BECS BECSys5 Operation And Maintenance Manual

Operation and Maintenance Manual

Operation and Maintenance Manual

Rev: L13

TABLE OF CONTENTS

Warnings......................................................................... 1

General Guidelines ......................................................... 2

Firmware Version ........................................................... 2

Environmental Conditions .............................................. 2

Electrical Specifications ................................................. 2

NSF Suggested Operation Ranges .................................. 3

Applicable Sensor Operation Ranges ............................. 3

Section A: Programming the Controller ........................ 4

A – 1: Adjusting the Display Contrast ....................... 4

A – 2: Security Settings ............................................. 4

A – 2.1: Access Codes and levels .......................... 4

A – 2.2: Setting Access Codes ............................... 4

A – 3: Navigating the menus ..................................... 4

A – 3.1: Common status messages ........................ 4

A – 3.2: The Menu Screens ................................... 5

A – 3.3: The Lock Screen Key .............................. 6

A – 4: Inputs .............................................................. 6

A – 4.1: pH Setup .................................................. 6

A – 4.2: ORP Setup ............................................... 6

A – 4.3: Cl Inputs Setup ........................................ 7

A – 4.3.1: Free Cl Setup ..................................... 7

A – 4.3.2: Total Cl Setup .................................... 7

A – 4.3.3: Combined Cl ...................................... 7

A – 4.4: Temperature Setup ................................... 7

A – 4.5: Conductivity/TDS Setup .......................... 8

A – 4.6: Flow Rate Setup ....................................... 8

A – 4.7: pH & Chlorine Inventory Setups ............. 8

A – 4.8: Turbidity .................................................. 8

A – 4.9: Surge Pit Level ........................................ 8

A – 4.10: Pressure & Vacuum Setup ..................... 8

A – 4.10.1: Filter Influent Pressure .................... 8

A – 4.10.2: Filter Effluent Pressure ................... 8

A – 4.10.3: Filter Differential Pressure .............. 9

A – 4.10.4: Pump Effluent Pressure................... 9

A – 4.10.5: Strainer Vacuum ............................. 9

A – 4.10.6: Total Dynamic Head ....................... 9

A – 5: Control Outputs ............................................ 10

A – 5.1: pH Control ............................................. 10

A – 5.2: Chlorine Control .................................... 11

A – 5.3: Chlorine Booster Control ....................... 13

A – 5.4: Super Chlorination ................................. 13

A – 5.5: Dechlorination ....................................... 14

A – 5.6: Ozone Control ........................................ 14

A – 5.7: Heater ..................................................... 14

A – 5.8: Autofill ................................................... 15

A – 5.9: TDS Control ........................................... 15

A – 5.10: Sensor Wash ........................................ 15

A – 5.11: Enzyme ................................................ 15

A – 5.12: UV Turndown ...................................... 15

A – 5.13: Polymer ................................................ 16

A – 5.14: Recirculation Pump.............................. 16

A – 5.9.1: VFD Control: ................................... 16

A – 5.15: Alarm Relay ......................................... 16

A – 6: Control Options ............................................. 17

A – 6.1: Flow Restored Feed Delay ..................... 17

A – 6.2: Power Saver ............................................ 17

A – 6.3: pH Lockout ............................................. 17

A – 7: Calculations ................................................... 18

A – 7.1: Enter Parameters ..................................... 18

A – 7.2: LSI Setup ................................................ 18

A – 8: System Configuration .................................... 18

A – 8.1: System Info ............................................. 18

A – 8.2: Communication ...................................... 18

A – 8.2.1: Direct Baud Rate ............................. 18

A – 8.2.2: Ethernet Setup ................................. 18

C – 8.2.3: Call Out Setup.................................. 18

A – 8.2.4: Installed Options .............................. 19

A – 8.3: Datalog Frequency .................................. 19

A – 8.4: Date, Time & Units ................................ 20

A – 8.5: User Setup .............................................. 20

A – 8.6: Display Options ...................................... 20

A – 9: VFD Turndowns ............................................ 20

A – 10: 4-20mA Outs ............................................... 20

A – 11: Access Menu ............................................... 21

Section B: The Normal Display ................................... 22

B – 1: Inputs and Feeds ............................................ 22

B – 2: Alarms & Status messages ............................. 22

Section C: Using the Face Panel Quick Keys ............... 23

C – 1: The Set Points Key ........................................ 23

C – 2: The Relay Mode Key ..................................... 23

C – 3: The Cal Key (calibration) .............................. 24

C – 4: The Reset Fail / Safe Key .............................. 24

C – 5: The Emergency Off Key ................................ 24

Section D: Maintenance ............................................... 25

D – 1: Potentiometric Sensors (pH and ORP) .......... 25

D – 2: Free Chlorine Sensor ..................................... 25

D – 3: Total Chlorine Sensor .................................... 26

D – 4: Conductivity Sensor ...................................... 27

Section E: Feed Charts ................................................. 28

E – 1: Spa Feed Charts ............................................. 28

E – 2: Pool Feed Charts ............................................ 29

Section F: Replacement Parts ....................................... 30

Section G: Warranty ..................................................... 32

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Operation and Maintenance Manual

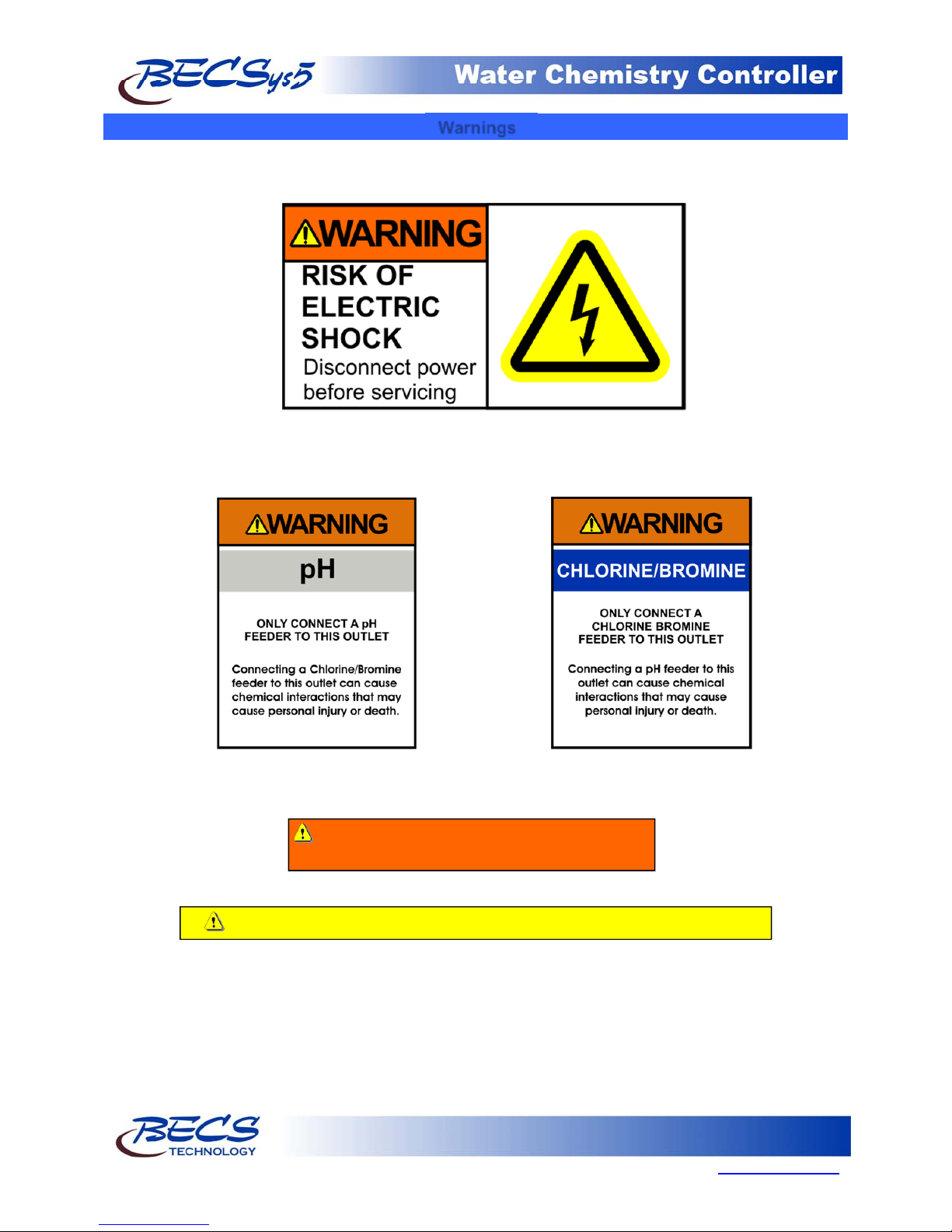

Warnings

Pay particular attention to the following warnings encountered while utilizing your

BECSys5 Water Chemistry Controller:

Rev: L13

Warning: Various other warning boxes may be

found throughout the manual text.

Caution: Various caution boxes may be found throughout the manual text.

Page 1

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Operation and Maintenance Manual

g

A

A

l

V

(

(12A

l

Rev: L13

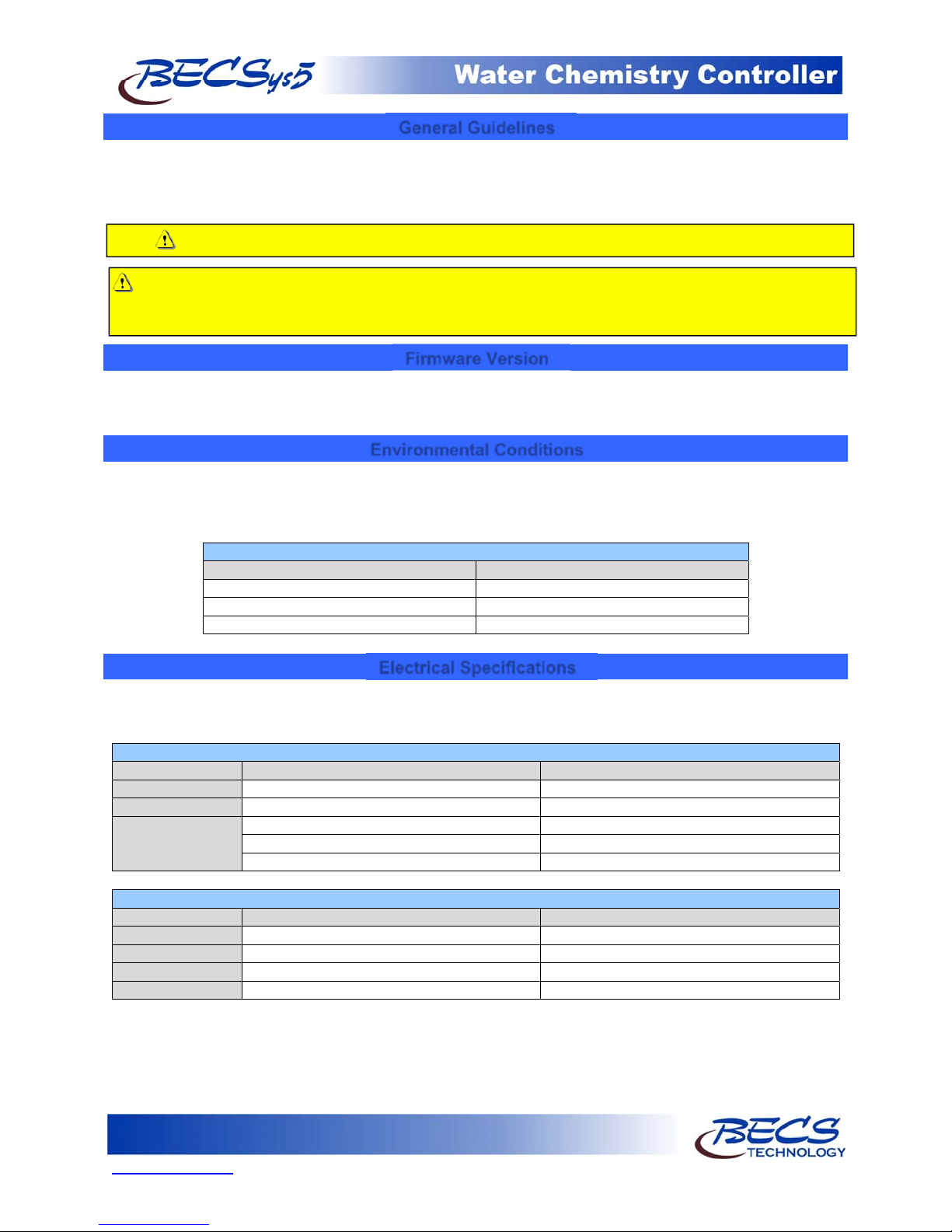

General Guidelines

Proper installation and use of the BECSys controller depends on the specific needs of the application. Read the manual

completely before starting the installation and ensure all guidelines and recommendations are followed. All components

should be mounted and the flow cell plumbing installed and pressure tested before wiring the controller. Ensure

compliance with all applicable plumbing and electrical codes during the installation as well.

Caution: The BECSys controller should be sealed while under operation. All IO, power cables, and unused

ports must be sealed using hardware rated NEMA4 or better. Damage to the controller caused by improper

Caution: The BECSys controller should not be installed where it is accessible to the public.

sealing of the enclosure is not covered under warranty.

Firmware Version

This manual was written for firmware v1.54. If you received newer firmware but did not receive a copy of the manual

covering that version of firmware, please contact your distributor.

Environmental Conditions

The BECSys5 is housed in a NEMA 4X (IP65) enclosure. It should not be used in explosive environments. The

BECSys5 should be mounted so that adequate ventilation is provided around the enclosure, preventing general

environmental specifications from being exceeded (see table below).

Environmental Specifications

Specification Ratin

Storage Temperature -40 to 85 Deg C

mbient Operating Temperature -18 to 50 Deg C

mbient Humidity 95% non condensing maximum humidity

Electrical Specifications

The BECSys5 may be ordered in either an 115VAC model or a 230VAC model. Following are the electrical

specifications for each model:

Controller Ratings

115VAC Model 230VAC Mode

oltage: 115VAC 60Hz 230VAC 50Hz

Phase: Single Single

Current: 12.25 Amps Full Load 12.125 Amps Full Load

(¼ Amp – Controller)

(12 Amps – Relay Outputs: 3A X 4)

Relay Output Ratings

115VAC Model 230VAC Mode

Relay 1 (K1) 250VAC (max) – 3 Amps 250VAC (max) –3Amps

Relay 2 (K2) 250VAC (max) – 3 Amps 250VAC (max) –3Amps

Relay 3 (K3) 250VAC (max) – 3 Amps 250VAC (max) –3Amps

Relay 4 (K4) 250VAC (max) – 3 Amps 250VAC (max) –3Amps

⅛ Amp –Controller)

mps –Relay Outputs: 3A X 4)

Page 2

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Operation and Maintenance Manual

V

V

T

A

T

V

V

T

–

–

Rev: L13

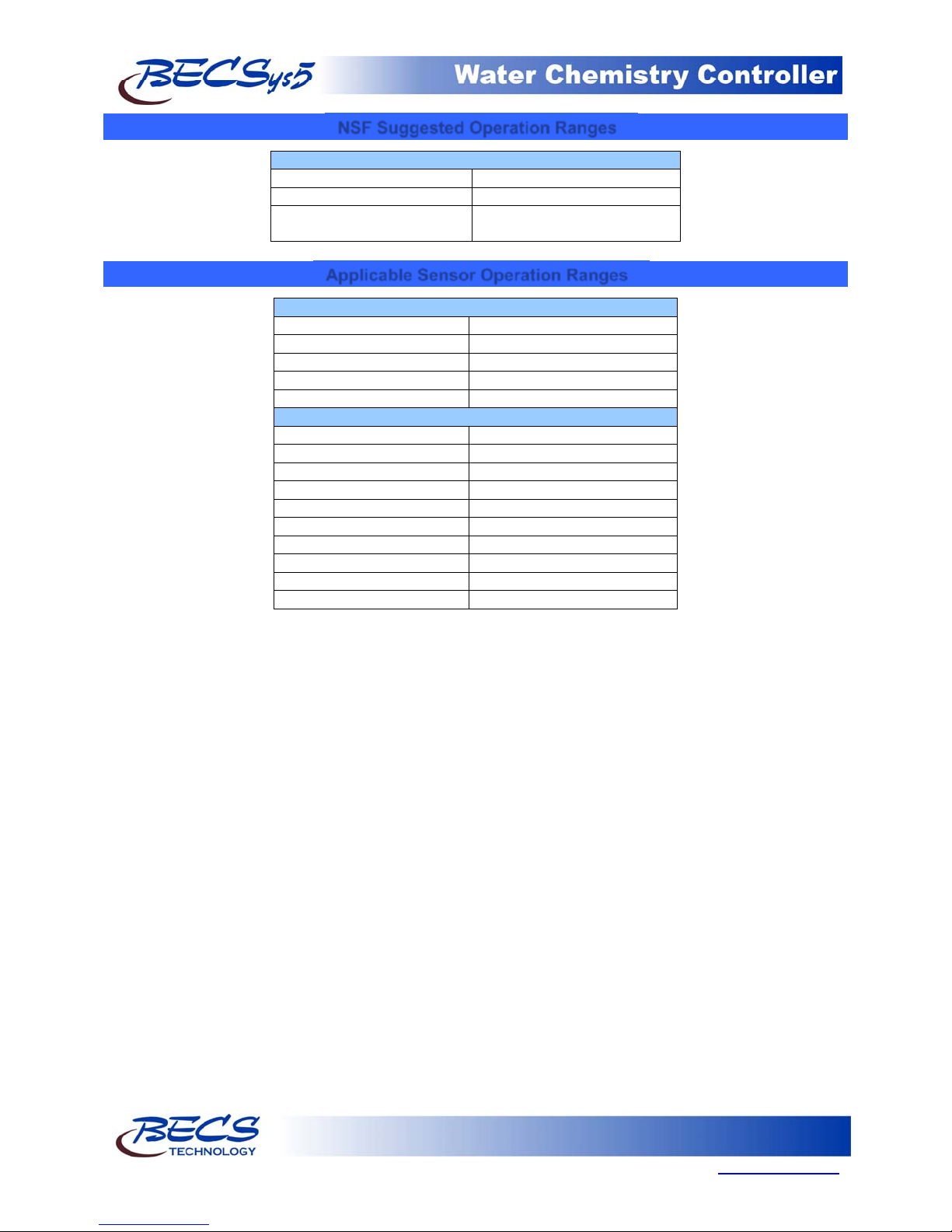

NSF Suggested Operation Ranges

ORP 650mV to 850m

pH 6.8 to 8.2

Free Available 0 to 10 ppm

Chlorine

Applicable Sensor Operation Ranges

Standard Sensors

pH 0.0 to 14.0 pH

ORP -1500mV to 1500m

emperature 32°F to 212°F (0°C to 100°C)

Reed Flow Switch Switch Point (On): 2.0 gpm

Rotary Flow Switch Switch Point (On): 1.5 gpm

Optional Sensors

mperometric ppm 0 ppm to 20 ppm

otal Chlorine 0 ppm to 20 ppm

Pressure Transducer 0 to 100 PSI

acuum Transducer -14.7 to 85 PSI

acuum Swichgage 0 –30 in. HG

Pressure Swichgage 0 –50 PSI

Differential Swichgage 0 –50 PSI

Conductivity Sensor 0 –20,000 micromho

urbidimeter 0

Flowmeter 0

20.0 NTU

655.35 Kgpm

Page 3

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Operation and Maintenance Manual

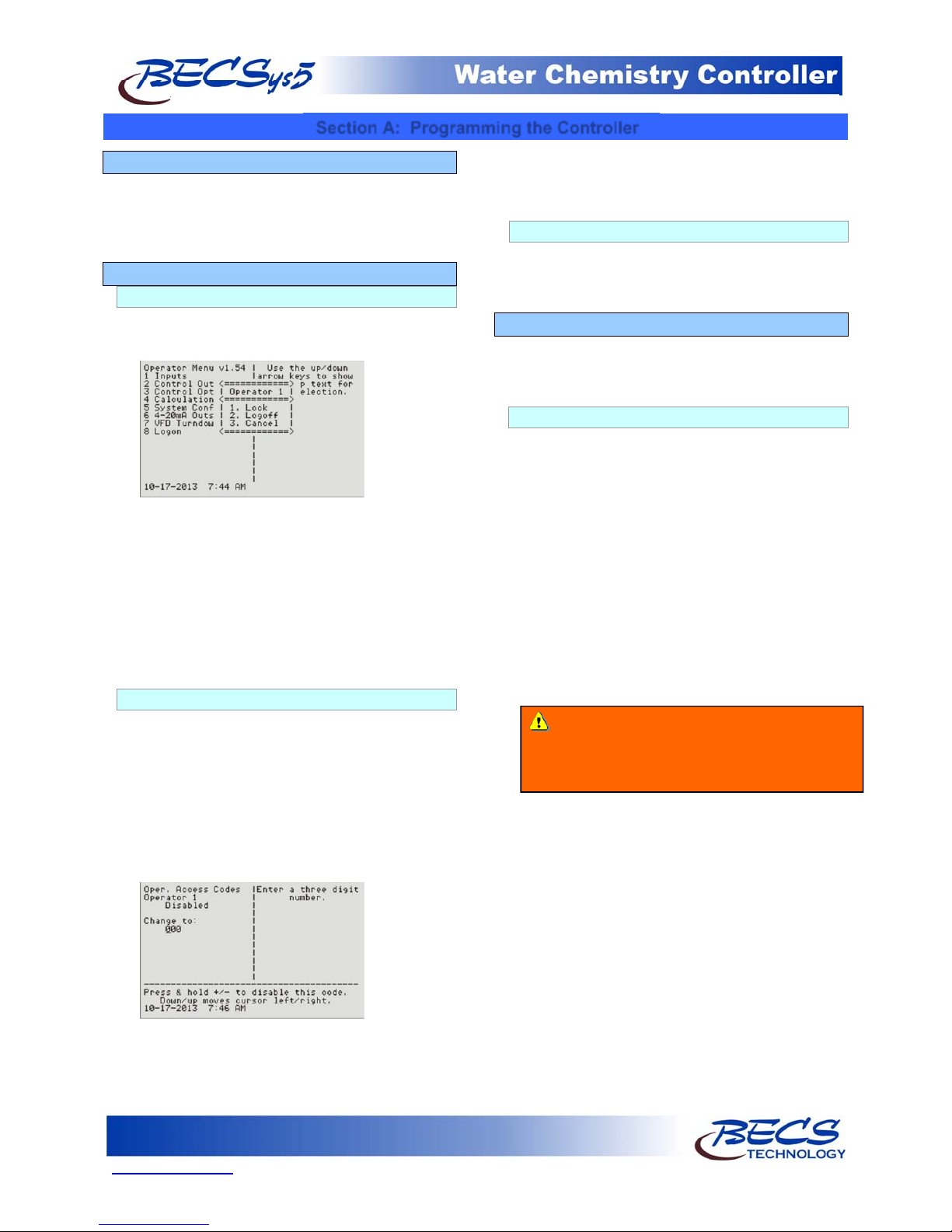

Section A: Programming the Controller

Rev: L13

A – 1: Adjusting the Display Contrast

You can adjust the display contrast by holding down

either the up or down arrow keys for two seconds,

then after the controller beeps three times, use the

up and down keys to adjust the contrast.

A – 2: Security Settings

A – 2.1: Access Codes and levels

To view what access level you were given, press

the lock screen button while in any menu.

The Main Menu will also display who is logged on

along with the version of firmware.

You do not need to set all the access codes for

each level if you do not wish to. Also, a disabled

access code is not equivalent to 000, so entering

000 when it prompts for an access code will only

work if you have specifically assigned an access

code to be 000.

A – 2.2: Setting Access Codes

To set an access code, press the menu button,

then:

Select System Config

Choose User Setup

Then select the access level you want to set an

access code for.

To set Operator 1's access code, you would select

Oper. Access Codes, then select Operator 1.

Pressing and holding the +/- button disables the

access code, while pressing enter will enable and

set the access code to the value on the screen.

Operators may only change their own access code.

Managers may change their access code and any of

the Operators.

A – 2.3: Controller Options

Depending on how a particular controller is

configured, not all of the options listed in this

manual may be available.

A – 3: Navigating the menus

The controller's menus incorporate built in help text

to aid in understanding the function of each

parameter, item, and option.

A – 3.1: Common status messages

The very bottom line of the display contains the

time and date on the left while the right is reserved

for a number of status messages; the most

common are as follows:

"Busy..." - Indicates the controller is busy doing

something critical and it cannot stop until it

finishes. Until this message disappears, the

controller will not respond to your key presses

(although it does record them any will process

them when done). Normally this message is only

seen briefly after changing a setting, but it is also

used for lengthier operations such as factory

defaults and in the extremely rare case where the

internal diagnostics detect a memory problem and

attempts to correct it.

Warning: Interrupting the controller by

turning the power off while it displays the busy

message could result in the complete loss of all

"(1 of 2) (More )" - and the like indicate there

are more options for you to choose from than the

controller could show at one time. Press the right

arrow key (Next) to view them. The left number

indicates the current page, while the right number

indicates the total number of pages.

"Bad Value, Retry..." - Accompanied by an error

beep, this indicates the value you just entered was

not within the allowable range of values and was

not stored.

of its settings.

Page 4

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Operation and Maintenance Manual

A – 3.2: The Menu Screens

Most of the features of the controller are

configured via the Menu button's menus. The

menu screens can be broken up into two types:

entry screens and lists.

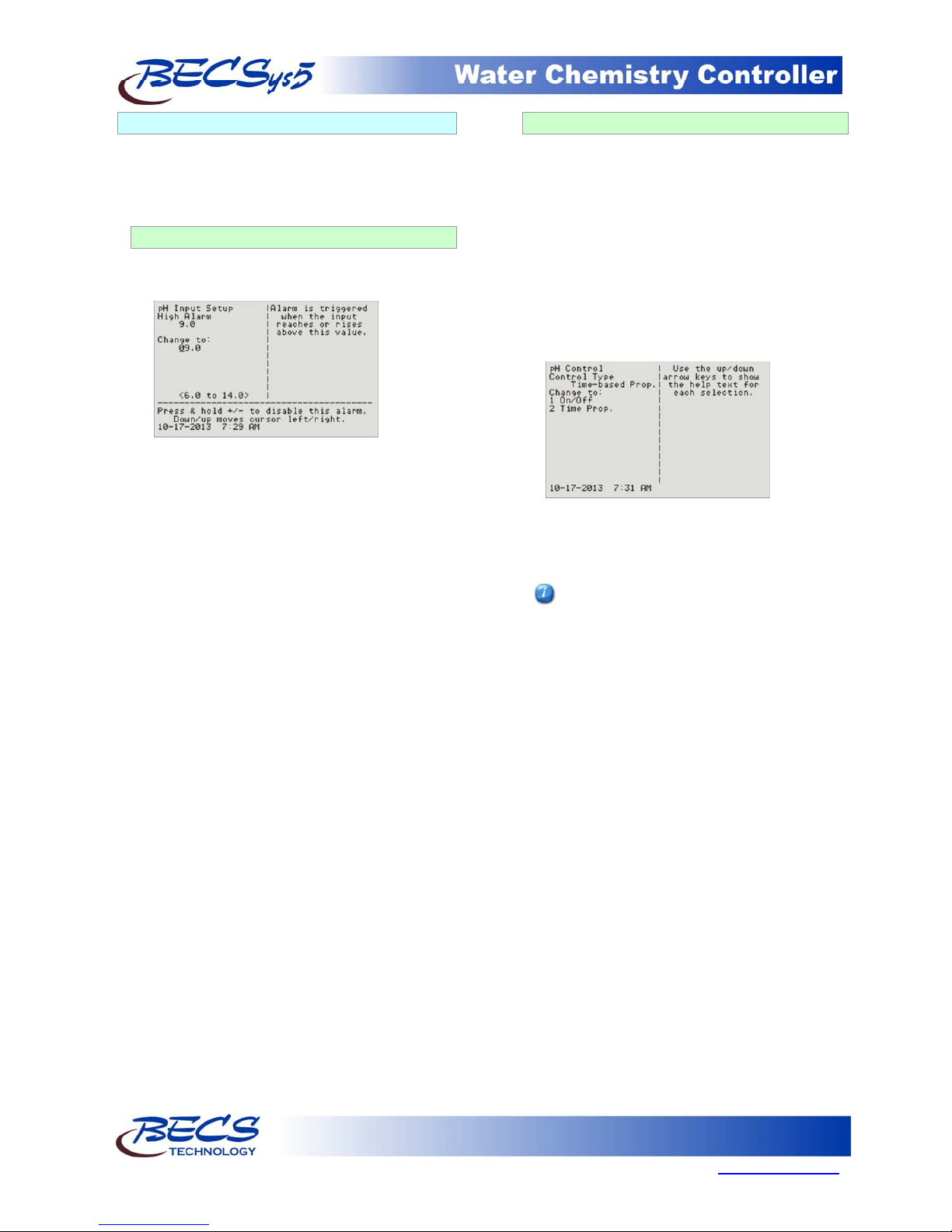

A – 3.2.1: Entry Screens

An entry screen is used to enter a value using

the keypad.

Rev: L13

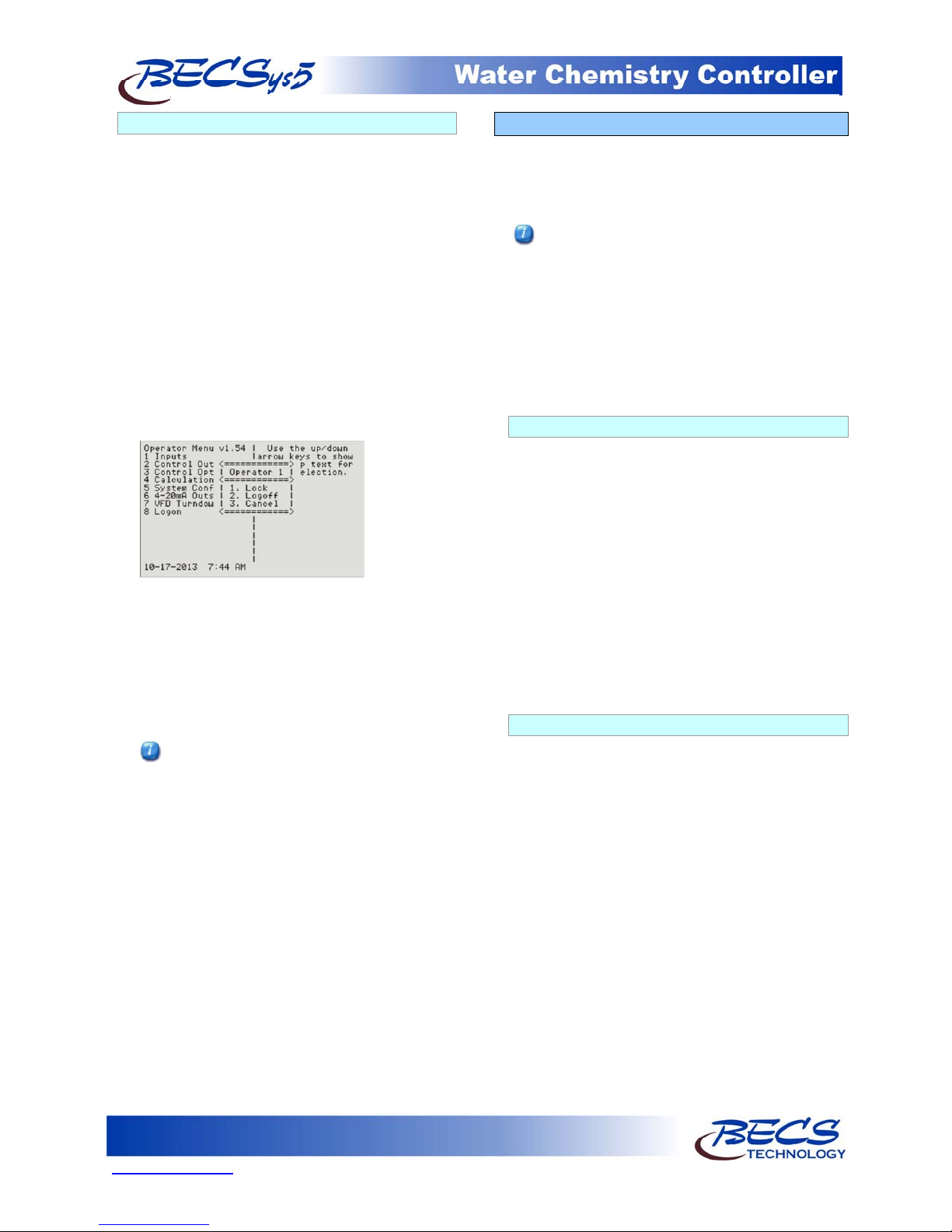

A – 3.2.2: List Screens

The list screens are mainly composed of lists of

menu items that you can choose from by either

pressing an item's number or by using the up

and down arrow keys to select it (indicated by

the arrow) and then pressing enter to choose it.

Using the up and down arrow keys also allows

you to view each item's help text. And if the

item leads to an entry screen or a list screen that

sets a setting (see below), the current value is

displayed in the lower right side.

Lists can also be used to change a setting:

The current value is usually displayed at the top

while the cursor will be positioned under the

current digit or character of the value you are

entering in. The up and down arrows allow you

to move the cursor right or left so you do not

have to retype the existing digits if you only wish

to change one.

Most numerical values will display the minimum

and maximum values you can enter in at the

bottom of the display in the format "< ### to

###>". These ranges many times will be

dependant on other values you have set, such as

alarm points or set points, while others are

simply fixed to stay within a reasonable range.

Entering a value that is not within the acceptable

range will result in an error beep and the

message "Bad Value, Retry..." being displayed in

the status area.

For some values, certain keys may take on

special functions that are explained in the lower

lines of the screen. The Down/up message in

the example above is one of them.

When a list is used this way, it will display the

current setting followed by the words "Change

to:". Because it is a list, you can select an item

with the up/down buttons to see help

information about that particular selection.

There are a few list screens that use the entire

width of the display for displaying values

associated with each item and therefore do

not have help. See Section C: Using the

Quick Set Face Panel Keys for examples of

these types of screens.

Page 5

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Operation and Maintenance Manual

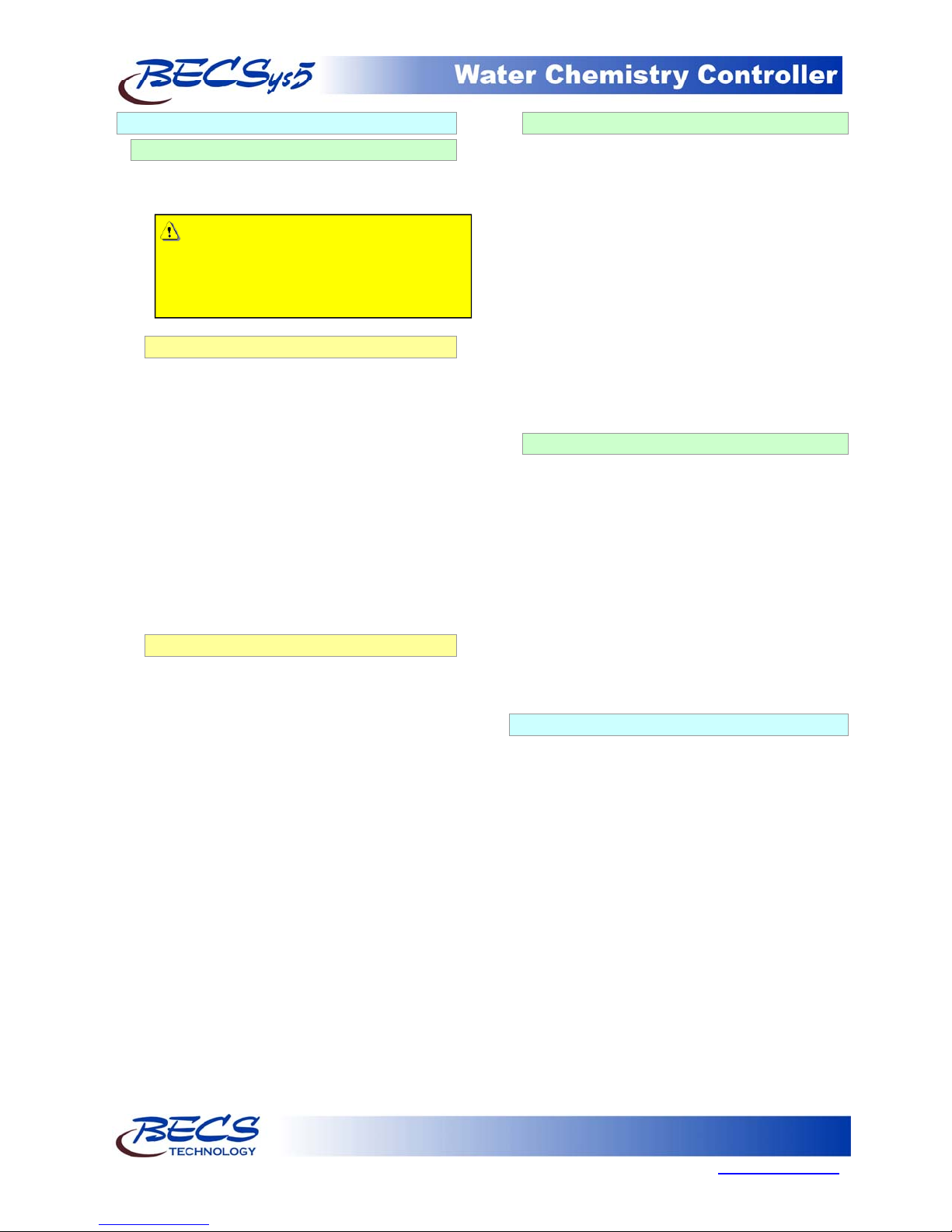

A – 3.3: The Lock Screen Key

When not in a menu (i.e. viewing the normal

display), pressing the lock screen key will prevent

the controller from paging the screen to show

more inputs, alarms, and other status information.

See Section B: The Normal Display for more info

about using the lock screen key in the normal

display.

While within any menu, if the user does not press

a key within sixty seconds of the last key press, the

current user is logged out and the screen is

returned to the normal display. To prevent the

controller from timing out, you may lock the

screen.

While within a menu, pressing the Lock Screen key

will bring up a popup menu:

The first option on the popup will be either to

lock or unlock the screen depending on the

current lock state. While the screen is locked, key

presses normally are ignored. However, in some

instances certain keys are given special functions

while the screen is locked, such as using the up

and down arrows to scroll the help text if all of the

help text cannot be displayed at once.

You can also lock/unlock the screen without

bringing up the popup menu by holding down

the lock button for one second. The

controller will acknowledge this action with a

triple beep and the yellow Lock Screen light

will turn on.

The Lock button popup menu also identifies who

is currently logged on, and provides an option for

the user to log off. You can also select cancel if

you pressed the lock button in error.

Rev: L13

A – 4: Inputs

To enter the program menu, press the Menu button

on the front face panel of your controller. This will

allow the viewing of the Main Menu where the

programming options are displayed.

The Cl inputs, Cl Inventory Input, Chlorine

Control, and Chlorine booster control are all

displayed as either Chlorine and Cl or Bromine

and Br depending on the chemical selected in the

Cl feed menu. This manual is written using the

Chlorine setting. If you select Bromine as the

sanitizing chemical, the controller will display

Bromine and Br instead of Chlorine and Cl, but

the menus and functions are otherwise exactly the

same as shown.

A – 4.1: pH Setup

If your controller is configured to monitor pH,

you will have the following options:

High Alarm (Op): The high alarm will activate

when the pH reaches or rises above this setting.

You may disable this alarm by holding down the

+/- key for 1 second.

Low Alarm (Op): The low alarm will activate

when the pH reaches or falls below this setting.

You may disable this alarm by holding down the

+/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets the

amount that the pH reading has to rise above the

high alarm or fall below the low alarm before the

alarm will shut off.

A – 4.2: ORP Setup

If your controller is configured to monitor ORP,

you will have the following options:

High Alarm (Op): The high alarm will activate

when the ORP reaches or rises above this setting.

You may disable this alarm by holding down the

+/- key for 1 second.

Low Alarm (Op): The low alarm will activate

when the ORP reaches or falls below this setting.

You may disable this alarm by holding down the

+/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets the

amount that the ORP reading has to rise above the

high alarm or fall below the low alarm before the

alarm will shut off.

Page 6

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Operation and Maintenance Manual

A – 4.3: Cl Inputs Setup

A – 4.3.1: Free Cl Setup

If your controller is configured to monitor Free

Cl, it may be either calculated or a probe may be

attached.

Caution: Amperometric chlorine sensors

require the use of a temperature sensor and

a properly calibrated pH sensor. Refer to

the instruction pamphlet included with the

sensor at the time of installation.

A – 4.3.1.1: Input Source: Calculated

High Alarm (Op): The high alarm will

activate when the free Cl reaches or rises

above this setting. You may disable this

alarm by holding down the +/- key for 1

second.

Low Alarm (Op): The low alarm will

activate when the free Cl reaches or falls

below this setting. You may disable this

alarm by holding down the +/- key for 1

second.

Alarm Hysteresis (Mgr): This value sets

the amount that the Cl input readings have

to rise above their high alarm or fall below

their low alarm before the alarm will shut

off.

A – 4.3.1.2: Input Source: Probe

High Alarm (Op): The high alarm will

activate when the free Cl reaches or rises

above this setting. You may disable this

alarm by holding down the +/- key for 1

second.

Low Alarm (Op): The low alarm will

activate when the free Cl reaches or falls

below this setting. You may disable this

alarm by holding down the +/- key for 1

second.

Alarm Hysteresis (Mgr): This value sets

the amount that the Cl input readings have

to rise above their high alarm or fall below

their low alarm before the alarm will shut

off. Note this value is used for free, total,

and combined Cl alarms.

Calibrate (Op): This selection allows you

to do a single point calibration of free Cl,

enter the reading from you test kit, and press

enter. The value entered must be 0.5 ppm

or greater.

Reset Calibration (Op): Resets the

calibration to the original factory setting.

A – 4.3.2: Total Cl Setup

If your controller is configured to monitor Total

Cl, you will have the following options:

High Alarm (Op): The high alarm will activate

when the total Cl reaches or rises above this

setting. You may disable this alarm by holding

down the +/- key for 1 second.

Low Alarm (Op): The low alarm will activate

when the total Cl reaches or falls below this

setting. You may disable this alarm by holding

down the +/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets the

amount that the Cl input readings have to rise

above their high alarm or fall below their low

alarm before the alarm will shut off. Note this

value is used for free, total, and combined Cl

alarms.

A – 4.3.3: Combined Cl

If your controller is configured to monitor

Combined Cl, you will have the following

options:

High Alarm (Op): The high alarm will

activate when the combined Cl reaches or rises

above this setting. You may disable this alarm

by holding down the +/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets the

amount that the Cl input readings have to rise

above their high alarm or fall below their low

alarm before the alarm will shut off. Note this

value is used for free, total, and combined Cl

alarms.

A – 4.4: Temperature Setup

If your controller is configured to monitor

temperature, you will have the following options:

High Alarm (Op): The high alarm will activate

when the temperature reaches or rises above this

setting. You may disable this alarm by holding

down the +/- key for 1 second.

Low Alarm (Op): The low alarm will activate

when the temperature reaches or falls below this

setting. You may disable this alarm by holding

down the +/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets the

amount that the temperature reading has to rise

above the high alarm or fall below the low alarm

before the alarm will shut off.

Rev: L13

Page 7

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Operation and Maintenance Manual

A – 4.5: Conductivity/TDS Setup

If your controller is configured to monitor

Conductivity/TDS, you will have the following

options:

High Alarm (Op): The high alarm will activate

when the input reaches or rises above this setting.

You may disable this alarm by holding down the

+/- key for 1 second.

Low Alarm (Op): The low alarm will activate

when the input reaches or falls below this setting.

You may disable this alarm by holding down the

+/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets the

amount that the Conductivity/TDS reading has to

rise above the high alarm or fall below the low

alarm before the alarm will shut off.

A – 4.6: Flow Rate Setup

If your controller is configured to monitor Flow

Rate, you will have the following options:

Low Alarm (Op): The low alarm will activate

when the flow rate reaches or falls below this

setting. You may disable this alarm by holding

down the +/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets the

reading that the flow rate must rise above the low

alarm before the alarm will shut off.

A – 4.7: pH & Chlorine Inventory Setups

If your controller is configured to monitor

chemical inventories, a sensor may be used or a

contact switch. If a sensor is used, you will have

the following options:

Low Alarm (Op): This value sets at what level or

weight the inventory low alarm will be activated.

You may disable this alarm by holding down the

+/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets at what

level the inventory level or weight has to rise

above the low level or weight alarm setting before

the alarm will shut off.

A – 4.8: Turbidity

If your controller is configured to monitor

Turbidity, you will have the following options:

High Alarm (Op): The high alarm will activate

when the input reaches or rises above this setting.

You may disable this alarm by holding down the

+/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets the

level that the turbidity reading has to rise above

the high alarm setting before the alarm will shut

off.

Rev: L13

A – 4.9: Surge Pit Level

If your controller is configured to monitor the

Surge Pit Level, a sensor may be used or a contact

switch. If a sensor is used, you will have the

following options:

High Alarm (Op): The high alarm will

activate when the input reaches or rises above

this setting. You may disable this alarm by

holding down the +/- key for 1 second.

Low Alarm (Op): The low alarm will activate

when the input reaches or falls below this

setting. You may disable this alarm by holding

down the +/- key for 1 second.

Alarm Hysteresis (Mgr): This value sets the

amount that the surge pit level has to rise above

the high alarm or fall below the low alarm

before the alarm will shut off.

A – 4.10: Pressure & Vacuum Setup

A – 4.10.1: Filter Influent Pressure

If your controller is configured to monitor the

Filter Influent Pressure, either a PSI transducer,

Vacuum transducer, or a gauge may be used. If

a transducer is used, you will have the following

options:

High Alarm (Op): The high alarm will activate

when the pressure reaches or rises above this

setting. You may disable this alarm by holding

down the +/- key for 1 second.

Low Alarm (Op): The low alarm will activate

when the pressure falls below this setting. You

may disable this alarm by holding down the +/key for 1 second.

Alarm Hysteresis: (Mgr) This value sets the

amount that the pressure reading has to rise

above the high alarm or fall below the low

alarm before the alarm will shut off.

Display Input (Op): This option

enables/disables displaying the influent pressure

on the normal display.

A – 4.10.2: Filter Effluent Pressure

If your controller is configured to monitor the

Filter Effluent Pressure, either a PSI transducer,

or a pressure gauge may be used. If a transducer

is used, you will have the following options:

High Alarm (Op): The high alarm will

activate when the pressure reaches or rises

above this setting. You may disable this alarm

by holding down the +/- key for 1 second.

Low Alarm (Op): The low alarm will activate

when the pressure reaches or falls below this

setting. You may disable this alarm by holding

down the +/- key for 1 second.

Page 8

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Loading...

Loading...