SERVICE

FOR

MANUAL

BD

BD

RATE

RATE

INFUSER

and

INFUSER

|

II

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

Re

Order

Rev-

1990

0

N*

8896

1

Table

of

contents

SECMON1

INTRODUCTION

THEORY

TABLE

SECTION2.........

INSPECTON

UNIT

SYRINGE

RATE

LOW

OCCLUSION

ACCURACY

ACCURACY

DATA

SECTIONS

.......

1 /

INITIALIZATION

SWITCH

VOLUME

SHEET

............................

AND

CAUTIONS

OF

OPERATION - RATE

SYRINGE

PROCEDURE

SWITCH

TEST

TEST

TEST

FOR

に

にし に に に

CHECK

Methode

Methode

TESTING

SIZES

TEST

.........

ee

ee

.,.................

INFUSER | and

AND RATES

rr

....................

.........oo

OO

/VOLUME

DELIVERED

A

weighttest............

В

linear

BECTON

DICKINSION

ee

RATE

INFUSER

................

ooo

ooo...

CHECK

displacement . .

eee

RATE

.......

INFUSER

,

II

sees

reere

. . . ..

6

6

.6

8

10

10

10

11

12

12

13

15

16

17

20

TROUBLESHOOTING

GENERAL

SECTION

COMPONENTS

SPARE

HOWTOORDER

FRONT

SPLIT

CURTANS

REAR CASE

FIG

BATTERY

WIRED

RI-RII-

TROUBLESHOOTING

4

...

PARTS

CASE

RING

5:REAR

DOOR

BATTERY

INSTRUCTION

US - A90

.........................

.4

AND

ASSEMBLY

LISTING

...........

ASSEMBLY

AND

RETAINER

....,...........4

ASSEMBLY

CASE

.............,..............

TERMINAL

LABEL

.......................

..........,............

.........<oooooooo

..

........o.oooooooooo

GUIDE

REPLACEMENT

,...................:

.,....................

©

Becton

...............

..........

Dickinson

«ο

and

sens

ooo...

oo...

Co.

6 36

νο,

1990

20

24

27

27

27

29

33

35

37

38

39

40

42

PC

BOARD

EPROM

REVISION3

REVISIONS

MICROPROCESSOR

LOD

LCD

し

に に

に に に

DISPLAYDRVER

CRYSTAL

BUZZER

CHASSIS

MOTOR

CLAMP

FIG

PUSHERBLOCK

PUSHER

CHASSIS

CLAMP

REAR

ASSEMBLY

WITH

GEAR

BLOCK

6:

CLAMP

BLOCK

2.00000.

BLOCK

ASSEMBLY

ASSEMBLY

BLOCK

ASSEMBLY

INSTRUCTION

WITH

......

LABEL-

EPROM-REVISION1

FRONT

CASE

ASSEMBLY

........................

............

に

.......

sous

MOTOR

.

νο ο νοκ

ee

eee

ccc

に に に に

1.

.................

cc

に に に に

ニュー

ee

eee

esse

eee

eee

ων ο ων ο ο ο

ccc

ce

tee

ュー

トーーーー

eens

ees

ων ο εν ων 57

eens

cesse.

0000

..........4.44........

eee...

REVISION 0 ..............,

.........................,

......

00

A

ees

43

45

47

48

50

52

54

55

59

61

62

64

64

64

65

65

65

SECTIONS

ALIGNMENT

INITIALSETUP

HOME

HOME

TACHOMETER

TACHOMETER

OCCLUSION

SAFETY

RESISTOR

Q4

RUN-AWAY

RI-RII-

US - A90

...........

TEST

. .

POSITION

POSITION

ALIGNMENT

VOLTAGE

ADJUSTMENT

CHEK

ADJUSTMENT

CHECKS

STRIP

TRANSISTOR

CHECK

CHECK...

TEST

o

PROCEDURE

.......

ADJUSTMENT

.....................

(Cont)

....................,.

.....................,

.......

......................,

に

©

Becton

ων ο ον

...................

ce

eee

44...

TABLE

..........

неннннных

LL...

이 예 의

Dickinson

and

Co.

1990

67

67

67

67

69

69

70

70

72

72

72

이오

72

NOTES

RI-RII-

US - A390

©

Becton

Dickinson

and

Co.

1990

4

NOTES

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

5

SECTION

1

INTRODUCTION

This

manual

troubleshooting,

Dickinson

AND

is

designed

has

two

and

both.

Before

familiar

will

the

attempting

with

the

perform

RATE

INFUSER , the

any

unit.

dependably

———responsiblityforthe

with

the

To

facilitate

SERs

Problems

engineer

to

device

include

but

incurred

maintenance

specific

and/or

repairs

should

1-201-633-5500.

To

purchase

SYSTEMS’

spare

dealer.

CAUTIONS

to

help

the

biomedical

modular

Rate

maintenance

This

will

performance

at

user-replaceable

not

be

referred

parts,

See

Section 4 for a description

repair

of

Infusers - Rate

or

repair

help

and

accurately

party

avoid

possible

performing

ofthe device

the

time

of

the

and

repair,

covered

to

please

in

our

call

BECTON

your

this

Technical

BECTON

Infuser | and

at

repair

parts

engineer

DICKINSON

functions,

damage

ail

times.

the

installation

and,

in

and

DICKINSON

(see

manual

local

should

Service

authorized

of

perform

Rate

Infuser

review

By

addition,

in

the

this

and

ensure

accepting

accepts

future.

has

Section

spare

4).

not

be

Department

BECTON

parts.

routine

RATE

II.

This

material

that the

delivery

of

said

designed

attempted

at

DICKINSON

maintenance,

INFUSERS.

manual

carefully

RATE

of

spare

components

any

liability

the

by

the

1-800-BECTON-6,

Becton-

applies

to

become

INFUSER

parts

accepts

associated

RATE

biomedical

INFUSION

basic

to

for

INFU-

or

THEORY

The

designed

OF

RATE

transport

is

capable

The

RATE

The

unit’s

beep sounds,

no

syringe

The

motor

the

unit

RI-RII-

US - A90

OPERATION - RATE

INFUSER | is a microprocessor

for

the

continious

or

in

of

INFUSER

POWER

is

runs

will

not

pediatric

delivery

the

present,

for

perform

units.

rates

ranging

Il

is

similar

ON

switch

four

indicator

the

unit

approximately

the

INFUSER | and

|V

admininistration

The

pump

except

activates

lights

performs

forty

motor

speed

©

Becton

from

flash

RATE

controlled,

of

medication

accepts

0.1

that

an

automatic

in

an

(40)

control

syringe

ml/hr

to

is

accepts

sequence,

additional

seconds

check.

Dickinson

INFUSER

battery

operated,

during

sizes

99.9

mi/hr.

syringes

system

and

the

diagnostic

during

and

this

Co.

1990

II

portable

surgery

ranging

ranging

from 5 cc

from

check. During

display

motor

test.

registers

speed

If a syringe

|

syringe

and

for

to

1cc

this

self-test

all

control

pump

patient

60

cc

to

60cc

zeros.

check.

is

in

place,

in

and

one

If

6

The

occlusion

the

syringe

displacement

established

automatically

and

the

Both

rate

clamp

resulting

in

interrupt

timer

off.

infusers

mechanism

against

from

the

product

the

feature

is

contained

an

internal

the

pressure

specification,

infusion,

many

activate

other

safety

within

the

spring.

on

the

the

audible

alarms

syringe

The

occlusion

spring.

If

occlusion

and

visual

and

checks.

clamp

and

wiper

the

displacement

alarm

is

alarms,

operates

by

constantly

exceeds

activated.

and

turn

both

depressing

monitors

The

the

the

unit

motor

the

value

will

Operation

manual.

Always

guides

refer

for

the

to

Rate

infuser | and

the

Operation

Rate

Guides

infuser

for

Il

are

instructions

included

on

at

use

the

of

end

the

of

this

pumps.

service

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

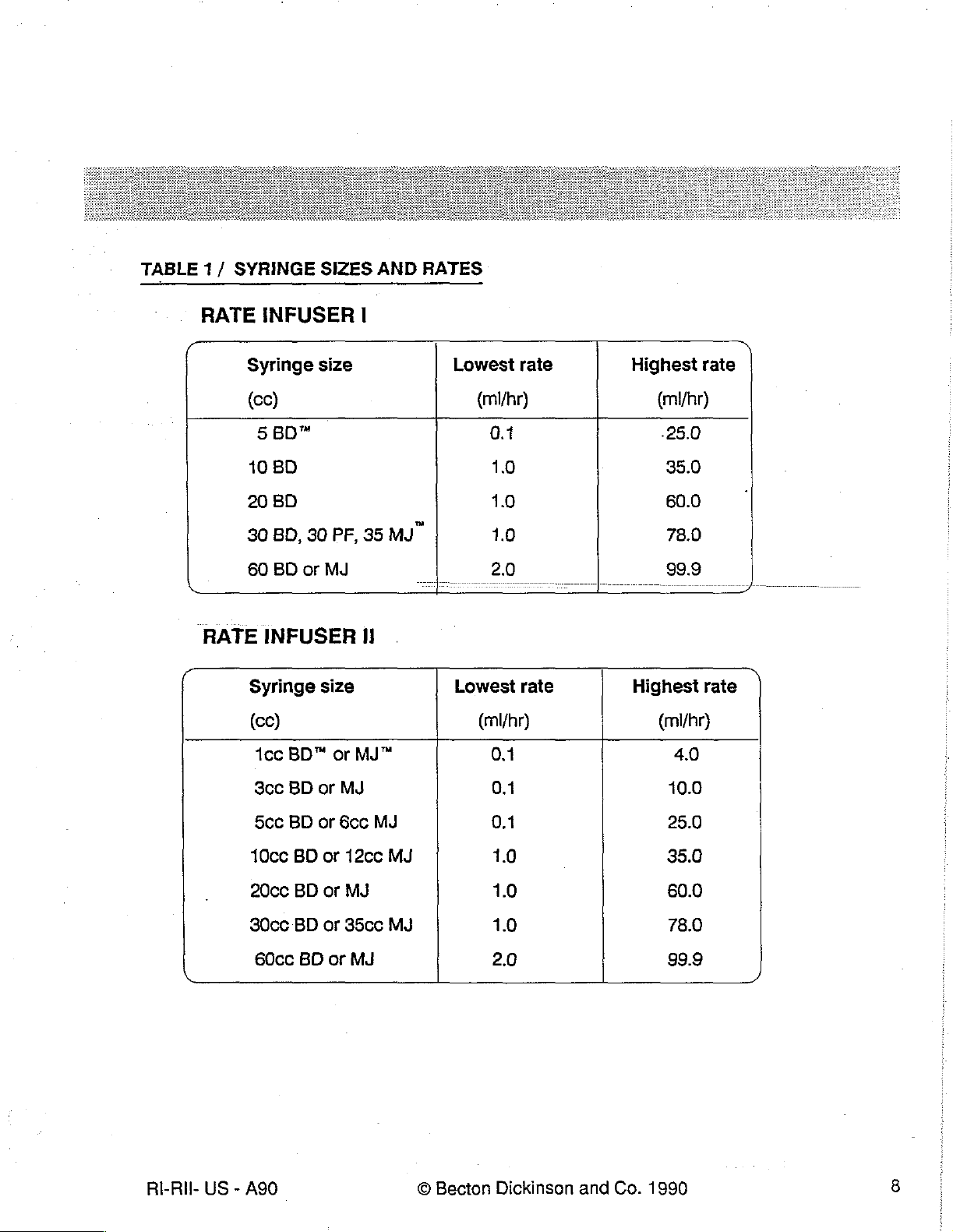

TABLE

1/

SYRINGE

SIZES

AND

RATES

RATE

RATE

INFUSER

Syringe

(cc)

5BD

10

BD

20

BD

BD,

30

60

BD

or

INFUSER

Syringe

(οο)

1ce

BD"

size

30

MJ

size

|

PF,

35

II

or

MJ"

MJ"

Lowest

(mi/hr)

0.1

1.0

1.0

10

2.0

Lowest

(ml/hr)

0.1

rate

rate

Highest

Highest

rate

(mhr)

.25.0

35.0

60.0

78.0

99.9

rate

(mi/hr)

4.0

ὴ

RI-RII-

US - A90

Scc

5cc

10cc

20cc

30cc

60cc

BD

BD

BD

BD

BD

BD

or

or

or

or

or

or

MJ

6cc

12cc

MJ

35cc

MJ

MJ

MJ

MJ

0.1

0.1

1.0

1.0

1.0

2.0

©

Becton

Dickinson

and

Co.

10.0

25.0

35.0

60.0

78.0

99.9

1990

ノ

NOTES

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

|

9

SECTION

2

INSPECTION

The

following

the

unit's

case.

as a diagnostic

opened.

EQUIPMENT

Stopwatch

Pressure

Syringes : BECTON

BECTON

Three

UNIT

Record

REQUIRED

(the

meter

DICKINSON

way

stopcock

INITIALIZATION

PROCEDURE

inspection

This

procedure

procedure

all

data

longest

(0-50

DICKINSON,

with

TEST

procedure

at

for

test

psig

minimum

Cat.

luer

may

the

completion

this

section.

will

be

approx. 1 hour.

PLASTIPAK*

No

2804

fittings.

permits

be

range,

testing

used

0.1

extension

for

periodic

of

every

psig

3

set

of

the

RATE

inspection.

repair,

and

Resolution

resolution)

cc,

10

cc,

20

(60

inch

microbore

INFUSER

after

should

cc,

60

It

should

the

be

at

cc.

tubing

without

pump

opening

be

performed

has

been

least 1 second).

set).

1

install

2

Press

3

Press

Mİ

Beep

EE

The 4 indicator

* © Plastipak

RI-Ril-

US - A90

batteries.

the

POWER

POWER

is

is a TM

Do

not

place a syringe

OFF

button.

ON

button.

activated

Observe

once.

lights

of

Becton

Dickinson

the

flash

in

©

Becton

in

the

clamp.

following

sequence

seguence

and

Co.

Dickinson

and

of

events

Co.

:

1990

10

4

ME

The

lf

Display

M

Al

ος".

Press

INFUSE

Il

Observe

E

unit

unit

will

registers

legends

button

double

does

not

run a motor

all

"8",

except

with

"ML/HR*

no

syringe

beep.

infuse.

self-test

displays

turn

in

place.

for

"BD",

off

approximately

("PF")*,

and

the

40

"MJ",

upper

seconds.

"CC"

and

lower

and

"ML/HR"

segments

.

show

all

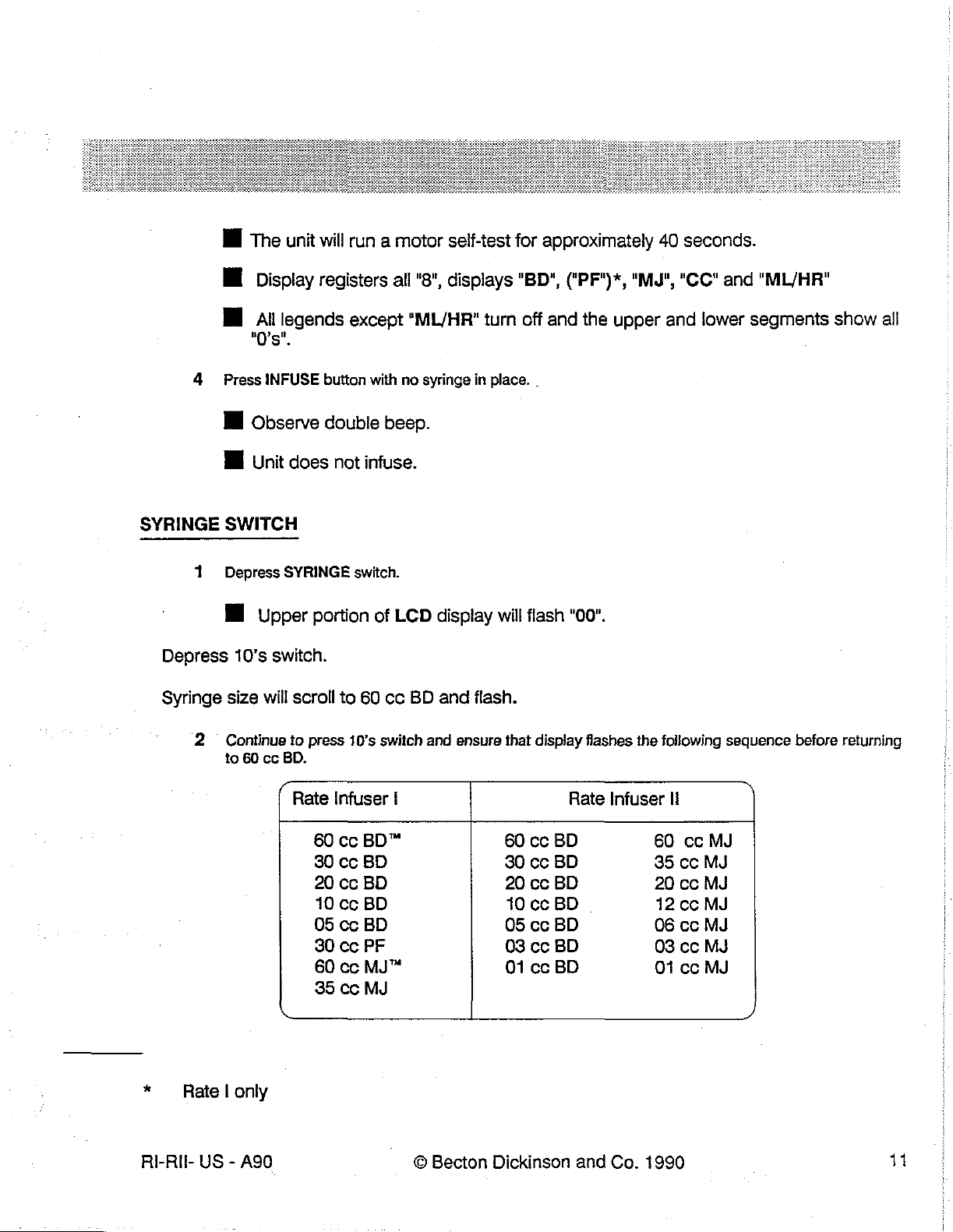

SYRINGE

1

Depress

Syringe

2

SWITCH

Depress

=

Upper

10’s

switch.

size

will

Continue

to

60

cc

SYRINGE

portion

scroll

to

press

BD.

(

Rate

60

30

20

10

05

80 cc

60

35

switch.

of

to

60

cc

10’s

switch

Infuser

cc

BD™

cc

BD

cc

BD

cc

BD

cc

BD

PF

cc

MJ™

cc

MJ

LCD

BD

|

display

and

and

ensure

will

flash.

that

60

30

20 cc

10

05

03 cc

01

flash

display

cc

BD

cc

BD

BD

cc

BD

cc

BD

BD

cc

BD

"00".

flashes

Rate

the

following

Infuser

60

35

20

12cc

06

03 cc

01

li

cc

cc

cc

ce

cc

sequence

MJ

MJ

MJ

MJ

MJ

MJ

MJ

)

before

returning

* — Rate | only

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

11

3

Depress

Syringe

SYRINGE

size

will

switch

stop

flashing

RATE

LOW

SWITCH

1

Depress

Lower

2

Press

3

Ensure

4

Repeat

5

Set

6

Depress

VOLUME

1.

Placea

flange.

RATE

switch

portion

10's

rate

of

LCD

switch.

that digits 0 to 9 are

for 1's

CHECK

to

60.0

RATE

20

ce

switch

ml/hr.

switch.

/VOLUME

syringe

display

and

.1's

in

clamp.

will

flash.

displayed

switch.

DELIVERED

Set

syringe

for

tens

place.

plunger

CHECK

to 5 cc

.2

00.

Move

pusher

block

down

onto

syringe

2

3

RI-RII-

US - A90

With

syringe

Mİ

Press

milliliters

E

Low

Volume

II

After

seconds.

ll

Press

№

Press

Moving

the

size

set

and

hold

delivered.

the

Low

the

SYRINGE

STOP

pusher

infusion

up

to

"20 cc

VOL

Release

LED

will

Volume

to

top

BD"

and

rate

DEL

switch.

VOL

begin

switch.

switch.

position

©

Becton

LED

Beeping

will

to

begins

Motor

to

"60.0

ml/hr",

"mi/hr*

DEL

switch

flash

within 1 to 5 minutes.

to

flash, a double

will

will

stop

turn

off

LOW

Dickinson

press

will

stop.

and

VOLUME

and

Co.

INFUSE

change

beep

infusion

LED.

1990

switch.

to

"mi".

LED

will

be

will

LCD

heard

turn

will

display

every

off.

5

12

OCCLUSION

1

2

(1

NOTE:

TEST

Turn

on

pressure

Place

an

unused 5 cc

pusher

syringes

block.

with

meter.

syringe

Do

not

push

abnormally

down

filled

with

on

the

high

5.0

cc + .2

syringe

using

friction

should

cc

of

pusher

water

into

block; a loose

not

be

used.

position

mounting

in

the

clamp

is

desired.

block

and

Depress

3

4

Set

Depress

Depress

Set

Depress

Connect

2804)(See

10

With

the

11

12

SYRINGE

syringe

SYRINGE

RATE

rate

to

RATE

the

the

system

released

Depress

Blinking

before

vent

27.0

(all

valve.

INFUSE

ATTENTION

size

switch.

25.0

mi/hr.

switch

pressure

FIG.

2).

air

is

PSIG.

to 5 cc

BD

meter

vented,

out

of

switch.

LED,

Minimurn

to

advance

the

system)

and

trigger

the

the

"Occ"

pressure

syringe

pusher

and

zero

ste

25

e

will

display,

through a three-way

toward

relative

mijir

dc

should

the

the

pressure

alarm

be

9.9

clamp

aq

‘

beeps

PSIG.

valve

until

is

applied

-

and

Record

and a BD

two

or

to

BVO

the

unit

pressure

three

the

shuts

extension

drops

pressure

psi

down

reading

set

(NO.

of

water

are

meter.

automatically

and

Close

results.

13

14

15

Ri-RIL-

US - A90

Depress

Repeat

"60

beeps,

pressure

Depress

STOP

steps 3 through

cc

BD" and

and

should

POWER

INFUSION.

rate

unit

shut

be

OFF.

to

down)

5.5

Alarm

12

using a 60

"99.0

PSIG.

bå

©

will

mi/hr’.

The

should

Record

60

GI

ml

Becton

stop

and

ATTENTION

cc

syringe

occlusion

be

activated

pressure

<

reading

SS

Ar

Dickinson

filled

with

alarms

before

and

and

LED

will

60 cc + 0.5

(blinking

the

results.

-

Co.

ATTENTION

pressure

ро

1990

stop

flashing.

mi

reaches

of

water.

296

Set

LED,

12.0

syringe

multiple

PSIG.

Minimum

size

alarm

to

13

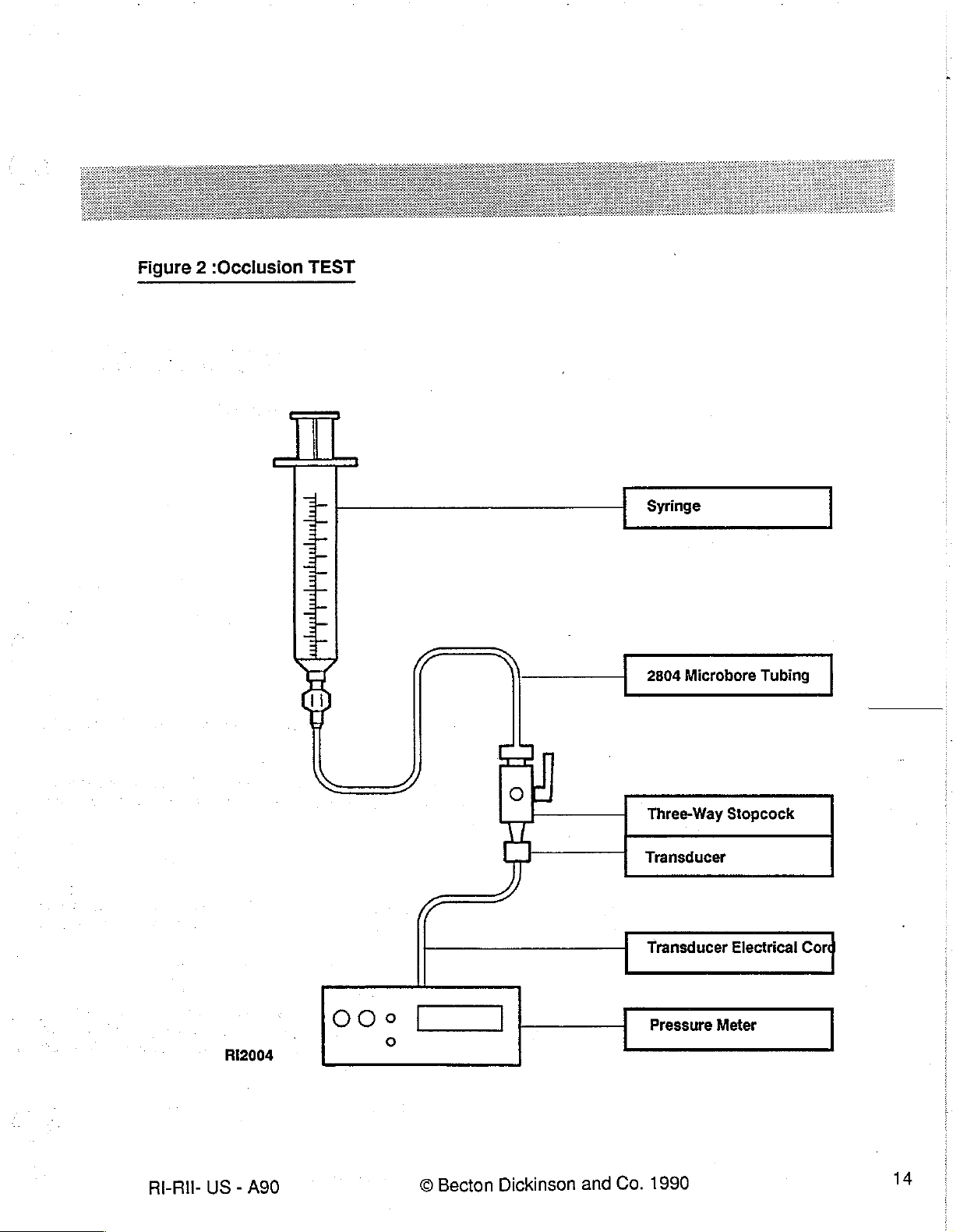

Figure 2 :Occlusion

TEST

Syringe

2804

Microbore

Tubing

RE-RII-

US

RI2004

Becton

A90

-

©

Dickinson

and

Three-Way

Transducer

Transducer

Pressure

1990

Co.

Stopcock

Electrical

Meter

14

ACCURACY

TEST

Method

1

2

"A"

weight

Insert a filled

Prime

Set

the

Run

the

Tare

(zero)

Run

the

Record

Volume

Repeat

between

60 cc

the

unit.

RATE

discharge

the

pump

the

weight

delivered

for a 5

0.95

test

syringe

for

99.9

of

the

balance.

for

30

minutes + 5

on

should

cc

syringe

and

1.03

into

mi/hour

tubing

the

balance.

be

between

set

gms.

the

pump.

set

into a container

seconds.

47.45

at

0.1

mi/hr.

Attach a tubing

on a balance.

and

51.45

gms.

Run

for

10

hours + 5

set.

seconds.

Volume

delivered

should

be

[

NOTE

starting

NOTE

is

utilized

RI-Ril-

US - ASO

1:

to

tests.

2:

Syringe

by

minimize

inaccuracies

BECTON

evaporation,

may

DICKINSON

©

Becton

place a thin film

affect

in

the

results

routine

testing.

Dickinson

and

of

light

oil

utilizing

Co.

1990

in

this

the

container

method.

before

Method

"B"

15

ACCURACY

Method

1

2

3

4

5

6

7

8

TEST

"B"

linear

Mount

the

force

pusher

Depress

Place

a5

Depress

Release

Set

syringe

Zero

dial

Simultaneously

Record

displacement

RATE

INFUSER

against

closest

POWER

ce

syringe

and

hold

switch

size

or

digital

ending

to

when

in a gage

the

pusher

the

pump

ON

in

syringe

PRIME

gage

to

"5

cc

BD"

gage

and

press

INFUSE

position.

Press

is

constant

housings

clamp.

switch

moves

and

record

and

volume

system

Push

to

prime

forward

rate

to

starting

start

which

can

and

less

syringe

the

unit.

at

least

"25.0

ml/hr",

position.

the

stopwatch.

delivered

switch.

measure

than

0.5

Ibs.

flange

down

0.30

inch.

After 5 min. + 2

Record

the

linear

Measure

to

reading.

travel

the

bottom

of

the

motion

of

travel.

seconds

pusher.

on

the

press

STOP

Assure

part

of

Infuse.

that

the

-

9

10

11°

12

RI-Ril-

Subtract

Displacement

Depress

Repeat

0.1328

US - A90

ending

POWER

test

and

position

should

for5

cc

0.1434

be

OFF.

BD

syringe

inches.

from

starting

between

run

Volume

©

Becton

position

.691

and

at0.1

mi/hr

delivered

Dickinson

and

record

.747

inches.

for 4 hours + 5

should

display

and

displacement.

Volume

delivered

seconds.

0.4 +

Co.

1990

should

Displacement

0.1

ml.

be

2.0

should

ml + 0.1 ml.

be

between

16

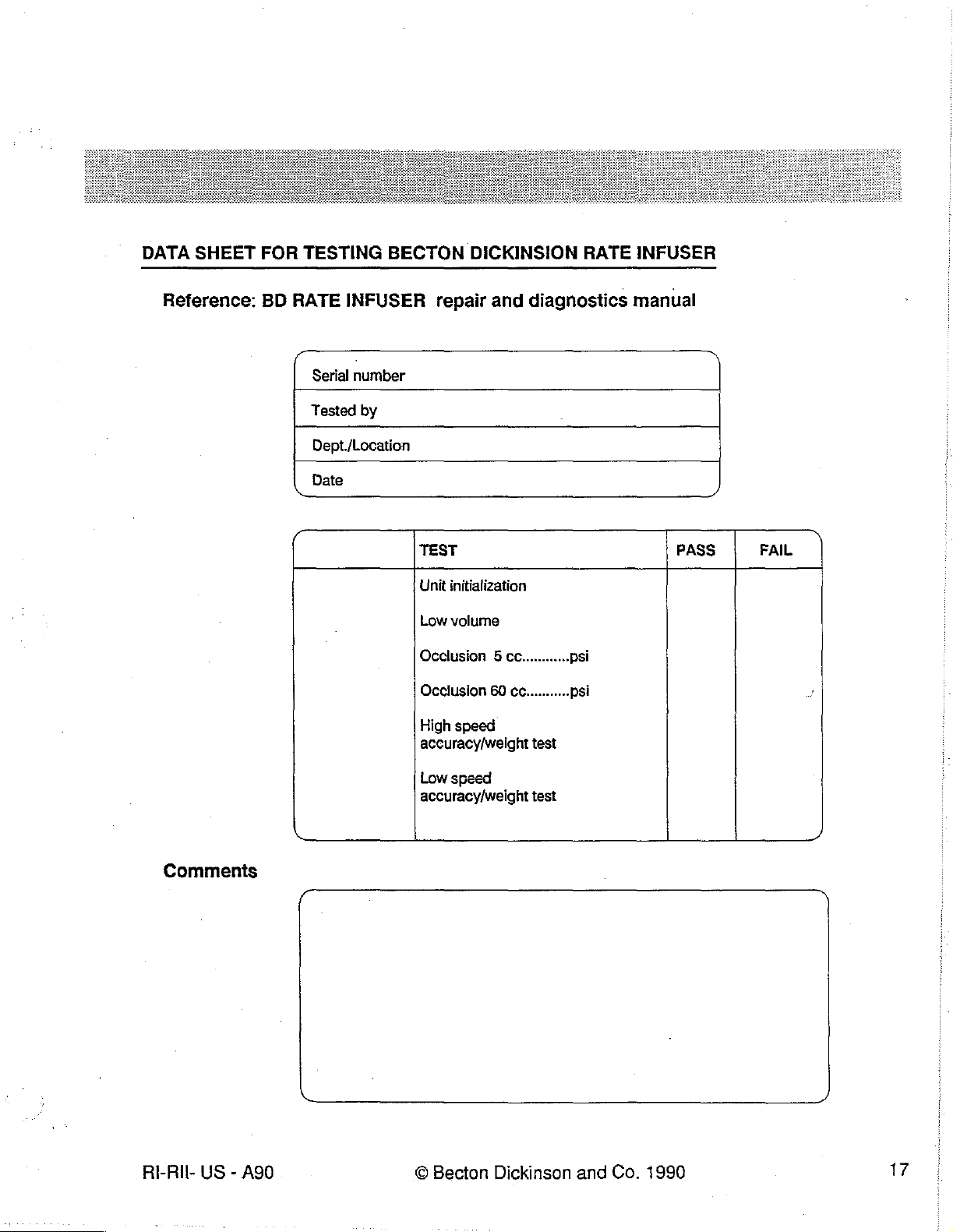

DATA

SHEET

FOR

TESTING

BECTON

DICKINSION

RATE

INFUSER

Reference:

BD

RATE

C

|

~

INFUSER

Date

.

Serial

number

Tested

Dept./Location

by

repair

TEST PASS

Unit

Low

Occlusion 5 cc............

Occlusion

High

accuracy/weight

and

diagnostics

initialization

volume

60

ce...........

speed

test

manual

N

psi

psi

)

FAIL

Commenis

RI-RIl-

US - A90

Low

speed

accuracy/weight

test

©

Becton

Dickinson

and

Co.

1990

NOTES

RI-Ril-

US - A90

©

Becton

Dickinson

and

Co.

1990

18

NOTES

RI-Ril-

US - A90

©

Becton

Dickinson

and

Co.

1990

19

SECTION

TROUBLESHOOTING

This

section

tion

of

aid

the

identified,

tion

on

provides

the

RATE

bioengineer

the

Assembly

ordering and

3

detailed

INFUSER . The

in

pinpointing

Replacement

procedures

information

regarding

troubleshooting

problems

section

for

replacement

and

of

this

the

guide

their

sources.

manual

and

repair.

mechanical

on

the

following

Once

(which

follows)

and

electrical

page

the

problem

provides

configura-

is

designed

has

informa-

to

been

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

20

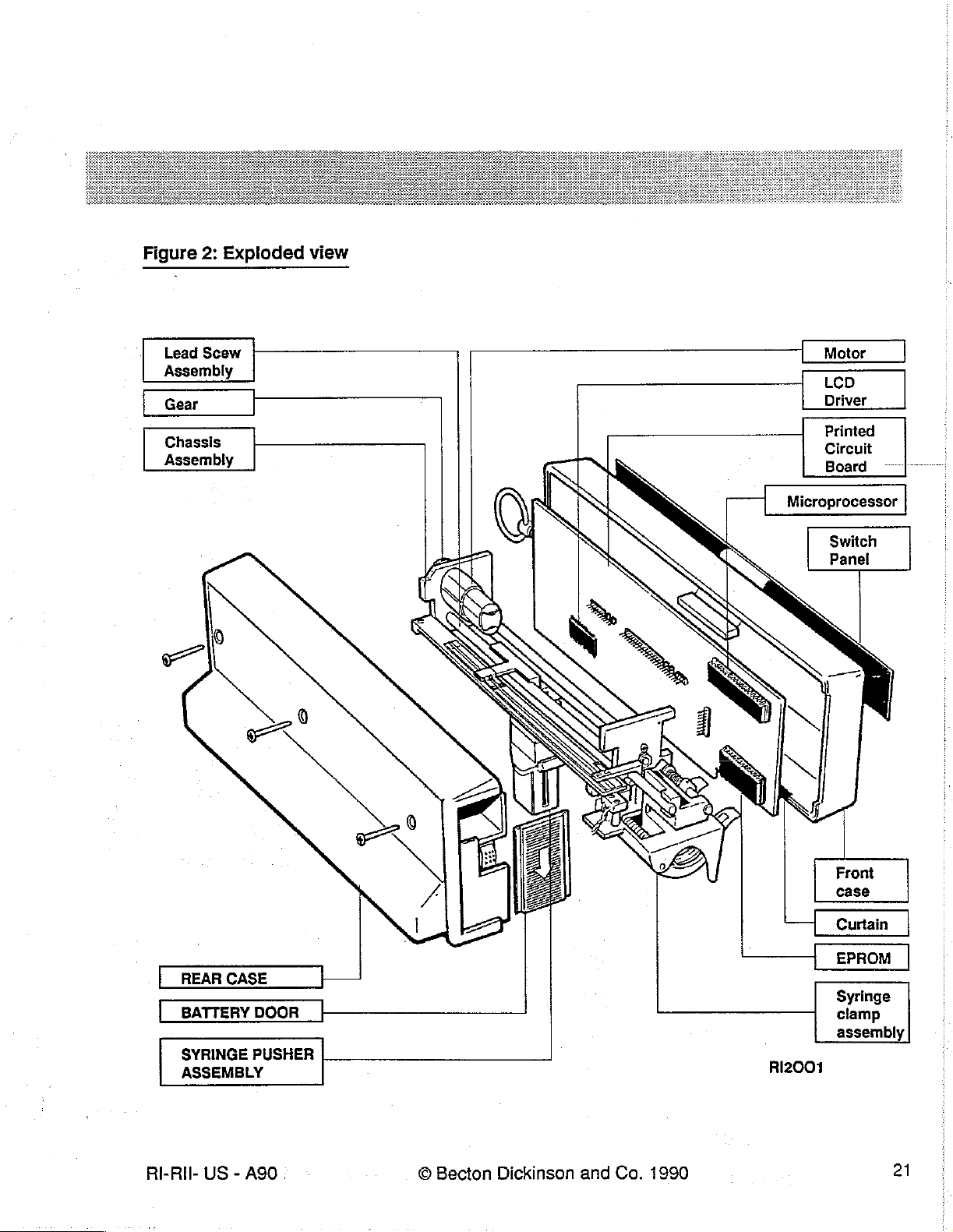

Figure

2:

Exploded

view

Lead

Scew

Assembiy

Ger

|

Chassis

Assembly

|

-

Motor

LCD

Driver

inted

Circuit

Board

Microprocessor

Switch

Panel

REAR

SYRINGE

ASSEMBLY

RI-RII-

US - A90

CASE

PUSHER

©

Becton

Dickinson

and

Co.

1990

RI2001

Syringe

clamp

assembly

21

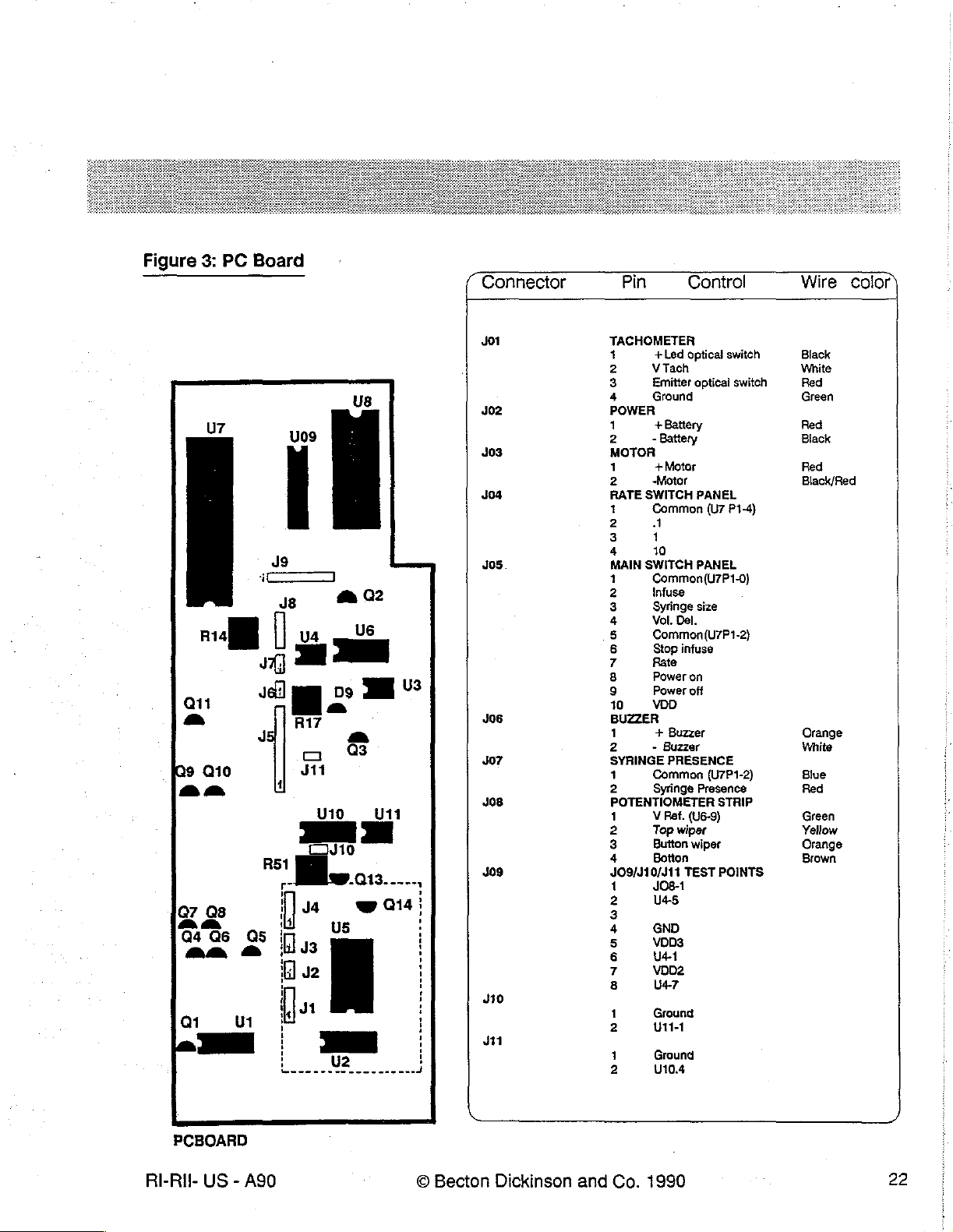

Figure

3:

PC

Board

(

Connector

Pin

Control

Wire

color)

J01

υ8

D9

a

o

a

=

3

Q13

2

U3

U11

7 1

J8

Ta

ma

圖

Q11

a

L

9

Q10

fa

U4

JA} р |

Jel]

R17

o

311

RSI

сто

ビ

a

U10

302

403

Jos

405

306

J07

Jos

409

TACHOMETER

1

+Led

2

V

3

4

РОМЕН

1

2

MOTOR

1

2

RATE

1

2

3

4

ΜΑΙΝ

2

3

4

5

6

7

8

9

10

BUZZER

1

2

SYRINGE

1

2

POTENTIOMETER

1

2

3

4

JO9/J10/J11

Tach

Emitter

Ground

+

Battery

-

Battery

+

Motor Red

„Motor

SWITCH

Common

A

1

10

SWITCH

Common(U7P1-0)

Infuse

Syringe

Vol. Del.

Common(U7P1-2)

Stop

Rate

Power

Power

VD

+

Buzzer

-

Buzzer

PRÉSENCE

Common

Syringe

V

Ref.

Top

Button

Botton

JO8-1

optical

optical

PANEL

(U7

PANEL

size

infuse

on

off

(U7P1-2)

Presence

(U6-9)

wiper

wiper

TEST

switch

switch

P1-4)

STRIP

POINTS

Black

White

Red

Green

Red

Black

Black/Red

Orange

White

Blue

Red

Green

Yellow

Orange

Brown

07

00

Gide

an

Qi

~

PCBOARD

RI-Ril-

US - A90

i]

! i

os

ls

a

| H

1

t 1

ἡ

9,131

U

| !

i !

|

nu

ya

A

U2

wa;

+

|

i

:

i

i

A

3 2

410

jn

©

Becton

Dickinson

and

3

6

7

8

1

2

1

Co.

us

NI

a

U4-1

von

U47

Ground

Ut

Ground

U10.4

1990

22

Figure

An

4:

electrical

Electrical

Schematic

schematic

has

been

enclosed

seperately

with

this

binder.

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

23

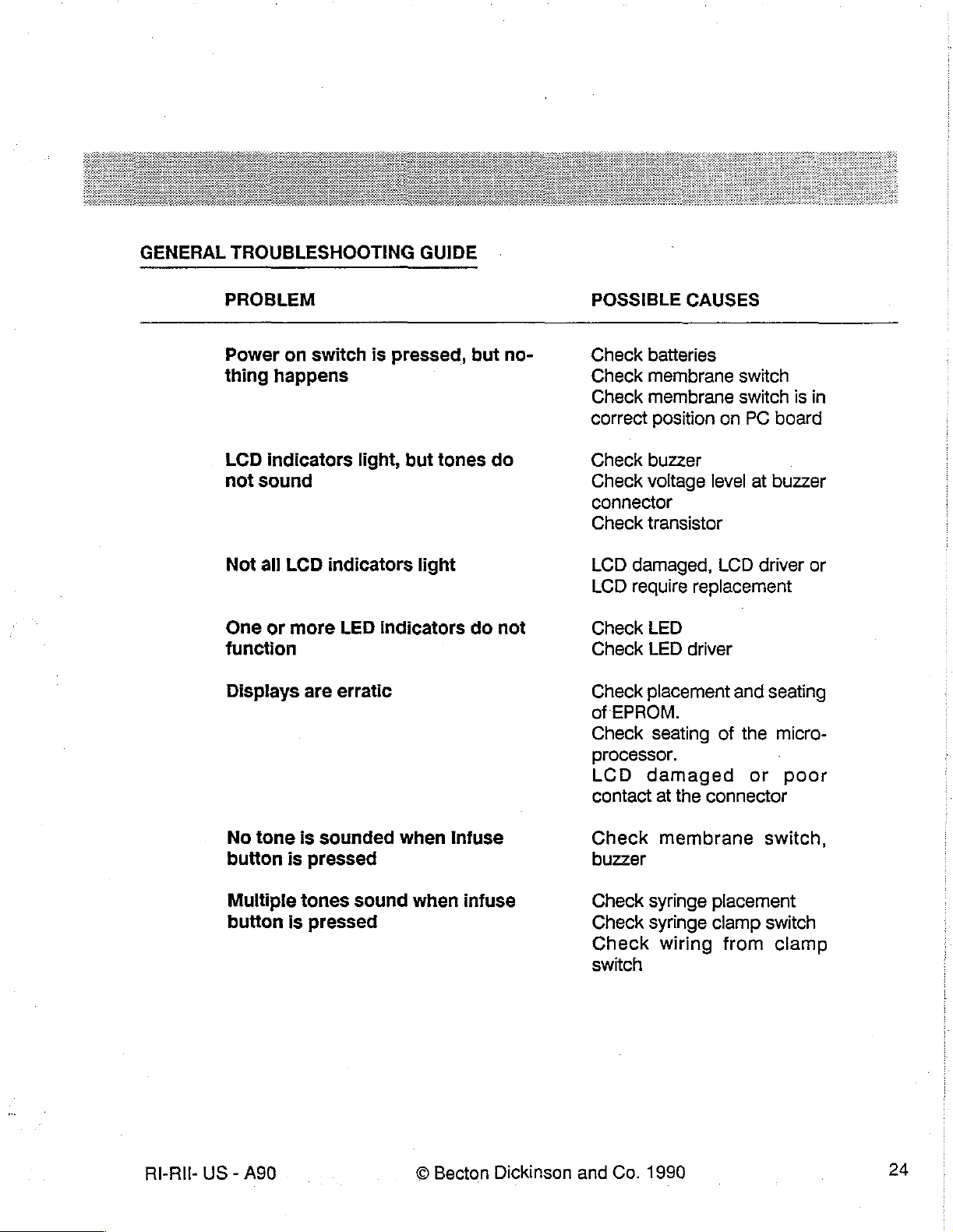

GENERAL

TROUBLESHOOTING

GUIDE

PROBLEM

Power

thing

LCD

not

Not

One

function

Displays

on

switch

happens

indicators

sound

all

LCD

indicators

or

more

are

is

pressed,

light,

LED

indicators

erratic

but

light

but

tones

do

no-

do

not

POSSIBLE

Check

Check

Check

correct

Check

Check

connector

Check

LCD

LCD

Check

Check

Check

of

Check

baiteries

membrane

membrane

position

buzzer

voltage

transistor

damaged,

require

LED

LED

placement

EPROM.

seating

CAUSES

switch

switch

on

PC

board

level

at

buzzer

LCD

driver

replacement

driver

and

seating

of

the

micro-

is

in

or

processor.

LCD

contact

damaged

at

the

connector

or

poor

RI-RII-

No

tone

button

Multiple

button

US - A90

is

sounded

is

pressed

tones

is

pressed

sound

when

when

©

Infuse

infuse

Becton

Dickinson

Check

buzzer

Check

Check

Check

switch

and

Co.

membrane

syringe

syringe

wiring

1990

switch,

placement

clamp

from

switch

clamp

24

PROBLEM

POSSIBLE

CAUSES

Attention

seconds

Infusion

mally

and

15

but

all

displays

minutes

alarm

of

starts

attention

sounds

starting

and

an

functions

alarm

flash,

within a few

infusion

nor-

sounds

after

approx.

Check

occlusion;

circuit

ger

with

just

Indicates

drive

perly.

train;

and

train.

syringe

and

driver

potentiometer

clamp

is

not

Check

Check

its

engagement

for

presence

Check

wiper;

wiper

occlusion

Check

and

strip;

assembly.

that

mechanical

functioning

motor

plunger

plun-

contact

and

drive

driver

with

drive

of

Ad-

pro-

RI-RII-

US - A90

.

©

Becton

Dickinson

and

Co.

1990

25

NOTES

RI-Ril-

US - A90

©

Becton

Dickinson

and

Co.

1990

26

SECTION

4

COMPONENTS

In

order

be

recommended

are

should

[)

NOTE:

when

SPARE

to

opened.

performed

be

itis

closing

PARTS

Descripion

Front

Pusher

AND

ASSEMBLY

replace

The

performed

very

any

batteries

that

the

on

every

important

the

unit.

LISTING

case

assembly

block

component

should

Alignment

unit

that

on

every

to

assembly

REPLACEMENT

or

assembly

be

removed

Test

Procedure

is

opened.

unit

after

it

avoid

pinching

Rate

Catalog

8880

8851

prior

In

has

been

infuser

(except

addition,

any

for

to

opening

and

the

ail

opened.

wires

!

N°

the

instruction

the

Occlusion

the

test

between

Rate

Catalog

8833

8837

label)

pump

procedures

the

Infuser

case.

Adjustment

studs

or

li

N°

the

unit

must

ft

is

strongly

Procedure

(Section

case

halves

5)

,

RI-Ril-

US - A90

LCD

display

Curtains

Rear

case

Chassis

motor,

and

optical

Motor

PC

with

board - revision 3 with

driver

(2)

assembly

assembly

encoder

switch

gear

gear,

EPROM

Optical

switch

with

LCD

©

Becton

8882

8853

8884

8885

8886

8887

8888

(rev.

8889

Dickinson

5)

and

Co.

8882

8853

8884

8838

8886

8887

8834

8889

1990

(rev.

1)

27

Descripion

Rate

infuser

|

Rate

Infuser

II

Encoder

Microprocessor

Wired

Battery

Split

Rear

Clamp

Buzzer

Crystal

Diagnostic

(this

LCD

gear

assembly

battery

door

ring

instruction

block

for

manual)

dispiay

terminals

with

retainer

assembly

PC

and

board

label

repair

manual

8890

8891

8863

8892

8865

8893

8894

8867

8872

8896

8881

(rev.

1)

8890

8891

8863

8892

8865

8835

8836

8867

8872

8896

8881

(rev.

0)

See

the

following

different

RI-Ril-

versions

US - A90

pages

of

the

for

information

RATE

INFUSER.

©

Becton

on

how

Dickinson

to

order

and

the

Co.

correct

1990

parts

for

the

28

HOW

TO

ORDER

DESCRIPTION

8833

8834

8835

8836

8837

8838

Front

(Rate

EPROM-

(Rate

Rear

Revision 0 (Rate

Clamp

(Rate

Pusher

(Rate

Chassis

encoder

case

assembly

Infuser

Infuser

Instruction

block

il

Only)

Revision

ll

Only}

Label-

assembly)

1

Infuser

Infuser l Only)

block

Infuser

assembly

I!

Only)

assembly

gear,

and

Il

with

motor,

optical

Only)

REQUIRED

Comes

door,

with

Does

label

Does

label.

tion

tion

screws.

instruction

not

not

Does

Does

not

label

not

label

INFORMATION

with

curtains,

Does

include

include

come

come

battery

not

label

instruction

instruction

with

instruc-

with

instruc-

come

switch

(Rate

Infuser

II

Only)

RI-RI

8851

US - A90

Pusher

(Rate

Infuser | Only)

block

assembly

©

Becton

Dickinson

Does

tion

and

label

Co.

not

1990

come

with

instruc-

29

DESCRIPTION

REQUIRED

INFORMATION

8853

8863

8865

8867

Curtains

Wired

Split

Buzzer

battery

ring

(2)

with

terminals

Retainer

Does

tion

not

label

Does

label

Does

label.

Does

label

not

not

not

come

with

include

include

include

instruc-

instruction

instruction

instruction

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

30

DESCRIPTION

REQUIRED

INFORMATION

8880

8881

8882

8884

8885

8886

Front

(Rate

case

infuser I Only)

LCD

LCD

display

Rear

case

Chassis

encoder

switch

(Rate

Motor

Infuser | Only)

with

assembly

driver

assembly

assembly

gear,

and

encoder

with

optical

gear

motor,

Comes

door,

with

Does

tion

Does

tion

Comes

come

Does

label

screws.

instruction

not

label.

not

label

with

Comes

screw

clude

instruction

with

curtains,

come

come

with

screws.

instruction

not

include

with

motor

for

gear.

Does

not

label.

with

with

Does

instruction

mounting

Does

label.

battery

come

instruc-

instruc-

not

label

not

in-

RI-RII-

US - A90

8887

8888

PC

board - revision

EPROM

(Rate

-

Revision

Infuser I Only)

©

Becton

3

5

Dickinson

Does

label.

and

Co.

not

1990

include

instruction

31

DESCRIPTION

REQUIRED

INFORMATION

8889

8890

8891

8892

8893

8894

8895

Optical

Encoder

Microprocessor

Battery

Rear

revision

(Rate

Clamp

(Rate

Crystal

switch

gear

door

instruction

1

Infuser | Only)

block

Infuser | Only)

for

assembly

label

assembly)

PC

board

Does

label

Does

label.

Does

label.

Includes

strip.Does

tion

Replace

Does

label.

wire

Does

label

not

include

not

include

not

include

not

label.

all

not

include

Comes

and

wiper.

not

include

copper

previous

instruction

instruction

instruction

contact

include

instruc-

revisions.

instruction

with

separate

instruction

Lİ

TO

ORDER

Call

Lİ

For

INFUSION

RI-RII-

US - A90

SPARE

your

local

technical

SYSTEMS

PARTS

authorized

information

TECHNICAL

FOR

YOUR

BECTON

regarding

Service

©

Becton

RATE

DICKINSON

spare

parts

at

Dickinson

INFUSER:

INFUSION

and

repair,

SYSTEMS

1-800-232-8666

and

Co.

1990

dealer.

call

BECTON

or

1-201-633-5500

DICKINSON

32

FRONT

1

Front

2

Curtains

1

Battery

3

Gase

CASE

ASSEMBLY : CATALOG

Materials

case

assembly

door

with

screws

Procedure

positive

battery

N°

8880

terminal

(Rate

Infuser 1 Only)

Remove

in

procedure. A heat

With

Remove

Remove

Replace

Remove

optical

Unscrew

front

Attach

Reinstall

order

the

switch

case.

the

the

instruction

to

prepare

pump

lying

the

back

the

buzzer

the

curtain

the

chassis

connector,and

the 3 screws

curtain

the

PC

the

gun

on

case.

connector

on

by

that

to

the

board

label

from

the

case

for

the

is

useful

in

removing

its

front

face,

and

the

the

back

case

disconnecting

the

resistor

hold

the

PC

new

front

case.

into

the

front

back

case.

replacement

the

remove

and

power

set

the

motor,

the

connector.

the

strip

board

in

case.

The

label

label

that

label.

Remove

three

back

back

case

the

switch

connector.

place

and

should

be

will

be

batteries.

case screws.

aside.

panel

connectors , the

Set the

set

the

chassis

PC

removed

applied

aside.

board

cleanly

at

the

aside.

and

completion

clamp

Discard

completely

of

connectors

the

damaged

this

,

10

11

12

13

RI-RII-

US - A90

Reinstall

Reconnect

the

connector,

Proceed

Reconnect

to

chassis.

the

motor

connector,

and

the

resistor

section 5 for

the

buzzer

connector

the

strip

connector

alignment

and

©

Becton

switch

and

occlusion

the

power

Dickinson

panel

.

connector

connector,

adjustment

.

and

Co.

the

clamp

test

procedures.

1990

connector,

the

optical

switch

33

14

Attach

(1

CAUTION : when

care

not

to

15

Test

16

Attach a new

the

back

bend

in

or

accordance

instruction

case

while

holding

reattaching

crimp

the

with

inspection

label*

the

battery

the

back

switch

and replace

panel

procedure

door

in

case

use

ribbon

in

Section

batteries.

its

channel

the

cables

2.

for

three

or

positioning.

screws

any

provided

other

wires.

and

take

*

Order

RI-RII-

US

separately

-

A90

©

Becton

Dickinson

and

Co.

1990

34

Split

1

Spiit

ring

and

Materials

ring

Procedure

retainer : Catalog

with

ring

retainer

i

N°

8865

O

1 | Remove

2 | With

3

4

5 | Attach

CAUTION

panel

6

7

the

instruction

in

order

to

prepare

procedure. A heat

the

pump

lying

Remove

Place

ribbon

Testin

Attach a new

the

the

ring

the

back

:

When

cables

accordance

back

retainer

reattaching

instruction

the

gun

on

case.

case

while

or

any other

with

label

from

case

is

useful

its

front

Remove

between

holding

inspection

label*

the

back

for

the

replacement

in

removing

face,

remove

any

broken

the

two

the

the

back

wires.

procedure

and repiace

case.

the

the

pieces

case

halves.

battery

door

case,

batteries.

The

label

label.

three

take

in

Section

label

Remove

back

of

the

in

its

care

should

that

will

batteries.

case

ring

retainer

channel

not

2.

be

removed

be

applied

screws.

from

inside

for

positionning.

to

bend

cleanly

at

the

the

or

crimp

and

completely

completion

pump.

the

of

this

switch

*

Order

RI-Ril-

US - A90

separately

©

Becton

Dickinson

and

Co.

1990

35

Curtains : Catalog

Materials

2

Curtains

Procedure

1°

Remove

in

procedure. A heat

2

Remove

3

With

4

Replace

5

Replace

order

the

the

to

the

pump

the

the

N°

8853

instruction

prepare

three

curtain on

curtain

the

gun

back

lying

on

on

label

case

is

useful

case

its

front

the

back

the

front

from

the

for

the

in

removing

screws.

face,

case

case.

back

case.

The

replacement

the

label.

remove

and

set

the

the

back

back

label

should

label that

Remove

case.

case

aside.

be

removed

will

be

applied

batteries.

cleanly

at

the

and

completely

completion

of

this

6 | Attach

CI

CAUTION : When

panel

ribbon

7

Testin

8

Attach a new

the

case

halves

reattaching

cables

accordance

instruction

or

with

any

while

holding

the

other

inspection

label*

and

the

battery

back

case, take

wires.

procedure

replace

door

in

Section

batteries.

in

its

care

2.

channel

not

for

positionning.

to

bend

or

crimp

the

switch

RI-RIf-

US - A90

©

Becton

Dickinson

and

Co.

1990

36

Rear

1

2

3

case

assembly : Catalog

Materials

Rear case

Curtains

Nº 6 Case

Procedure

1

Remove

in

order

procedure. A heat

2

With

3

Remove

assembly

screws

the

instruction

to

prepare

the

pump

and discard

gun

lying

the

is

on

the

N°

8884

label

from

case

for

useful

its

front face,

damaged

the

back

the

replacement

in

removing

remove

back

case.

the

case.

The

label.

the

three

label

label

Remove

back

should

that

will

case

be

removed

be

applied

batteries.

screws.

cleanly

at

the

and

completely

completion

of

this

(1

*

4 | Replace

5

6

CAUTION

pane!

7

8

Order

the

Connect

Attach

ribbon

Testin

Attach a new

the

the

:

When

cables

accordance

separately

curtain

case

on

buzzer

halves

reattaching

or

with

instruction

the

new

connector

while

holding

any

other

inspection

label*

back

case

and

power

the

the

back

wires.

procedure

and replace

and

on

connector

battery

door

case,

in

batteries.

the

front

to

the

in

its

take

care

Section

case.

PC

channel

not

2.

board.

for

to

bend

positioning.

or

crimp

the

switch

RI-Ril-

US

-

A90

©

Becton

Dickinson

and

Co.

1990

37

Fig

5:Rear

Case

RI2005

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

38

_

Battery

Materials

1

Battery

Procedure

door : Catalog

door

with

positive

N°

8892

battery

terminal

1 . Remove

in

procedure. A heat

2

With

3

Remove

4

Altach

[I

CAUTION : When

panel

5

6

ribbon

Test

Attach

the

order

to

the

pump

the

the

cables

in

accordance

the

instruction

prepare

back

case

the

gun

lying

case.

halves

on

reattaching

or

with

new

instruction

label

fram

case

is

useful

its

front

while

holding

any

other

inspection

label*

for

in

face,

the

the

and

the

back

replacement

removing

remove

the

new

back

case, take

wires.

procedure

replace

case.

The

label that

the

label.

the

three

battery

in

Section

batteries.

label

Remove

back

door

care

2.

should

will

batteries.

case

in

its

channel

not

be

removed

be

applied

screws.

for

to

bend

cleanly

at

positioning.

or

the

completion

crimp

and

completely

of

the

switch

this

*

Order

RI-Ril-

separately

US - A90

©

Becton

Dickinson

and

Co.

1990

39

Wired

1

Wired

battery

terminal : Catalog

Materials

battery

Procedure

terminal

N°

8863

Remove

in

procedure. A heat

With

Remove

Remove

Remove

if

and

Slide

the

the

Pinch

the

the

order

to

the

pump

the

the

the

necessary,

the

back

the

positive

end

clip

two

case

the

metal

battery

instruction

prepare

lying

back

buzzer

damaged

trim

case.

up

and

halves.

contact

compartment

the

gun

on

case.

connector

battery

the

back

Do

end

of

over

label

case

is

useful

its

front

case

not

crimp

the

the

shoulder

on

the

spring.

from

the

for

the

in

removing

face,

and

the

terminal

so that

the

battery

terminal

at

negative

back

case.

replacement

the

remove

terminai’s

power

and

there

the

connector

discard.

is

clearance

onto

the

far

side

end

of

The

label

label.

three

metal

its

of

the

the

battery

label

should

that

will

Remove

back

case

.

between

contact.

mounting

mounting

terminal

be

removed

be

applied

batteries.

screws.

the

positive

location

as

this

and

of

will

slide

cleanly

at

the

end

the

back

cause

it

onto

of

and

completely

completion

the

battery

case.

interference

the

Do

post

terminal

not

between

portion

of

this

slide

of

9

Proceed

10

Reconnect

11

Attach

El]

CAUTION : When

panel

RI-RII-

ribbon

12

Test

US - A90

to

section 5 for

the

the

back

cables

in

accordance

alignment

buzzer

case

connector

while

holding

reattaching

or

any

other

with

inspection

and

the

wires.

©

Becton

and

occlusion

the

power

the

battery

back

case,

procedure

Dickinson

adjustment

connector

door

in

take

in

Section

and

.

its

channel

care

2.

Co.

test

procedures.

for

not

to

1990

positioning.

bend

or

crimp

the

switch

40

13

Attach a new

instruction

label*

and

replace

batteries.

RI-RII-

US - A90

*

Order

separately

©

Becton

Dickinson

and

Co.

1990

41

Instruction

Materials

1

Instruction

Procedure

1

Remove

in

procedure. A heat

2

Aïttachthe

label

label

order

revision

the

instruction

to

prepare

new

instruction

0:

the

gun

Catalog

label

from

case

for

is

useful

label*.

N°

the

the

replacement

in

removing

8893

back

(Rate

case.

the

label.

infuser

The

label

label

Remove

should

that

will

Il

Only)

be

removed

be

applied

batteries.

cleanly

at

the

and

completely

completion

of

this

*

Order

RI-RII-

separately

US - A90

©

Becton

Dickinson

and

Co.

1990

42

PC

board

Materials

1

PC

Procedure

revision 3 :

board

Catalog

N°

8887

Remove

in

procedure. A heat

With

Remove

Remove

Remove

switch

Unscrew

Remove

EPROM's

Discard

Install

the

the

order

to

the

pump

the

the

the

connector,

the

the

the

screws.

instruction

prepare

lying

back

buzzer

chassis

the 3 screws

EPROM

pins.

Check

damaged

new

PC

label

from

the

the

case

for

the

gun

is

useful

in

removing

on

its

front

face,

case.

connector

by

the

clamp connectors , and

that

from

the

PC

board

and

the

disconnecting

hold

the

PC

the

damaged

EPROM

board.

into

orientation.

the

front

back

case.

replacement

the

label.

remove

power

the

the

connector

motor

the

board

in

PC

board

case.

Do

not

The

label

should

label

that

will

Remove

three

back

case

.

connector , the

resistor

place

and

and

install

forget

strip

set

the

to

use

be

removed

be

applied

batteries,

at

screws.

switch

panels

connector . Set

front

case

aside.

it

in a new

insulating

PC

washers

cleanly

the

connectors , the

the

board.

and

completely

completion

chassis

Do

under

aside.

not

the

bend

of

this

optical

heads

the

of

10

11

12

13

14

RI-RII-

US - A90

Reinstall

Reconnect

the

chassis.

the

connector , and

Proceed

Reconnect

Attach

to

section 5 for

the

the

back

motor

connector , the

the

resistor

buzzer

case

connector

while

strip

connector

alignment

and

holding

©

Becton

switch

and

occlusion

the

power

the

battery

Dickinson

panels

.

connector

door

connectors , the

adjustment

test

.

in

its

channel

and

Co.

1990

clamp

connector

procedures.

for

positioning.

,the

optical

switch

43

LJ

CAUTION:

-

panel

ribbons

15

Test

16

Attach a new

When

cables

in

accordance

reattaching

or

any

with

inspection

instruction

label*

the

back

other

wires.

procedure

and replace

case,

take care

in

section

batteries.

2.

not

to

bend

or

crimp

the

switch

* — Order

RI-RII-

US - A90

separately

©

Becton

Dickinson

and

Co.

1990

44

EPROM

1

Programmed

revision 5 :

Materials

Procedure

1

Remove

in

order

procedure. À heat

2

With

the

3

Remove

4

Remove

5

Remove

switch

connector,

Catalog

EPROM

the

instruction

to

prepare

pump

lying

the

back

the

buzzer

the

chassis

N°

label

the

case

gun

is

useful

on

its

front face,

case.

connector

by

disconnecting

the

clamp

8888

(Rate

from

the

for

the

in

removing

and

the

connector,

Infuser I Only)

back

case.

The

replacement

the

label.

remove

power

the

motor

and

the

three

connector

the

resistor

label

should

label

that

will

Remove

back case screws.

.

connector,

the

strip

connector.

be

removed

be

applied

batteries.

switch

panels

cleanly and

at

connectors,

Set the

the

completion

chassis

completely

the

optical

aside.

of

this

6

Pry

7

install

orientation

8

Reinstall

9

Reconnect

connector,

10

Proceed

11

Reconnect

12

Attach

U

CAUTION : When

panei

ribbon cables

13

Test

up

the

damaged

the

new

indicator

the

chassis.

the

and

to

section 5 for

the

the

back

in

accordance

EPROM

EPROM

making

marking

motor

connector,

the

resistor

buzzer

case

strip

alignment

connector

while

holding

reattaching

or

any

other

with

inspection

and

discard.

sure

on

the

the

connector

and

the

back

the

orientation

PC

board).

switch

and

the

panels

.

occlusion

the

power

battery

case,

wires.

procedure

is

correct

Do

not

bend

connectors,

adjustment

connector.

door

in

its

take

care

in

section

(note

the

the

test

channel

not

2.

the

notch

EPROM’s

clamp

connector,

procedures.

for

positioning.

to

bend

on

pins.

or

the

EPROM

the

crimp

and

optical

the

switch

switch

the

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

45

14

Attach a new

instruction

label*

and

replace

batteries.

*

RI-RII-

Order

US - A90

separately

©

Becton

Dickinson

and

Co.

1990

46

Microprocessor : Catalog

Materials

1

Microprocessor

Procedure

1

Remove

in

procedure. A heat

2

With

3

Remove

4

Remove

5

Pry

order

the

up

the

to

pump

the

the

the

prepare

damaged

instruction

lying

back

case.

buzzer

N°

8891

fabel

from

the

case

for

gun

is

useful

on

its

front

connector

microprocessor

the

the

in

removing

face,

and

back

replacement

remove

the

power

and

discard.

case.

The

the

label.

the

three

connector

label

label

Remove

back

should

that

case

.

be

will

be

applied

batteries.

screws.

removed

cleanly

at

the

and

completely

completion

ot

this

6 Install

cessor

7.

Proceed

8

Reconnect

9

Attach

CJ

CAUTION : When

panel

*

ribbon

10

Test

31

Attach a new

Order

separately

the

new

and

the

to

section 5 for

the

the

back

cables

in

accordance

microprocessor,

orientation

buzzer

case

indicator

alignment

connector

while

holding

reattaching

or

any

other

with

inspection

instruction

label*

making

the

and

sure

making

and

occlusion

and

the

the

battery

back

wires.

procedure

replace

the

orientation

on

the

adjustment

power

connector

door

case,

take

in

Section

batteries.

PC

board).

in

its

is

.

channel

care

2

correct

Do

not

test

procedures.

for

not

to

(note

the

notch

bend

the

microprocessor's

positioning.

bend

or

crimp

on

the

micropro-

the

pins.

switch

RI-RII-

US - A90

©

Becton

Dickinson

and

Co.

1990

47

LCD:

1

Catalog

Materials

LCD

display

Procedure

N°

8881

Remove

in

order

the

instruction

to

prepare

procedure. A heat

With

the

pump

lying

Remove

Remove

Remove

switch

Unscrew

Unsolder

Install

Reinstall

the

back

the

buzzer

the

chassis

connector,

the 3 screws

the

damaged

the

new

LCD

the

PC

board.

tabel

the

case

gun

is

useful

on

its

case.

connector

by

disconnecting

the

clamp

that

LCD

being

Do

from

the

for

the

in

removing

front

face,

and

connector,

hold

the

out

of

carreful

not

not

forget

back

case.

replacement

the

remove

the

power

the

motor

and

PC

board

its

socket

to

heat

the

insulating

The

label

label.

the

three

connector

connector,

the

resistor

in

place

and

discard.

up

the

washers.

label

that

Remove

back

.

strip

and

PC

board.

shauld

will

be

be

applied

removed

batteries.

case screws.

the

switch

connector . Set

set

the

front

panels

case

cleanly

at

the

completion

connectors,

the

chassis

aside

and

completely

the

aside.

of

this

optical

10

11

12

13

14

RI-RII-

Reinstall

Reconnect

connector

Proceed

Reconnect

Attach

US - A90

the

chassis.

the

and

to

Section 5 for

the

the

back case

motor

connector , the

the

resistor

buzzer

connector

while

strip

connector

alignment

and

holding

©

Becton

switch

and

occlusion

the

the

battery

Dickinson

panels

.

power

connectors , the

adjustment

connector

door

in

and

.

its

channel

Co.

clamp

test

procedures.

for

1990

connector , the

positioning.

optical

switch

48

(1

CAUTION : When

panel

ribbon

15

Test

16

Attach a new

cables

in

accordance

instruction

reattaching

any other

with

inspection

fabel*

the

back

wires.

and

case,

procedures

replace

batteries.

take care

in

Section

2.

not

to

bend

or

crimp

the

É

switch

*

Order

RI-RII-

US - A90

separately

©

Becton

Dickinson

and

Co.

1990

49

LCD

1

dispiay

Materials

LCD

display

Procedure

driver : Catalog

driver

N°

8882

Remove

in

procedure. A heat

With

Remove

Remove

Remove

switch

Unscrew

Desolder

Install

orientation

Clean

order

the

connector,

the

the

the

instruction

to

prepare

pump

lying

the

back

the

buzzer

the

chassis

the 3 screws

the

LCD

new

display

indicator

PC

board.

label

the

case

gun

is

on

its

case.

connector

by

disconnecting

the

clamp

that

driver

straight

driver,

marking

Install

from

for

useful

in

front

face,

and

connectors,

hold

making

on

the

new

the

the

removing

remove

the

the

PC

back

the

PC

LCD

back

case.

replacement

the

label.

the

power

connector

the

motor

and

the

board

in

out

of

its

socket

sure

the

orientation

board).

Take

driver.

The

label

label that

Remove

three

back

.

connector,

resistor

place

and

and

care

should

will

be

batteries.

case

screws.

the

switch

strip

connector . Set

set

the

front

set

it

aside.

is

correct

not

to

solder

be

removed

applied

case

(note

at

panels

the

aside.

the

notch

adjacent

cleanly

connectors,

the

completion

chassis

on

legs

or

and

the

pads

completely

of

this

the

optical

aside.

chip

and

together.

the

10

11

12

13

14

RI-Rit-

US - ASO

Reinstall

Reinstail

Reconnect

clamp

Proceed

Reconnect

the

the

connector , and

to

PC board

into

chassis.

the

motor

connector , the

the

section 5 for

the

buzzer

connector

the

front

resistor

alignment

and

©

Becton

case.

Do

switch

strip

connector

and

occlusion

the

power

Dickinson

not

forget

panels

.

adjustment

connector

and

the

insulating

connectors , the

test

procedures.

.

Co.

1990

washers

optical

switch

connectors , the

50.

15

Attach

C]

CAUTION : When

pannel

ribbon cables

16

Test

17

Attach a new

the

back

reattaching

in

accordance

instruction

case

or

with

while

holding

the

any

other

inspection

label*

the

back

wires.

procedure

and

replace

battery

door

case,

in

batteries.

in

its

take

care

Section

2.

channel

for

not

positioning.

to

bend

or

crimp

the

switch

* > Order

RI-RII-

US - A90

separately

O

Becton

Dickinson

and

Co.

1990

-

51

Crystal:

Catalog

Materials

1

Quartz

Procedure