ANTI-DITHER MODULE DIN RAIL MOUNT

WHY USE AN ANTI-DITHER MODULE ?

CASE 1 – STARTS AND STOPS

In certain applications, such as conveyor systems or

web processes it may be necessary to stop the line

to clear a jam or reset the process. There is no way

to control where the encoder is in its output cycle

when this occurs: it may have stopped at the rising or

falling edge (a transition) of an output channel or

somewhere in between. When it stops on a

transition, there can be ambiguity in the controller.

HOW IT WORKS:

This interface module uses the

position information in a dual

channel quadrature encoder to

remove spurious counts caused

by mechanical vibration. Logic

gates in the Anti-Dither Module

use the quadrature relationship to

discriminate between dithering

and actual movement. The

resulting output is a phase-shifted

quadrature signal with ± 1/4 cycle

of hysteresis. The index pulse

from the encoder is optically

isolated and passed directly to the

controller for use as a reference.

The output of the encoder may dither from its HI state

to its LO state due to mechanical noise in the

conveying system. This fluctuation can be read as

true motion in the controller. The Anti-Dither Module

creates hysteresis so mechanical dithering does not

create a false count.

CASE 2 – HIGH VIBRATION

Another situation arises where the end use involves

very high vibration -- construction machinery or mill

duty applications for example. This is especially true

when the encoder is being used as a single channel

tachometer. In this instance the encoder output can

have a vibration signal superimposed on the data

channel, leading to multiple transitions on every

cycle. This effect can be eliminated in the controller

if the encoder has dual channels in quadrature,

however that is not always an option. In this case,

the Anti-Dither module can clean things up

t c

Specification No.02125-003 Rev0611

Note: Refer to BEI Opto Isolator Module Applications guide

for mechanical specifications and connection instructions.

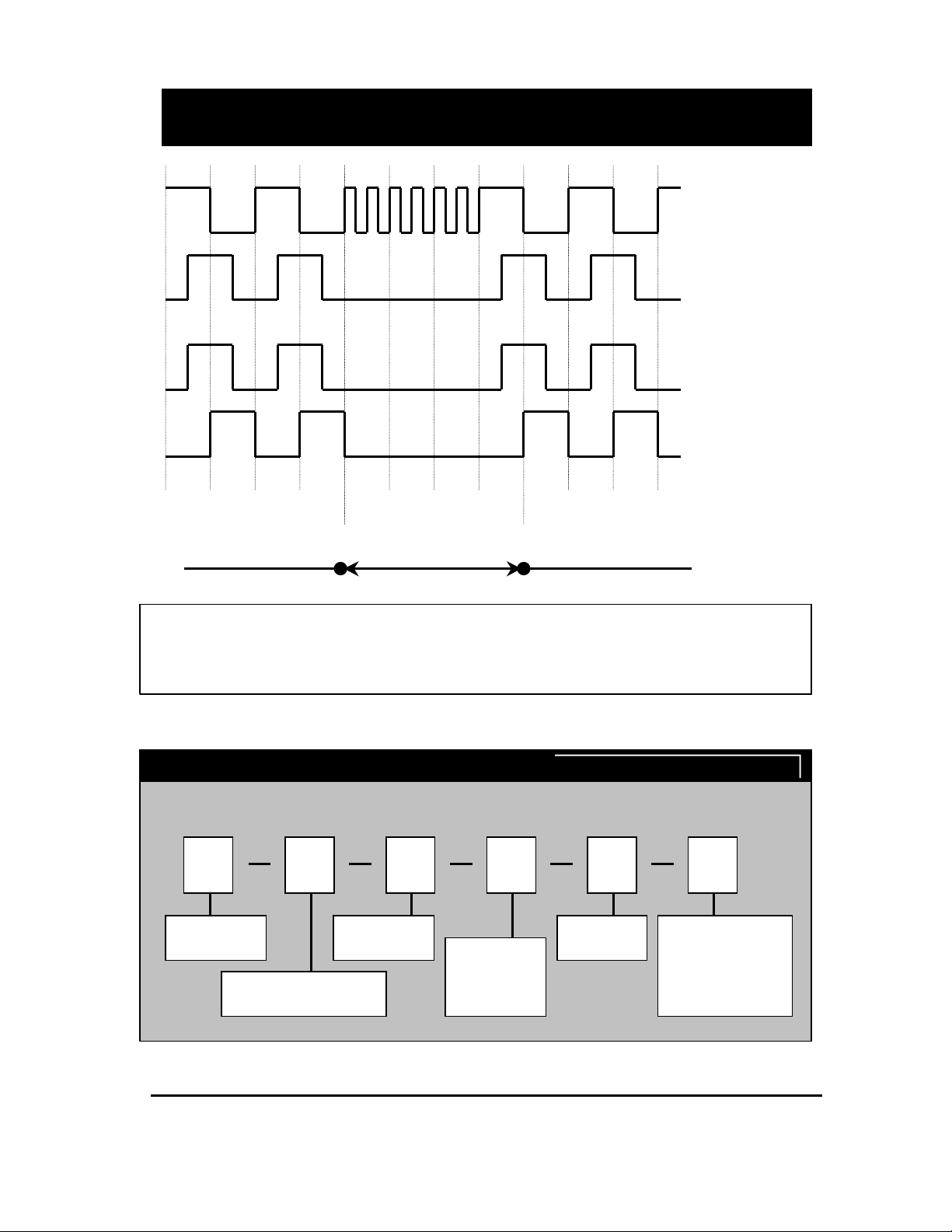

WAVEFORM DIAGRAM

ILLUSTRATING OPERATION OF THE ANTI-DITHER FUNCTION

Mechanical system stop

-- Or -- vibration imposed

Dither or vibration – could

produce error in controller

Mechanical system restart

-- Or-- vibration removed

ENCODER

OUTPUTS

A CHANNEL

B CHANNEL

OUTPUT FROM ANTI-

DITHER MODULE

A’ CHANNEL

B’ CHANNEL

Note: For simplicity of illustration, the inverted channels, A/ and B/ have not been shown.

The index, or Z, channel is also not shown in the above diagram but is passed through directly

as an optically isolated signal and maintains its original relationship to the encoder output

channel.

Anti-Dither Module Order Options

Use this diagram, working from left to right to construct your model number:

Example: EM-DR1-AD-24-TB-28V/V

EM AD DR1 24 TB 28V/V

EM = Electronic

Module

DR1 = 114.5mm X 99mm X

22.5mm DIN Rail Package

AD = Anti-Dither

Function

Output from

Encoder

5 = 5VDC

15 = 12-15 VDC

24 = 24VDC

TB = Terminal

Block

Supply Voltage/Output

from AD Module

28V/V: V

28V/5: V

28V/OC: Vout = Open

Collector

= Vin

out

= 5 VDC

out

Specification No. 02125-003 Rev0611

Loading...

Loading...