Page 1

Installation and Operating instructions for

Built-in Control Panel CP68xx

Version: 2.0

Date: 2007-11-05

Page 2

Page 3

General Notes

Table of contents

1.

General Notes 2

Notes on the documentation 2

Liability conditions 2

Description of safety symbols 2

Basic safety measures 3

Operator's obligation to exercise diligence 4

Operator requirements 4

UL-Certificate of Compilance 4

2.

Product Description 5

Appropriate Use 5

Connections 5

Pin assignment 5

Connector description 6

DVI (Digital Visual Interface) 6

Power supply 6

USB interfaces 6

Protective Earthing 6

Cable Set for connecting the Control Panel 6

3.

Installation Instructions 7

Transport and Unpacking 7

Transport 7

Unpacking 7

Assembly 8

Assembly dimensions 8

Mounting of the Control Panel 10

Connecting the Control Panel 11

Connecting cables 11

Protective Earthing 11

4.

Operating Instructions 12

Functional description 12

Keyboard codes 12

Servicing and maintenance 14

Cleaning the Control Panel 14

Servicing 14

Replacing the fluorescent lamps in the display 14

Lamp sets 15

Emergency procedures 15

Shutting down 15

Disposal 15

5.

Troubleshooting 16

Fault correction 16

Service and Support 17

Beckhoff's branch offices and representatives 17

Beckhoff headquarters 17

Beckhoff Support 17

Beckhoff Service 17

6.

Appendix 18

Technical data 18

Approvals 18

FCC: Federal Communications Commission Radio Frequency Interference

Statement 18

FCC: Canadian Notice 18

CP68xx 1

Page 4

General Notes

General Notes

Notes on the documentation

This description is only intended for the use of trained specialists in control

and automation engineering who are familiar with the applicable national

standards. It is essential that the following notes and explanations are

followed when installing and commissioning these components.

Liability conditions

The responsible staff must ensure that the application or use of the

products described satisfy all the requirements for safety, including all the

relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described

are, however, constantly under development. For this reason, the

documentation may not always be have been fully checked for consistency

with the performance data, standards or other characteristics described.

None of the statements in this manual represent a guarantee for as set out

in § 443 of the German Civil Code or a statement about the assumed use

according to the contract as set out in § 434 para. 1 clause 1 no. 1 of the

German Civil Code. In the event that it contains technical or editorial errors,

we retain the right to make alterations at any time and without warning. No

claims for the modification of products that have already been supplied

may be made on the basis of the data, diagrams and descriptions in this

documentation.

© This documentation is protected by copyright. Any reproduction or third

party use of this publication, whether in whole or in part, without the written

permission of Beckhoff Automation GmbH, is forbidden.

Description of safety symbols

The following safety symbols are used in this operating manual. They are

intended to alert the reader to the associated safety instructions.

This symbol is intended to highlight risks for the life or health of personnel.

This symbol is intended to highlight risks for equipment, materials or the

environment.

This symbol indicates information that contributes to better understanding.

i

Danger

Warning

Note

2 CP68xx

Page 5

General Notes

Basic safety measures

Before opening the control panel housing, and whenever the control

panel is not being used for control purposes (such as during

functional checks after a repair), all parts of the equipment must first

be switched off, after which the control panel is to be disconnected

from the equipment.

Disconnect the device by unplugging the connectors on the Control Panel

side.

Items of equipment that have been switched off must be secured

against being switched on again.

Displays used for the control panel’s LC-display are operated with a

voltage of up to 1000 V, depending on type. For that reason:

The supply voltage must be disconnected before the housing of the

Control Panel is opened.

Assembly work on the Control Panel during operation may damage the

panel:

• if metal objects such as screws or tools fall onto operating circuit

boards.

• if connecting cables internal to the control panel are removed or

inserted during operation

i

Warning

Danger

Note

CP68xx 3

Page 6

General Notes

Operator's obligation to exercise diligence

The operator must ensure that

• the Control Panel is only used for its intended purpose (see

Product Description section);

• the Control Panel is only operated in a sound condition and in

working order;

• the instruction manual is in good condition and complete, and

always available for reference at the place of installation of the

Control Panel;

• the Control Panel is operated, maintained and repaired only by

suitably qualified and authorized personnel.

• the personnel is instructed regularly about relevant occupational

safety and environmental protection aspects, and is familiar with

the operating manual and in particular the safety notes contained

herein.

• none of the safety and warning notes attached to the Control Panel

are removed, and all notes remain legible.

National regulations

depending on the machine

type

Procedure in the event of a

fault

Depending on the type of machine and plant in which the Control Panel is

used, national regulations governing the controllers of such machines will

apply, and must be observed by the operator. These regulations cover,

amongst other things, the intervals between inspections of the controller.

The operator must initiate such inspections in good time.

In the event of faults at the Control Panel, the list in the section

Troubleshooting can be used to determine the measures to be taken.

Operator requirements

Read the operating

instructions

Software knowledge

Anyone who uses the Control Panel must have read these operating

instructions.

Every user must be familiar with all the functions of the software installed

on the Control Panel to which he has access.

UL-Certificate of Compilance

We herewith confirm that the Built-in Control Panel CP68xx of Beckhoff

Automation GmbH meets the requirements of the Underwriters

Laboratories Inc.

Certificate Number: 280607 – E220403

Report Reference: E220403, April 16th, 2007

Issue Date: 2007 June 28

Standards for Safety The correspondance of the mentioned product with these requirements is

proved by the fact that this product meets with the following single

standards:

• UL 60950-1, 1st Edition, 2006-07-07 (Information Technology

Equipment – Safety - Part 1: General Requirements)

• CSA C22.2 No. 60950-1-03, 1st Edition, 2006-07 (Information

Technology Equipment - Safety - Part 1: General Requirements)

4 CP68xx

®

(UL)-standard:

Page 7

Product Description

Product Description

Appropriate Use

The CP68xx Control Panel is designed for industrial application in machine

and plant engineering. An aluminum housing contains a TFT display, touch

screen/pad (optional) and a PC keyboard (optional). The Control Panel is

installed in the front of control cabinets.

Do not use the Control

Panel in areas of explosive

hazard

The Control Panel must not be used where there is a risk of

explosion.

Connections

Control Panel CP68xx

connections

X 101

DVI Interface

X 102

Power supply

X 103

USB input

Pin assignment

DVI-D 3 X 8-pole digital PCB installation

(MOLEX 74320-9000 / 74320-9004)

SLWG 1X2-pole WAGO built-in CAGE

CLAMP (WAGO 721-602 / 019-000)

USB type B, PCB installation

(FCI 61729-0010B USB Receptacle B-Type)

Pin Signal Pin Signal

1

Rx2-

2

Rx2-

3

GND

4

Rx4-

5

Rx4+

6

DDC CLK

7

DDC DAT

8

AV SYNC

9

Rx1-

10

Rx1+

11

GND

12

Rx3-

Pin Signal Pin Signal

1

+ 24V

Pin Signal Pin Signal

1

5V

2

D-

13

Rx3+

14

+ 5V DVI

15

GND

16

HPD

17

Rx0-

18

Rx0+

19

GND

20

Rx5-

21

Rx5+

22

GND

23

RxC+

24

RxC-

11

GND

3

D+

4

GND

CP68xx 5

Page 8

Product Description

X 104 USB1, USB2

USB ports

USB Type-A twin circuit board mounting

(FCI 72309-0030B USB Double Receptacle

A-Type)

Pin Signal Pin Signal

1

5V

2

D-

3

D+

4

GND

Connector description

DVI-D

Power supply

USB input

USB1 – USB2

Protective Earthing

DVI (Digital Visual Interface)

The DVI connection (X 101) is used for transferring the video signal from

the Industrial PC to the Control Panel.

The purely digital part (DVI-D) is supported.

Power supply

The power supply for the Control Panel is established via the Cage clamp

socket (X 102).

USB interfaces

The Control Panel is connected with the Industrial PC via the USB1.1 port

(X 103, connector type B) .

USB1.1 standard with a maximum data rate of 1.5 or 12 Mbps is

supported.

The two USB1.1 interfaces (X 104, connector type A) are used for

connecting peripheral devices with USB connection.

USB1.1 standard with a maximum data rate of 1.5 or 12 Mbps is

supported.

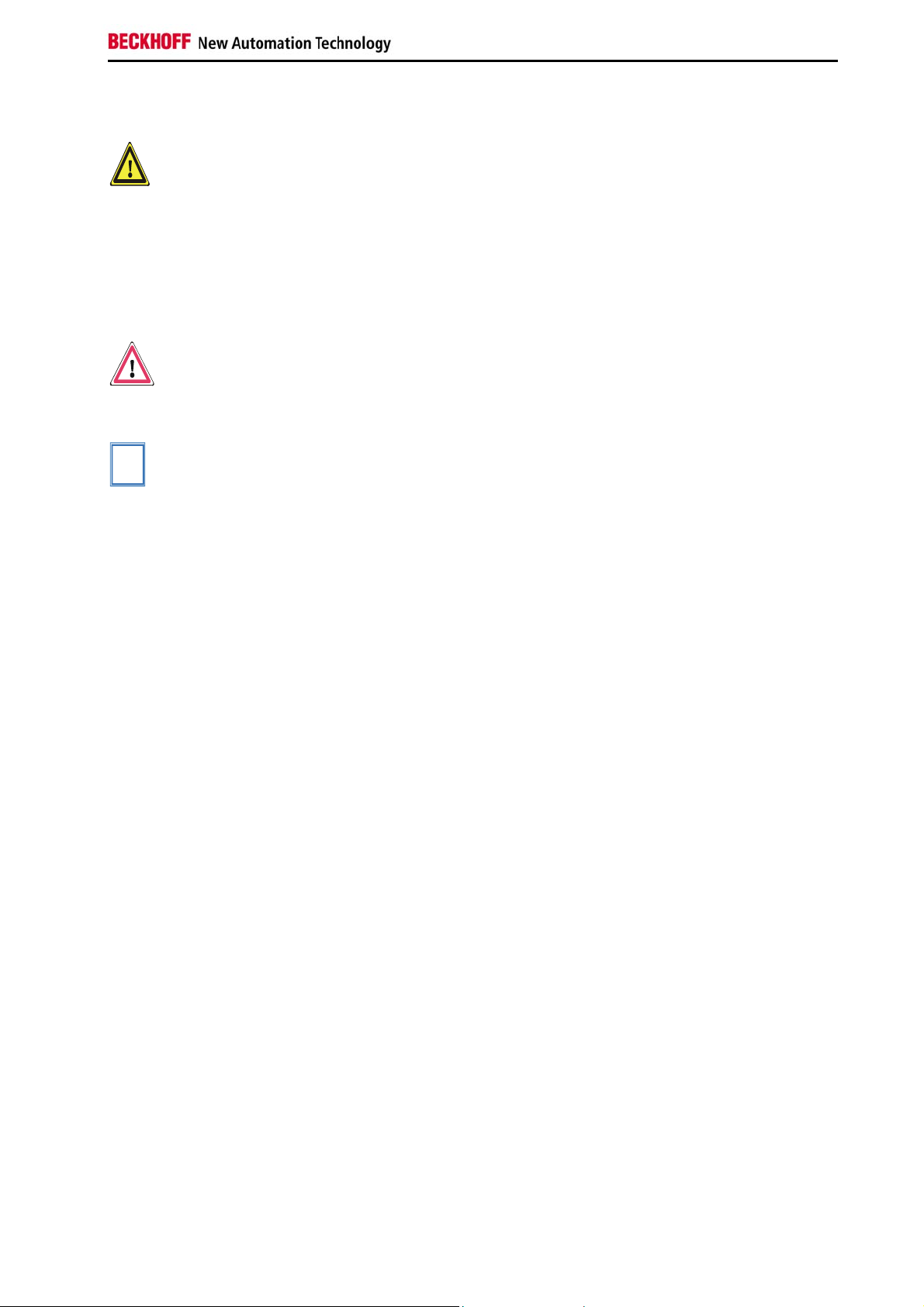

Protective Earthing

The low resistance protective earthing connection is

established via the ground bolt, which is located at the rear of

the housing.

Cable Set for connecting the Control Panel

Cable Set

C9900-K510

Kit for connecting CP68xx, containing:

DVI-cable 3 m, USB-cable 3 m and power supply connector

6 CP68xx

Page 9

Installation Instructions

Installation Instructions

Please also refer to chapter General Notes.

Transport and Unpacking

The specified storage conditions must be observed (see chapter Technical

data).

Transport

Despite the robust design of the unit, the components are sensitive to

strong vibrations and impacts. During transport, your Control Panel should

therefore be protected from excessive mechanical stress. Therefore,

please use the original packaging.

Danger of damage to the unit!

Warning

If the device is transported in cold weather or is exposed to extreme

variations in temperature, make sure that moisture (condensation) does not

form on or inside the device.

Prior to operation, the unit must be allowed to slowly adjust to room

temperature. Should condensation occur, a delay time of approximately 12

hours must be allowed before the unit is switched on.

Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important

information for handling the unit.

5. Check the contents for visible shipping damage.

6. If you notice any shipping damage or inconsistencies between the

contents and your order, you should notify Beckhoff Service.

CP68xx 7

Page 10

Installation Instructions

Assembly

Assembly dimensions

All dimensions are in mm.

Control Panel CP68xx

Connectors

Wall thickness 2-5

Control Panel CP680x

Control Panel CP681x

Dimensions a b t A B

CP6809 6,5“ Display 272,3 181 42 258,3 167

CP6800 10“ Display 370 336 32 356 322

CP6801 12“ Display 372,2 342,2 32 358,2 328,2

CP6802 15“ Display 430,4 403 32 416,4 389

CP6803 19“ Display 508,4 463 43 494,4 449

CP6804 20“ Display 529 434 46 515 420

Dimensions C D E F

CP6809 6,5“ Display 14 27 50 108

CP6800 10“ Display 12 80 22 50

CP6801 12“ Display 12 80 20 50

CP6802 15“ Display 10 80 25 50

CP6803 19“ Display 12 80 22 50

CP6804 20“ Display 105 270 10 27

Dimensions a b t A B

CP6819 6,5“ Display 272,3 221 42 258,3 207

CP6810 10“ Display 370 336 32 356 322

CP6811 12“ Display 372,2 342,2 32 358,2 328,2

CP6812 15“ Display 430,4 403 32 416,4 389

CP6813 19“ Display 508,4 463 43 494,4 449

CP6814 20“ Display 529 434 46 515 420

Dimensions C D E F

CP6819 6,5“ Display 14 27 50 108

CP6810 10“ Display 12 80 22 50

CP6811 12“ Display 10 80 20 50

CP6812 15“ Display 10 80 25 50

CP6813 19“ Display 12 80 20 50

CP6814 20“ Display 105 270 10 27

8 CP68xx

Page 11

Installation Instructions

Control Panel CP682x

Dimensions a b t A B

CP6829 6,5“ Display 340,4 221 42 326,4 207

CP6820 10“ Display 414 336 32 400 322

CP6821-0000/1 12“ Display 414 336 32 400 322

CP6821-0002 12“ Display 444,2 336 32 430,2 322

CP6822 15“ Display 519,4 378,2 32 505,4 364,2

CP6823 19“ Display 567,4 434 43 553,4 420

CP6824 20“ Display 610 434 46 596 420

Dimensions C D E F

CP6829 6,5“ Display 14 50 20 80

CP6820 10“ Display 10 80 22 50

CP6821-0000/1 12“ Display 10 80 22 50

CP6821-0002 12“ Display 45 80 22 50

CP6822 15“ Display 10 80 15 50

CP6823 19“ Display 17 80 30 50

CP6824 20“ Display 40 500 40 80

Control Panel CP683x

Dimensions a b t A B

CP6830 10“ Display 410,4 378,2 32 396,4 364,2

CP6831-0000/1 12“ Display 410,4 378,2 32 396,4 364,2

CP6831-0002 12“ Display 430,4 378,2 32 416,4 364,2

CP6832 15“ Display 489,4 418,2 32 475,4 404,2

CP6833 19“ Display 508,4 543 43 494,4 529

CP6834 20“ Display 529 514 46 515 500

Dimensions C D E F

CP6830 10“ Display 10 80 60 50

CP6831-0000/1 12“ Display 10 80 60 50

CP6831-0002 12“ Display 10 80 20 50

CP6832 15“ Display 35 80 70 50

CP6833 19“ Display 42 80 100 50

CP6834 20“ Display 15 80 27 50

CP68xx 9

Page 12

Installation Instructions

Mounting of the Control Panel

Please refer to the tables for Control Panel cutout dimensions.

Mounting of the Control

Panel

Release clamping levers,

Insert the Control Panel into the

cutout.

Release the clamping levers

with a No. 2.5 Allen key.

Folding them out

and retighten them.

Turn the clamping levers to the

side through 90°

and retighten the screws.

10 CP68xx

Page 13

Installation Instructions

Connecting the Control Panel

The Control Panel must never be connected or disconnected in an area

Danger

Warning

Protective Earthing

that is subject to explosion hazard! Risk of explosion!

The mains plug of the Control Panel must be disconnected!

Please read the documentation for the external devices prior to connecting

them.

During thunderstorms, plug connector must neither be inserted nor

removed.

When disconnecting a plug connector, always handle it at the plug. Do not

pull the cable!

Connecting cables

The connections are located at the rear of the Control Panel and are

documented in the Product Description section.

When connecting cables to the Control Panel, please adhere to the

following order:

• Disconnect the Control Panel from the power supply

• Connect all cables at the Control Panel and at the devices to be

connected

• Ensure that all screw connections between connectors and

sockets are tight!

• Reconnect all devices to the power supply.

Protective Earthing

The low resistance protective earthing connection is

established via the ground bolt, which is located at the rear of

the housing.

CP68xx 11

Page 14

Operating Instructions

Operating Instructions

Please also refer to chapter General Notes.

Functional description

Switch on

Switching off

Operation

i

Note

The Control Panel does not have its own mains power switch. As soon as

the power supply is switched on the control panel is activated.

Control software, as typically applied in Control Panels, enables the

assignment of different rights to all users. A user who is not entitled to shut

down the software may not switch off the Control Panel as an attempt to

shut it down when the software is running could result in the loss of

software data on the Compact Flash memory card (CF card).

If the control panel is shut down while the software is writing a file onto the

CF card, the file will be destroyed. Control software typically writes

something to the CF card every few seconds, so that the probability of

causing damage by switching off while the software is running is very high.

The Control Panel’s membrane keypad may only be actuated by fingertips.

Attempts to actuate it with other objects can easily result in the destruction

of the device. Neither may the membrane keypad be operated with a touch

screen pen.

The touch screen may only be actuated by finger tips or with the touch

screen pen. The operator may wear gloves but there must be no hard

particles such as metal shavings, glass splinters embedded in the glove.

Keyboard codes

Type-dependent number of

keys

Operation

Hom e En d

Pg Up Pg Dn

L

Del

Ins

Pr i n t

R

Depending on the precise type, the Control Panel can have fewer keys

than those described here.

The cursor is the blinking character that marks the point at which the next

character entered will be displayed. The cursor is also known as the

insertion point. The cursor keys each move the cursor one place in the

associated direction.

The Home key moves the cursor to the beginning of the line, while the End

key moves it to the end of the line.

The Pg Up key scrolls one page back, the Pg Dn key scrolls one page

forward.

The Tab key takes the cursor to the next input field, while Shift and Tab

moves to the previous input field.

The mouse cursor can be moved over the screen with the aid of the touch

screen or of the touch pad (optional). The keys correspond to the left and

right hand keys of a Microsoft mouse.

The Del key deletes the character to the right of the cursor.

The Ins key causes characters to the right of the cursor to be overwritten.

The overwrite mode is cancelled by pressing the key again.

Print-Screen prints a hard copy of a text screen on the printer.

12 CP68xx

Page 15

Operating Instructions

Pau se

En t e r

Sh i f t

Ca p s

Lock

Ct r l Al t

Esc

Q W

F1 F2 F3 F4

...

!

1

The Pause key stops the computer until another key is pressed (only under

MS-DOS).

Your input is confirmed with the Enter key.

Backspace deletes the character to the left of the cursor.

If the Shift key is pressed at the same time as another key, then instead of

the numbers you obtain the character printed above the number, and you

obtain upper case letters instead of lower case letters.

Pressing the Caps Lock key once activates and locks the Shift key.

Pressing the Shift key cancels this function.

Rather like the effect of the Shift key, Ctrl and Alt also change the meaning

of another key that is pressed at the same time.

This key brings up the Start menu of the operating system in use (Windows

95, 98, ME, NT, 2000, XP).

Pressing this key opens the property sheet of the active (or marked) object.

The Esc key has the effect of closing dialog windows and of interrupting

some of the computer’s working operations.

@

All other keys bring the character printed on them onto the display at the

2

position of the cursor.

The meaning of the function keys, F1 to F10, is determined by the software

and is displayed at the bottom edge of the display.

F5 F6 F7 F8

F9 F1 0 F1 1 F1 2

Ei n s c h u b

St r e i f e n

Ei n s c h u b

St r e i f e n

Ei nschub

St r e i f e n

Ein sch ub

St r e i f e n

The function of the special keys above the display is also determined by

the software. The function is displayed at the top edge of the display.

The special keys each have an orange LED controlled by the software.

CP68xx 13

Page 16

Operating Instructions

Please also refer to chapter General Notes.

First switch off the Control

Panel

The Control Panel is maintenance-free.

Since fluorescent lamps represent a consumable item in a display, they

Servicing and maintenance

Cleaning the Control Panel

Switch off the Control Panel and all devices connected to it, so that keys

cannot be unintentionally actuated.

The front of the Control Panel can be cleaned with a soft, damp cleaning

cloth. Do not use any aggressive cleaning materials, thinners, scouring

material or hard objects that could cause scratches.

Servicing

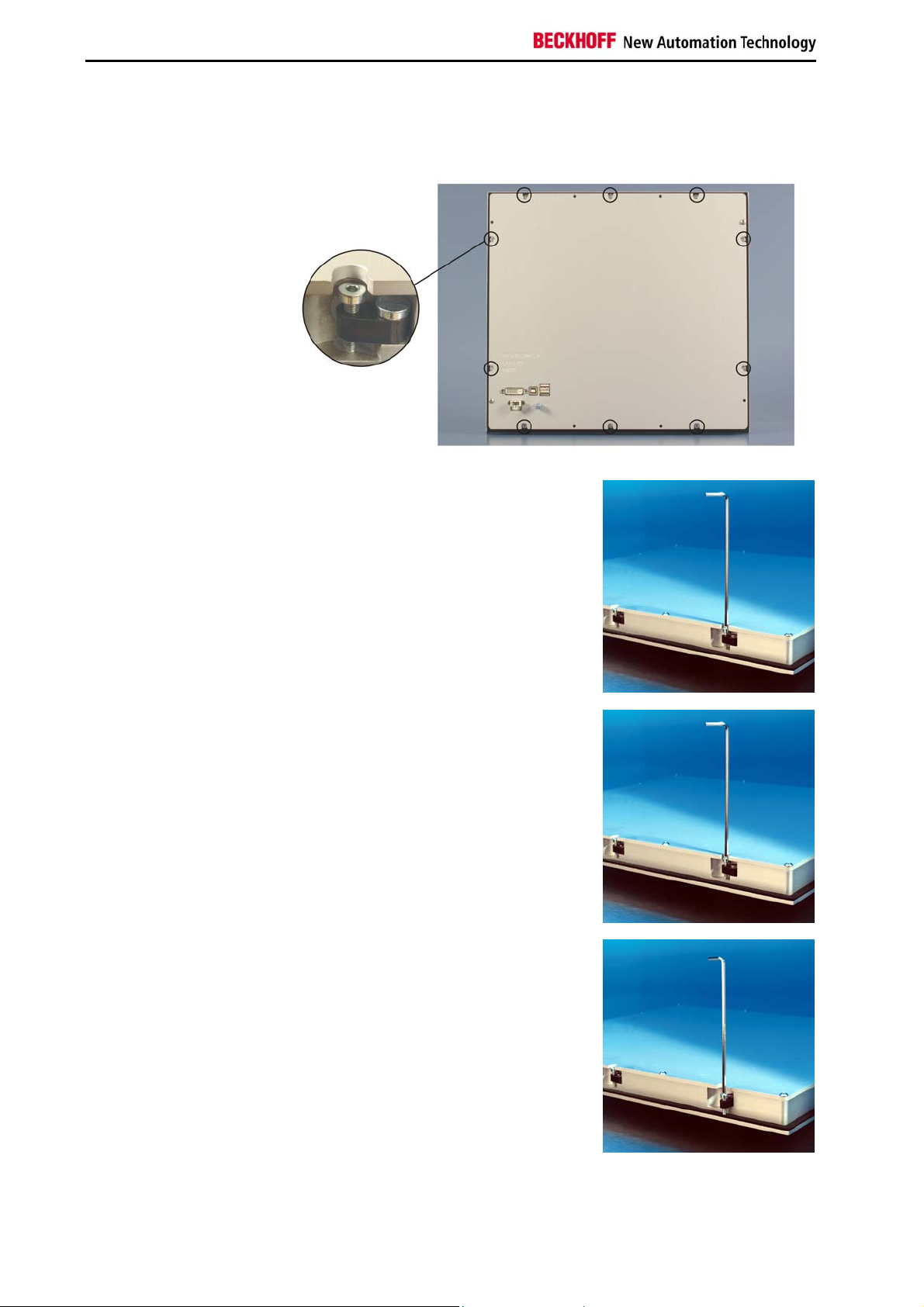

Replacing the fluorescent lamps in the display

must be replaced after a few years, depending on the number of operating

hours.

The fluorescent lamps of the 6.5 inch, 12 inch and 15 inch displays can be

replaced by a technically competent person.

i

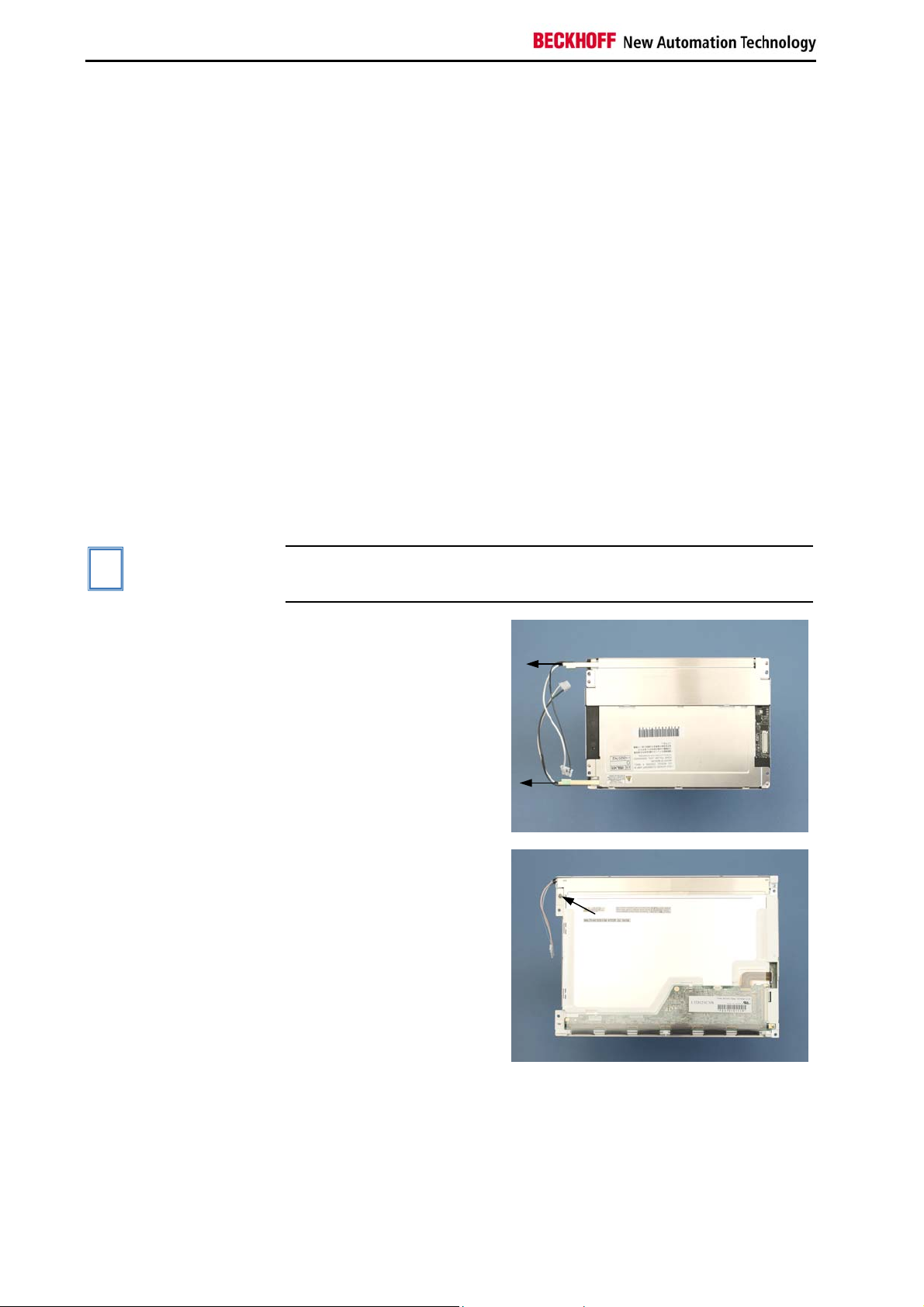

Note

Replacement for the

6.5 inch display

Replacement for the

12 inch display

Replacement of the fluorescent lamps may require partial disassembly of the display!

Press down the plastic clips

below the supply cable of the

lamps while you carefully pull

out the fluorescent lamps in

direction of the arrows.

After the exchange of the

fluorescent lamps the

installation takes place in

reverse order.

First release the screw (2)

with a small Philips

screwdriver, then tilt the

fluorescent tubes with their

brackets (1) carefully

outwards.

After the exchange of the

fluorescent lamps the

installation takes place in

reverse order.

2

1

14 CP68xx

Page 17

Operating Instructions

Replacement for the

15 inch display

First release the two screws

(1) and (2) with a small Philips

screwdriver, then carefully pull

out the fluorescent lamps in

direction of the arrows.

After the exchange of the

fluorescent lamps the

installation takes place in

reverse order.

Lamp sets

Order number

C9900 - L360

C9900 - L364

C9900 - L366

Background illumination unit for

6.5 inch TFT display NL6448BC20-08

12 inch TFT display LTD121C30S

15 inch TFT display LQ150X1LW71N

Emergency procedures

1

2

Dismantle the Control

Panel

Observe national

electronics scrap

regulations

In case of fire, the control panel should be extinguished with powder or

nitrogen.

Shutting down

Disposal

The device must be fully dismantled in order to dispose of it. The housing

can be sent for metal recycling.

Electronic parts such as lamps and circuit boards must be disposed of in

accordance with national electronics scrap regulations.

CP68xx 15

Page 18

Troubleshooting

Troubleshooting

Please also refer to chapter General Notes.

Pixel errors in the TFT display are production-caused and represent

i

Note

Fault Cause Measures

The Control Panel shows no

function when the Industrial PC has

been started

The Industrial PC does not boot

fully

Computer boots, software starts,

but control does not operate

correctly

Floppy disk or CD access error Faulty disk or CD

The Control Panel has only partial

function, or only functions some of

the time, for instance the picture is

dark or absent

no complaint-reason!

Fault correction

No power supply to Control Panel

Cable not connected

Floppy disk or CD in the drive

Hard disk damaged (e.g. by

switching off while software running)

Setup settings are incorrect

Other cause

The cause of the error is in the

software or in parts of the

equipment outside the control panel

Faulty disk drive

Faulty fluorescent bulb in the

display

Defective components in control

panel

Check power supply cable

1. Correctly connect cable

2. Call Beckhoff Service

Remove floppy disk or CD

and press any key

1. Boot with boot diskette

2. Start SCANDISK

Check the setup settings

Call Beckhoff Service

Call the manufacturer of the

machine or the software

Check disk or CD in another

drive

Call Beckhoff Service

Replace fluorescent tube in

the display in accordance

with description

Call Beckhoff Service.

16 CP68xx

Page 19

Troubleshooting

Service and Support

Beckhoff and their partners around the world offer comprehensive service

and support, making available fast and competent assistance with all

questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local

support and service on Beckhoff products!

The addresses of Beckhoff's branch offices and representatives round the

world can be found on her internet pages:

Quote the project number

http://www.beckhoff.com

You will also find further documentation

Beckhoff headquarters

Beckhoff Automation GmbH

Eiserstraße 5

D-33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you no

only with the application of individual Beckhoff products, but also with

other, wide-ranging services:

• world-wide support

• design, programming and commissioning of complex automation

systems

• and extensive training program for Beckhoff system components

Hotline:

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

+49(0)5246/963-157

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales

service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline:

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

If servicing is required, please quote the project number of your Industrial

PC.

+49(0)5246/963-460

for Beckhoff components there.

CP68xx 17

Page 20

Appendix

Appendix

Technical data

Dimensions

Operation in areas that are

subject to explosion hazard

The following conditions must be observed during operation:

Environmental conditions

Shock resistance Sinusoidal vibration:

Protection class

Power supply

EMC compatibility

Transport and storage

Dimensions (W x H x D): see section Assembly dimensions

The Control Panel must not be used where there is a risk of

explosion.

Ambient temperature: 0 to 55°C

Atmospheric humidity: Maximum 95%, non-condensing

(EN 60068-2-6)

58 to 500 Hz: 0.5 G (~ 5 m/ s2)

Impact:

(EN 60068-2-27/ 29) 5 G (~ 50 m/ s²), duration: 30 ms

Front side: IP65

Rear side: IP20

Supply voltage: 24 V

Power consumption: approx. 15 W with 6.5“ display

approx. 17 W with 10“ display

approx. 19 W with 12“ display

approx. 30 W with 15“ display

approx. 37 W with 19“ display

Resistance to interference: conforms to EN 61000-6-2

Emission of interference: conforms to EN 61000-6-4

The same values for atmospheric humidity and shock resistance are to be

observed during transport and storage as in operation. Suitable packaging

of the Control Panel can improve the resistance to impact during transport.

The ambient temperature during storage and transport must be between

-20°C and +65°C.

10 to 58 Hz: 0.035 mm

(20.4 – 28.8 VDC)

DC

i

Note

FCC Approval for USA

FCC Approval for Canada

Pixel errors in the TFT display are production-caused and represent no complaint-reason!

Approvals

FCC: Federal Communications Commission Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own

expense.

FCC: Canadian Notice

This equipment does not exceed the Class A limits for radiated emissions

as described in the Radio Interference Regulations of the Canadian

Department of Communications.

18 CP68xx

Loading...

Loading...