BeefEater BS79900 Installation Guide

BBQ AND SIDE BURNER

WARNING

GAS CONVERSION INSTRUCTIONS

95164K

DISCOVERY i-1000

NATURAL GAS

CONVERSION KIT

Suits Discovery Series (2002 onwards)

Kit includes:

1 x NG Hose and Regulator (Sold separately in USA)

5 x 1.9mm Injectors Hex N/G M5 Thread (code: 040145)

1 x 1.7mm Injector Hex N/G M5 Thread (code: 040170)

1 x NG Label (code: 020404) SL4000 Series

95170K and 95170SL

SIGNATURE 3000S AND

SL4000 NATURAL GAS

CONVERSION KIT

Suits the following BeefEater models:

Signature S-3000 Series (August 2002 onwards)

Balcony Series (August 2002 onwards)

Kit includes:

1 x N/G Hose and regulator (Sold separately in USA)

6 x 2.10mm Hex Head N/G injectors M5 Thread

1 x Pilot jet Injector 0.95mm 040259

– previously 95170SL only

(Not required for Signature 3000S)

1 x NG Label (code: 020404)

95167

SIGNATURE 3000E

NATURAL GAS

CONVERSION KIT

Suits models from 2011 onwards

Kit includes:

1 x Label “NATURAL GAS” Black 020404

5 x Injector NG 2.10 mm M6 040178

1 x Injector NG 2.10 mm M5 040168

1 x Nat/Gas Hose & Reg PVC 750mm 95162

(Sold separately in USA)

Important Safety Instructions

WARNING

All service to the appliance must be undertaken by a

qualified gas service agent.

Do not smoke or use a naked flame within the vicinity of the

appliance or gas line when performing gas conversion or

service of any kind.

Always carry out a gas leak test after any work has been

carried out on the appliance.

If your barbecue is fitted with an optional side burner, gas

conversion must be carried out at the same time.

Always use the correct size socket spanner / wrench to

remove or replace the gas injectors. Do not use pliers or

any other type of tool that may squeeze the head of the gas

injector. This may cause the gas orifice to change shape

thereby adversely affecting the gas flow to each burner.

Gas injectors are made of brass and have a fine thread which

must be treated with care when being handled. Remove and

replace injectors with care.

TIPS & INFORMATION

BBQ AND SIDE BURNER GAS CONVERSION INSTRUCTIONS

DISCOVERY i-1000 SERIES

LPG to Natural Gas Conversion

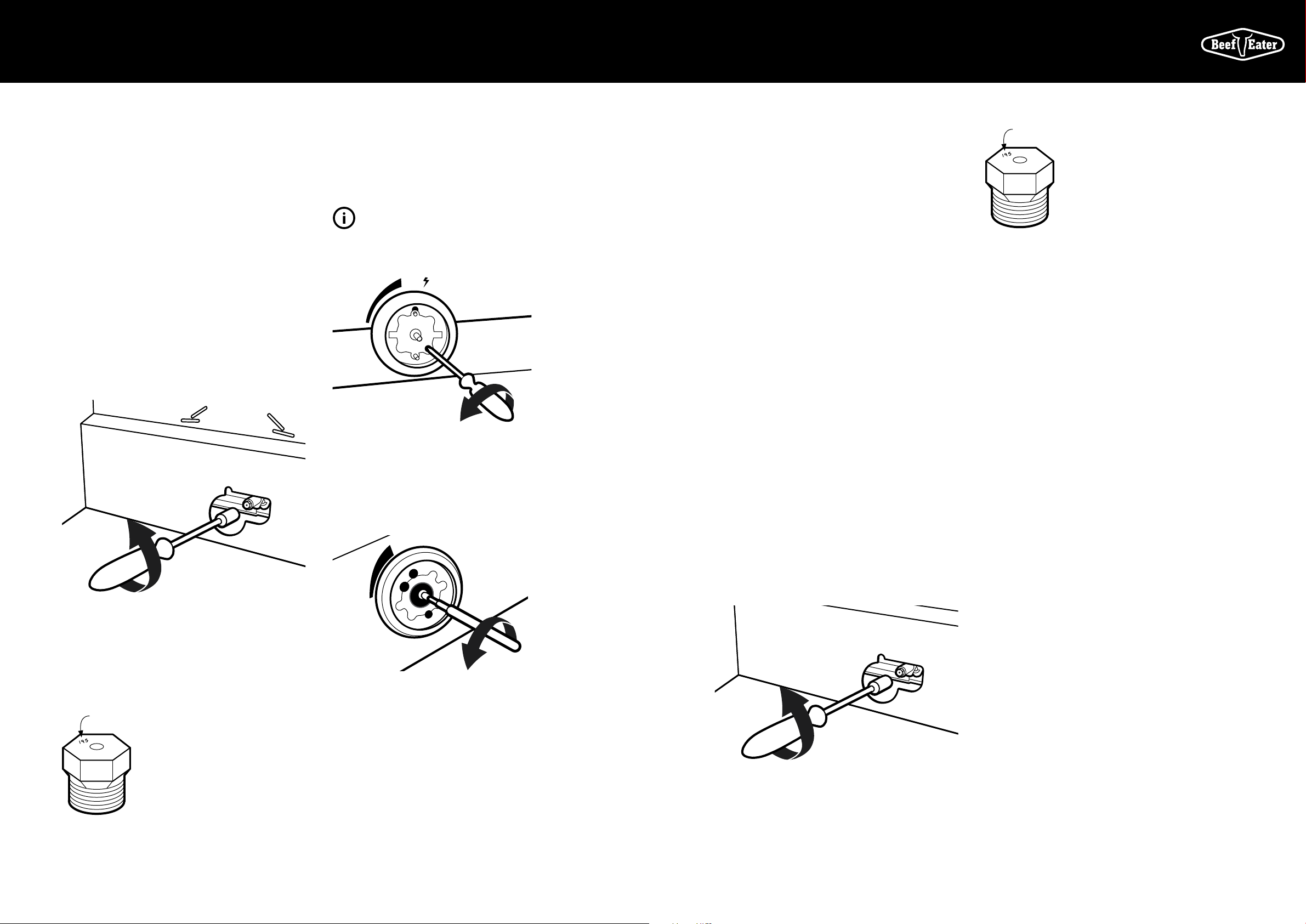

1. Removing And Replacing Gas Injectors

• Turn off the gas supply valve on the gas cylinder. Ensure

that all gas controls on the barbecues are in the OFF

position.

• Disconnect the hose and regulator from the gas cylinder

and disconnect the gas hose from the barbecue gas inlet

using a 19mm open-ended spanner / wrench.

• Remove all cooking plates, grills, and Vaporizers from

the barbecue.

• Remove the ‘R’ shaped locking clips that hold each

burner in place and remove all burners from the

barbecue. This needs to be done at the rear of the BBQ.

• The gas injectors for each burner are located within

deep pockets on the front firewall of the barbecue.

Remove each gas injector from the end of each valve body

using a 6mm socket spanner / wrench, turning gently in a

counter clockwise direction.

Be careful not to block the orifice at the end of the valve

where the gas injector is fitted and do not remove any of the

thread sealing compound from the orifice where the injector

is located.

Look here for

identification reference

Check the identification mark stamped on the Hex Head

of the injector to confirm that it is the correct size (NG:

1.90mm) before proceeding to fit it into the valve.

When fitting the NG gas injectors to the end of the valve body

be sure to seat the injector correctly on the thread before

turning it in a clockwise direction until it is seated firmly in

place. Do not over tighten.

2. Adjusting Low Flame Control Screw

IMPORTANT

For 3000E - Valves do not have Low-Flame adjustment

screw, and are adjusted at factory.

Low flame

adjustment

The low flame adjustment must be carried out for each

burner. The low flame adjustment screw in Ignition valves

is located on the lower right hand corner of the front of the

valve body. The screw can be accessed from the front of the

BBQ by removing the control knob of each burner. To set the

low flame adjustment for Natural Gas, use a 4mm wide, flat

blade screwdriver.

Non Ignition

Valve Low flame

adjustment

To set the Natural Gas low flame adjustment for Non Ignition

Valves: Use a 2.5mm wide, flat blade screwdriver. The screw

is located inside the knob spindle.

The Low flame adjustment screw must be turned counterclockwise ¾ turn.

3. Connecting the Natural Gas Hose and Regulator.

Connect the Natural Gas hose and regulator (where

applicable) to the gas inlet on the barbecue using a 19mm

spanner / wrench. Tighten firmly but do not over tighten.

Connect gas regulator to gas source line and perform a gas

leak test as per instructions in the barbecue operating and

assembly instructions.

4. Replace all Burners into Position in the Barbecue.

Refit the locking clips that hold each burner in position.

Replace all Vaporizers, cooking plates and grills.

Check the operation of each burner. It may be required to

open the Air-Mixture screw, located at the burner venture, a

couple of turns to get the correct flame.

5. Change the gas type label.

Peel the “Natural Gas” gas Type label from backing sheet

and place this over the existing LPG Gas label to indicate that

the unit is configured for Natural Gas.

6. Side Burner

Side burner uses the 1.7mm injector. Other details are same

as described for main burners above.

SIGNATURE SERIES

LPG to Natural Gas Conversion

1. Removing And Replacing Gas Injectors

• Turn off the gas supply valve on the gas cylinder. Ensure

that all gas controls on the barbecues are in the OFF

position.

• Disconnect the hose and regulator from the gas cylinder

and disconnect the gas hose from the barbecue gas inlet

using a 19mm open-ended spanner / wrench.

• Remove all cooking plates, grills, Vaporizers and heat

reflectors (where fitted) from the barbecue.

• Remove the ‘R’ shaped locking clips that hold each

burner in place and remove all burners from the

barbecue. This needs to be done at the rear of the BBQ.

BETTER PIC TO COME

The gas injectors for each burner are located within deep

pockets on the front firewall of the barbecue. Remove

each gas injector from the end of each valve body using a

6mm socket spanner / wrench, turning gently in a counter

clockwise direction.

Be careful not to block the orifice at the end of the valve

where the gas injector is fitted and do not remove any of the

thread sealing compound from the orifice where the injector

is located.

Look here for

identification reference

Check the identification mark stamped on the Hex Head

of the injector to confirm that it is the correct size (NG:

2.10mm) before proceeding to fit it into the valve.

When fitting the NG gas injectors to the end of the valve body

be sure to seat the injector correctly on the thread before

turning it in a clockwise direction until it is seated firmly in

place. Do not over tighten.

2. Adjusting Low Flame Control Screw

The low flame adjustment must be carried out for each

burner. The low flame adjustment screw is located on

the lower right hand corner of the front of the valve body.

The screw can be accessed from the front of the BBQ by

removing the control knob of each burner.

To set the low flame adjustment for NG, use a 4mm wide, flat

blade screwdriver.

The Low flame adjustment screw must be turned counterclockwise ¾ turn.

NOTE: For Signature 3000E, no adjustment is needed

3. Connecting The Natural Gas Hose And Regulator

Connect the Natural gas hose and regulator (where

applicable) to the gas inlet on the barbecue using a 19mm

spanner / wrench. Tighten firmly but do not over tighten.

Connect gas regulator (if required) to the gas source line and

perform a gas leak test as per instructions in the barbecue

operating and assembly instructions, or see page 4 of this

instruction manual.

4. Replace All Burners into Position in the Barbecue

Refit the locking ‘R’ clips that hold each burner in position.

Replace all vaporizers, cooking plates and grills. Check the

operation of each burner. It may be required to open the

Air-Mixture screw, located at the burner venture, a couple of

turns to get the correct flame.

5. Change the gas type label.

Peel the “Natural Gas” gas Type label from backing sheet

and place this over the existing LPG Gas label to indicate that

the unit is configured for Natural Gas.

6. Side Burner

Side burner uses same injector as main burners*, and

converted in same manner as above.

* On the SL4000 Side Burner, also need to replace the Pilot

Nozzle. see last page for details.

NOTE: To convert from NG to LPG, reverse the above steps.