

3 places equally spaced

on a Ø 2.00 bolt circle.

1.38

Installation and Programming

INSTALLING THE DRIVER AND SOFTWARE

Step 1 Go to www.beisensors.com/downloads to view the download page

Step 2 Click on the “Windows: USB Virtual COM Port Driver” and save the file to your hard drive.

(Omnicoder Programming is currently supported on WIndows only).

Step 3 Unzip the USB driver to a directory on your hard drive

Step 4 Run “setup” to install drivers

Step 5 From the BEI download web page, click on the “Windows: Omnicoder Program” and save the file

to your hard drive

Step 6 Unzip the program to a directory on the hard drive.

Step 7 Run “setup” to install the Omnicoder Programming software.

Step 8 The program should start automatically. You have finished installing the software and are

now ready to program your Omnicoder. (All Omnicoders are shipped pre-programmed for 1024 CPT).

Below is a screen shot of the program interface.

PROGRAMMING THE OMNICODER

Step 9 Using the Omnicoder programming cable, plug the USB connector end into your PC.

The red X (No cable detected) should change to a green check mark, indicating that the

USB Programming Module was detected. (This may take up to 15 seconds)

Step 10 Plug the M18 connector end into the Omnicoder unit. The red X (No encoder detected)

should change to a green check mark, and the current Omnicoder resolution will be

displayed on your computer screen.

Step 11 To change the Omnicoder resolution, enter a new resolution as an integer between 1 and 10000 in the

box labeled “Program New Resolution.” Then click the “Program” button. In a few seconds, the

new resolution will be uploaded to the Omnicoder. The Omnicoder is now programmed and can be

disconnected. To program a new resolution, repeat Steps 9-11.

Tel: 805-968-0782 /800-350-2727 | Fax: 805-968-3154 / 800-960-2726

7230 Hollister Ave., Goleta, CA 93117-2807 | www.beisensors.com

Figure 1

Output Waveform

1 CYCLE

90 Deg.

A

B

Z

A

B

Z

CCW Rotation Viewing Shaft

Table 1

Incremental Output Terminations

M18 CONNECTOR

PIN CHANNEL

A A

B B

C Z

D +V

E —

F 0V

G CG

H A

I B

J Z

Notes

1. Mounting is usually done either using the D-style square flange mount,

E- or G-style servo mounts, or one of the standard face mounts, F1 for

example. Consult factory for additional face mount options.

2.The shaft seal is recommended in virtually all installations. The most

common exceptions are applications requiring a very low starting torque

or those requiring operation at both high temperature and high speed.

3. Output IC’s: Output IC’s are available as either Line Driver (LD) or

NPN Open Collector (OC) types. Open Collectors require pull-up resistors, resulting in higher output source impedance (sink impedance

is similar to that of line drivers). In general, use of a Line Driver style

output is recommended. Line Drivers source or sink current and their

lower impedance mean better noise immunity and faster switching

times. Warning: Do not connect any line driver outputs directly to

circuit common/OV, which may damage the driver. Unused outputs

should be isolated and left floating. Our applications specialists would

be pleased to discuss your system requirements and the compatibility

of your receiving electronics with Line Driver type outputs.

28V/V: Multi-voltage Line Driver (7272): 100 mA source/sink. Input

voltage 5 to 28 VDC +/- 5% standard (Note: V

TTL compatible when used with 5 volt supply. Supply lines are protected

against overvoltage to 60 volts and reverse voltage. Outputs are short circuit protected for one minute. Supply current is 120 mA typical (plus load

current). This is the recommended replacement for 3904R and 7406R

open collector outputs with internal pullup resistors. It is also a direct

replacement for any 4469, 88C30, 8830 or 26LS31 line driver use

4. Special –S at the end of the model number is used to define a variety of

non-standard features such as special shaft lengths, voltage options, or special testing. Please consult the factory to discuss your special requirements.

5. Higher frequency response may be available. Consult factory.

6. Mating straight plug receptacles may be ordered from the factory:

For M18 use MS3106F18-1S

Manufactured under U.S.patent numbers 7,349,821, 6,789,041

7,336,756

Model H25® and Omnicoder® are trademarks of BEI Sensors &

Systems Company.

= Vin). This driver is

out

HI

LO

Loading...

Loading...