NOxBOX®mobile

breath analysis is the new blood test

www.bedfont.com

NOxBOX®mobile with NOxBOX

®

+

or NOxBOX®O

2

www.bedfont.com

2

NOxBOX® mobile Operating Manual

English

Contents

1 Introduction 3

Intended Use 3

2 Environment 3

3 Safety 3

Basic Safety Recommendations 3

4 Warnings 4

Contraindications 4

5 System Contents 5

6 Instrument Layout 5

7 General Description 6

8 Manual Handling 7

9 Maintenance 8

10 Commissioning 8

11 Installing a Gas Cylinder 9

12 Cylinder Changeover 10

13 Initial Purge 11

14 Connecting to a Patient Circuit 12-13

15 Decommissioning 14

16 Dose Calculation 15

17 Manual Bagging 16

18 Calibration 17

19 Spares 18

20 Specification 18

21 Warranty 19

22 Troubleshooting 20-21

www.bedfont.com

3

NOxBOX® mobile Operating Manual

English

Introduction

Nitric oxide (NO) is administered as a selective

pulmonary vasodilator for conditions such as:

● Persistent pulmonary hypertension in new-

born babies (blue baby syndrome)

● Adult respiratory distress syndrome

● Acute post-operative cardiac patients

Intended use

The NOxBOXmobile is intended for use by

healthcare professionals in a medical environment

to administer nitric oxide (NO) to the breathing

circuits of patients undergoing inhaled NO (INO)

therapy.

The NOxBOXmobile has been designed to provide

adjustable continuous ow NO delivery to the

patient ventilator circuit to achieve the required

dose of NO to the patient.

The NOxBOXmobile must be used in conjunction

with a suitable Inhaled Nitric Oxide (INO) Therapy

monitor to conrm the correct dose of NO is

being delivered to the patient. Specically, the

NOxBOX+ and NOxBOXO2 monitors from the

Bedfont Scientic range of products are suitable

for use with the NOxBOX mobile. Refer to the

monitor Instructions for Use for correct operation,

maintenance and safety instructions.

Environment

The NOxBOX®O2 complies with the directive

EN60601-1-2 electromagnetic compatibility

but can be affected by cellular phones and by

electromagnetic interference exceeding the levels

specied in EN50082:1

Safety

Do not operate this equipment until you have read

and understood the operating, maintenance and

safety instructions included in this manual and any

manuals supplied with the INO Therapy monitor

being used.

Only trained and responsible personnel should

work with or around this equipment.

To avoid serious injury, pay attention to all

precautionary labels attached to equipment,

cylinders, containers and boxes prior to start-up.

Do not remove or obscure any label. If a label

is missing, becomes worn, or is difcult to read,

replace it with a new one. Product labels for the

NOxBOXmobile are available from your Distributor

or Bedfont Scientic representative.

Basic Safety

Recommendations

Prevent formation of unsafe atmospheres Ensure that properly engineered ventilation and

atmospheric monitoring systems are installed and

operating properly. Creating a conned space

presents the potential for unsafe atmospheres. If

dangerous levels of a gas are detected, evacuate

the affected area immediately. Do not re-enter the

area until safe conditions are restored.

Prevent injury - Ensure that all tools and

instruments used are in good condition. Be aware

that high-velocity gas may be released at vents and

safety relief valves.

Maintain safety devices - Check all safety devices

at least annually or as otherwise required by local

codes or manufacturer recommendations. Properly

maintain safety valves. Never bypass safety

devices, and never operate the equipment outside

its specied limits.

Ensure safe maintenance and repair - Only

qualied personnel should repair the equipment.

Ensure equipment is maintained according to the

manufacturer’s recommendations, including any

calibration or inspection routines.

www.bedfont.com

4

NOxBOX® mobile Operating Manual

English

Warnings

DANGER: Mishandling of pressurized process

equipment or gas cylinders can result in death,

serious injury, or property damage. Handle

pressurized equipment and cylinders with

extreme care and in accordance with the

manufacturer’s instructions.

DANGER: Both high-pressure connection

hoses should be correctly attached to the

NOxBOXmobile system at all times whilst the

system is pressurized.

DANGER: Poisonous gases can be fatal if

inhaled, even in very small quantities. Provide

adequate ventilation and appropriate personal

protective equipment (PPE).

This equipment contains poisonous gases.

The Threshold Limit Value (TLV) for each gas

refers, in general, to airborne concentrations

at or below which nearly all workers may be

repeatedly exposed without adverse effects.

The TLVs for the specialty gases used with this

equipment should be stated on the cylinder

body labels and the MSDSs (Material Safety

Data Sheets) for each gas.

Nitric Oxide (NO):

At room temperature and atmospheric pressure,

NO is a colourless, odourless, toxic, nonammable gas. It will readily combine with

atmospheric oxygen to form NO2.

Nitrogen Dioxide (NO2):

NO reacts with atmospheric oxygen to produce

NO2; the NO2 may react further with water to

produce nitric and nitrous acid which can both

be extremely corrosive. The human lungs

are a wet environment, so inhalation of this

extremely toxic gas can have severe effects and

every reasonable measure should be made to

minimise exposure to NO2.

Current UK HSE guidelines recommend

following the Chemical Hazard Awareness

Notice (CHAN) for nitrogen oxides (including

NO and NO2) state that time weighted average

(TWA) over eight hours should not exceed

1ppm.

Nitrogen (N2):

Nitrogen gas is an asphyxiant. A major

component of air, it is colourless and odourless

at room temperature. Care should be taken to

avoid excessive release of Nitrogen into the

atmosphere without adequate ventilation to

protect the user from a low-oxygen atmosphere

being created.

Contraindications

● Refer to your NO drug manufacturer’s

instructions for use, safety and warning

statements regarding contraindications for

the application of nitric oxide gas for the

purpose of INO therapy.

● NO gas is toxic at high concentrations and

appropriate continuous monitoring of the

applied patient dose concentration should

be used.

● WARNING: Sudden cessation of INO

therapy can cause complications such as

rebound hypoxia to occur.

www.bedfont.com

5

NOxBOX® mobile Operating Manual

English

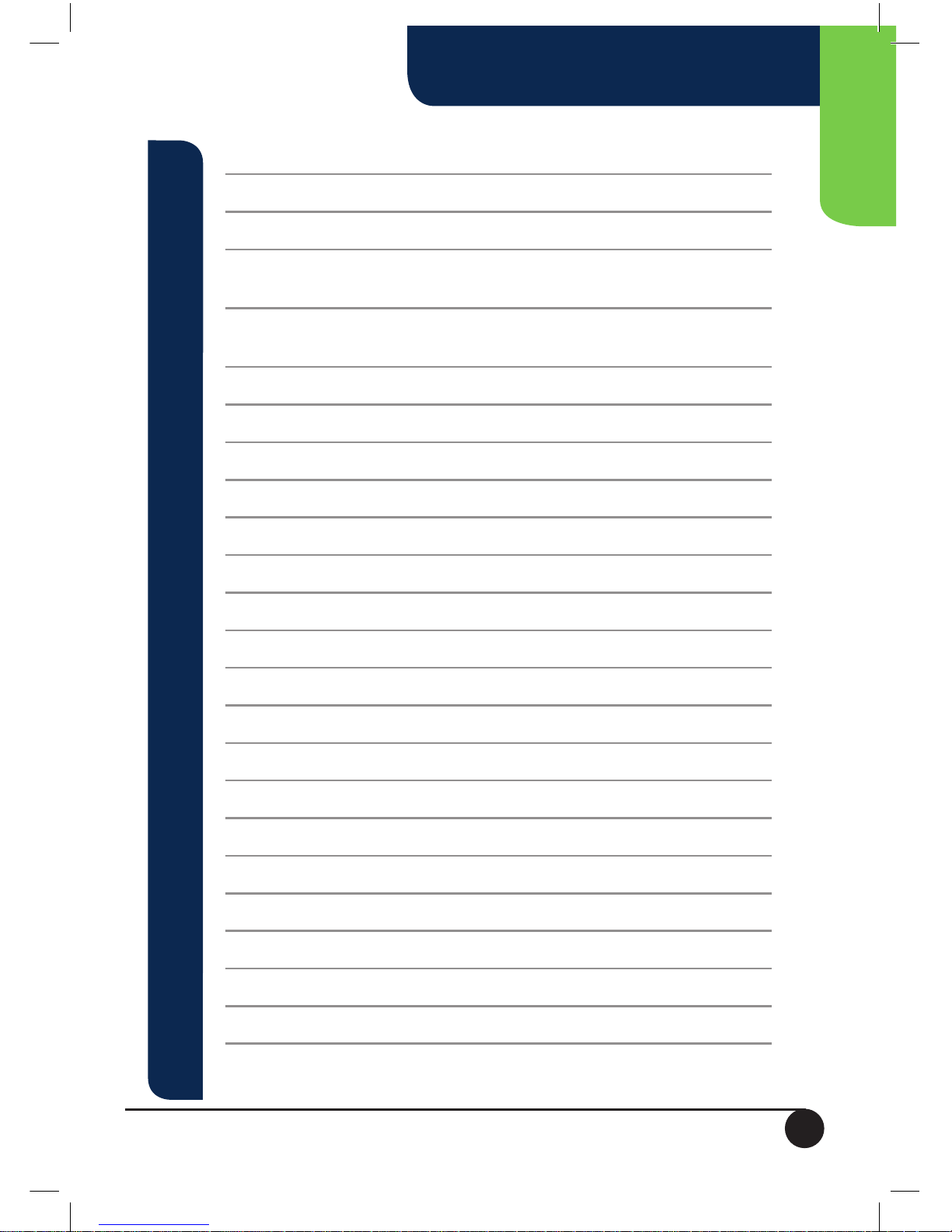

NOxBOX+ monitoring instrument

1. NOxBOX

+

2. Mains power adapter

3. Magnum screwdriver

4. Calibration screwdriver

5. Sample line

6. Water trap

7. Naon tubing

8. Calibration T-piece adapter

9. Operating manual

10.PU tube from the naon to the inlet

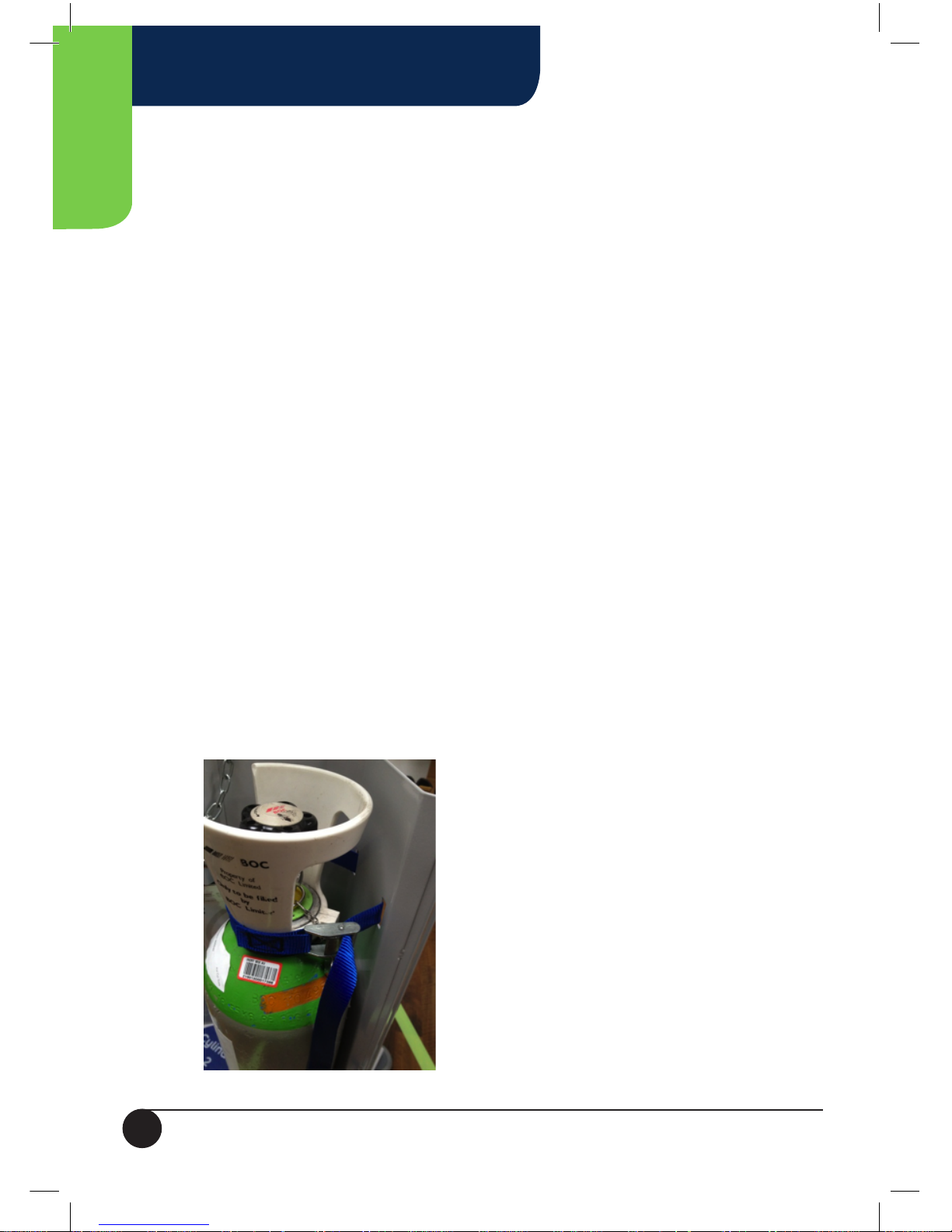

NOxBOXmobile delivery system

A. Gas cylinder pressure gauges

B. Changeover unit

C. NOxAIR NO2 environmental sensor

D. Single stage regulator

E. Outlet pressure gauge

F. Trolley

G. Low ow indicator

H. High ow indicator

I. NOxAIR NO environmental sensor

J. Spanner attached by chain

System Contents

E

F

G H

I

J

A

B

C

D

A

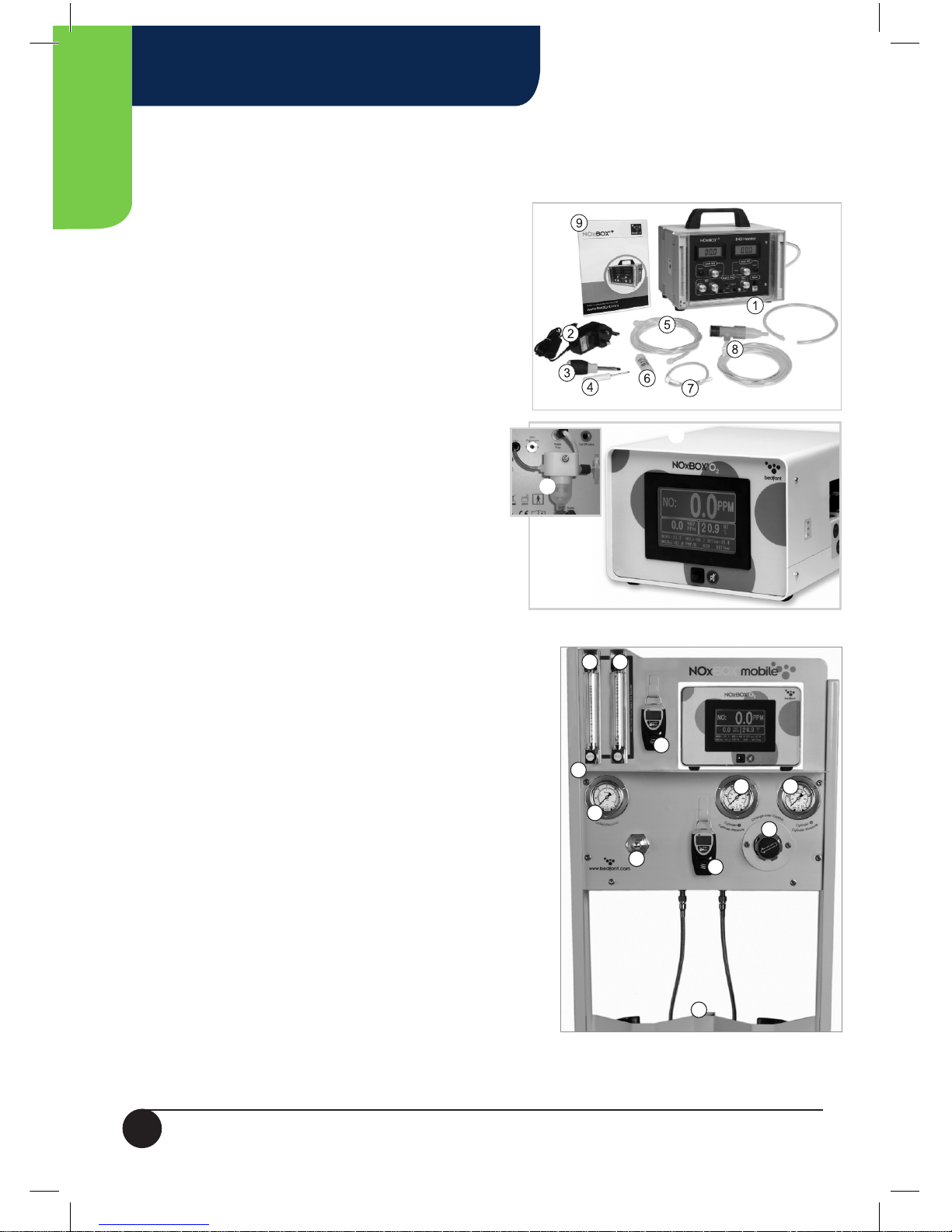

NOxBOXO2 monitoring instrument

1. NOxBOXO

2

2. Water trap

Also supplied with:

Mains power adapter

Calibration screwdriver

Bacterial lter

Sample line

Water trap drainage accessory

Calibration Y-piece adapter

Operating manual

1

2

Figure 1

Instrument Layout

www.bedfont.com

6

NOxBOX® mobile Operating Manual

English

General Description

The NOxBOXmobile is used to control the

pressure and ow of NO gas into a patient

breathing circuit. The ow of NO gas is

controlled by the user via the adjustable

ow meter (See Fig.1, item G). When used

in conjunction with a NOxBOXO2 monitor, a

complete delivery and monitoring system is

formed that allows the user to set the patient

dose level and continuously monitor the dose

gas at patient side.

The NOxBOXmobile system is mounted to an

epoxy coated, mild steel trolley designed to be

situated close to the patient’s bedside ventilator.

The NOxBOXmobile system provides capacity

for two NO supply cylinders, up to 20L water

capacity, which when combined with the auto-

changeover system ensures uninterrupted

delivery of NO is possible. When used correctly,

this helps guard against sudden unexpected

withdrawal from INO therapy.

The system is tted with stainless steel high-

pressure hoses that attach to the cylinders

via suitable cylinder connectors (specic to

individual region). These hoses are tted with

a safety-cord to restrain the hose in the event

of a catastrophic pressure burst. Further safety

control measures are provided by a pressure

relief valve tted after the rst stage regulator,

with a second pressure relief valve tted after

the second stage regulator.

INO Therapy Monitor

The system trolley is provided with a shelf that

allows a NOxBOXO2 monitor to be xed to the

system, providing the monitoring capability.

Refer to the NOxBOXO2 manuals for safe use

and maintenance.

Environmental Alarms

Optional NOxAIR environmental gas detectors

can be provided to warn personnel of any

leaks in the NO supply. These portable alarms

continuously monitor the atmosphere for NO

or NO2 levels (depending on model), capable

of measuring down to 0.1ppm. Each monitor

has a set of alarms that can be set to ensure

best-practice environmental monitoring. These

alarms can be worn by an individual, positioned

in the vicinity of the patient or left on the hooks

provided on the NOxBOXmobile. Refer to the

NOxAIR environmental gas detector manuals

for safe use and maintenance.

Note: The NOxAIR alarms are personal alarms,

designed to alert staff in the immediate vicinity

of the alarm. They are not designed to be heard

from a long distance or from a different room.

NO Gas Cylinders

The NOxBOXmobile system is designed for

use with a medical-grade gas mixture of NO

balanced in Nitrogen (N2). The maximum

recommended concentration for use is

1000ppm NO. Bedfont Scientic do not provide

therapeutic gas mixtures for INO therapy.

Refer to the manufacturer’s labels regarding the

concentration and precise mixture of the NO/

N2 gas.

Please refer to the manufacturer’s instructions

on safe handling of the gas, gas cylinder and

any additional gas handling equipment provided.

All safety notices and warning should be read

and understood prior to use.

Warning: N2 gas is an asphyxiant, and care

should be taken to understand that adding

large quantities of N2 to the patient circuit may

cause dilution of the oxygen content of the

patient gases. It is recommended at all times

during INO therapy to use a monitor such as the

NOxBOXO2 that provides oxygen monitoring

capability to maintain awareness of this

phenomenon possibly occurring.

www.bedfont.com

7

NOxBOX® mobile Operating Manual

English

Manual Handling

The NOxBOXmobile system is handling a toxic

gas at high pressures. Care should be taken

when moving the trolley to ensure that it is

protected from excessive percussive knocks.

Before moving, ensure system brakes are

disengaged. Always use the metal frame of the

trolley to manoeuvre the system, ensuring a

secure grip to prevent unexpected movement.

Never attempt to move the equipment by pulling

on the system connection lines or gas cylinders.

When in use and attached to the patient, the

NOxBOXmobile should be placed to avoid any

tension within the connection lines to the patient

circuit. The system brakes should be applied to

prevent accidental movement of the equipment,

which could cause lines to disconnect from

the patient circuit or damage to any monitor

connections.

Gas cylinders can be heavy. Appropriate manual

handling techniques should be observed when

lifting cylinders on and off the system trolley.

Always engage system trolley brakes to stabilise

the platform prior to attempting to replace any

gas cylinders. Gas cylinders should be properly

restrained when on the trolley, using the

provided straps.

www.bedfont.com

8

NOxBOX® mobile Operating Manual

English

Maintenance

User

Single-patient use items such as the NOxKIT

must be disposed of after every treatment. No

processing instructions are available for these

items. Follow local procedures for safe disposal

of such items.

Qualied Technician

Maintenance procedures should only be

undertaken by technicians that have received

the appropriate technical and maintenance

training from Bedfont Scientic Ltd for the

relevant equipment.

Correct and safe operation of the

NOxBOXmobile system should be checked

regularly. Bedfont recommend inspecting the

system on a monthly schedule for obvious signs

of wear and tear.

Flow and pressure regulation checks should

be performed in accordance with the expected

operating parameters. Perform a leak decay

test to ensure there are no leaks within the

system. Details of these tests will be provided

by Bedfont on request.

Replace any missing, worn or damaged

components in accordance with the

NOxBOXmobile maintenance manual.

Cleaning

All new equipment, as well as used equipment

that may have become contaminated during

service, must be thoroughly cleaned.

Perform cleaning in accordance with applicable

cleaning standards to ensure that the equipment

has been safely prepared for the application

for which it is to be used. Carefully inspect all

cleaned parts. If any evidence of contamination

is noted, clean the part again.

● Do not immerse the system in cleaning

uids.

● Do not use abrasive cleaning materials

on the system, as this may damage the

protective nish or affect the legibility of

control panel items.

NOTE: If using with a NOxBOXO2 or NOxBOX+

monitor, ensure the guidelines for cleaning

these monitors are followed separately. These

monitors can be easily damaged by using

cleaning materials containing alcohol or VOCs.

Avoid immersing electronic equipment.

Commissioning

NOxBOXmobile

The NOxBOXmobile is supplied as an

assembled system.

Carefully remove the trolley from the packaging

case and pallet. NOTE: the trolley system

is heavy and requires at least two people to

handle during lifting operations.

The system has a high-pressure gas-handling

system. This should only be set-up and used

by experienced individuals that have had the

appropriate training in safe set-up and handling

of the NOxBOXmobile system. Contact Bedfont

or your distributor for full details.

Monitor System

If supplied, remove the NOxBOXO2 monitor

from its packaging and position on the provided

shelf on the NOxBOXmobile trolley. The system

should lock into place at the back, using the key

provided with the system.

Refer to the NOxBOXO2 operating manual for

instructions on safe use and maintenance.

NOxAIR alarms

If supplied, remove the monitor alarms from

their packaging and position on the hooks

provided on the NOxBOXmobile trolley.

Refer to the NOxAIR alarm operating manuals

for instructions on safe use and maintenance.

www.bedfont.com

9

NOxBOX® mobile Operating Manual

English

Figure 2-a: Connection

Including NOxBOX Mobile

Installing a Gas Cylinder

Before installing the gas cylinder, ensure the

NOxBOXmobile trolley is placed on a rm level

surface, positioned such that easy access to

the cylinder mounting platform is available, and

engage the trolley brakes before manoeuvring

cylinders on or off the trolley.

For safe cylinder handling refer to “Manual

Handling” notes (page 7).

Place the cylinder onto the trolley platform,

seating it against the upright supports provided.

Cylinder must sit inside the raised rim of the

trolley base. Restrain the cylinder with the

provided nylon webbing straps correctly tted to

prevent the cylinder from toppling in use. Place

the strap around the cylinder and pull the free-

end until the strap lies tight around the cylinder,

the metal buckle will automatically grip onto the

strap and hold in place.

WARNING: gas cylinders can be very

dangerous if they topple over. All safety

measures must be in place to ensure the

cylinders are properly secured when on the

trolley platform.

Prior to connecting the cylinder:

● Ensure the gas control valve is shut (this

should be the default position for the valve).

Any leaking unregulated gas should be very

obvious.

● Remove any safety caps from the threaded

valve connection on the cylinder.

Cylinder connections vary depending on

territory. Refer to your local distributor for details

on your connection type.

Figure 2: BS14 connector with PTFE sealing

washer

● Visually inspect the connector on the hose

for any wear or damage

● If there should be a sealing element, ensure

it is present and free from apparent wear or

damage. If it is damaged it must be replaced

prior to use. (see Figure 2, illustrating a

BS14 style connector with PTFE washer

seal)

● Introduce the connector to the cylinder valve

and carefully hand-tighten the nut. Do not

force the nut if it sticks, reverse the nut and

ensure the nut is not cross-threading and

that the thread is free from damage before

attempting to reconnect.

● Once hand-tight, use the supplied

adjustable spanner to tighten the connection

to the cylinder until it feels rmly tight.

Over-tightening the connection can cause

damage.

● Refer to the gas manufacturer’s instructions

for specialist connections. Do not use any

inappropriate tools on hand-tighten only

type connections.

Repeat the above steps to attach the second

cylinder.

www.bedfont.com

10

NOxBOX® mobile Operating Manual

English

Cylinder Changeover

The NOxBOXmobile has a continuous NO

supply feature consisting of a two-cylinder

supply attached to an automatic change-over

unit (See Fig. 3)

The automatic change-over unit has a control

knob with an arrow (as shown).

When both supply cylinders are connected and

available, the unit will use the cylinder the arrow

is pointing at to supply to the patient (see Fig. 3,

supply is from Cylinder 2 in this example).

When the primary supply cylinder reaches

approximately 10 bar, the auto-changeover

unit will switch to using the secondary supply

cylinder, this automatic switch is controlled by

the available pressure and is independent of

where the control arrow is pointing.

Once the system has switched over the supply

cylinders, it is good practice to replace the

empty cylinder for a full cylinder to ensure backup gas supply is available to the unit.

To safely change an empty supply cylinder:

1. Ensure the system brakes are on and that

you have full and easy access to the gas

cylinder to be changed. Be aware of any

connections in place to other systems (e.g.

patient circuit) before moving the system to

avoid stretching lines.

2. Turn the auto-changeover control so that

the arrow is pointing at the new (full) supply

cylinder (i.e. away from the cylinder about

to be replaced, see Fig. 4, where cylinder

2 is being changed). This step is best

practice, if the control remains pointing

at the empty cylinder, when the supply is

replenished the system will switch back to

this cylinder, rather than continuing to use

the secondary cylinder.

3. Fully close the control valve on the empty

cylinder.

4. Using the spanner provided, very carefully

release the connection nut at the cylinder

valve. There will be a short sharp release

of gas at high pressure. Continue to

release the nut. NOTE: if there is sustained

gas release, then the cylinder control valve

is not fully closed. This MUST be closed

before removing the nut.

5. Once the nut is sufciently loosened, use

your hands to undo the nut and remove the

gas line connector from the empty cylinder.

6. Loosen the straps from the empty cylinder

and remove from the trolley. Be aware,

an empty cylinder can be very heavy; see

“Manual Handling” (Page 7).

7. Install the new gas cylinder by following the

steps detailed in “Installing a Gas Cylinder”

(Page 9).

Figure 3 Figure 4

www.bedfont.com

11

NOxBOX® mobile Operating Manual

English

Initial Purge

IMPORTANT: Residual NO gas left in the

system may convert to NO2 during storage. This

purge procedure MUST be followed prior to use

on a patient to ensure that any residual gas from

previous use has been ushed out.

SAFETY: Refer to all safety notices regarding

handling the gas and using suitable ventilation

to prevent build-up of unsafe atmospheres.

During purge, the exhaust from the unit should

be fed through an appropriate atmospheric

scrubber or a scrubber lter for NOx gases.

This will safely remove the toxic nitrogen oxides

from the gas exhaust. Contact Bedfont or your

distributor for NOx scrubber information.

NOTICE: If system is left pressurised following

purge for more than 4 hours without use, this

purge procedure must be repeated to ensure

safe application.

● Ensure the Changeover Dial (See Fig.5,

item B) arrow is pointing to cylinder 1. Turn

on cylinder 1 by opening the cylinder valve

carefully.

● The Pressure 1 gauge dial should register

the contents pressure of the cylinder (See

Fig. 5, item A). Ensure there is sufcient

pressure in the cylinder to commence

treatment. A full cylinder is approximately

150 - 200 bar (check with your supplier). A

cylinder is “empty” at 10 bar.

● The outlet pressure gauge dial (Fig. 5, item

E) should read 2 bar.

● Open the valve on the ow meter (Fig. 5,

item G) until the ow reads approximately

600 cc/min. IMPORTANT: do not open valve

beyond maximum ow indicated on the ow

meter (Fig. 3, item H) as this may damage

the instrument control.

● Allow the system to purge for 10 minutes

before switching off cylinder 1 at the cylinder

valve. Do not over-tighten the cylinder valve

when closing.

● Repeat this purge procedure for cylinder 2.

● Close the valve on cylinder 2 and carefully

close-off the ow meter. NOTE: when fully

closing the valve, be careful to not over-

tighten as this may cause damage to the

control valve mechanism.

● Ensure both cylinder valves are shut off

by end of the purge procedure and prior to

connecting to patient.

Figure 5

www.bedfont.com

12

NOxBOX® mobile Operating Manual

English

Connect To Patient

1. Position the NOxBOXmobile as close as

practical to the patient ventilator to enable

ease of connection. Engage the system

brakes and make sure the system is stable

before connecting to the patient.

2. Connect a fresh dose line from a new

NOxKIT to the outlet of the NOxBOXmobile

ow meter, pushing the soft bung rmly

over the metal barb. Attach the luer lock on

the free-end to an appropriately sized vent

connection adaptor from the NOxKIT; the

size should match the circuit size in use on

the patient circuit.

3. Insert the dose line adaptor into the patient

ventilator circuit inspiratory limb. The dose

line should be connected approximately

1m (between 0.7m and 1.3m) back from

the patient sample point being taken by the

NOxBOXO2 monitor (See Figure 6). Refer

to the NOxBOXO2 monitor User Manual

for correct set-up of the monitor to patient

circuit.

4. The system is now ready to commence

delivery of NO to the patient.

5. Refer to the NOxBOXmobile Quick

StartGuide (QSG) for dose setting tables.

An illustrated example is shown in Figure 6:

for 1000ppm supply, patient vent ow of 6L/

min, desired dose of 15ppm; the NO ow

setting should be approx. 90 cc/min.

6. Check the NO gas cylinder concentration on

the cylinder label and refer to the table with

the matching concentration value.

7. The top row of values indicates the patient

ventilator ow setting. At the value that best

matches the patient ventilator ow, read

down the column to reach the desired target

NO dose.

8. The corresponding value of NO Flow Rate

(cc/min) shown on the far left column is the

guideline starting value to set the NO ow

rate on the NOxBOXmobile.

9. Carefully and fully open the valve on

cylinder 1. Check the ow meter setting and

adjust to match the guide value calculated

using the QSG for the patient.

Figure 6

www.bedfont.com

13

NOxBOX® mobile Operating Manual

English

10. Carefully and fully open the valve on

cylinder 2 to ensure the back-up NO supply

is available in the event of cylinder 1

reaching empty during therapy. The cylinder

supplies will automatically change-over in

the event of the primary supply cylinder

reaching the empty level. See “Cylinder

Changeover” (Page 10) for more details.

11. Leave the system to settle for 2 minutes,

and carefully observe the monitored value

for the NO dose. The 2 minute settling time

allows any changes in the settings to be

fully observed.

12. Make any minor adjustments to the NO ow

as indicated by the dose reading of NO on

the NOxBOXO2 monitor.

IMPORTANT: The dose table calculations are

approximate guides to the NO ow setting

required to achieve the desired dose. Variations

between ventilator set-ups and individual

systems may require slight adjustments (e.g.

+/- 10%) to this guideline ow rate to achieve

the exact dose level. If large adjustments are

required to the guideline ow rate to achieve

the dose rule out any system error with the

equipment (monitoring or delivery systems)

by following the troubleshooting actions in the

relevant manual.

If the monitor reading is very high or very low

compared to the expected value, ensure that

the monitor is functioning correctly and has

been appropriately serviced and calibrated

prior to use. Refer to the monitor manual

for troubleshooting actions in the event of

unexpected gas reading parameters.

In the event of high NO2 readings with very low

expected NO, refer to the troubleshooting tips in

this manual as the set-up purge procedure may

not have been correctly implemented prior to

use, or a system fault may have developed.

Figure 5

www.bedfont.com

14

NOxBOX® mobile Operating Manual

English

Decommissioning

Once treatment is complete, and patient

weaned off of the INO Therapy, it is safe to

remove the NOxBOXmobile system and prepare

it for storage.

1. Fully shut off the control valves on cylinder 1

and cylinder 2.

2. Remove the dose line and dose line adaptor

and dispose of these single-patient use

items in accordance with applicable local

practices for disposal of such materials.

3. Connect the outlet of the NOxBOXmobile

to a NOx scrubber lter or an appropriate

atmospheric scavenger. Contact Bedfont

or your distributor for details of the NOx

scrubber.

4. Open the ow meter control until the NO

ow reading is approximately 600 cc/min.

Observe the inlet (high) pressure gauges

(Fig.8, A), these will gradually decrease until

the high pressure system is empty. Then

observe the low pressure gauge as this

dials down.

5. When the low pressure gauge (Fig.8, E)

reads approx. 5psi and the ow meter no

longer registers a ow, the system has

safely depressurised and is ready for

cleaning or storage as appropriate.

Figure 8

www.bedfont.com

15

NOxBOX® mobile Operating Manual

English

Dose Calculation

The dose of NO delivered to the patient must be

dened by the acting clinician.

The NOxBOXmobile is provided with a Quick

Start Guide (QSG) that contains a series of

dose guidance tables that provide approximate

NO ow rates required to achieve the required

patient dose for given conditions of patient

ventilator ow and the supply gas concentration.

The calculations in the table are based on the

following formula:

NO ow (cc/min) = 1000 x Vent Flow (L/min)

[(NO supply concentration (ppm)/NO patient dose (ppm)) – 1]

Worked Example:

For a patient ventilator setting of 5 L/min, a

supply concentration of 1000ppm and a desired

patient dose of 4ppm, the set NO ow (cc/min)

NO ow (cc/min) = 1000 x 5 = 5000 = 20 cc/min

[(1000/4)-1] 249

NOTE: the actual patient dose being delivered

should always be conrmed by use of a

continuous INO monitor designed for the

purpose, such as the NOxBOXO2.

The guideline NO ow calculated using this

formula should be considered as a guide value.

Fine-tune the actual delivered dose by making

an appropriate adjustment to the ow to achieve

the correct dose on the monitor display.

IMPORTANT: Leave at least 2 minutes between

changes for any ow adjustments to fully take

effect.

WARNING: In the event that the indicated

ow is not producing a dose value close to

the expected dose, ensure all equipment is

correctly connected, calibrated and functioning

as expected before making large increases

or decreases in the NO ow value. See

“Troubleshooting” section (page 20) for common

diagnostic issues.

www.bedfont.com

16

NOxBOX® mobile Operating Manual

English

Manual Bagging

The layout of the manual bagging option of the NOxBOXmobile is shown below in Figure 9.

The outlet from the standard NOxBOXmobile

ow meter is attached to the rear of the manual

bagging unit. The NO ow rate is still controlled

by the main adjustable ow meters on the

NOxBOXmobile system. The NO ow meter (B,

g. 9) on the manual bagging unit is purely for a

simple side-by-side reference of ow against the

oxygen ow setting.

The oxygen (O2) inlet is to the rear of the

unit and is tted with a BS5682 1998 tting

as standard (other standard connections are

possible, contact Bedfont or your distributor for

details). Connect this tting to an appropriate

O2 source. The O2 ow rate can be set by the

manual bagging unit O2 ow meter (C, Fig. 9),

between 1 and 10 L/min.

The nitric oxide ow is connected to the regular

patient ventilator circuit via the dose line exiting

the left of the unit (need to label this up, Fig. 9).

This inserts into the circuit in the same location

described within the “Connect to Patient”

section (page 12). The NO ow will be delivered

normally through this dose line to the patient

ventilator circuit when the control lever is turned

such that the arrow points towards this dose line

“Ventilator Option”. (create a detail photo of this,

it’s the reverse of the control position above).

The manual bagging system can be connected

up to the outlet valves D (for NO ow) and E

(for O2 ow). This allows a swift transfer of the

delivery gas feeding the ventilator, to be simply

diverted to the manual bagging apparatus by

turning the control lever (A, Fig. 9) such that the

arrow points towards the ow meters, “Manual

Option” (as pictured above).

IMPORTANT: A small delay may occur on

switching the system between ventilator ow

and manual bagging ow. Allow time for the

pneumatic ow to be read by the INO monitor

before making ne-tune adjustments. This may

take up to 2 minutes.

Figure 9

www.bedfont.com

17

NOxBOX® mobile Operating Manual

English

Calibration

The system should undergo checks to verify

the operation of the system is within expected

operating parameters. Any element found to

be operating outside of these safe operating

parameters should be reported to Bedfont or

your distributor for repair or replacement as

appropriate. Do not attempt to calibrate or repair

this device unless authorised to do so by the

manufacturer.

Flow Meters:

The NOxBOXmobile ow meters are calibrated

on N2 with a 5psi back-pressure. The ow

readings should be checked and veried.

All calibration, repair or refurbishment of this

equipment can only be undertaken by the

original manufacturer. These are safety critical

devices and must not be tampered with as this

could put patients at risk.

Pressure Regulators:

The pressure regulator performance should be

checked and the output pressure veried as 2

bar.

All calibration, repair or refurbishment of

this equipment can only be undertaken by

the original manufacturer. These are safety

critical, high-pressure devices and must not be

tampered with as this could put all users and

patients at risk.

WARNINGS: All operational checks will need

to be performed with N2 or NO/N2 mixes of

the appropriate purity grade. Ensure that safe

working practices are followed. Read the safety

notices at the front of this manual for guidance.

Do not undertake these system checks without

the appropriate PPE and ventilation in place.

www.bedfont.com

18

NOxBOX® mobile Operating Manual

English

Spares

NOxBOX

+

NO-S-V Replacement NO sensor for NOxBOX

+

NO2-S-V Replacement NO2 sensor for NOxBOX

+

NOXBOX-SCS-V Sample conditioning system – complete NOxBOX

+

NOXNAF-V Naon drying tube

NOXWT-V Water trap NOxBOX

+

18-0210 Pack of 6 size C batteries

NOXMAIN-V Mains adapter

NOX-T-CAL Calibration system (T-piece, calibration adapter and restrictor)

NOxBOXmobile spares

FIL020 BS14 Gas cylinder connector washer (PTFE)

Specication

Dimensions: 1590(H) × 500(W) × 528(D) mm

Weight: Approx. 40kg (complete trolley and cylinders)

Construction: Powder coated steel

Wheels: 75mm anti-static castors, with kick stop lock

Flowmeters: 0-100cc/min and 0-600cc/min

Regulator: Single stage, stainless steel, 2 bar max. outlet

Changeover: Regulator stainless steel

Storage conditions: Dry, clean atmosphere, 0-40ºC

NOxBOXO

2

NOXO2-NO Replacement NO sensor for NOxBOXO

2

NOXO2-NO2 Replacement NO2 sensor for NOxBOXO

2

NOXO2-O2 Replacement O2 sensor for NOxBOXO

2

NOXO2-NAF Naon drying tube

NOXO2WT-COMPLETE Water trap

FIX053 Power lead (UK)

FIX054 Power lead (EU)

NOX-Y-CAL Calibration system consisting of Y-piece and male luer

NOXKIT-V Selection of connectors NO and O2 to vent

NOXO2-FIL Bacterial lter

CON139 Leur tting for NOxBOXO2

CON136 Leur tting for NOxBOXO2

NOXO2-BAT Replacement battery unit for NOxBOXO2

NOXO2-INT-FIL Internal Filter for NOxBOXO2

NOXO2-PUMP Internal pump for NOxBOXO2

PUMP-FLO-MTR Flow meter for for calibrating pump ow on NOxBOXO2

NOXO2-SOLE Solenoid for NOxBOXO2

NOxBOX+ and NOxBOXO

2

058-18 -00520-V* Calibration gas – 25ppm NO in N2 (581 disposable cylinder)

058-20-01010-V* Calibration gas – 10ppm NO2 in air (581 disposable cylinder)

REGSS-1.0-V* Stainless steel gas regulator – 1l/min ow rate

CCG-V* Carry case to hold cans and regulators

NOXBOX-PLUS-CALKIT Consists of the four items marked * above

RECYCLER-V Puncture tool for recycling empty canisters

WIPES Instrument cleansing wipes

www.bedfont.com

19

NOxBOX® mobile Operating Manual

English

Warranty

Bedfont Scientic Ltd warrants instruments of its

manufacture to be free from defects in material

and workmanship for a period of ve years from

the date of shipment. Bedfont’s sole obligation

under this warranty is limited to repairing or

replacing, at its choice, any item covered under

this warranty when such item is returned intact,

prepaid, to the factory. The warranty does not

apply to any products which have been repaired

or altered by unauthorised persons, or which

have been subject to misuse, negligence or

accident.

www.bedfont.com

20

NOxBOX® mobile Operating Manual

English

Troubleshooting

The NOxBOXmobile is a device for use in

critical care applications. As such, any actions

carried out on the device must take into

consideration the condition and treatment of the

patient as the overall dening factor.

In all cases, in the event of a peripheral monitor

alarm sounding, rst check the health and

condition of the patient and take necessary

actions to best serve the patient’s needs.

Details on remedial actions to take in the event

of the monitor alarm should be covered by the

monitor user manual.

Q: The INO monitor attached to the patient

circuit is indicating high NO2 levels and a low

NO dose

A: Oxidation may have occurred in the NO highpressure supply line.

If qualied and you assess it to be safe to do so,

the fastest purge method is to crack pressure

at the high pressure line by following the steps

below:

● Turn-off the cylinder control valve fully.

● Using spanner provided, carefully turn

the connection nut until a sharp hissing

indicates the gas is being relieved in the

pressure line. This should stop within a few

seconds.

● Fully tighten the connection nut with the

spanner

● Open the cylinder control valve

Repeat for second supply lines.

During the above procedure, the regulated gas

in the system will continue to feed to the patient.

If deemed safe and appropriate for the patient,

reduce the ow of NO to minimise the level of

gas being delivered to the patient.

WARNING: sudden withdrawal from NO

therapy can have severe effects on the patient,

including, but not limited to, hypoxic rebound.

Ensure that best practice is observed at

all times to ensure the patient is not put at

unnecessary risk.

If the above procedure cannot be followed for

a quick system purge, then the system must be

purged through the ow meters. This must be

done without connection to the patient circuit

to prevent delivering high NO2 for prolonged

periods of time.

● Remove outlet from patient circuit (note

warning on sudden NO cessation)

● Turn off the cylinder control valve on both

cylinders

● Open the ow meter to approximately 600

cc/min (do not open valve above maximum

delivery scale, risk of damage to the control

mechanism)

● Allow rst system line to purge for 12

minutes

● Turn the auto-changeover control knob to

the second system line and allow to purge

for 12 minutes.

● Close the ow meter (do not over-tighten,

this may cause damage to the control

mechanism)

Open both cylinder valves to re-pressurise the

system. The system is ready to reconnect to

the patient circuit safely. Open ow meter to

appropriate setting to recommence delivery of

NO.

Q: Is the outlet pressure adjustable?

A: No, the outlet pressure is factory set and

is not user adjustable. This pressure has

been carefully designed to provide optimal

performance for the system. The ow control

equipment has been calibrated to operate at

this pressure. If any adjustment were made to

this pressure setting, the ow accuracy of the

NO ow meters cannot be guaranteed. This will

affect system performance and invalidate any

existing equipment warranty.

www.bedfont.com

21

NOxBOX® mobile Operating Manual

English

Q: The system is not achieving the desired dose

when I set the NO ow as indicated by the ow

tables in the Quick Start Guide (QSG).

A: The ow tables in the QSG are a reference

level, and some deviation from the value can be

expected. Large variation (e.g. +/-25%) however

may indicate a problem with the system:

● Check that the delivery pressure (low

pressure gauge) is set to 2 bar to ensure

that the NO ow reading is as calibrated.

● Check the supply cylinder concentration

matches the table being referred to for dose

setting.

● Check the patient ventilator ow conditions

are as expected.

● Check the sample line connection feeding

the INO therapy monitor is free from

blockages or leaks.

Q: On opening the NO ow control valve, the

oat rises as expected, but then there is a

noticeable drop before the oat rises again. Why

is this?

A: The ne control valve on the ow meter may

have been damaged by excessive opening of

the valve control. This can create deep scoring

on the valve surface which affects the ow

control performance across the ow range.

Please report to Bedfont or your distributor for

corrective action.

Q: Do Bedfont supply the manual bagging circuit

systems?

A: No, Bedfont cannot supply such materials.

These should be sourced by the medical care

provider. Any assistance regarding connection

to the NOxBOXmobile that Bedfont can provide,

please contact us.

Q: In the event of any other technical questions

regarding the NOxBOXmobile, how do I contact

Bedfont Scientic Ltd?

A: If this equipment was sourced through a

local distributor, please contact them in the rst

instance for assistance. Visit www.bedfont.com

and click on “Support”, use one of the contact

tools to connect with our technical support team.

Issue 5 - April 2013, Part No: LAB211

©Bedfont Scientic Ltd

Bedfont Scientic Limited reserves the right to change or update this literature without prior notice.

Registered ofce: England and Wales. Registered No: 1289798

Station Road, Harrietsham, Maidstone, Kent

ME17 1JA, England

Tel: +44 (0)1622 851122

Fax: +44 (0)1622 854860

Email: ask@bedfont.com

www.bedfont.com

Bedfont Scientic Ltd

ISO 9001:2008

Cert. No. FM 31664

ISO 13485:2003

Cert. No. MD 502905

Loading...

Loading...