Page 1

865

7

RWF40... complete with housing

Compact

RWF40...

Universal Controllers

The RWF40... is a universal digital boiler temperature / pressure controller with

functions designed specifically for the control of heat generating plant.

The RWF40... and this Data Sheet are intended for use by OEMs which integrate

the controller in their products!

Mechanical design

The controller is supplied complete with housing for flush panel mounting. The

RWF40... is matched to the controlled variable and the required setpoint range by making parameter settings. The control parameters can be set and optimized while the

burner is running. All settings are made with 4 buttons located on the unit front and are

directly displayed.

LEDs on the front indicate the following operating states:

- Control ON / OFF

- Positioning pulses ON or OFF for driving the burner´s air damper when using

modulating burner control, or stage I / stage II when using 2-stage burner control

- «2-stage» operating mode

- Position of the configurable contact «K6»

- Manual control ON / OFF

During operation, the digital display above the LEDs shows the setpoint (green), the

actual value (red) and – when making parameter settings – the relevant parameters.

CC1N7865en

01.09.2005

Building Technologies

HVAC Products

Page 2

Warning notes

Mounting notes

Installation notes

To avoid injury to persons, damage to property or the environment, the following

warning notes should be observed!

Do not open, interfere with or modify the controller!

• All activities (mounting, installation and service work, etc.) must be performed by

qualified staff

• When selecting the cables, when making the installation and the electrical connec-

tions, observe the regulations of VDE 0100 «Erection of power installations with

rated voltages below AC 1000 V» and the relevant national regulations

• Provide double-pole isolation of the controller from the mains supply if there is a

risk of touching live parts while work is carried out

•

Check to ensure that wiring is in an orderly state

• Fall or shock can adversely affect the safety functions. Such units must not be put

into operation, even if they do not exhibit any damage

• Ensure that the relevant national safety regulations are complied with

• Please observe the notes given in the user documentation B7865

Commissioning notes

Standards and certificates

Service notes

• Prior to commissioning the plant, check to ensure that wiring is in an orderly state

Conformity to EEC directives

- Electromagnetic compatibility EMC (immunity)

- Electromagnetic compatibility EMC

NAMUR recommentation

89 / 336 EEC

NE21, EN 50 081 part 1

and EN 50 082 part 2

ISO 9001: 2000

Cert. 00739

ISO 14001: 1996

Cert. 38233

• For service purposes, the controller can be removed from its housing with no need

for tools

• The electrical connections ar e made via the screw terminals located at the rear of

the housing

• Each time a unit has been replaced, check to ensure that wiring is in an orderly

state and that the wires are firmly connected

Disposal notes

The unit contains electrical and electronic components and must not be disposed of

together with household waste.

2/10

Building Technologies CC1N7865en

HVAC Products 01.09.2005

Local and currently valid legislation must be observed.

Page 3

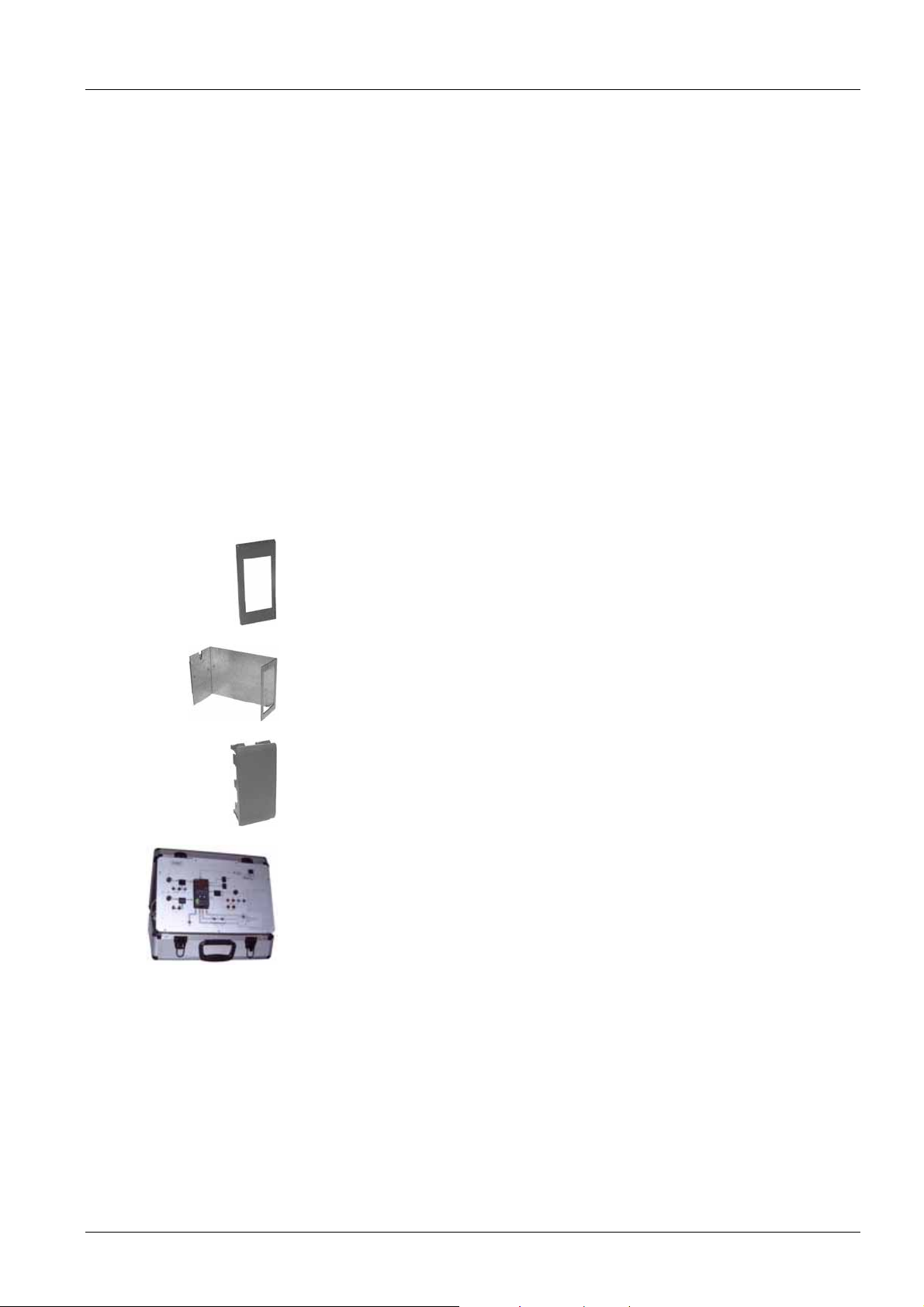

Type summary

A

ccessories

Controller with RWF40.000A97

- 3-position output

- housing

- fixing material and seal

Controller with RWF40.001A97

- 3-position output

- analog output

- housing

- fixing material and seal

Controller with RWF40.002B97

- 3-position output

- analog output

- RS-485 port

- housing

- fixing material and seal

Packaging variants (20 pieces, without documentation) RWF40.010A97

RWF40.011A97

Adapter frame for replacing the RWF32... ARG40

Bracket ARG41

For mounting the RWF40... on 35 mm DIN rails to DIN 46277

Dummy cover AVA10.200/109

For covering a panel cutout for the RWF40...

Demo case KF8892

For demonstrating the functions of the RWF40... controller

3/10

Building Technologies CC1N7865en

HVAC Products 01.09.2005

Page 4

Technical data

General controller data

Environmental

conditions

Mains voltage AC 110...240 V +10 % / -10 %

Mains frequency 48...63 Hz

Safety class II to DIN 0631

Mounting position optional

Terminals for 2 x 1.5 mm² or 1 x 2.5 mm²

Power consumption max. 10 VA

Safety extra low-voltage DC 24 V

Contact rating of the control outputs

(relays «K1...K3»)

- Up to 2 x 10

- Up to 10

5

switching cycles

7

switching cycles

2 A / AC 24...240 V

0.1 A / AC 24...240 V

Weight complete with housing approx. 760 g

Recommended actuator running time 15...60 s

Degree of protection of housing

- Front

- Base

IP 65, EN 60529

IP 20, EN 60529

Storage

DIN EN 60 721-3-1

Temperature range -20...+60 °C

Humidity < 75 % r.h.

Transport

Temperature range -40...+70 °C

Humidity < 75 % r.h.

Operation

Temperature range -20...+50 °C

Humidity < 75 % r.h.

Condensation, formation of ice and ingress of water are not permitted!

4/10

Building Technologies CC1N7865en

HVAC Products 01.09.2005

Page 5

Function

Block structure

The RWF40... provides the following functions:

- One digital PID controller with a 3-position or analog output (optional)

- To control 2-stage burners, the RWF40... can be switched over to provide 2-

position control

- Automatic thermostat (or pressurestat) function in low-fire operation

- One shift controller for weather-dependent setpoint shifting

- One minimum limiter and on e maximum limiter for the boiler temperat ure or the

boiler pressure

- One limit thermostat to DIN 3440 (output 1)

- One potential-free configurable contact

- Manual operating mode

- Communication via serial port (option)

- Self-setting function

3 analog inputs

Input 1:

Actual value

for Pt100, Ni100, Pt1000,

LG-Ni1000,

thermocouples

or standard signals

Input 2:

External setpoint,

setpoint shifting

for 0...1 k resistor

or linearized

standard signals

Input 3:

Outside temperature

for Pt1000, LG-Ni1000

Ω

Release of burner

Output 1:

- Relay (N.O. contact)

Floating ou tput

Output 2:

-Relay (actuating device open)

Output 3:

- Relay (actuating device closed)

Limit comparator

Output 4:

- Relay (N.O. contact)

2 binary inputs

For potential-free

contacts

Input 1:

Operating mode changeover

Input 2:

Setpoint shifting /

changeover

Power supply

AC 110 ...240 V +10%/-10%,

48...63 Hz, max. 10 VA

7865f01e/0905

RWF40...

Power supply measuring transducer

DC 24 V, 30 mA

(short-circu it proof)

Analog output (optional)

Output 5:

Analog output

DC 0...10 V, DC 0...20 mA,

DC 4...20 mA

Serial port (optional)

RS-485

MOD bus protocol

5/10

Building Technologies CC1N7865en

HVAC Products 01.09.2005

Page 6

Function of the controller when used for burner control

Low-fire operation

In low-fire operation, the RWF40... operates like a control thermostat or pressurestat.

This means that it operates as a 2-position controller maintaining the required setpoint

by switching the burner on and off. The switching differential for 2-position operation

can be adjusted within a wide range. If the demand for heat increases, the controller

switches to high-fire operation only when an adjustable limit is exceeded. This function

is aimed at optimizing the burner´s switching ratio.

High-fire operation,

2-stage control

In that case, the RWF40... operates as a 2-position controller with adjustable switching

thresholds. Using the relays of the 3-position output, the RWF40... drives the actuator

to the 1

switches between the minimum signal for the 1

for the 2

st

and 2nd output stage. In this operating mode, the optional analog output

nd

stage.

High-fire operation,

modulating control

In that case, the RWF40... operates as a PID / PI controller with a 3-position output

without position feedback signals or, optionally, with a modulating output. By making

use of its self-setting facility, the RWF40... is able to determine the PID / PI control

parameters, or the parameters can be set manually.

Binary input 1 (changeover of operating mode)

Using a potential-free contact, the RWF40... can be switched from the modulating

mode to 2-stage operation.

Binary input 2 (setpoint

shifting or setpoint

changeover)

In the case «setpoint shifting» is configured, the current setpoint is shifted by an adjustable amount. Configuration of «setpoint changeover» provides changeover between 2

setpoints adjusted on the RWF40... If analog input 2 is configured for an «external setpoint», changeover is provided between the setpoint adjusted on the RWF40... and an

external setpoint.

Limit comparator

Potential-free contact «K6» can be assigned a number of functions.

Example:

Limit value supervision

Operation

4 buttons on the unit front are used to operate and program the RWF40... During operation and programming, the 7-segment displays show the parameter values and parameter names.

Weather-dependent

setpoint shifting

The controller´s standard configuration ex works is such that when connecting a

QAC22… outside sensor, automatic changeover to weather-dependent setpoint shifting

takes place.

The signal delivered by the QAC2... outside sensor must not be fed parallel to several RWF40...!

st

stage and the maximum output signal

6/10

Building Technologies CC1N7865en

HVAC Products 01.09.2005

Page 7

Function of the controller when used for burner control (cont´d)

A

A

nalog input 1 (actual

value sensor)

To acquire the actual value, a number of sensors can be connected to the RWF40...

Measurement range

2-or 3-wire resistance

sensors

Thermocouples NiCr-Ni / type «K» -200...+1372 °C (-328...+2502 °F)

Cu-Cu-Ni / type «T» -200...+400 °C (-328...+752 °F)

NiCroSil-NiSil / type «N» -100...+1300 °C (-148...+2372 °F)

FeCuNi / type «J» -200...+1000 °C (-328...+1832 °F)

Pt-RhPt / type «S» 0...1768 °C (-32...3214 °F) ¹)

Pt-RhPt / type «R» 0...1768 °C (-32...3214 °F) ¹)

Pt-RhPt / type «B» 0...1820 °C (32...3308 °F) ¹)

Linearized standard

signals

Pt100 / IEC 751 -200...+850 °C (-328...+1562 °F)

Pt1000 / IEC 751 -200...+850 °C (-328...+1562 °F)

Ni100 / DIN 43760 -60...+230 °C (-76...+482 °F)

Ni1000 / DIN 43760 -60...+230 °C (-76...+482 °F)

LG-Ni1000 -50...+160 °C (-58...+320 °F)

0...20 mA scalable -1999...+9999

4...20 mA scalable -1999...+9999

DC 0...10 V scalable -1999...+9999

DC 0...1 V scalable -1999...+9999

¹) Only RWF40.0X2B97

The power provided for the measuring transducers is DC 24 V / 30 mA.

nalog input 2 (external

setpoint shift or external

setpoint)

Feeding a signal to analog input 2, the controller´s setpoint can be influenced. The

influence can be scaled.

The following signals can be used:

- Input signals DC 0...1 V, DC 0...10 V, 0...20 mA, 4...20 mA

- 1 kΩ potentiometer in a 2-wire circuit

7/10

Building Technologies CC1N7865en

HVAC Products 01.09.2005

Page 8

Connection diagram (basic diagram)

Temperature and pressure control on a dual-fuel burner.

Burner control and supervision are provided by burner control type LAL... or LFL...

Note

DC 24 V at terminals «G+» and «G-» is used for powering the QBE... pressure sensor!

LN

G1+ M1B9

RWF40...

M9

XB6 M6

Q13

Q14

Y1

Y2D1Q

GND

D2

Legend

LAL..., LFL...

19

45

ST

B

MB M

QAE...

QAC...

MR

BSG...

0

I

L

N

GAS

18

BS

2

1

0

BV1

LK

N

RV

BV1

BV2

v

7865a01/1004

a

OIL

9

20

1110

z

M

~

m

MIN.

int. ext.

S1

SQ...

RWF40...

SQ...

GND

D2

int. ext.

S1

G+ M1 XU 6 M6

LN

U1-

G-

Q13

Q14

Y1

Y2D1Q

LAL..., LFL...

19

45

ST

B

G

M

18

BS

2

1

0

9

20

1110

QBE...

0...10 V

BSG...

0

I

L

N

GAS

BV1

LK

N

RV

BV1

v

BV2

a

OIL

7865a02/0905

z

M

~

m

MIN.

a Limit switch for air damper position OPEN QAE... Immersion temperature sensor

BS Operation selector QBE... Pressure sensor

1 = firing on gas RV Gas control damper

(modulating burner control) S1 Internal / external setpoint switch (E)

2 = firing on oil SQ... Actuator of burner´s air damper and gas

(2-stage burner control) control damper

BV... Fuel valve ST Connections for burner control´s start

BSG... Remote setpoint adjuster (active when control loop

«S1» is closed) v Auxiliary switch for the release of the

L... Burner control 2nd fuel valve depending on the air damper

LK Burner´s air damper position

m (MIN) Auxiliary switch for controlling low-fire z End switch for the fully CLOSED

operation positi on of the air damper

QAC... Outside sensor for weather-dependent

setpoint shifting

8/10

Building Technologies CC1N7865en

HVAC Products 01.09.2005

Page 9

Dimensions

A

Dimensions in mm

48

RG40 adapter frame

RWF40

PGM EXIT

43,5

K6

96

15,5

91,5

127,5

112

Panel cutout to DIN 43 700

+0,6

45

+0,8

92

7865m01e/0300

7865m02/0799

Building Technologies CC1N7865en

HVAC Products 01.09.2005

9/10

Page 10

Dimensions (cont´d)

A

RG41

94

8

3

35,5

Dimensions in mm

61,4

45

13

60

153

68

83

45

7,5

12,5

7865m04/1004

© 2005 Siemens Building Technologies Production GmbH

10/10

Building Technologies CC1N7865en

HVAC Products 01.09.2005

Subject to change!

Loading...

Loading...