Beefeater BS30050 User Manual

Assembly and Operating Instructions

SIGNATURE

SERIES

PLUS, S-3000E, S-3000S

BALCONY

FOR OUTDOOR USE ONLY AUSTRALIA / NEW ZEALAND

WARNING

WARNING

TIPS & INFORMATION

ENVIRONMENTAL TIPS

CONTENTSCONGRATULATIONS

Dear customer,

Congratulations and thank you for choosing our barbecue�

We are sure you will find it a pleasure to use� Before you use

the barbecue, we recommend that you read through the

relevant sections of this manual, which provide a description

of your appliance and its functions�

To avoid the risks that are always present when you use

an appliance, it is important that the appliance is installed

correctly and that you read the safety instructions carefully to

avoid misuse and hazards�

We recommend that you keep this instruction booklet

for future reference and pass it on to any future owners�

After unpacking the appliance, please check it is not

damaged� If in doubt, do not use the appliance but contact

your local customer care centre�

This appliance complies with requirements of Australian

Standards AS4557�

CONDITIONS OF USE

These important notes apply to your appliance

• This appliance MUST be installed and serviced only

by a qualified licensed person�

• This product is intended for personal, domestic or

household use only, not commercial use�

• This product is intended for outdoor use only�

• This product must be installed, operated and maintained

as per the instructions�

• Ventilation holes in the unit must not be obscured by the

installation�

Please ensure you read the instruction manual fully

before you call for service, or a full service fee could

be applicable.

Record model and serial number here:

Important safety instructions ��������������������������������������������������������3

Gas cylinder safety ������������������������������������������������������������������������4

Gas leak test procedure ����������������������������������������������������������������4

Tools required ��������������������������������������������������������������������������������5

Assembly instructions �������������������������������������������������������������������6

Installation instructions ����������������������������������������������������������������9

Assembly and gas connection instructions for side burner ������10

Assembly instructions for trolley ������������������������������������������������11

Operating instructions ����������������������������������������������������������������18

Hood assembly instructions��������������������������������������������������������22

Getting the most from your roasting hood ���������������������������������23

Help guide ������������������������������������������������������������������������������������25

Care and maintenance ����������������������������������������������������������������27

Locating your barbecue and side burner �����������������������������������31

Outdoor installation instructions ����������������������������������������������� 32

Specifications ����������������������������������������������������������������������������� 33

Notes ������������������������������������������������������������������������������������������� 34

Warranty ��������������������������������������������������������������������������������������35

Please read the user manual carefully and store in a handy

place for later reference�

The symbols you will see in this booklet have these

meanings:

WARNING

This symbol indicates information concerning your

personal safety.

CAUTION

This symbol indicates information on how to avoid

damaging the appliance.

IMPORTANT

This symbol indicates tips and information about use

of the appliance.

Model number: �������������������������������������������������������������������������������

Serial number: ��������������������������������������������������������������������������������

PNC: ������������������������������������������������������������������������������������������������

2 CONTENTS

ENVIRONMENT

This symbol indicates tips and information about

economical and ecological use of the appliance.

TIPS & INFORMATION

ENVIRONMENTAL TIPS

WARNING

WARNING

WARNING

IMPORTANT SAFETY INSTRUCTIONS

Please read the user manual carefully and store in a handy

place for later reference�

IMPORTANT

Important – check for any damages or marks

If you find the barbecue is damaged or marked, you must

report it within 7 days if you wish to claim for damage/

marks under the manufacturer’s warranty. This does not

affect your statutory rights.

ENVIRONMENT

Information on disposal for users

• Most of the packing materials are recyclable. Please

dispose of those materials through your local recycling

depot or by placing them in appropriate collection

containers.

• If you wish to discard this product, please contact

your local authorities and ask for the correct method

of disposal.

WARNING

This appliance must be serviced only by a qualified

licensed person.

Improper installation, adjustment, alteration or

maintenance can cause injury or property damage.

Please contact your nearest Electrolux Service

Department for additional information or assistance

for an approved installer.

NOTE: This manual must remain with the owner for

future reference�

WARNING

• Do not lean over barbecue when lighting.

• Do not leave the barbecue unattended when alight.

• Do not delay lighting once the gas has been turned on.

• Do not store or use aerosol cans in the vicinity of

the barbecue.

• Do not store flammable liquids in the vicinity of the

barbecue.

• Do not use caustic or abrasive based cleaners on

the barbecue.

• Do not attempt to dismantle or adjust the control

valves.

• Do not attempt to dismantle or adjust the regulator.

• Do not test for leaks with a naked flame.

• Do not modify the construction of this appliance or

modify the injector orifice size.

• Do not obstruct any ventilation of the barbecue.

• Do not allow children to operate or play near the

barbecue.

CAUTION

Barbecue is supplied set for LPG. A Natural Gas Conversion

kit is available. A Universal LPG and propane conversion kit

is included if required. Conversion of this unit to Universal

LPG or propane must be carried out by a qualified licensed

person and a Certificate of Compliance must be issued

to the owner at the completion of the installation and

conversion.

3SAFETY

GAS CYLINDER SAFETY GAS LEAK TEST PROCEDURE

Gas Cylinder Safety Information

This appliance is designed to be used with a gas cylinder not

exceeding 9KG (20lbs) capacity�

The Gas cylinder must be constructed and marked in

accordance with specifications for LP Gas Cylinders of

the:(USA) U�S� Dept� of Transportation (DOT) or the National

Standard of Canada, CAN/CSA - B339, Cylinders, Spheres or

Tubes for the transportation of dangerous goods�

The gas cylinder supply valve must be turned off when

the appliance is not in use� Gas cylinders must be stored

outdoors, out of reach of children and must not be stored in

a building, garage or any other enclosed area�

The gas cylinder used must incorporate a safety collar to

protect the valve assembly�

IMPORTANT!

When disconnecting and removing the gas cylinder for the

purpose of refilling, always observe the following procedure�

Ensure that all gas control valves on the appliance and the

gas cylinder are turned off before disconnecting the gas line

from the cylinder�

Do not smoke or use a naked flame near the appliance or

gas cylinder while disconnecting the gas line between the

appliance and gas cylinder�

Remove the gas cylinder from the enclosure before

disconnecting the gas line from the appliance�

Tighten all connections before placing the gas cylinder back

in its enclosure�

The Gas Leak Testing Procedure should be conducted every

time the gas cylinder is refilled and reconnected to the

appliance - before using the appliance�

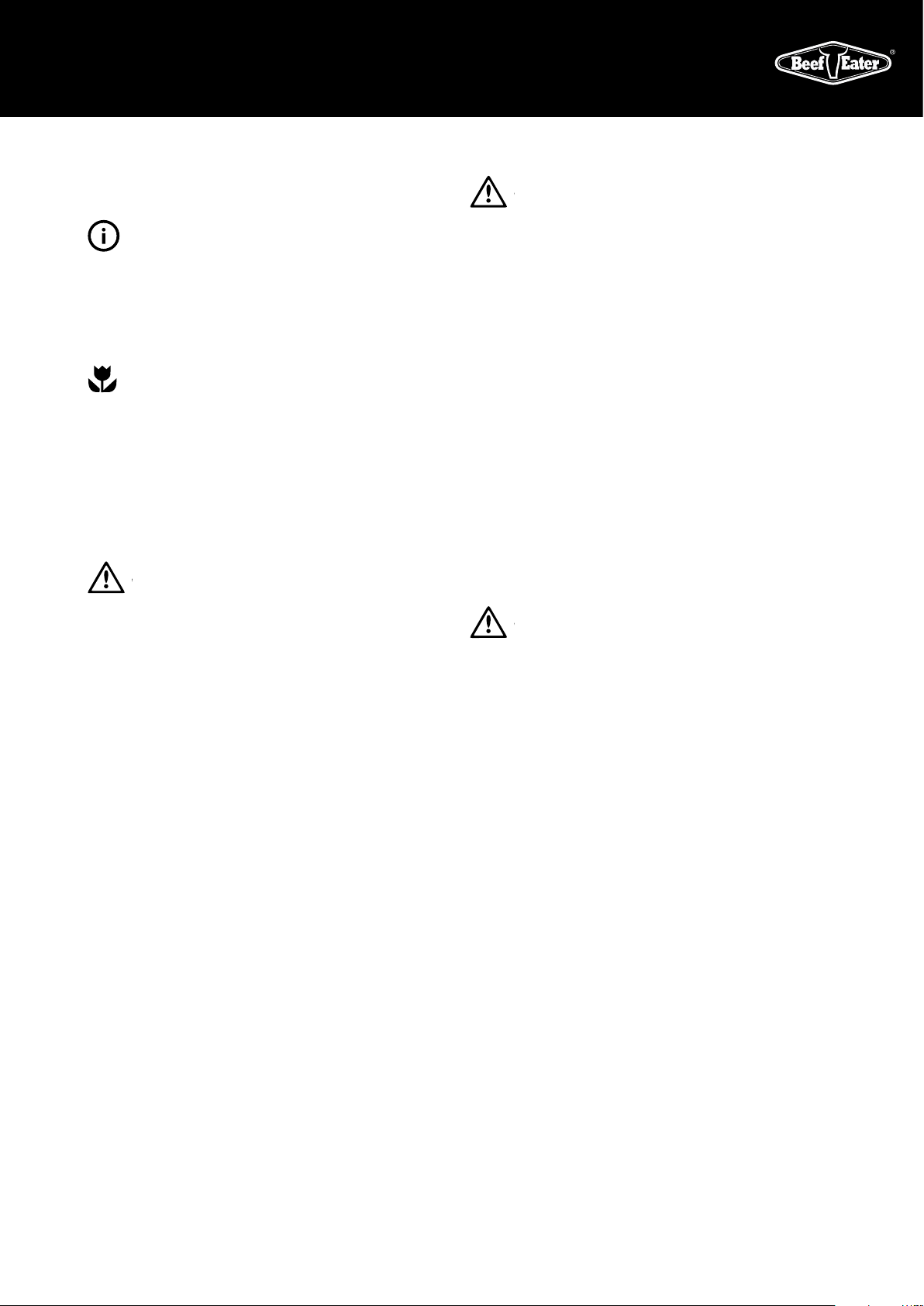

Regulator connection (Fig 1 & 2)

1� Check that all control knobs are in the ‘Off’ position�

2� Make sure the cylinder valve is off by turning the valve

knob clockwise�

3� Remove the protective cap from the cylinder if present�

4� Leak test the connection with a soapy water solution

(See Gas Leak Testing Procedure)

Hose and regulator replacement must be a genuine part

specified for this appliance and is obtainable from your

nearest BeefEater stockist�

Use the following procedure to check for gas leaks�

Never use a naked flame to check for gas leaks�

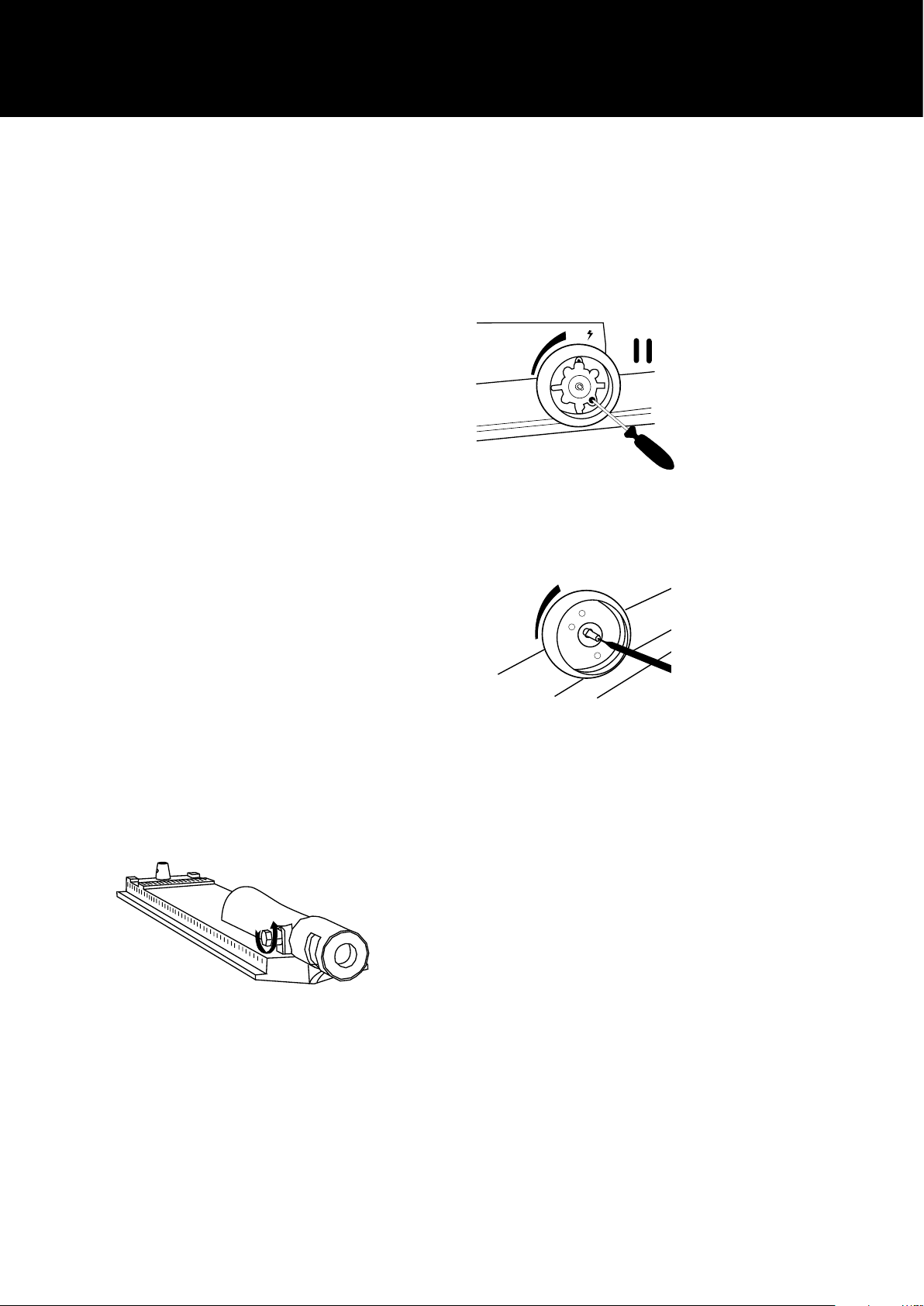

FIG 1

Standard POL regulator

Gas shutoff valve

Tighten in this direction

Regulator and hose

Gas cylinder

Protector cap

FIG 2

Bleeder valve screw

Quick connect regulator

Gas shutoff valve

Tighten in this direction

Regulator and hose

Gas cylinder

Protector cap

Bleeder valve screw

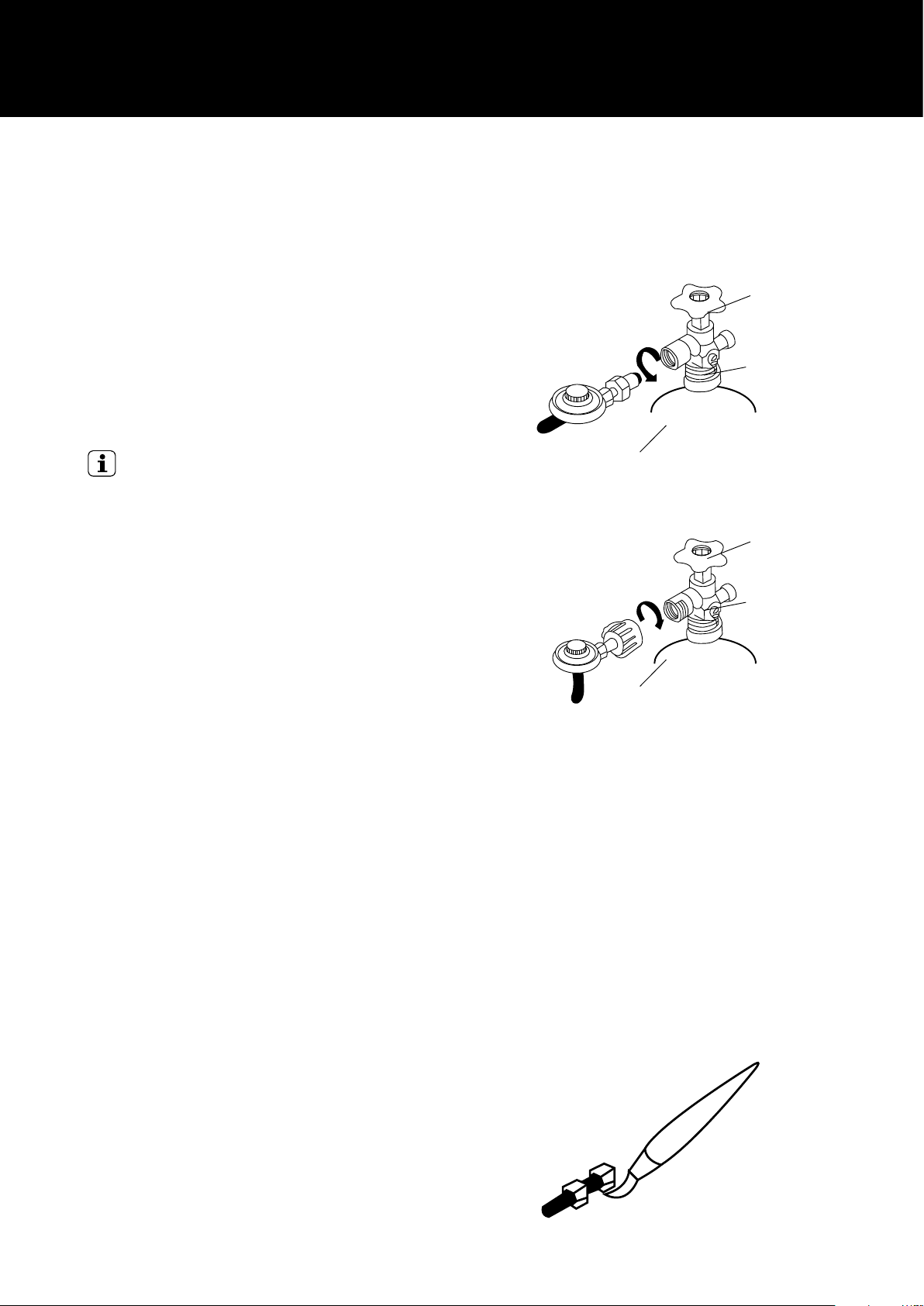

1� In a small container, mix up a solution of water and

detergent or soap� Mix the solution well�

2� For LPG make sure that the gas supply valve on the gas

cylinder is turned on� For Natural gas make sure that

the gas line is correctly fitted to the appliance�

3� Make sure that the gas control valves on the appliance

are all turned off�

4� Using a brush or spray bottle apply the solution to the

gas line and each join in the gas line� See Fig 3�

5� Bubbling of the solution will indicate that there is a

leak present�

6� Re-tighten or re-seal any joints that are leaking�

7� If a leak persists then contact your distributor or the

manufacturer for assistance�

4 GAS CYLINDER SAFETY

FIG 3

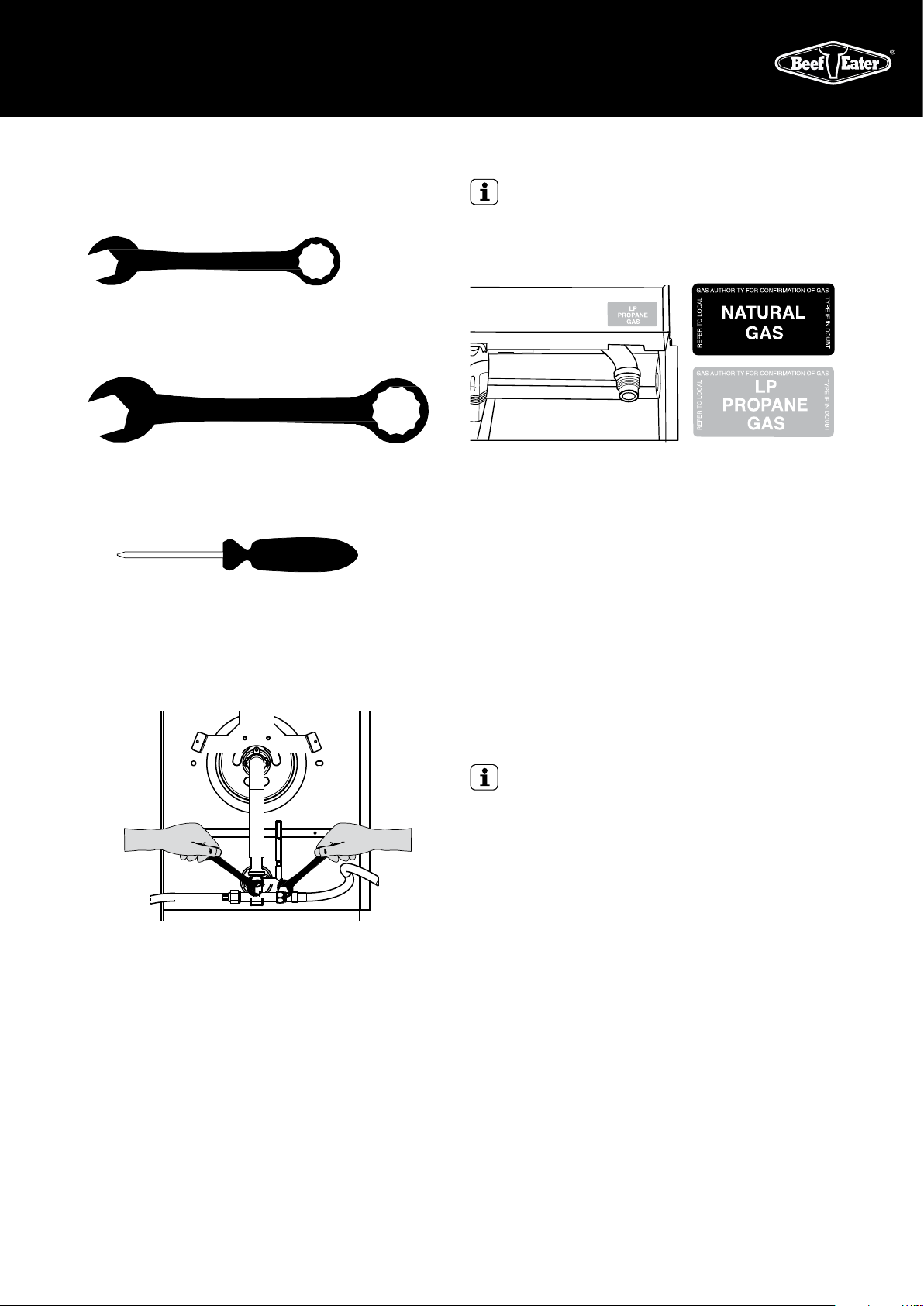

TOOLS REQUIRED

You will need the following tools to assemble your barbecue�

10mm Spanner (wrench) all body nuts

19mm Spanner (wrench) for gas inlet connection

Phillips Head Screwdriver

NOTE: Always use the correct size spanner (wrench) to

tighten gas fittings� Ensure that all gas fittings are spanner

tightened and then leak tested before continuing with

operation of the appliance�

FIG 4

IMPORTANT!

Always check the gas label on the appliance to ensure that

you have the correct gas configuration.

FIG 5

For Your Safety

If you smell gas:

1� Shut off gas to the appliance�

2� Extinguish any open flame�

3� Open lid�

4� If odour continues, immediately call your gas supplier or

your fire department�

For Your Safety

1� Do not store or use gasoline or other flammable vapours

or liquids in the vicinity of this or any other appliance�

2� An LPG cylinder not connected for use shall not be

stored in the vicinity of this or any other appliance�

IMPORTANT!

• The cylinder supply system must be arranged for

vapour withdrawal. This normally means the cylinder

must be upright.

• Do not store a spare LP-gas cylinder under or near

this appliance.

• Never fill the cylinder beyond 80% full.

If these directions are not followed exactly, a fire causing

death or serious injury may occur.

5TOOLS

ASSEMBLY INSTRUCTIONS

Assembly notes

Before any assembly or installation is attempted it is

important that you check for damage or missing parts�

Your dealer or the manufacturer must be notified of any

problems immediately before proceeding�

The main frame of the barbecue has been factory assembled

requiring only the following simple steps for completion�

Check the “Gas Type “ label attached to barbecue and side

burner to be certain this gas type is the one required for your

use eg� Propane / LPG or Natural Gas� See Fig 5�

Trolleys, roasting hoods and side burners are optional so

read this manual in conjunction with the manual that comes

with each accessory before attaching any other components�

Attach the roasting hood last of all�

Assembly procedure

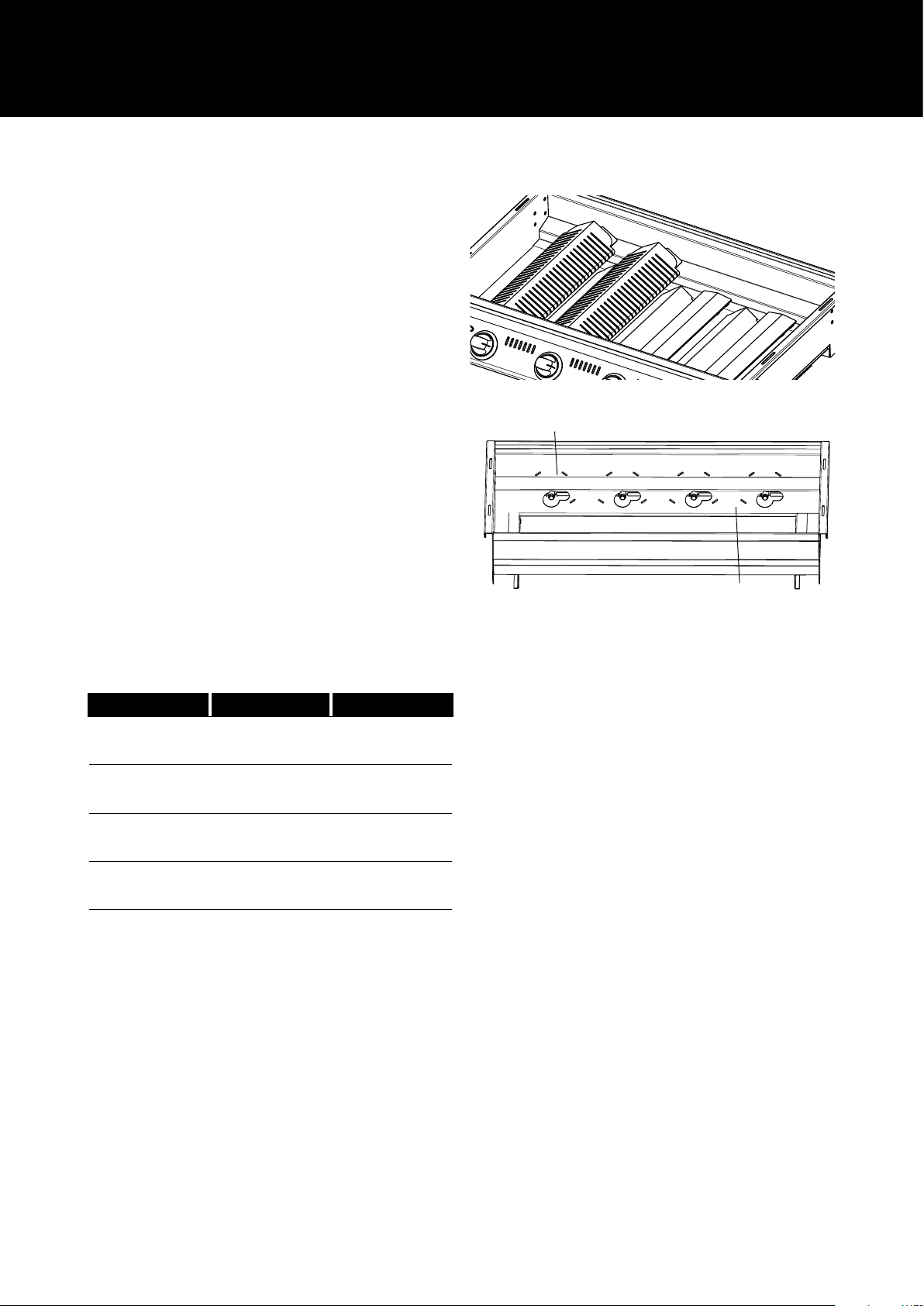

Heat reflectors, burners and vaporisers

The modular vaporiser grid system has been designed to

maximise the performance of your BeefEater barbecue the

reflectors fit between each burner� They reflect heat from the

burners, upwards to the cooking surfaces�

The vaporizers are designed to vaporise fats and juices from

the meat� One vaporiser is fitted over each burner that is

located under the grill� The vaporisers reduce flare-ups and

help to add that great barbecue flavour�

FIG 6

FIG 7

Upper slots for vaporisers

Lower slots for heat reflectors

How many vaporisers and reflectors are there?

MODEL VAPORISER REFLECTOR

2 BNR 2 1

3 BNR 2 2

4 BNR 3 3

5 BNR 3 4

6

ASSEMBLY INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

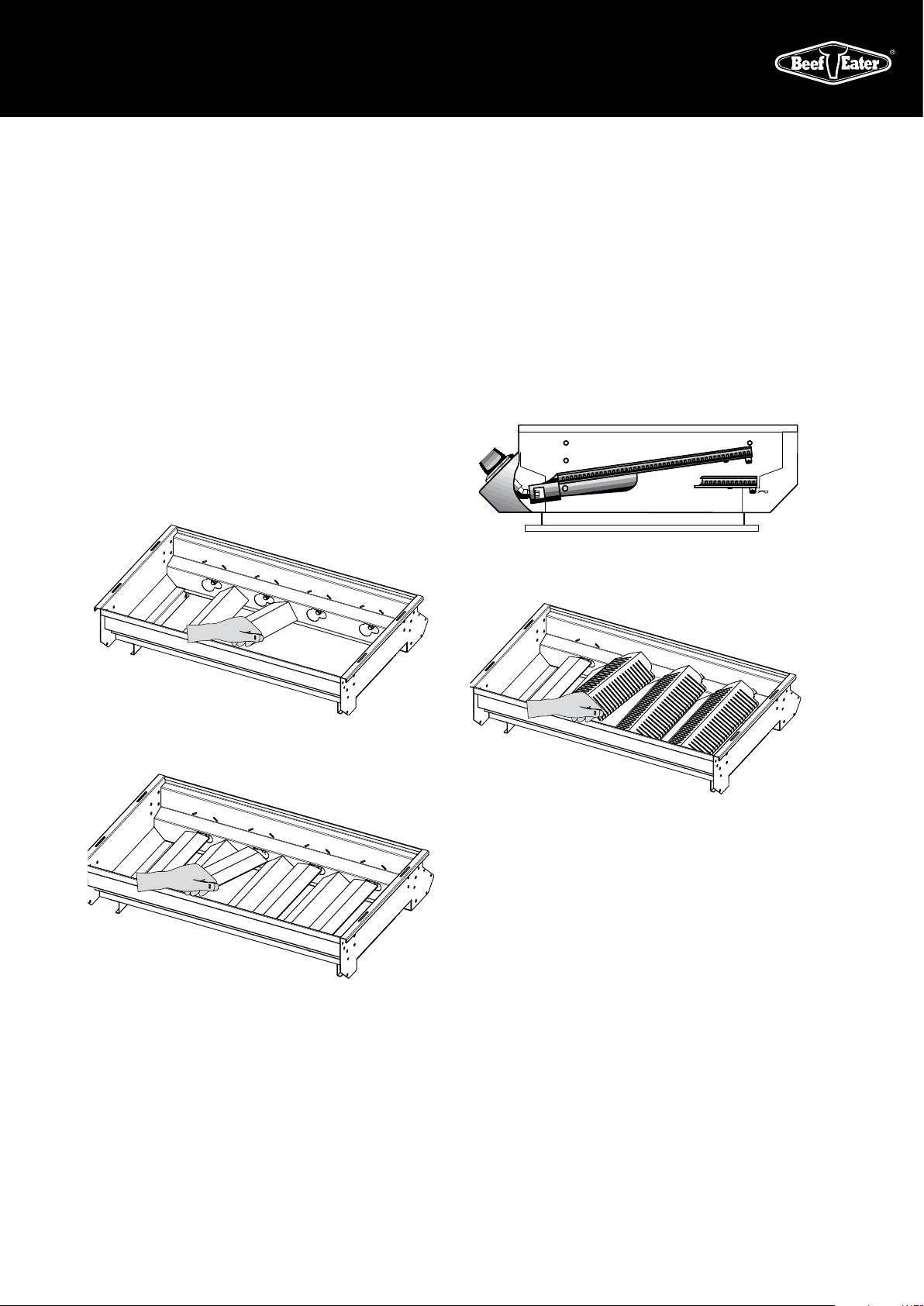

Fitting the heat reflectors

Completely remove all of the plastic film from the reflectors�

The tabbed ends of the heat reflectors face forward to the

front of the barbecue frame� The tabs fit into the slots in the

front end of the barbecue (behind the control fascia)� Key

the tabs of the vaporisers into the lower slots (between the

burners)� Key the tabs of each reflector into the slots� If slots

are partially covered with enamel, work the tabs until the

enamel clears� See Fig 8�

Fitting the burners

Remove the retaining clips from the burners, then fit the

burners - open end first, over the brass stem of the control

valves at the front of the barbecue, allowing the rear

burner lug to locate into the cross-lighting channel and

corresponding hole in the support panel at the rear or the

barbecue� To secure burners fit retaining clips (“R” shape)

into burner lugs� See Fig 9 & 10�

FIG 8

Fitting the vaporisers

Remove the protective plastic film from each vaporiser and

then fit the vaporisers to the barbecue� The tabbed ends

of the vaporisers face forward to the front of the barbecue

frame� The tabs fit into the slots in the front end of the

barbecue (behind the control fascia)� Key the tabs of the

vaporisers into the upper slots� The vaporisers should be

fitted to the same side of the barbecue to which the grill is

to be placed� (They will not work if fitted under the plate)� If

slots are partially covered with enamel, work the tabs until

the enamel clears� See Fig 11 & 12�

FIG 10

FIG 11

FIG 9

7ASSEMBLY INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

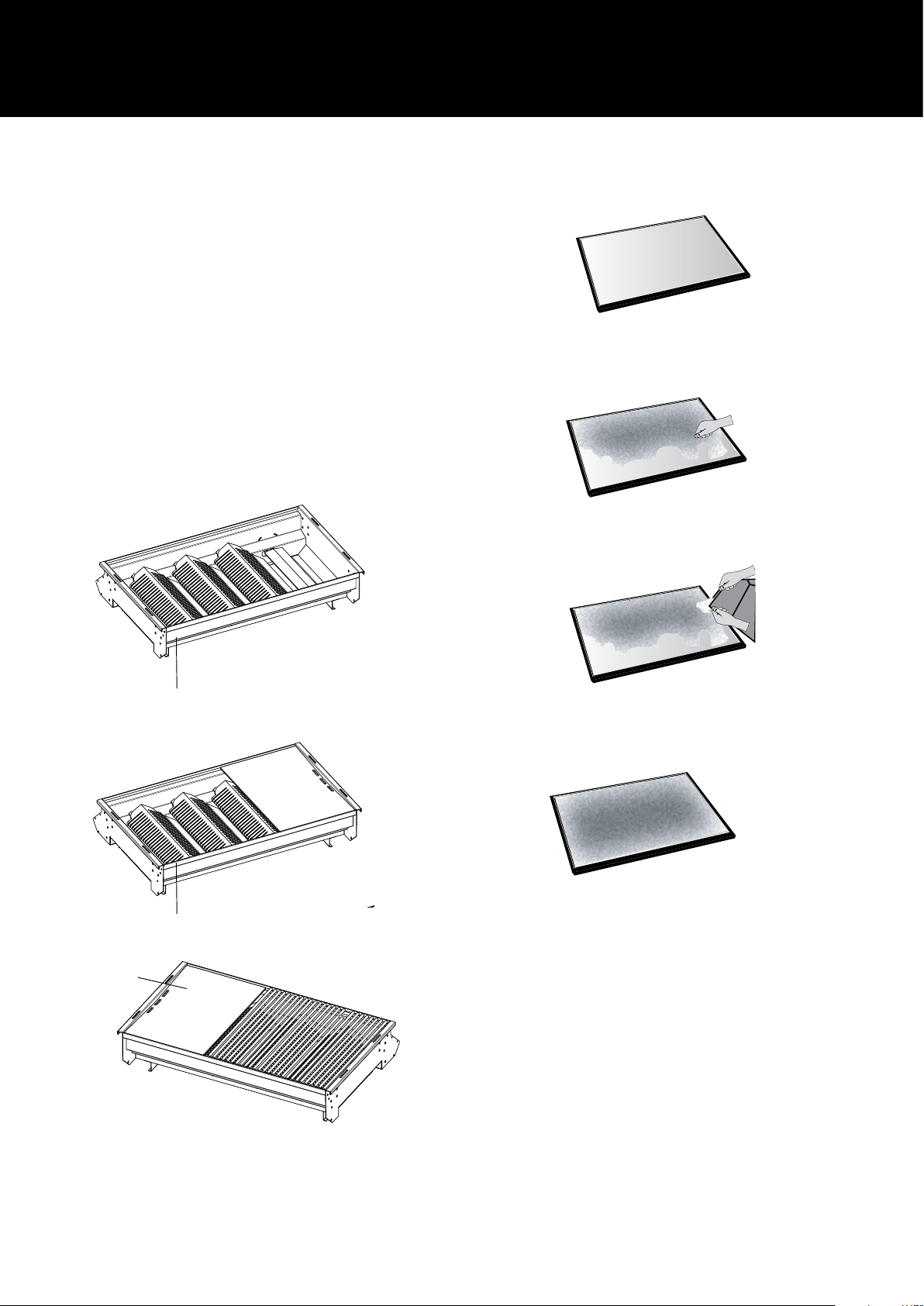

Fitting the cooking plates and grills

We recommend fitting the plate to the left-hand side of the

barbecue frame (with the drain hole to the extreme left)�

The grill or grills can be fitted to the right hand side of the

barbecue frame� Grills must always be positioned over the

Vaporizer grids� See Fig 13�

BeefEater 2, 3 & 4 burner barbecues come standard with 1/2

plate and 1/2 grill and are approved for use with a maximum

of 50% plate over the entire cooking area� Do not replace

the grill with another plate as this will cause severe heat

damage to the appliance�

BeefEater 5 burner barbecues come standard with 1/3 plate

and 2/3 grill and are approved for use with a maximum of

2/3 plate� Do not cover the entire surface of the barbecue

frame with plates as this will cause severe heat damage to

the appliance�

FIG 12

FIG 15

Neatly line the drip tray with aluminium foil

FIG 16

Add absorbent material

FIG 17

Rear of barbecue

FIG 13

Rear of barbecue

FIG 14

Grease drain hole

Spread the absorbent material out evenly

FIG 18

Ensure that the absorbent material is not more

than 6mm deep�

Fitting the grease tray

Neatly line the drip tray with a couple of sheets of

aluminium foil� Cut the foil to shape and make sure that the

foil sits on the bottom of the tray or corners of the foil so

that it does not foul in the tray sliders on the bottom of the

barbecue frame� The foil will aid in clean up & help reduce

leakage� Fill the tray with a 6mm (1/4”) layer of dry sand

or other non-combustible absorbent material to absorb

grease� Change the foil and absorbent material regularly to

reduce the likelihood of a drip tray fire� See Fig 15-18�

8

ASSEMBLY INSTRUCTIONS

INSTALLATION INSTRUCTIONS

WARNING

IMPORTANT

This appliance must be installed in accordance with the

installation requirements of the LOCAL GAS and ELECTRICITY

supply authority, or the appropriate installation code issued

by the A.G.A. and the A.L.P.G.A. Servicing should only be

carried out by an authorised person.

This appliance:

Must have a minimum clearance from combustible

materials of all sides of the barbecue of 450 mm (18”).

Should not be installed under or on any combustible surface.

Must be tested for safe and proper operation on completion

of installation and prior to leaving the site. Keep ventilation

opening of any cylinder enclosure clear and free of any debris.

Check ‘Gas Type’ label & data plate attached to right side

of barbecue.

LP Gas / Propane

A� Fit the regulator to the LPG cylinder� See regulator

connection page 2, Fig 1�

B� Connect the hose and regulator to the gas inlet at the

right hand side of the barbecue� The gas inlet of the

barbecue is 3/8 SAE male flare fitting� Do not subject the

hose to twisting�

C� Secure all joints spanner (wrench) tight but do not over-

tighten� Check for leaks after turning on gas supply by

brushing onto all joints a solution of water and detergent�

Bubbling of the solution will indicate leaks� Re-tighten or

reseal any leaking joints� If leaks persist turn off the gas

supply and consult your dealer�

D� Following operating instructions light each burner and

check for a clear blue flame with just a tip of yellow�

Excess yellow tipping can be adjusted using the screw

on the side of the burner� Turn the screw in a counter

clockwise rotation to remove the yellow�

E� For mobile trolley installations, when using a flexible

hose to a fixed fuel source, a chain or similar restraining

device must be fitted to prevent strain on the gas supply

hose or accidental uncoupling� Do not subject the hose

to twisting�

F� For build-in situations allow adequate ventilation for

the barbecue and cylinder� Keep the cylinder away

from heat and allow clear access to the gas supply

hose and regulator�

WARNING

The flexible PVC hose assembly supplied must not be

exposed to temperatures in excess of 60°C (140°F).

DO NOT expose to the sun’s direct heat and DO NOT allow

the hose to come in contact with the hot surface of the

barbecue body.

Recommended minimum LPG cylinder capacity for use with

this appliance is 4kg� Maximum LPG cylinder capacity for

use with this appliance is 10kg�

Do not install the gas cylinder beneath the barbecue unless

in conjunction with an approved separator panel�

Natural Gas

(Natural Gas installation should be carried out by a qualified

gas fitter).

A� BeefEater Natural Gas barbecues are designed

for low pressure (4�0” WC, 1�00KPa) to be used

as freestanding units, trolley mounted, or built

into brickwork�

B� Fit the natural gas regulator supplied directly to the gas

inlet via hard plumbing and install a shutoff valve within

easy reach in the gas line� Secure all joints spanner tight

but do not over-tighten� Check for leaks after turning

on gas supply by brushing onto all joints a solution

of water and detergent� Bubbling of the solution will

indicate leaks� Re-tighten or reseal any leaking joints�

If leaks persist turn off the gas supply and consult the

manufacturer or dealer�

C� Test gas pressure by removing the last burner from the

left hand side of the barbecue and attaching a hose and

pressure gauge to the end of the gas valve� Turn on two

burners and check the pressure� Inlet pressure should

be 4�0” WC or 1�00 KPa�

D� Following operating instructions light each burner and

check for a clear blue flame with just a tip of yellow� Avoid

excess yellow tipping by adjusting the screw on the side of

the burner, counter-clockwise rotation removes yellow�

E� For mobile trolley installations a chain or similar

restraining device must be fitted to prevent strain or

accidental uncoupling of the gas supply line�

D� For build-in situations allow adequate ventilation for

the barbecue�

The barbecue appliance must be isolated from the gas

supply piping system by closing its manual shutoff valve

during any pressure testing of the gas supply piping system�

Installation to Natural Gas must be carried out by an

authorised person.

Yellow tipping

Light blue

Dark blue

Right Wrong

Yellow tipping

Light blue

Dark blue

INSTALLATION INSTRUCTIONS

9

ASSEMBLY AND GAS CONNECTION INSTRUCTIONS FOR SIDE BURNER

Converting the unit to natural gas

1� Turn off the gas supply valve on the gas cylinder� Ensure

that all gas controls on the BBQ are in the OFF position�

2� Disconnect the hose and regulator from the gas

cylinder and disconnect the gas hose from the barbecue

gas inlet using a 19mm open-ended spanner / wrench�

3� Open hood and remove all cooking plates, grills and

vaporisers from the BBQ�

4� Remove the ‘R’ shaped locking clips that hold each

burner in place and remove all burners from the

barbecue� This needs to be done at the rear of the BBQ�

5� The gas injectors (also known as jets or nozzles) for

each burner are located within deep pockets at the rear

of the BBQ�

6� Remove each gas injector from the end of each jet

holder using a 6mm socket spanner/ wrench, turning

gently in a counter clockwise direction� Be careful not

to block the orifice at the end of the valve where the gas

injector is fitted and do not remove any of the thread

sealing compound from the orifice where the injector is

located�

7� Check the identification mark stamped on the Hex Head

of the injector to confirm that it is the correct size (NG:

2�10mm)� Screw correct Jets back into place�

8� When fitting the NG gas injectors to the end of the jet

holder be sure to seat the injector correctly on the

thread before turning it in a clockwise direction until it

is seated firmly in place� Do not over-tighten�

9� Replace all parts into position in the BBQ

10� Refit the burners and secure with the locking clips that

hold each burner is position� Replace the vaporisers,

grills and cooking plates� Note: Check the operation

of each burner- it may be necessary to open the airmixture screw (located at the burner venturi) a couple of

turns to get the correct flame�

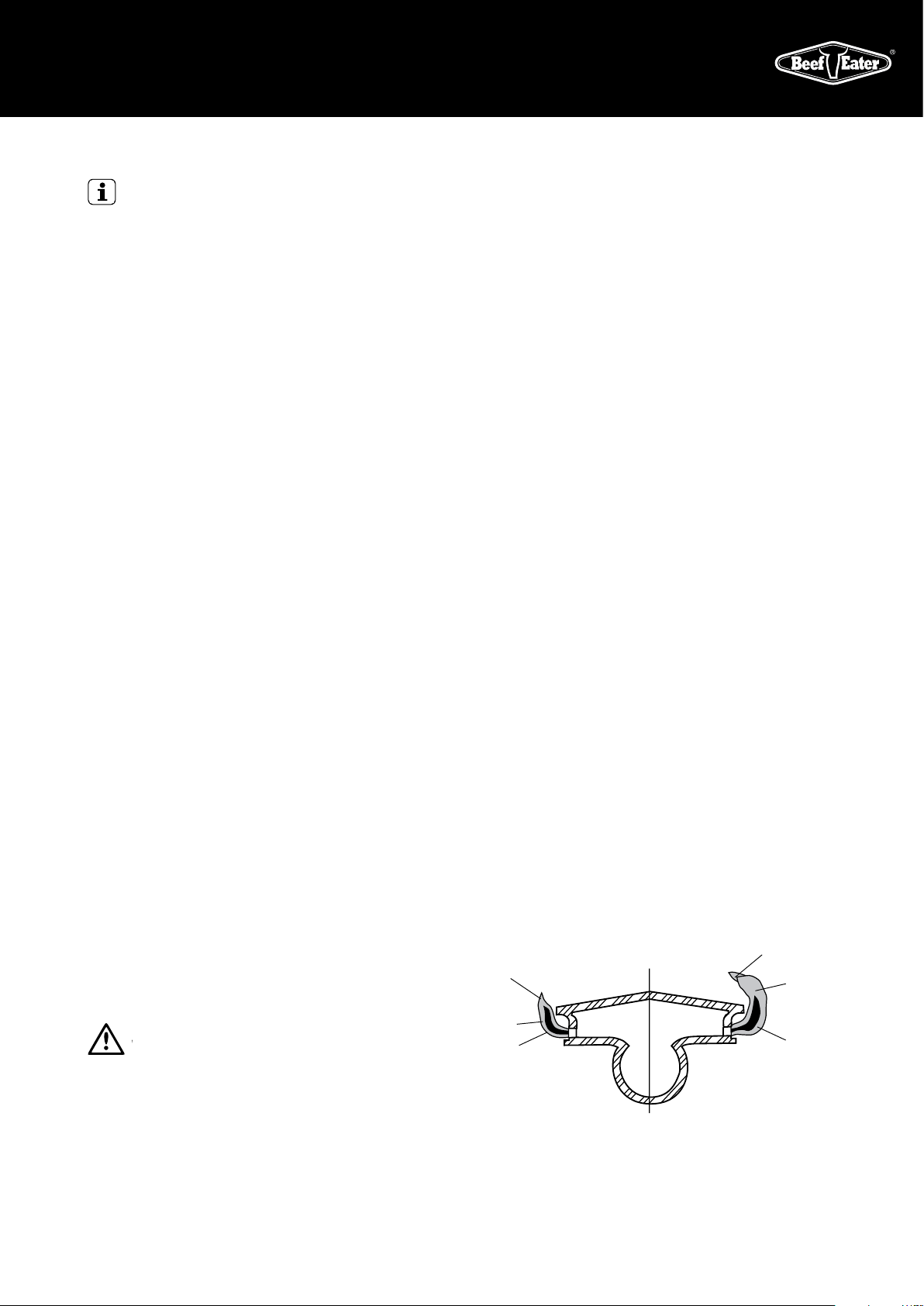

Aeration Screw Adjustment

11� Replace the LPG gas type label with the natural gas

label supplied� 12� Leak test using same procedure for

LPG, as detailed on page 4�

12� Connect the natural gas hose and regulator (where

applicable) to the gas inlet on the barbecue� Tighten

firmly but do not over tighten� Connect gas regulator

to gas source line� Perform leak test using same

procedure as for LPG�

Turn down adjustment

When converting to natural gas the turndown setting will

need to be adjusted to give a satisfactory flame on low

setting on each burner�

• Remove knobs from valve shafts� For ignition valves

the low flame adjustment screw is located on the lower

right hand corner of the front of the valve body�

High

Low

Off

• Using a flat bladed screwdriver, turndown adjustment

screw should be fully inserted and then rotated

• For non-igntion valves the screw is located inside the

knob spindle� Use a 2�5mm wide flat blade screwdriver

full inserted and make a ¾ turn counter clockwise�

Low

• Repeat for other valve�

• Following of the gas and leak testing as per previous

steps, light both burners and set to high�

• One burner at a time turn the valve shaft to lowest

setting, observe the flame to ensure a small steady

flame in achieved�

• Turn off burners and replace control knobs, ensuring

the knob is in the correct orientation when valve is in

“OFF” position�

Fixed Installation - Portable LP Gas/Propane.

BeefEater LPG/propane barbecues are designed to operate

at 2�75Kpa (11”WC)�

Connect the gas supply line to the barbecue inlet located on

the right side of the appliance using either hard plumbing,

or a flexible hose connected to a bayonet point, also known

as a quick connect fitting�Refer to AS 5601 or your local

installation code for pipe sizing details�Secure all joints

spanner (wrench) tight but do not over-tighten�

10

ASSEMBLY AND GAS CONNECTION INSTRUCTIONS FOR SIDE BURNER

ASSEMBLY INSTRUCTIONS

FOR TROLLEY

Test gas pressure by removing the last burner from the

left hand side of the barbecue and attaching a hose and

pressure gauge to the end of the gas valve�Turn on 2

burners and check the pressure�Inlet pressure should be

11�0” WC or 2�75 kPa�

Fixed Installation - Natural Gas

(Natural Gas installation should be carried out by a qualified

gas fitter)�

BeefEater Natural Gas barbecues are designed as lowpressure appliances (4�0” WC, 1�00KPa)�

Fit the natural gas regulator supplied directly to the

barbecue inlet located on the right side of the appliance

using either hard plumbing, or a flexible hose connected to

a bayonet point, also known as a quick connect fitting�Refer

to AS 5601 or your local installation code for pipe sizing

details�Secure all joints spanner (wrench) tight but do not

over-tighten�

Test gas pressure by removing the last burner from the

left hand side of the barbecue and attaching a hose and

pressure gauge to the end of the gas valve�Turn on 2

burners and check the pressure�Inlet pressure should be

4�0” WC or 1�00 kPa�

Australia only (applies to all gas types) : Where a mobile

appliance is to be connected to a fixed gas supply via a

flexible hose connection, a retaining tether of adequate

strength shall be fixed to the appliance and be suitable to

be fixed to the wall within 50mm of each connection

point� The length of the tether shall not exceed 80% of the

length of the hose assembly� In this way, if the barbecue

is accidentally moved, the chain stops the barbecue from

stretching the hose�

The barbecue appliance must be isolated from the gas

supply piping system by closing its manual shutoff valve

during any pressure testing of the gas supply piping system�

Before You Start

Note the tools you will need before you begin�

Check for damaged or missing parts, and consult your

retailer if necessary�

Many components and panels are covered with a protective

sheet of plastic� You will need to remove this plastic covering

from all surfaces, especially where two panels join� It is

a good idea to leave some plastic on the panels during

assembly to protect the stainless steel during the assembly

process� Ensure however that all plastic covering is removed

on completion�

Always assemble on a clean, smooth, flat working surface

that will not scratch the surface of the stainless steel�

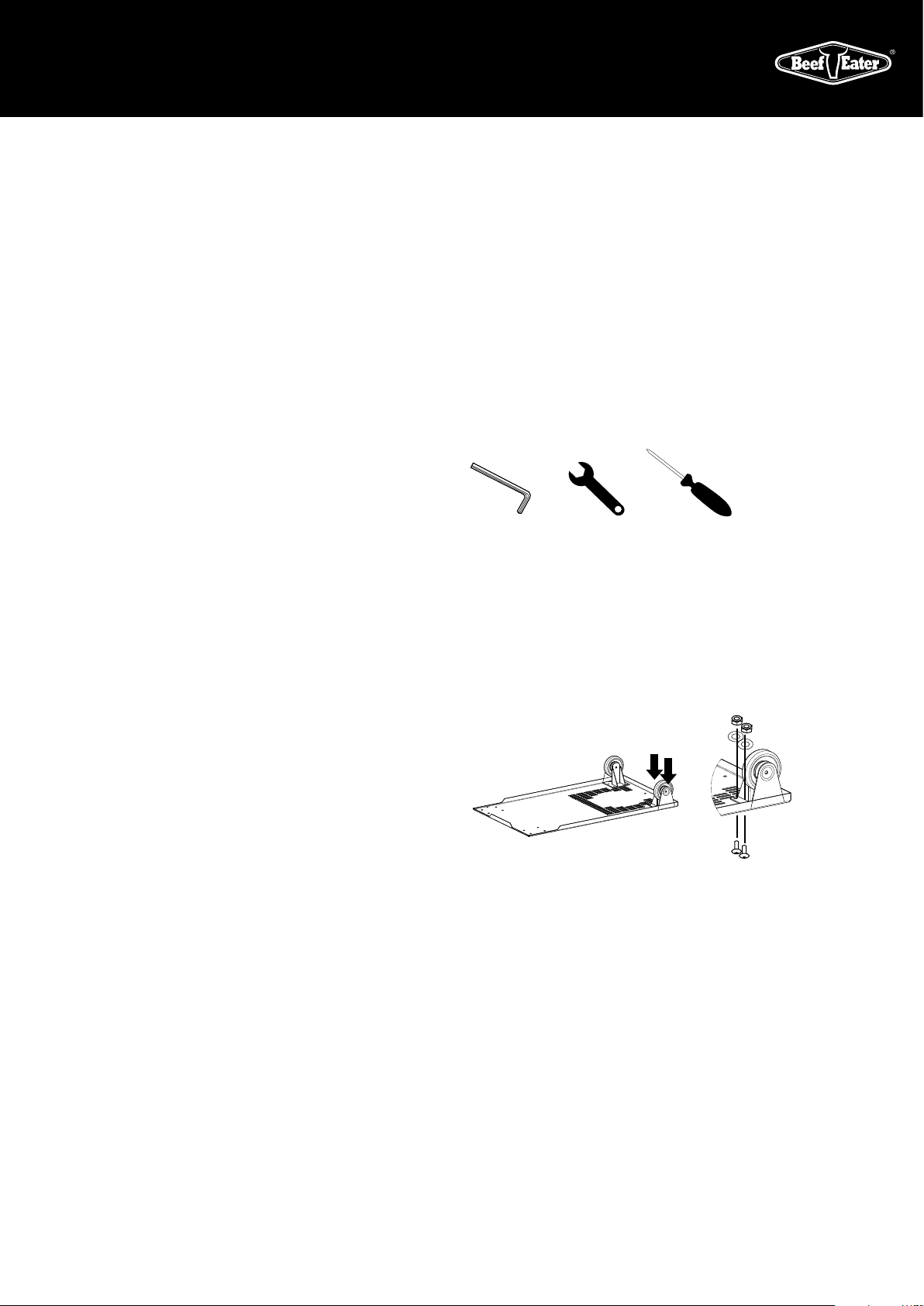

Allen Key Adjustable

spanner/

wrench

1) Fit The Fixed Castors

Fit the fixed castors into the holes in the bottom of the base�

At this step, use only two Allen head screws, washers and

nuts for each castor in the positions shown� The two outside

screws will be put on in step 3�

Spanner/wrench tighten immediately�

Phillips head

screwdriver

Note lip

ends here

11ASSEMBLY INSTRUCTIONS FOR TROLLEY

Loading...

Loading...