Page 1

P3/30PSF - P9/16PSF

en

Assembly and Operating Instructions

Drives for Sunshades/Awnings

with integrated radio receiver

Important information for:

•

Fitters

• Electricians

• Users

Please forward accordingly!

These instructions must be kept for future reference.

Becker-Antriebe GmbH

35764 Sinn/Germany

www.becker-antriebe.com

Page 2

Assembly and Operating Instructions

Table of Contents

General ...................................................................................................................................................................... 2

Warranty ..................................................................................................................................................................... 3

Safety Information ....................................................................................................................................................... 3

Intended Use .............................................................................................................................................................. 5

Mounting and installation instructions ..........................................................................................................................5

Setting the end limits ................................................................................................................................................... 8

Technical Data .......................................................................................................................................................... 13

What should you do, if...? ........................................................................................................................................... 13

General

These tubular drives are high-quality products with the following features:

• Optimized drives for sun protection applications (for use in roller shutter types P5/16PRF+ to

R40/17C PRF+ )

• Suitable for awnings and winter garden shades.

• No external limit switches

• The end limits do not have to be readjusted: changes in shutter curtain/canopy length are adjusted

automatically thanks to the use of end stops

• Optimum adjustment of the tensile load to the mechanical requirements of the sun shade system

• Minimum curtain and seam load

• Automatic end stop detection

• Extension length can be easily set using the transmitter (direct setting)

• Left or right-hand installation

• Radio-operated individual and group control

• No additional wiring to the switch or a relay control

• Drive and transmitters can be freely combined

• Easy group selection

• End limits can be programmed and deleted by remote control

• „Complex code“ remote control system with variable code lengths up to 64 bit, allowing more than 1

billion different codes

• Transmitter data can be easily copied

When installing and setting the system please ensure that the assembly and operating instructions provided are followed

closely.

2

Page 3

Warranty

Structural modications and incorrect installation which are not in accordance with these and our other instructions can result

in serious injuries, e.g. crushing of limbs. Therefore, structural modications should only be carried out with our prior approval

and in accordance with our instructions, particularly the information contained in these Assembly and Operating Instructions.

Any further processing of the products which does not comply with their intended use is not permitted.

The end product manufacturer and tter have to ensure that all the current statutory, ofcial regulations and, in particular,

EMC regulations are adhered to during utilisation of our products, especially with regard to end product assembly, installation

and customer advice.

Safety Information

The following safety instructions and warnings are intended to avert hazards and to prevent damage to property and personal

injuries. Please retain for future reference.

Caution

Attention

Note

Important safety instructions for the user

Caution! Failure to observe these instructions can lead to serious injuries.

• All operational work including maintenance and cleaning, on electrical installations as well as other parts of the

construction must always be performed by authorised specialists, especially by qualied electricians.

• Do not allow children to play with control units.

• Systems have to be regularly checked by authorised specialists for wear and damages.

• Always put damaged systems out of operation immediately until they are repaired by an authorised specialist.

• Do not operate equipment if people or objects are within the danger zone.

• Observe the danger zone of the equipment during operation.

• Bring the equipment to a stop and disconnect the mains power supply when maintenance and cleaning jobs are

performed either on the system itself or in the immediate vicinity of it.

• Ensure that there is an adequate distance (at least 40 cm) between moving parts and adjacent objects.

• Crushing and shearing points must be avoided or protected.

Denotes a potentially hazardous situation. If this is not avoided, injuries may

result.

Denotes a potentially hazardous situation. If this is not avoided, the product

or something in its vicinity may be damaged.

Denotes user tips and other useful information.

3

Page 4

Assembly and Operating Instructions

Important safety instructions for the installation and commissioning

Caution! Failure to observe these instructions can lead to serious injuries.

• Please comply with the safety instructions EN 60335-2-97. Please note that these safety instructions cannot

be assumed as being complete, since this standard does not consider all the possible causes of risk. For example, the construction of the operated product, the effectiveness of the drive in the location of installation or the

mounting of the nal product in the end user’s place of usage cannot be taken into consideration by the drive

manufacturer.

If any questions or concerns regarding the safety instructions contained in the standard arise, please contact

the manufacturer of the respective part or end product.

• All operational work, including maintenance and cleaning, on electrical installations as well as other system

parts must always be performed by authorised specialists, especially qualied electricians.

• During operation of electrical or electronic equipment and units, certain components are subject to a hazardous

electrical voltage. Physical injuries or damage to property can result in the event of unqualied interventions or

failure to comply with the warning notices.

• All applicable standards and regulations for the electrical installation must be complied with.

• Only use spare parts, tools and additional equipment which have been approved by the drive manufacturer.

• Unapproved third party products or modications to the system and its accessories represent a risk to your

safety and the safety of others. This means that the utilisation of unapproved third party products, or modications which have not been agreed with or approved by us are prohibited. We shall not accept liability for damages arising from such actions.

• Before installation, shut down all lines and control devices that are not essential for operation.

• Position control devices within sight of the driven product at a height of over 1.5 m.

• Stationary mounted control units have to be xed in sight.

• Ensure that there is an adequate distance (at least 40 cm) between moving parts and adjacent objects.

• Nominal torque and duty cycle must be suitable for the requirements of the driven product.

• Technical data nominal torque and service life are located on the type plate of the tubular drive.

• Moveable parts of the drive have to be mounted at a height of more than 2,5 m above ground or on a different

level, which allows access to the drive.

• Crushing or shearing points must be avoided or protected.

• When installing the drive, an all-pole separation capability from the mains with at least 3 mm contact opening

width per pole must be provided (EN 60335).

• If the mains cable is damaged, it must be replaced with an identical mains cable (pluggable) supplied by the

drive manufacturer.

• Never handle the drive via the mains cable.

• Drives with a H05VV-F connection cable are only to be used inside the building.

• Drives from Becker Antriebe are to be mounted and operated solely with mechanical accessory components

shown in the current Becker product catalogue.

4

Page 5

Intended Use

A

B

C

B

The tubular drives P3/30PSF to P9/16PSF are designed for operating awnings, screens and winter garden shades only. Linked

operation is only possible if all sub systems run exactly synchronously and reach the top end limit at the same time.

Other applications, utilisation and modications are not permitted in order to protect the safety of the users and others, since

these actions can impair the system’s safety, resulting in personal injuries and property damage. Becker-Antriebe shall not

accept liability for damages arising from such actions. Always observe the information in these instructions when operating or

repairing the system. Becker-Antriebe shall not accept liability for damages resulting from incorrect usage.

Mounting and installation instructions

1

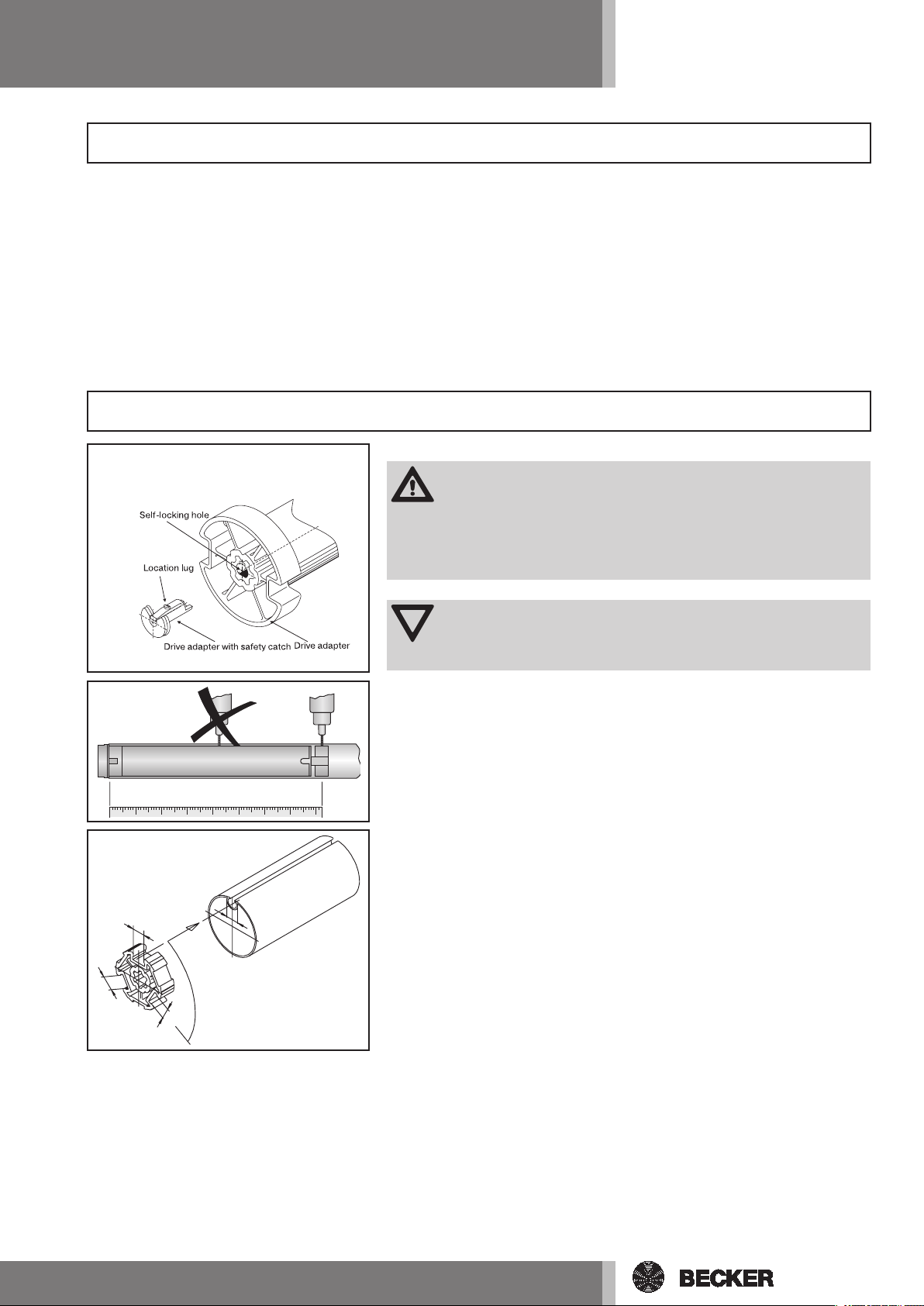

Drive adapter safety catch

2

3

Installing the tubular drive

Caution!

All electrical connections must be made by a qualied elec-

trician. The current supply must be disconnected before installation. These installation instructions must be given to

the electrician installing the equipment. Ensure that no damage occurs to the antenna insulation. The antenna carries

electric potential.

When installing the drive, the following steps must be carried out:

Attention

Drives from Becker Antriebe are to be mounted and operated

solely with mechanical accessory components shown in the

current Becker product catalogue.

1) Installing a drive adaptor with safety catch:

The insert direction of the drive adaptor safety catch is prescribed by its

shape. When installing the drive adaptor, always ensure that the safety catch

engages. A „clicking“ sound can be heard when the drive adaptor safety

catch engages properly. Pull on the drive adaptor to check that it is located

securely (Fig. 1).

2) Before inserting the drive into the tube, measure the dimensions from the

end of the tube to the centre of the drive adaptor and mark the dimensions on

the tube (Fig. 2).

3) Tubes with shaped sections:

With some drive adaptors, groove widths tolerances in different barrels can

be compensated for by turning the drive adaptor into another groove recess.

These groove recesses have different dimensions and allow you to install the

drive so that it ts exactly (Fig. 3).

5

Page 6

Assembly and Operating Instructions

4

5

4) Round tubes:

Release the tube at the motor end to allow the cam of the limit ring adapter

to be slid into the tube. There must be no clearance between the cam of the

limit ring adapter and the tube (Fig. 4). For limit ring adapters without locating cams the roller tube must be connected to the limit ring adapter using a

4.8 x 10 mm tapping screw.

5) Mount the drive using a suitable limit ring adaptor (A) and drive adaptor

(B). Slide the drive with pre-mounted limit ring adaptor and drive adaptor into

the tube into it connects positively. Ensure that the limit ring adaptor and drive

adaptor are tted into the tube securely (Fig. 5).

The drive adaptor of the tubular drive must be connected to the tube as follows:

Size of drive

[mm]

Ø 35

The drive manufacturer also recommends screwing the opposite end

bracket to the barrel.

Roller shutter tubes–Ø

[mm]

40 mm plastic drive

adapter

Attention!

When drilling the tube ensure that you never drill in the area

around the tubular drive! When inserting the drive into the

tube, do not drive it in or drop it into the tube! (Fig. 2 and 5)

When installing the sun shade system, always ensure that the

motor connection cable and the antenna cannot be damaged

or squashed when the system is in operation.

Torque max.

[Nm]

13

Fastening screws

for drivers (4 x)

at-headed sheet-metal

screw ST 4.8 x 10 DIN 7982

6

Page 7

1) +2a)

Action Response

1) Connecting the tubular drive

Connect the tubular drive to the power supply.

2) Activating programming mode for tubular drive

2a) Activating programming mode for tubular drive by switching on

power supply

Now switch on the power supply. The tubular drive will be in programming mode

for 3 minutes.

Note

If several tubular drives are to be operated in parallel, the pro-

gramming mode for one tubular drive can be deactivated by

sliding the radio switch into the outer position after the power

has been switched on.

If the radio switch is already in this position, slide the switch

back inwards and back to the outer position again.

2b)

3)

4)

Clack-Clack

Rotation switch

Radio switch

2b) Activating programming mode for tubular drive using the radio

switch

Slide the radio switch into the inner

position. If the radio switch is already

in this position, slide the switch outwards and back to the inner position

again.

The tubular drive goes into programming mode for 3 minutes.

3) Programming the master transmitter

Note

Follow the instructions given in the operating manual for the

transmitter. If a transmitter has already been programmed into

the receiver, press and hold the programming button for 10 seconds.

Press the programming button for 3

seconds when the programming mode

is activated.

The tubular drive makes a „clackclack“ sound to conrm.

The programming process is complete.

4) Checking the rotation setting

Press the RETRACT or EXTEND button.

If the curtain moves in the wrong direction, the rotation setting must be changed.

Proceed as follows to do so:

Slide the rotation switch into the opposite position.

The curtain moves in the desired direction.

=> The rotation setting is OK.

Radio switch

Rotation switch

The rotation setting has been changed.

Recheck the rotation setting.

7

Page 8

Assembly and Operating Instructions

Setting the end limits

5) There are two ways to set the end limits:

a) Extend curtain/canopy to desired position and retract to desired position with no end stop

b) Extend curtain/canopy to desired position and retract to end stop

The nal limit position becomes xed, after the tubular drive has turned off automatically, in the desired position, three times.

Note

The end limits can only be set using the master transmitter. The rotation setting must be correct. When

end limits are being set, the tubular drive remains in maintained command mode. The lower end limit must

always be programmed rst.

If, during extension or retraction, the tubular drive stops due to an obstruction, it is possible to extend or

retract the curtain/canopy as necessary in order to move it away from the obstruction. The obstruction

can then be removed and the curtain/canopy adjusted into the desired end limit position.

Action Response

5a)

5a) Lower end limit to upper end limit with no end stop

Note

With this end limit setting there is no automatic curtain/canopy

length adjustment.

Move the curtain/canopy to the desired lower end limit.

5b)

Clack

Clack

Clack

First press the programming button

and, within 3 seconds, also press the

EXTEND button and keep both buttons

pressed.

Then move to the desired upper end

limit.

Now press the programming button

and, within 3 seconds, the RETRACT

button and keep both buttons pressed.

5b) Lower end limit to end stop

Move the curtain/canopy into the desired lower end limit.

First press the programming button

and, within 3 seconds, also press the

EXTEND button and keep both buttons

pressed.

Then move to the xed end stop. The tubular drive switches off auto-

The tubular drive makes a „clack“

sound to conrm.

The tubular drive makes a „clack“

sound to conrm.

The end limits are set.

The tubular drive makes a „clack“

sound to conrm.

matically.

The end limits are set.

8

Page 9

6a)

Action Response

6) Changing the end limit settings

Note

End limit settings can only be changed using the master trans-

mitter.

6a) Reducing the operating range (the desired end limit is within the

possible operating range)

Move to the desired new end limit.

6b)

Clack

Clack-Clack

Clack

First press the programming button

and, within 3 seconds, also press the

EXTEND button for the lower end limit

or the RETRACT button for the upper end limit and keep both buttons

pressed.

6b) Increasing the operating range (the desired end limit is outside the

possible operating range)

Move the curtain/canopy to the end

limit of the direction in which you wish

to increase the operating range.

First press the programming button

and, within 3 seconds, also press the

STOP button and keep both buttons

pressed for 10 seconds.

Move the curtain/canopy to the desired new end limit.

First press the programming button

and, within 3 seconds, also press the

EXTEND button for the lower end limit

or the RETRACT button for the upper end limit and keep both buttons

pressed.

The tubular drive makes a „clack“

sound to conrm.

The new end limit is stored.

The tubular drive makes a „clackclack“ sound to conrm.

The end limit has been deleted.

The tubular drive makes a „clack“

sound to conrm.

The new end limit has been stored.

7a)

Clack-Clack

7) Deleting the end limits

Note

The end limit settings can only be deleted using the master

transmitter.

7a) Deleting the end limits individually

Move the curtain/canopy to the end

limit to be deleted.

First press the programming button

and, within 3 seconds, also press the

STOP button and keep both buttons

pressed for 10 seconds.

The tubular drive makes a „clackclack“ sound to conrm.

The end limit has been deleted.

9

Page 10

Assembly and Operating Instructions

Action Response

7b)

7b) Deleting both end limits

Move the curtain/canopy to any position between the two end limits.

8a)

8b)

Clack-Clack

Clack

First press the programming button

and, within 3 seconds, also press the

STOP button and keep both buttons

pressed for 10 seconds.

The tubular drive makes a „clackclack“ sound to conrm.

The end limits have been deleted.

8) Intermediate position I in extend direction

Note

Intermediate position I is an intermediate position for the cur-

tain/canopy and can be set at any given position between the

upper and lower end limits. Intermediate position I can only be

set if both end limits have already been set.

8a) Setting intermediate position I

Move the curtain/canopy to the desired intermediate position I.

First press the STOP button and, within

3 seconds, also press the EXTEND button and keep both buttons pressed.

8b) Adjustment to intermediate position I

Note

The curtain/canopy moves to the intermediate position I from

the upper end limit.

Press the EXTEND button twice within

one second.

The tubular drive makes a „clack“

sound to conrm.

Intermediate position I has been

stored.

The curtain/canopy moves to intermediate position I.

8c)

10

Clack-Clack

8c) Deleting intermediate position I

Move the curtain/canopy to the desired intermediate position I.

First press the STOP button and, within

3 seconds, also press the EXTEND button and keep both buttons pressed.

The tubular drive makes a „clackclack“ sound to conrm.

Intermediate position I has been deleted.

Page 11

Action Response

9) Intermediate position II in retract direction

Note

This function allows you to move the curtain/canopy from the

lower end limit to intermediate position II. Intermediate position

II can only be set if both end limits have already been set.

9a)

9b)

9c)

Clack

Clack-Clack

9a) Setting intermediate position II

Move the curtain/canopy to the desired intermediate position II.

First press the STOP button and, within

3 seconds, also press the RETRACT

button and keep both buttons pressed.

The tubular drive makes a „clack“

position II

Press the RETRACT button twice within one second.

9c) Deleting intermediate position II

Note

The curtain/canopy moves to intermediate position II from the

lower end limit.

Move the curtain/canopy to the desired intermediate position II.

First press the STOP button and, within

3 seconds, also press the RETRACT

button and keep both buttons pressed.

The tubular drive makes a „clack-

sound to conrm.

Intermediate position II has been

stored.

9b) Adjustment to intermediate

The curtain/canopy moves to intermediate position II.

clack“ sound to conrm.

Intermediate position II has been deleted.

10)

Clack

Clack

Clack-Clack

10) Programming additional transmitters

Note

In addition to the master transmitter, up to 15 additional trans-

mitters can be programmed in the tubular drive.

The end limits must be set prior to programming the radio sun-

and wind sensor.

Press the programming button of the

master transmitter programmed according to point (3) for 3 seconds.

Now press the programming button of

a new transmitter which is not yet programmed in the tubular drive for 3 seconds. In doing so, the programming

mode for the tubular drive is activated

for a new transmitter for 3 minutes.

Now press the programming button of

the new transmitter to be programmed

once again for 3 seconds.

The tubular drive makes a „clack“

sound to conrm.

The tubular drive makes a „clack“

sound to conrm.

The tubular drive makes a „clackclack“ sound to conrm.

The new transmitter has now been

programmed in the drive.

11

Page 12

Assembly and Operating Instructions

Action Response

11a)

11b)

Clack

Clack

Clack-Clack

Clack

Clack

Clack-Clack

11) Deleting transmitters

11a) Deleting transmitters individually

Note

The master transmitter which was programmed in the drive ac-

cording to Point (3) cannot be deleted. It can only be overwritten (see Point 12).

Press the programming button on the

master transmitter for 3 seconds.

Now press the programming button

of the transmitter to be deleted for 3

seconds.

Then press the programming button

of the transmitter to be deleted once

again for 10 seconds.

11b) Deleting all transmitters (except master transmitter)

Press the programming button on the

master transmitter for 3 seconds.

Now press the programming button on

the master transmitter once again for

3 seconds.

Now press the programming button on

the master transmitter once again for

10 seconds.

The tubular drive makes a „clack“

sound to conrm.

The tubular drive makes a „clack“

sound to conrm.

The tubular drive makes a „clackclack“ sound to conrm.

The transmitter has been deleted from

the tubular drive.

The tubular drive makes a „clack“

sound to conrm.

The tubular drive makes a „clack“

sound to conrm.

The tubular drive makes a „clackclack“ sound to conrm.

All transmitters (except master transmitter) have been deleted from the

receiver.

12a)

Clack-Clack

12) Overwriting master transmitter

There are two ways of overwriting the master transmitter:

a) Put tubular drive into programming mode by switching on power supply

b) Put tubular drive into programming mode using radio switch

12a) Putting tubular drive into programming mode by switching on

power supply

Switch off the power supply to the tubular drive and reconnect after 5 seconds.

Note

To ensure that the new master transmitter is programmed in the

desired tubular drive only, the programming mode for all other

tubular drives which are connected to the same power supply

must be deactivated. To do so, after the power supply has been

switched back on, execute a command control (adjust or stop)

with the transmitter of these tubular drives or move the radio

switch from the inner to the outer position. If the radio switch is

already in this position, slide the switch to the inner position and

back to the outer position again.

Now press the programming button of

the new master transmitter for 10 seconds.

The tubular drive goes into programming mode for 3 minutes.

The tubular drive makes a „clackclack“ sound to conrm.

The new master transmitter has been

programmed in and the old deleted.

12

Page 13

12b)

Action Response

12b) Putting the tubular drive into programming mode using the radio

switch

Slide the radio switch into the inner

position. If the radio switch is already

in this position, slide it outwards and

back to the inner position again.

The tubular drive goes into programming mode for 3 minutes.

Now press the programming button of

the new master transmitter for 10 seconds.

Clack-Clack

The tubular drive makes a „clackclack“ sound to conrm.

The new master transmitter has been

programmed in and the old deleted.

Technical Data

Type P3/30PSF P5/20PSF P5/30PSF P9/16PSF

Nominal torque (Nm) 3 5 5 9

Output speed (min

Limit switch range 64 revolutions

Mains voltage 230V/50Hz

Power consumption (W) 85 115 11 5 110

Nominal current consumption (A) 0,36 0,47 0,47 0,47

Operating mode S2 4 Min.

Protection class IP 44

Min. tube diameter (mm) 37

Frequency 868,3 MHz

-1

) 30 20 30 16

What should you do, if...?

Malfunction Cause Solution

Tubular drive is not running. 1. No transmitter has been programmed.

2. Transmitter is outwith the range of the

tubular drive.

3. Transmitter has been operated outwith the

range several times.

4. Batteries in the transmitter have been

incorrectly inserted, not inserted at all or

are empty.

5. Faulty electrical connection.

6. Thermal cut-out function in the tubular

drive has been activated.

You are unable to change the

axle direction.

The axle direction is incorrect

after deleting the end limits.

Tubular drive has stopped at

random and won’t run in the

given direction.

End limits are stored in the tubular drive. Start up the tubular drive via a start com-

The axle direction switch is in the wrong position.

1. Tubular drive has detected an assumed

load.

2. Tubular drive is overloaded.

1. Programme new transmitter.

2. Move transmitter into the range of the

tubular drive.

3. Activate the control or stop button on the

transmitter at least 5 times.

4. Insert batteries properly or replace batteries.

5. Check electrical connection.

6. Wait 5-10 minutes.

mand and deactivate with a stop command.

Then delete the end limit settings using the

programming and stop buttons.

Slide the axle direction switch to the opposite

position.

1. Run the drive briey in the opposite direction, then activate the desired direction

again.

2. Use a tubular drive with a greater torque.

13

Page 14

Assembly and Operating Instructions

14

Page 15

15

Page 16

2010 300 258 0d 06/11

Loading...

Loading...