Page 1

Instruction Manual

for

the HPP-5

High Pressure

Positioner

Table of Contents

Section Page

Introduction 2

Description 2

Scope of Manual 2

Technical Assistance 2

Applications 3

Guidelines for usage 3

Technical Information 4

Specifications 4

Materials of Construction 4

Accessories 4

Principals of Operation 5

Close on increasing 5

Open on increasing 6

Adjustment Procedure 7

Deadband Setting 8

Bias Adjustment 9

Range Adjustment 10

Section Page

Changing Positioner Action 12

Conversion to Split Range 13

Assembly Procedures Separate Manual

Inspection Procedures 15

Parts Ordering 16

Parts List 16

Seal Kits 16

Appendix – Parts & Mounting detail

Open on increasing (parts) 18

Close on increasing (parts) 19

Page 2

HPP-4 Positioner

Instruction Manual

Introduction

The Becker HPP-5 series positioner

represents a breakthrough in valve control technology for the natural gas industry. Built to exacting specifications,

the easily maintained unit offers highly

accurate control with excellent control

characteristics in a broad range of operating environments. The HPP-5 series

positioner is designed such that upon

reaching a valve position and achieving

a steady state, the gas consumption is

very low. Additionally, its bleed gas

can be routed to a lower pressure

downstream or fuel gas system, eliminating bleed gas completely. This

means significant savings to your company in terms of minimizing expensive

bleed gas as well as a cost saving

means of minimizing the environmental

impact of atmospheric hydrocarbons

and diminishing natural resources.

Description

The Becker HPP-5 positioner is used in

control valve assemblies with a controller or I/P transducer and double acting

actuator to provide accurate flow or

pressure control. The HPP-5 can be

used with various valve types that utilize

a double acting pneumatic piston actuator. The HPP-5 design positioner

represents Becker’s commitment to

continuos development of new products

and updating of existing products to

maximize their performance while retaining simple operation and minimum

maintenance.

Valves over 16” in diameter require the

use of a Becker HPP-4 positioner with

Volume boosters.

Scope of Manual

This manual provides information on installation, operation, adjustment, and

maintenance of the Becker HPP-5 po-

sitioner. For information concerning actuators, valves, and accessories, refer

to the instruction manuals provided with

the specific product.

Note: Only those qualified through training or

experience should install, operate, or maintain

Becker positioners. If there are any questions

concerning these instructions, contact your

Becker sales representative, sales office, or

manufacturer before proceeding.

Technical Assistance

Should you have any questions, you

may contact your local Becker Precision sales representative or Becker

Precision technical assistance at:

Becker Precision Equipment, Inc.

Attn: Technical Assistance

950 Pratt Boulevard

Elk Grove Village, IL 60007 USA

Toll Free: (800) 323-8844

Tel: (847) 437-5940

Fax: (847) 437-2549

e-mail: becker@bpe950.com

HPP-5 2 September 1999

Page 3

HPP-5 Positioner

Instruction Manual

Applications

• Primary Pressure Control

• Overpressure Protection (Monitor)

• Underpressure Protection

(Standby)

• Relief Valve

• Backpressure Control

• Power Plant Type Applications*

• When Unique "Bleed to Pressure

System" BPS™ feature can be

utilized

• Any large downstream systems

(city gate stations, inter-system

pressure limiting)

• Suction control to reciprocating

compressors*

• Double-stage cut (working monitor regulator*

* (consult Becker for additional information)

Guidelines for Usage

Large Volume Control Valve Actuators:

Control Valves that require large volume

actuators may require Model VB-250

Volume Boosters to ensure adequate

stroking speed. HPP-5 positioners are

NOT compatible with volume boosters.

The HPP-4 positioner must be used

Bleed to Pressure System: The HPP-5

Positioner is typically utilized for applications where no discharge pressure of

less than 350 psig is available. The very

low steady state bleed of the positioner

makes it efficient for minimizing atmospheric emmisions. The HPP-5 is also

compatible with the Becker BPS (Bleed

to pressure system).

High Gain Systems: The HPP-5 is not

preferred for this application. It may be

successfully used with small diameter

(4” and smaller) ball valves for this application, but its limited orifice capacity

makes it too slow for controlling larger

valves on short systems.

CVE Globe Pattern Control Valves: The

Becker HPP series positioners are compatible with the Globe style control valve,

but require a minimum of 2” of actuator

stroke for proper feedback and operation. This makes it impossible to use

this positioner with most globe valves

smaller than 4” port size.

Compatible Actuators:

• Becker RPDA Actuators (Rotary Pis-

ton Double-Acting)

• Becker LPDA Actuators (Linear Pis-

ton Double-Acting)

• Other manufacturer’s double-acting

piston actuators*

*consult Becker for additional informa-

tion

Retrofit Compatibility:

Optimum performance is achieved by

pairing the HPP-5 with genuine Becker

control valve actuators. Should you already have existing control valve actuator

(s) in service, the addition of a Model

HPP-5 can improve performance and

eliminate atmospheric bleed emissions if

using the BPS (Bleed to a pressure system) feature.

Some Compatible Actuators:

• Bettis T-Series Piston Actuators

• Fisher Type 470 Piston Actuators

• Fisher Type 1061 Piston

HPP-5 3 September 1999

Page 4

HPP-5 Positioner

Specifications

Technical Specifications

Input Signal: Standard: 3-15 psi or 6-30 psi.

Output Signal: Pneumatic pressure as required by the

Loss of Signal: Reverse Acting: Open on loss of signal.

Connections: All Ports: ¼” N.P.T.

Action: Direct and Reverse Acting:. Field-

Performance: Resolution: 0.4%*

Flow Capacity: CV = 1.5

Steady State

Consumption:

Power Gas Requirement:

Operative Temperature

Limits:

Housing: Meets NEMA 3 classification (weather

Installation Orientation:

Approximate Weight: 15 pounds.

Adjustable: Zero is adjustable from 230 psig, span is adjustable from 5-24

actuator up to full supply pressure.

Direct Acting: Close on loss of signal.

reversible

Hysteresis: .6%*

Near Zero

Use clean, dry filtered (100 micron)

gas.

Discharging to Atmosphere:

150 psig maximum.

-20 to 160°F

(-28 to 70°C).

tight).

Vertical or horizontal position allowable.

Materials of Construction

External Parts: Anodized 2024 Aluminum

Internal Parts: 316 Stainless Steel and 2024 Ano-

Feedback Lever: 316 Stainless Steel

Range Spring: Plated Music Wire

Diaphragms: Buna-N with Nylon Reinforcement

Seats and O-Rings: Buna-N

Tubing: 316 Stainless Steel

Fittings: 316 Stainless Steel

Gauges: 2 ½” Dial Liquid filled Brass Con-

Maximum Supply Regulator Capacity

Q = 312.86 x P1 x CV x

Q = Min. Supply Regulators Capacity (scfh)

G = Specific Gravity of Gas

T = 460 + Operative Temperature (°F)

Cv = Flow Factor

P

= Supply Pressure to Positioner (psig)

1

dized Aluminum

nection with Stainless Steel Case.

(Stainless Steel connection op-

1

+× TG

460

)(

* Resolution and repeatability figures reflect a

positioner that is adjusted with a minimum deadband to reduce bleed gas. If the deadband is

eliminated (slightly increasing the bleed gas),

resolution and repeatability will improve.

Accessories

• Atmospheric Bleed Control (AB Control):

maintains minimum pressure differential

across the cylinder. The AB Control is required in order to provide the necessary

output to operate the control valve under all

design conditions.

• NBV No Bleed valve – same function as

DPS, no adjustments or tubing required.

Works up to 150 psig power gas.

• DPS Series Non-Bleed Sensor: achieves

non-bleeding conditions in either full open

or full closed positions. Selection based

upon power gas pressure and discharge

gas pressure.

HPP-5 4 September 1999

Page 5

HPP-5 Positioner

“How-It-Works”

Power

Gas

InstrumentSignal

Cylinder

Top

Exhaust

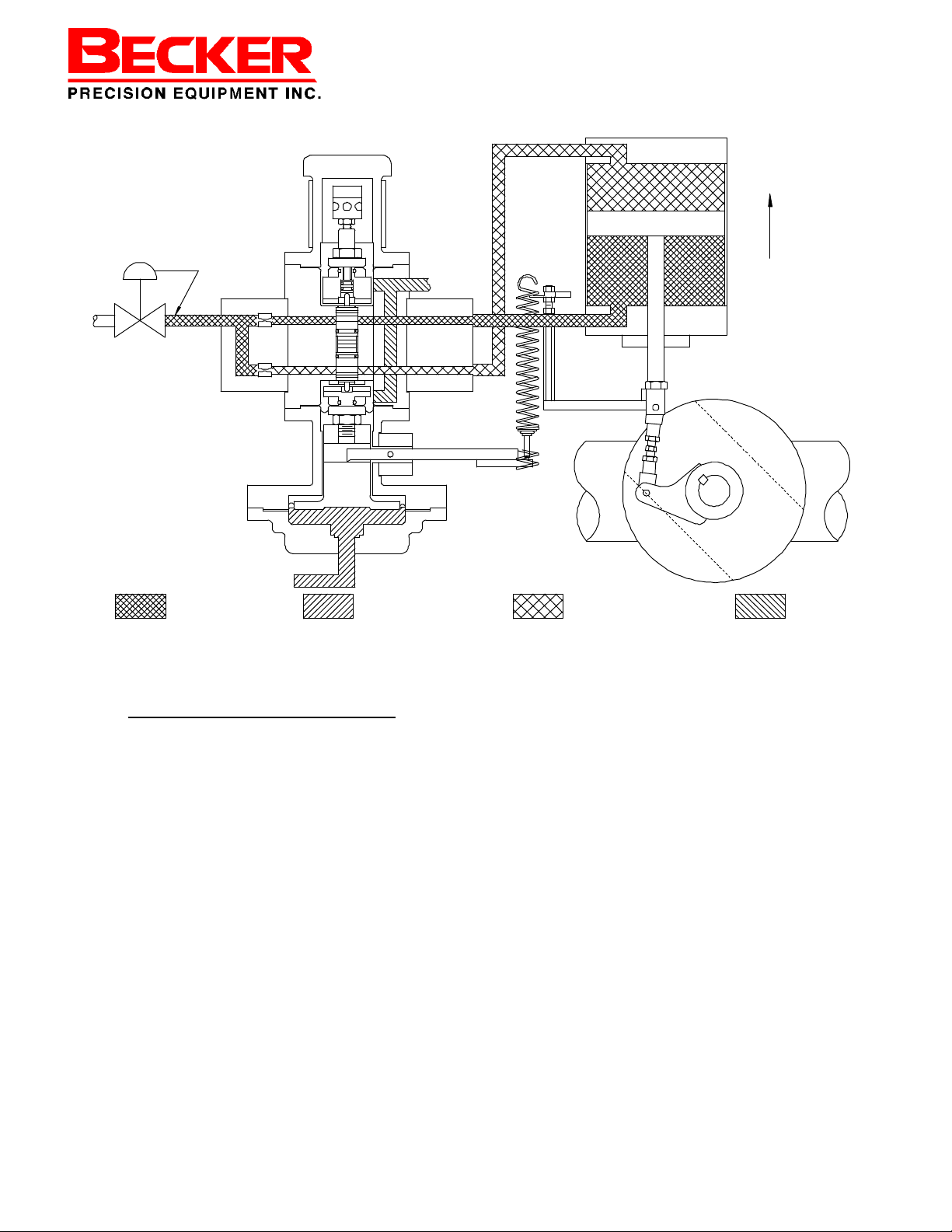

Principles of Operation

Close on Increasing Signal

The positioner is a force-balanced instrument that provides a control valve position proportional to the pneumatic input signal. The control valve will open on loss

of input signal. The energy to operate the control valve is obtained from the differential between the supply and discharge pressures. In steady state, the forces imposed on the balance beam by the input signal diaphragm and the range spring are

equal; therefore, the top and bottom balance valves in the positioner are at or near

their closed positions. The cylinder top and bottom pressures are both equal to

power gas pressure, and the control valve is stationary. An increase in the input

signal pressure results in the opening of the lower balanced valve due to an imbalance in the beam forces. This decreases the pressure in the cylinder top., while

the pressure in cylinder bottom remains at power gas. The control valve begins to

close. The actuator rod stretches the range spring, increasing its tension. This

force, which opposes the force on the balanced beam caused by the increasing input signal, continues to increase until the balance beam forces are in equilibrium.

At this point the valve is in the correct position for the applied input signal. The positioner has a sensitivity adjustment which permits a balance between greater accuracy (from a smaller deadband) and minimal bleed gas.

HPP-5 5 September 1999

Page 6

HPP-5 Positioner

“How-It-Works”

Power

Gas

InstrumentSignal

Cylinder

Top

Exhaust

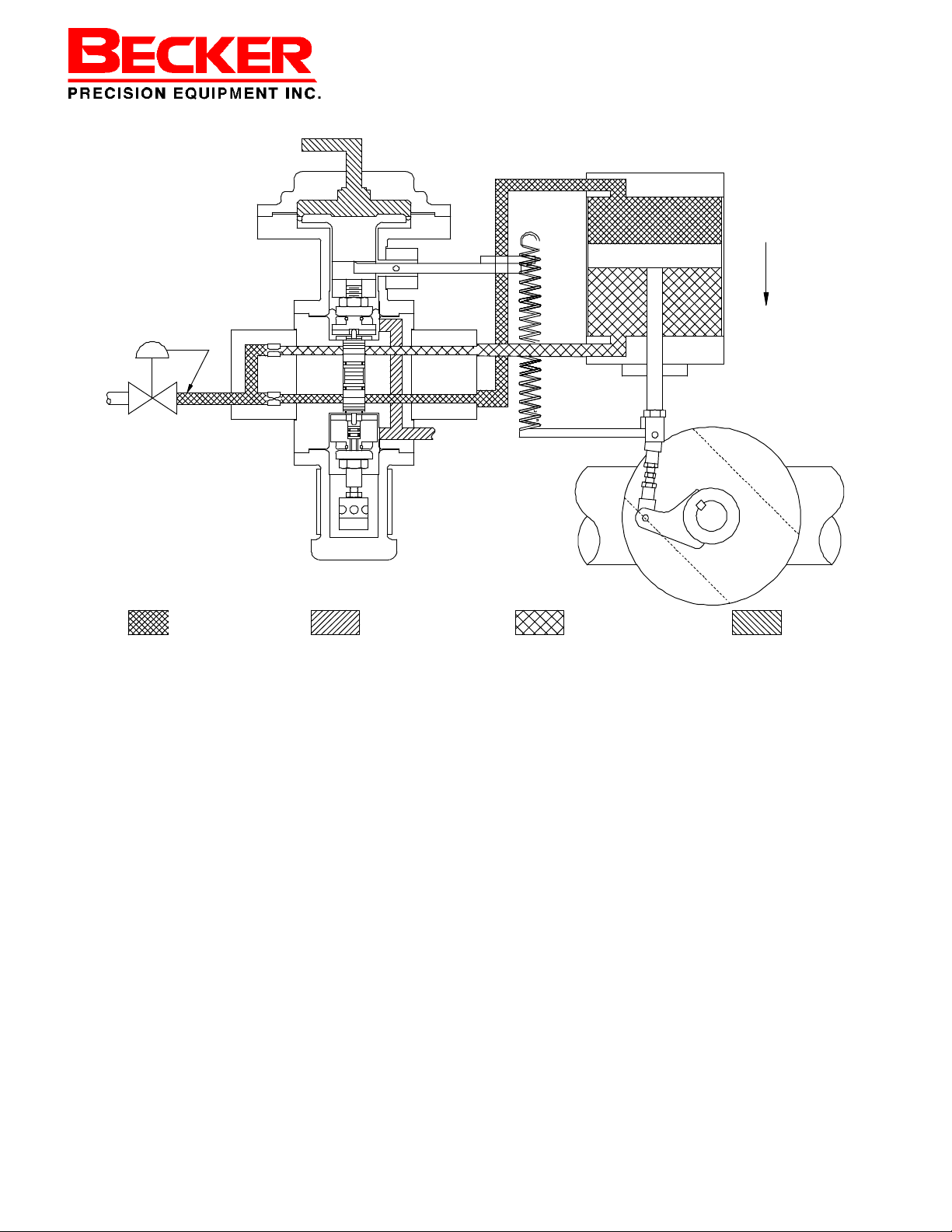

Open on increasing Signal

The positioner is a force-balanced instrument that provides a control valve position proportional to the pneumatic input signal. The control valve will close on loss of

input signal. The energy to operate the control valve is obtained from the differential

between the supply and discharge pressures. In steady state, the forces imposed

on the balance beam by the input signal diaphragm and the range spring are equal;

therefore, the top and bottom balance valves of the positioner are at or near their

closed positions. The cylinder top and bottom pressures are both equal to power

gas, and the control valve is stationary. An increase in the input signal pressure results in the the opening of the upper balance valve due to an imbalance in the beam

forces. This decreases the pressure in the cylinder bottom, while the pressure in

the cylinder top remains at power gas pressure. The control valve begins to open.

The actuator rod stretches the range spring, increasing its tension. This force, which

opposes the force on the balanced beam caused by the increasing input signal, continues to increase until the balance beam forces are in equilibrium. At this point the

valve is in the correct position for the applied input signal. The positioner has a sensitivity adjustment which permits a balance between greater accuracy (from a

smaller deadband) and minimal bleed gas.

HPP-5 6 September 1999

Page 7

HPP-5 Positioner

Adjustment Procedures

Your HPP-5 positioner will come factory

adjusted for your particular application.

The use of the adjustment procedures

will be necessary upon installation of a

rubber goods replacement kit or any

other disassembly or reassembly of

the positioner.

Adjustment Procedure

The sensitivity adjustment drum on one

end of the positioner determines the

sensitivity of the unit.

The variable orifices determine the

stroking speed of the positioner.

Initial Adjustment

1. Adjust the supply regulator:

Adjust the supply regulator to the desired Power Gas pressure. Refer to the

original invoice paperwork supplied

with the product for the appropriate

Power Gas pressure setting. It is imperative that adequate supply gas pressure be supplied to the VRP-CH in order to ensure proper operation of the

system and all accessories.

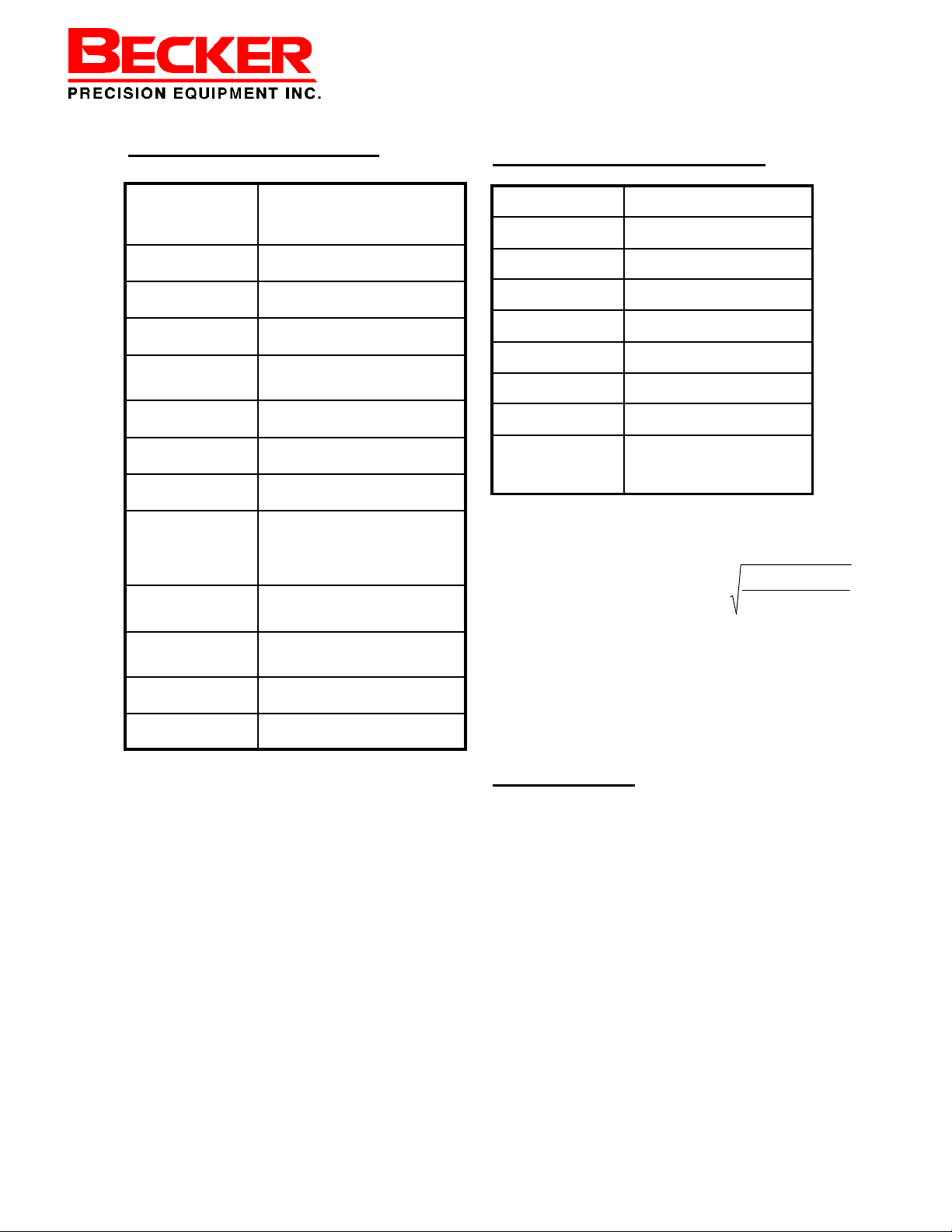

Table A – Exhaust vented to Atmosphere

SUPPLY

PRESSURE

(psig)

4 5 6 8 10 12 14

VARIABLE ORIFICE NUMBER

2. Adjust the adjustable orifices:

The adjustable orifices are utilized to

control the volume of gas that is supplied to the HPP-5.

The stroking speed of the system is

proportional to the numerical value of

the adjustable orifice. Adjustable orifice settings are typically equal for both

orifices. However, a few applications

may require unequal settings for each

adjustable orifice. Refer to Fine Tuning

for more information on utilizing unequal adjustable orifice settings. Set

both orifices according to the table below.

Notes:

• To determine the cylinder bore, look

at the model number stamped on

the stainless steel tag on the top of

the cylinder. The cylinder bore will

be the first number following the first

capital letter “H”. This one or two

digit number following the first “H”

will be the diameter in inches and

will be followed by another letter

(For example, a unit with the model

number 6H8F6FG-H4 has an

CYLINDER BORE (IN.)

Up to 50 3 3 3 4 4 5 6

51-200 2 2 3 3 4 5 5

201-600 2 2 2 3 3 4 5

Table B – Exhaust vented to Pressure System

SUPPLY

PRESSURE

(psig)

Up to 50 3 3 3 4 4 5 6

51-200 4 4 4 5 5 6 6

201-600 2 2 2 3 3 4 5

HPP-5 7 September 1999

4 5 6 8 10 12 14

CYLINDER BORE (IN.)

VARIABLE ORIFICE NUMBER

Page 8

HPP-5 Positioner

Adjustment Procedures

Deadband Setting

1. Turn the deadband adjustment drum

in the direction of increasing the

numbers until the drum can no

longer turn. Then turn the adjust-

ment drum one full turn in the oppo-

site direction (use the numbers on

the drum as a guide).

2. If not already attached, wind 3-4

coils of the range spring onto the re-

tainer.

3. If not already adjusted, set the bias

adjustment screw in the middle of

its travel range.

4. Apply power gas to the HPP-5 posi-

tioner

5. Set the instrument signal pressure

at the midpoint of its range (e.g.. 9

psig for a 3-15 psig range, 18 psig

for a 6-30 psig range). Allow the ac-

tuator to stroke the valve to an inter-

mediate position and the gauge

pressures to balance. (if the valve

does not stroke, insure that the po-

sitioner is communicating with the

actuator cylinder. If equipped with

an MCV-3, make sure the MCV-3

left handle is in automatic.

6. If the actuator is equipped with an

MCV-3 Manual Control Valve), place

the left MCV-3 handle in the manual

position. If the actuator is not

equipped with an MCV-3, use the

block valve (1/4 “ ball valve) installed

between the positioner output and

the actuator. Once the actuator has

reached its desired position (based

on the mid-signal applied to the instrument port – Step 5), place the

block valve in the closed position.

7. Final Sensitivity Drum Adjustment

For positioner’s bleeding to atmosphere:

Disconnect any bug vent or tube fitting

from the exhaust port.

Turn the deadband adjustment drum in

the direction of decreasing numbers,

until the exhaust port begins to bleed

gas. Than turn the drum in the opposite direction until the exhaust port just

stops bleeding.

The unit is properly adjusted if increasing or decreasing the input signa by .2

psig causes the cylinder top and bottom gauges to develop differential

equal to at least 20% of power gas.

Replace the exhaust fitting

For Positioner’s bleeding to a pressure system:

Slowly decrease the setting of the

deadband (decreasing numbers) until

both cylinder gauges are equal and

read 90 to 95% of power gas pressure.

Signal Line from Control-

HPP-5 8 September 1999

Page 9

HPP-5 Positioner

Bias Adjustment

Note: When increasing or decreasing

the instrument signal, the output pressure should swing up and down. When

changing direction of the false instrument signal, the output pressure should

immediately reverse direction. Any

“bump” or initial reaction of the gauge in

the wrong direction indicates friction

(requiring the unit be rebuilt to eliminate

the friction).

8. Place the instrument signal to automatic and open the block valves or

return the left handle of the MCV to

automatic.

Span Adjustment

Spring Lock

Balanced Beam

Proportional Topworks

Bias Adjustment

Bias Lock Nuts (Qty. 2)

Spring Retainer

Bias Adjustment

For Standard (Non-split range) Systems:

1. To increase the bias setting, increase tension on the range spring.

This is accomplished by either raising the spring retainer or screwing

the bias adjustment stud into the indicator bar or tail rod. Note the two

jam nuts tightened against one another to adjust the length of the

stud. When properly adjusted,

tighten the bias lock nut(s).

2. In order to decrease the bias setting, decrease tension on the range

spring by either lowering the spring

retainer or screwing the bias adjustment stud out of the indicator bar or

tail rod. Note the two jam nuts tightened against one another to adjust

the length of the stud. When properly adjusted, tighten the bias lock

nut(s).

For Split Range Systems (see Table 1 )

3. Find the bias adjustment screw (1/220 thread with 3/8 flats) on the end

of the positioner opposite the pneumatic signal input port. Loosen the

jam nut located on the adjustment

screw.

4. To increase the bias setting, tighten

the adjustment screw.

5. To decrease the bias setting, loosen

the adjustment screw.

6. Holding the adjustment screw in

place, tighten the jam nut against

the positioner body.

HPP-5 9 September 1999

Page 10

HPP-5 Positioner

Range Adjustment

Spring Range

Green (20-2592) 1-6

Silver (25-1038) 2-11

Blue (25-1036) 4-20

Red (25-1037) 8-30

Table 1: Adjustable Bias Springs

Spring Range

Stroke (Part Number)

(psi)

4 6 8 12

6

12

18

24

01-6288 01-6287 01-6287 01-6801

25-1151 25-1152 25-1153 25-1154

25-1599 25-1600 25-1601 25-1602

25-1218 25-1219 25-1220 25-1221

Table 2: Range Spring Configurations

Note: For intermediate ranges, use the next

size range spring.

Range Adjustment

Note: There will be some interaction between

range and bias adjustments. It may therefore

be necessary to readjust the bias and re-check

the range after completing the following steps.

The range, or the amount of travel between the lower and upper limits of the

input signal, is set with the range

spring. This range will typically be 12

psi for a 3-15 psi system or 24 psi for a

6-30 psi system. The limits of the range

can be defined as the initial point at

which the instrument signal

to the HPP-5 starts valve

movement until the end of

the valve stroke and full

pressure differential across

the cylinder output gauges.

1. After setting the bias for

the start of the valve travel,

continue increasing the in-

strument signal until the

valve strokes is completed AND the

cylinder output gauges show full

power gas pressure differential.

2. Be sure not to overshoot at this

point as any signal level above this

upper limit will show the same reading on the cylinder gauges. This

point is the highest end of the range

and the value may not necessarily

be equal to the desired upper range

value.

HPP-5 10 September 1999

Page 11

3. If the range is less than desired (i.e.

the actuator reaches its full travel in

less than the specified input range),

strengthen the range spring by

winding it counterclockwise onto

the spring retainer. If the range is

greater than desired, weaken the

range spring by winding it clockwise. Repeat adjustments until the

desired range provides full or zero

output pressure.

4. If the desired range is not achieved

after making the above adjustments, readjust the bias (per the

previous instructions) to allow

proper range adjustment.

5. It may be necessary to change the

range spring retainer for some nonstandard ranges (refer to Table 3).

HPP-5 Positioner

Range Adjustment

Type Typical Use

Short (01-2509 ) 8” and 12” Stroke

Intermediate (11-2572 ) 6” Stroke

Long ( 01-2042 ) 4” Stroke

Table 3: Range Spring Retainer

HPP-5 11 September 1999

Page 12

HPP-5 Positioner

Positioner Action

Changing Action of Positioner

To change the positioner from open on increasing signal to close on increasing signal, or vice versa, the following parts kits

must be ordered:

To change open on increasing to close on

increasing: Part #25-1444 plus an Exten-

sion Rod (item #13 in drawing 35-0516,

see Table 4). The serial number of the actuator must be specified. The exact part

number of the extension rod will vary

based on the actuator stroke.

To change close on increasing to open on

increasing: Part #25-1289. Note: If con-

verting a close on increasing signal positioner to open on increasing signal, the

wide end of the tube (item #9) may be

shortened by 11/16" with a hack saw in

place of ordering part #25-1289.

The stroke length of the actuator cylinder

MUST be specified when ordering the

above part numbers. If the actuator serial

number cannot be found, the stroke length

can be found in the regulator model number. The stroke length is the first letter after the "H" in the model number. For example model 10H12L6FG-SR-S-HSB40/35-100-O has a stroke length of "L", or

12 inches ["L" is the 12th letter in the alphabet]).

Refer to the drawings 35-0515 and 350516 in the Appendix for the following:

1. Disconnect all supply lines, instrument

line, and output line from the positioner.

2. Remove the range spring (item #4) at

both ends and those items connecting

it to the rod (item #23) and the posi-

3. Remove the positioner from the

bracket (item #18). The tubing and

fittings on each side of the positioner

must be taken off and installed in the

opposite corner from their original position (see piping schematic provided

by Becker Precision Equipment) then

reattached to the positioner. This will

allow the positioner to maintain the

actuator failure mode when the positioner is turned upside down.

4. Move the bracket assembly (item

#18), tube assembly (items #16 and

#17), and cover plate (item #11) to

the positions shown on the desired

drawing.

5. Install the positioner in the opposite

of its original position (upside down if

it was right side up, right side up if it

was upside down).

6. Using parts from the factory kit, as-

semble the spring and surrounding

hardware according to the drawing of

the desired configuration. (Note: all

original parts may not be used when

converting from close on increasing

to open on increasing).

7. The entire bracket assembly (item

#18) or the outer angle may need to

be turned upside down to accommodate the new spring height.

8. Reconnect the supply, instrument,

and output lines according to piping

schematic supplied.

Note: The flow direction must be maintained through the positioner bodies

when re-piping. (I.e. the flow [supply or

exhaust] moves from P1 to P2 and P3 to

HPP-5 12 September 1999

Page 13

Stroke With Without

4

6

8

25-8265 25-8001

25-8136 25-1093

25-1402 25-1423

Table 4: Extension Rods for Positioners to

Close on Increasing Signal

Conversion to Split Range

Converting a standard positioner to a

split range positioner (pneumatic input

other than 3-15 psi or 6-30 psi), requires

ordering the proper conversion kit from

the factory. This kit will include a bias

spring and bias spring cartridge. If required, it will also contain a new range

spring and mounting spacers.

1. For close on increasing positioner:

Remove the cap on the top of the positioner along with the spring inside

it.

For open on increasing positioner:

Remove the mounting bracket holding the cap on the bottom of the positioner. Then remove this cap along

with the spring inside it.

2. Replace the cap and spring with the

larger bias spring cartridge and bias

spring found in the kit. Make sure

the bias adjustment screw in the

bias spring cartridge is snug against

the bias spring and the spring is cen-

tered before tightening the spring

cartridge.

3. For open on increasing positioner:

Remove the washer and jam nut from

the adjusting screw in the bias spring

HPP-5 Positioner

Split Range

3. (Cont.) Reattach the mounting

bracket upside down from its original

position.

4. Slide the thread spacer (brass

bushing) over the adjusting screw

and tighten the washer and jam nut

against the thread spacer.

5. If a range spring was sent with the

kit, remove the existing range spring

and replace it with the new one.

6. Adjust the unit per the Adjustment

Procedures.

Stroke Close on

Increasing

4” 25-6014 25-1464 Proportional:

6” 25-6014 25-1465 Proportional:

8” 25-6014 25-1466 Tailrod:

Table 5: Split Range Conversion Kits

Note: Refer to Table 1 and Table 2 for

Bias and Range Spring part numbers.

Open on

Increasing

Reference

Drawings

35-0513

35-0313/A

35-0511

35-0511/A

Tailrod

Mount:

35-0522

HPP-5 13 September 1999

Page 14

HPP-5 Positioner

Maintenance and Inspection

Maintenance and Inspection

As with all precision equipment, it is

necessary to periodically test the positioner to ensure optimum performance.

We recommend the following procedure once a year.

1. Shut off supply pressure and bleed

down at positioner. Note the settings of the variable orifices and remove them from the orifice assembly. Clean them thoroughly and reinstall using new o-rings, being sure

to install each orifice in the same

hole from which it was removed (the

orifice and block have matching

numbers for this purpose). Reset

orifices to original settings. Turn on

supply pressure.

2. Apply a midrange signal to the positioner. Allow the control valve to become stationary at about 50% of the

range. Close the cylinder block

valves or move the MCV-3 handle to

the manual position. The positioner

is now isolated from the cylinder.

Apply a ± ¼ PSIG signal change.

Observe the response in the output

gauges. The output pressure

should develop differential pressure

equal to 20% of the power gas pressure. If the output pressure does

not show immediate response, the

positioner may have too much deadband. Reduce the deadband by

turning the drum in the direction of

decreasing numbers. If the pressures do not respond in the correct

direction when reversing the instrument signal change, the unit has internal friction. Disassemble the unit

and replace all rubber goods.

3. Check the integrity of the balanced

3. (Cont.) Check the integrity of the

balanced valve seats by increasing

the dead band by 1 full number.

When the cylinder top and bottom

gages are equal to the power gas,

the exhaust port should not exhibit

any bleed gas. If either of these

tests fail, then the positioner is not

properly adjusted or the unit needs

to be reassembled with new rubber

goods.

4. Soap test around all diaphragm interfaces, orifice assemblies and

vents. If any leaks are found around

the diaphragms, refer to the assembly instructions for replacement of

all internal rubber parts.

5. Observe the operation of the

gauges. If any gauges are defective,

replace them.

6. Check range and bias. If necessary, readjust per Adjustment Procedures.

Should problems arise or more information is required, call toll free (800)

323-8844 for assistance

HPP-5 14 September 1999

Page 15

HPP-5 Positioner

Maintenance and Inspection

Model HPP-5 Single-Acting Positioner Annual Maintenance Checklist

1. __________ Soap test all diaphragm mating surfaces to check for leaks.

2. __________ Replace rubber goods utilizing Becker Model HPP-4 Single-Acting

Positioner Repair Kit (Part # 30-9501) if necessary.

Refer to Pages 12-17, HPP-SB Assembly Procedures.

3. __________ Confirm Power Gas Supply Pressure is correct.

Refer to original Becker invoice paperwork for proper power gas setting.

4. __________ Observe operation of gages and replace if defective.

5. __________ Check integrity of HPP-4 positioner seats. Varying input signal 1 psig

should send one cylinder output gauge to full power gas.

Refer to Procedure 7 note, pages 9, Adjustment Procedure.

6. __________ Check response of HPP-4 positioner. Varying input signal 1/4 psig

should produce cylinder output gauge differential equal to 40% of

power gas.

Refer to Procedure 6-8, pages 8-9, Adjustment Procedure.

7. __________ Check range and bias of HPP-4 positioner and adjust if necessary.

Refer to Pages 9-11 of adjustment procedure.

8. __________ Inspect and Verify Proper Operation of all HPP-4 Positioner Accesso-

ries.

Refer to technical manual included with each specific instrumentation ac-

cessory for further instruction.

Note: It is not necessary to replace any rubber goods in Becker

instrumentation or instrumentation accessories on a regular basis. However, common

practice suggests that replacement of rubber goods on a 5-year cycle basis provides

adequate preventative maintenance.

HPP-4 15 September 1999 HPP-5 15 September 1999

Page 16

HPP-5 Positioner

Parts List

Parts Ordering

The following is provided to allow the ordering of replacement parts. Please specify the Becker

instrument serial number when ordering parts (this can be found on the Stainless Steel tab attached to the pilot by the 7/16 hex head cap screws. If the instrument was supplied as a complete valve regulator package, the Stainless tag attached to the actuator piston can also provide

the serial number. See Drawing #30-0601

Key Description Part No.

1 Pilot base 30-7005

2 Lexan Cover 25-1034

3 Adjusting Drum 35-1520

4 Washer 25-1016

5 Inside piston 35-1507

6 Orifice Assembly 35-1015

7 Seat Cover 35-1519

8 1/2-20 Jam Nut 98-3056

9 Beam Adjusting Drum 25-1124

10 Diaphragm 25-1213

11

12

13 1/8 Roll Pin SS 98-2950

14 8-32 x 1” SHCS 98-3144

15 Beam Block 25-1086

16 Outside piston 25-1018

17 3/16 x 1/2 Roll Pin SS 98-3089

Key Description Part No.

29 Pilot Post S.S. 35-1521

30 Double pilot Body 35-1504

31 Valve Adjusting Screw 35-1517

32 Balance valve assembly 35-1510

33 Seat assembly 01-7082

34 S.S. Control tag 25-1061

35 10-32 x 3/8 FHMS 98-2684

36 #10 Lockwasher 98-3178

37 Strainer for Balance valve 35-1559

38 Seat Spacer 35-1526

39 Beam 25-1084

Seal Kit

A seal kit containing diaphragms, orings, and seats, for the HPP-5 positioner is available directly from Becker.

Simply contact Becker Precision Equipment and order part number 30-9501

18 1/4-20 x 2-1/2 HHCS 98-3180

19 Gauge Manifold 35-1013

20 O-Ring –012 95-2615

21 1/4-28 Jam Nut 98-3214

22 Diaphragm w/ Convolute 25-1027

23 Beam Spacer 30-7055

24 1/4-20 x 1” HHCS 98-2579

25 3-15 pressure cartridge 25-1082

26 5-40 x 1/4 SHCS 98-2629

27 1/4-20 x 3/4 SHCS 98-3137

28 8-32 x 1/2 SHCS 98-2614

HPP-5 15 September 1999

Page 17

HPP

-

5 Positioner

Parts List

HPP-5 17 September 1999

Page 18

HPP-5 Positioner

Appendix

HPP-5 18 September 1999

Page 19

HPP-5 Positioner

Appendix

HPP-5 19 September 1999

Loading...

Loading...