BeefEater BB95140 Installation and Operation Guide

WARNING

WARNING

WARNING

NATURAL GAS CONVERSION INSTRUCTIONS

BUGG BBQ NATURAL GAS

CONVERSION KIT

Kit Model 95140 includes:

2 x 1.50mm injectors (Part No. 040261)

2 x 1.83mm injectors (Part No. C090015NG Bigg Bugg Only)

2 x Aeration shutters (Part No. A04722501 Bigg Bugg Only)

1 x Natural Gas Label (020404)

1 x Hose and Regulator assembly (Part No. 95162)

1 x Restraining Cable (95111)

1 x Instructions 020686

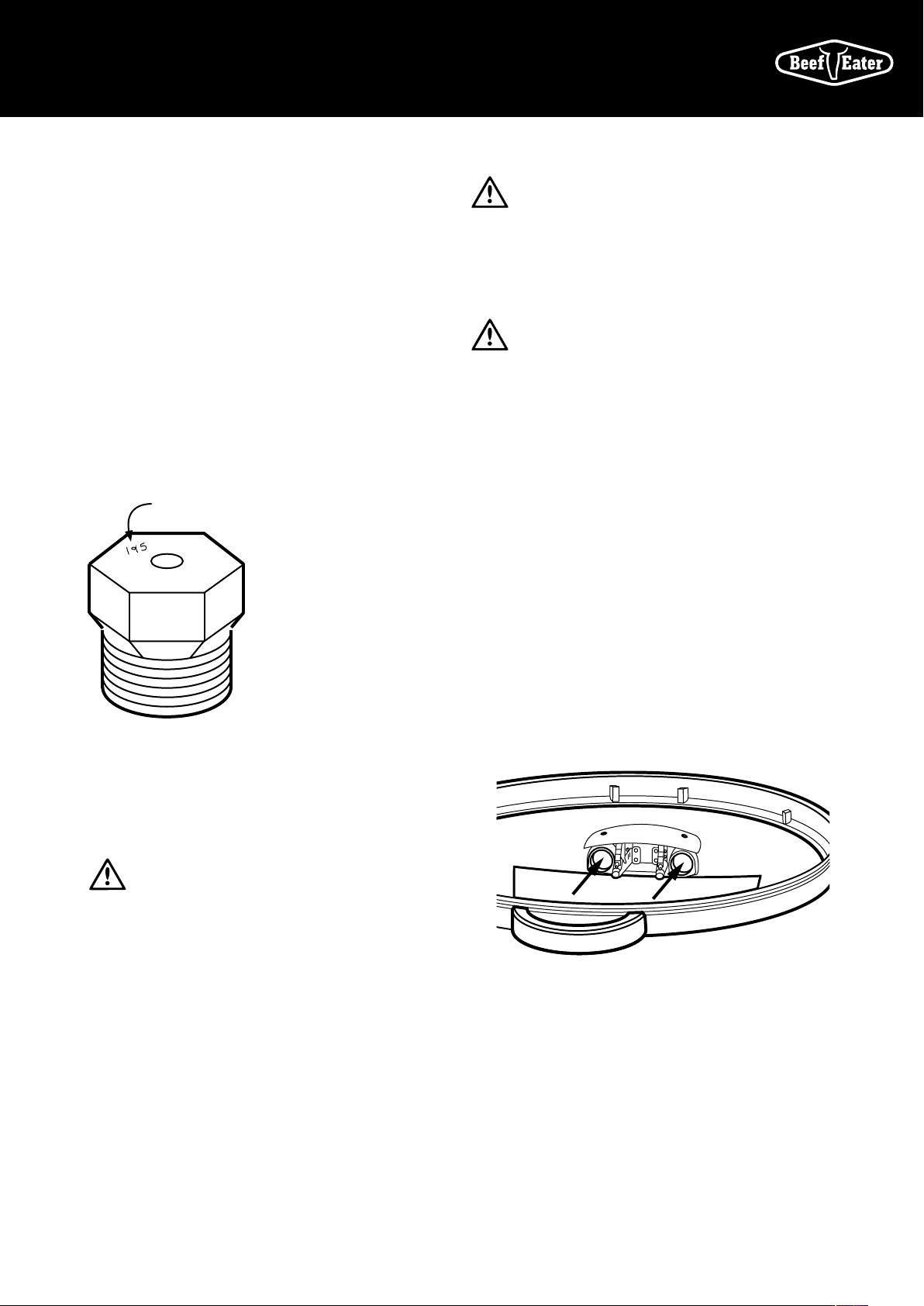

Look here for

identification reference

WARNING

The manufacturer accepts no responsibility for any

consequential damage, malfunction or loss due to incorrect

conversion of installation.

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL VOID

THE APPLIANCE WARRANTY.

BIGG BUGG

INSTRUCTIONS FOR BIGG BUGG NATURAL GAS

CONVERSION ARE DETAILED IN THE BIGG BUGG

MANUAL SUPPLIED WITH THIS BBQ. FAILURE TO

FOLLOW THOSE INSTRUCTIONS WILL VOID THE

APPLIANCE WARRANTY

Remove and Replace Gas Injectors (Jets)

1. Turn off the gas supply valve on the gas cylinder. Ensure

that all gas controls are in the OFF position.

2. Disconnect the hose and regulator from the gas cylinder

and disconnect the gas hose from the barbecue gas inlet

using a 19mm open-ended spanner / wrench.

3. Open hood and remove the cooking plate and grill from

the BBQ.

4. Remove each burner by unscrewing the 3 screws

holding it to the body.

5. The gas injectors (Jets) for each burner are located

within deep pockets at the rear of the BBQ.

Please read the user manual carefully and store in a handy

place for later reference.

Important Safety Instructions

WARNING

All service to the appliance must be undertaken by a

qualified gas service agent.

Do not smoke or use a naked flame within the vicinity of the

appliance or gas line when performing gas conversion or

service of any kind.

Always carry out a gas leak test after any work has been

carried out on the appliance.

If your barbecue is fitted with an optional side burner, gas

conversion must be carried out at the same time.

Always use the correct size socket spanner / wrench to

remove or replace the gas injectors. Do not use pliers or

any other type of tool that may squeeze the head of the gas

injector. This may cause the gas orifice to change shape

thereby adversely affecting the gas flow to each burner.

Gas injectors are made of brass and have a fine thread which

must be treated with care when being handled. Remove and

replace injectors with care.

6. Remove each gas injector from the end of each jet

holder, turning gently in a counter clockwise direction.

Ensure the jet holder is firm and won’t turn while

unscrewing the nozzle.

7. Check the identification mark stamped on the Hex Head

of the injector to confirm that it is the correct size –

1.50mm. Screw correct Jets back into place.

8. When fitting the NG gas injectors to the end of the jet

holder be sure to seat the injector correctly on the

thread before turning it in a clockwise direction until it is

seated firmly in place. Do not over-tighten.

WARNING

WARNING

NATURAL GAS CONVERSION INSTRUCTIONS

Replace all parts into position in the BBQ

Refit the burners and secure with the locking clips that hold

each burner in position. Replace the cooking plate.

NOTE: Check the operation of each burner

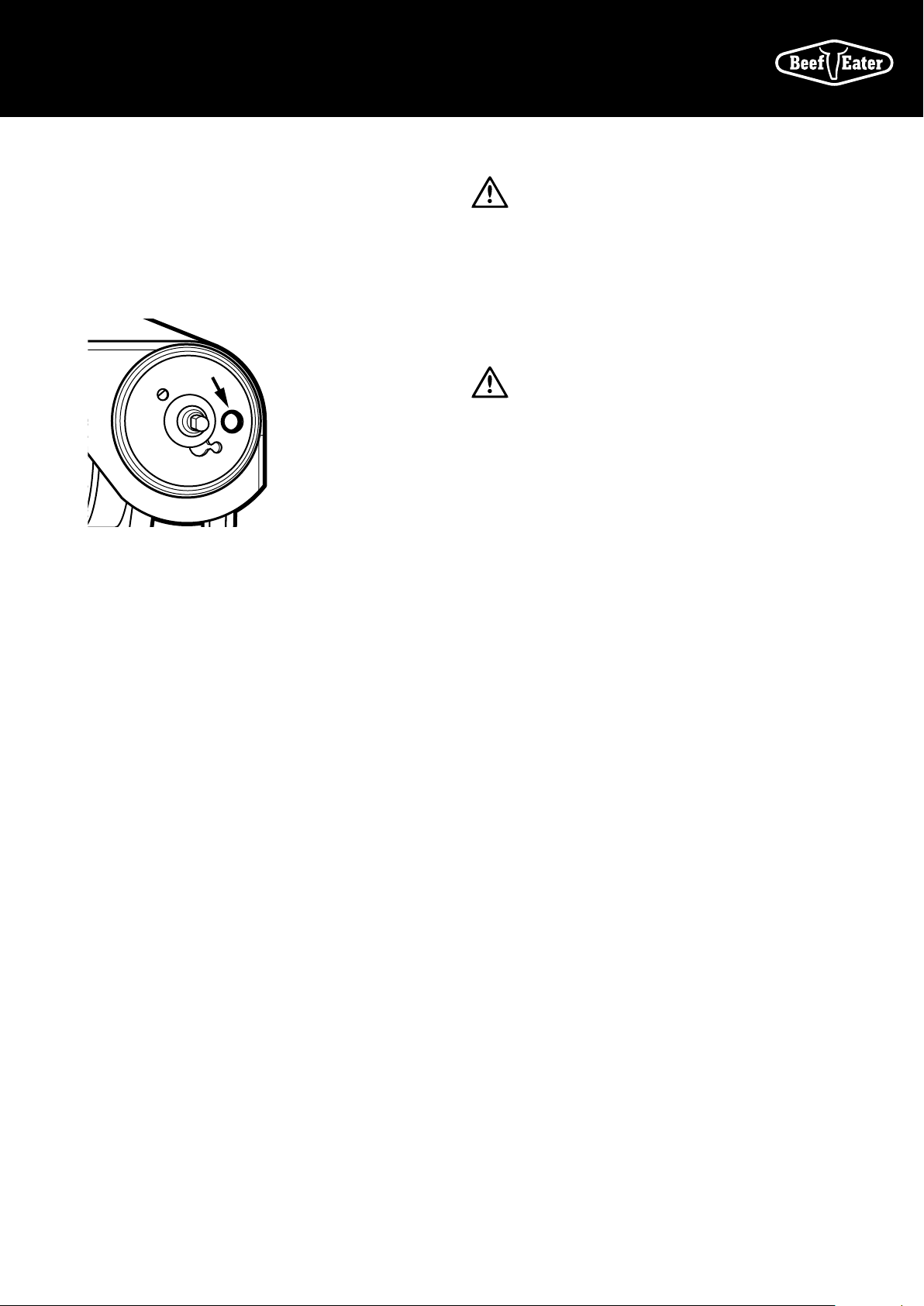

Adjustment of Low Flame Control Screw

WARNING

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odour continues, immediately call your gas supplier or

your fire department.

WARNING

1. Do not store or use gasoline or other flammable vapours

or liquids in the vicinity of this or any other appliance.

2. An LPG cylinder not connected for use shall not be

stored in the vicinity of this or any other appliance.

Replace the Data Label

Adjustment must be carried out for each of the burners.

Low flame adjustment screw is located in each valve,

under the knob. To set the low flame adjustment for NG,

the low flame adjustment screw is to be turned a full turn

anticlockwise. Use a 4mm wide, flat blade screwdriver.

Gas Leak Test Procedure

Use the following procedure to check for gas leaks. Never

use a naked flame to check for gas leaks.

1. In a small container, mix up a solution of water and

detergent or soap. Mix the solution well.

2. For LPG make sure that the gas supply valve on the gas

cylinder is turned on. For NG make sure that the gas

line is correctly fitted to the appliance.

3. Make sure that the gas control valves on the appliance

are all turned off.

4. Using a brush or spray bottle apply the solution to the

gas line and each join in the gas line.

5. Bubbling of the solution will indicate that there is a

leak present.

6. Re-tighten or re-seal any joints that are leaking.

7. If a leak persists then contact your distributor or the

manufacturer for assistance.

Use the following procedure to test the pressure.

8. Remove the right hand side burner.

9. Place a hose and pressure gauge over the right hand

side injector.

10. Turn the other burner on.

11. Turn the RH valve with measuring device on as well, and

take reading.

12. With at least one burner operating, the pressure reading

for Natural Gas should be 1.00KPa (10 mbar).

Peel the gas type label from backing and cover existing data

label to indicate Natural Gas.

Technical Data Clubman BBQ

Bugg BBQ Main Burner

Natural Gas Jet size 1.50mm

LPG Jet size 0.9mm

Gas consumption 10Mj/9500BTU

Inlet pressure NG: 1KPa

LPG: 2.75 KPa

For more information on all BeefEater products, or for

dimension and installation information, call into your retailer,

phone or email our customer care team or visit our website:

AUSTRALIA

phone: 1300 307 939

fax: 1800 356 669

email: customercare@electrolux.com.au

web: beefeaterbbq.com

NEW ZEALAND

phone: 0800 436 245

fax: 0800 225 088

email: customercare@electrolux.co.nz

web: beefeaterbbq.com

© 2017 Electrolux Home Products Pty Ltd. ABN 51 004 762 341

BMAN_BUGG_GASCONV_Oct17

P/N 020686

Loading...

Loading...