Page 1

HazardControl

HC520

en

Assembly and Operating Instructions

Escape route control unit for the second

emergency route

Important information for:

• Fitters / • Electricians / • Users

Please forward accordingly!

These instructions must be kept safe for future reference.

4007 630 030 0d25/09/2019

Becker-Antriebe GmbH

Friedrich-Ebert-Straße 2-4

35764 Sinn/Germany

www.becker-antriebe.com

Page 2

Table of contents

General ................................................................................................... 3

Warranty ................................................................................................. 3

Safety instructions ................................................................................... 4

Intended use ........................................................................................... 5

Device overview ....................................................................................... 6

Wiring ..................................................................................................... 7

Explanation of functions ........................................................................... 9

Setting and function of the DIP switches ...................................................10

Setting the limit positions without connecting to the control unit..................11

Maintenance ..........................................................................................12

Technical data ........................................................................................12

What to do if...?.......................................................................................13

Simplified EU declaration of conformity.....................................................14

Handover report for the customer ............................................................15

Handover report for the installing company ...............................................17

2-en

Page 3

General

The control unit, delivered ex works, controls a DC tubular drive automatically

or via external drive commands. The control unit offers the opportunity of

automatically raising the shading solution in the event of power failure, due to

a fire, for example.

Explanation of pictograms

CAUTION

ATTENTION

CAUTION indicates a hazardous situation

which, if not avoided, could result in injury.

ATTENTION indicates measures that must

be taken to avoid damage to property.

Denotes user tips and other useful information.

Warranty

Structural modifications and incorrect installation which are not in accordance

with these and our other instructions can result in serious injuries, e.g., crushing of limbs. Therefore, structural modifications may only be carried out with

our prior approval and strictly in accordance with our instructions, particularly

the information contained in these Assembly and Operating Instructions.

Any further processing of the products which does not comply with their intended use is not permitted.

The end product manufacturer and fitter have to ensure that all the relevant

current statutory, official and, in particular, EMC regulations are adhered to

during utilisation of our products, especially with regard to end product manufacture, installation and customer advice.

3-en

Page 4

Safety instructions

The following safety instructions and warnings are intended to avert hazards

and to prevent property damage and personal injury.

General information

• Always comply with the regulations of local energy supply companies as

well as the VDE 100 provisions for wet and damp rooms during installation.

• Only use in dry rooms.

• Observe the signal tone for the battery’s change interval

• Only use unmodified original parts from the control unit manufacturer.

• Observe all pertinent country-specific regulations.

• Keep people out of the system’s range of travel.

• If the system is controlled by one or more devices, the system’s range of

travel must always be visible during operation.

• Keep children away from control units.

Caution

• Risk of injury due to electric shock.

• The mains connection must be established by a trained

electrician.

• Disconnect the connecting cable from the power supply

prior to assembly.

• When connecting the control cables (protected extra-low

voltages), only use cables with sufficient electric

strength.

• Following commissioning, check that the system is work-

ing correctly in the event of power failure according to the

handover report.

4-en

Page 5

Intended use

The escape route control unit for the second emergency route described in

these instructions is intended for the supply and operation of an M19 model

DC tubular drive from Becker-Antriebe, which can be activated even in the

event of power failure.

Use of the control unit is only permissible for the second escape route and it

must only be used for roller shutters and venetian blind systems.

The use of a two-pole changeover switch as a safety switch is absolutely essential.

The connection of external devices must be carried out in consultation with

specialist retailers.

There are no clear legal requirements regarding the use of battery-buffered

control units in the second emergency route. The manufacturer cannot, therefore, grant generally valid or project-related product approvals for the aforementioned use. The final decision is taken by the respective fire safety authority.

Country-specific special regulations as well as local regulations and guidelines

concerning this matter must be observed and applied under all circumstances.

5-en

Page 6

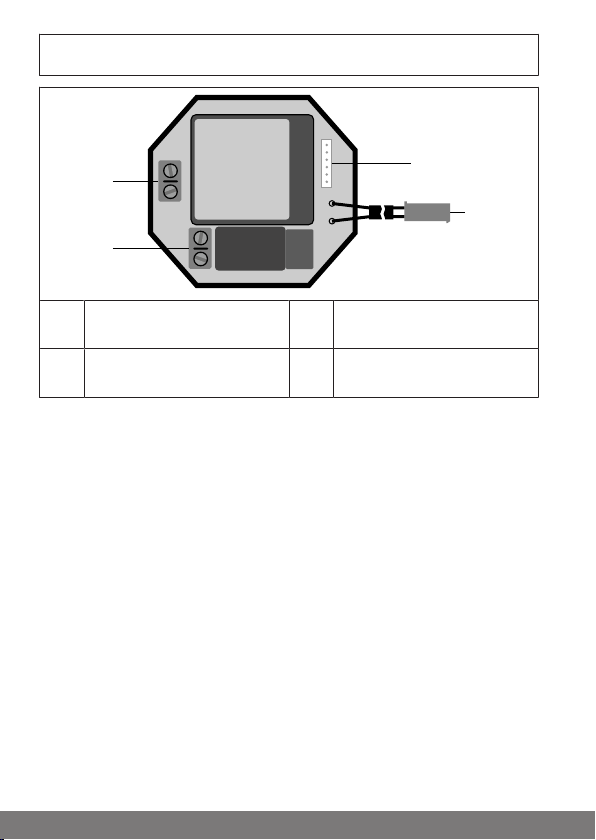

Device overview

1

2

3

4

Connection for individual and

1

central operation

Connection for the battery

2

and the safety switch

Connection for the safety

3

switch and drive

Mains connection

4

6-en

Page 7

Caution

L

N

+

-

M

M

+ -

M

Optional

Battery

Individual operation

(push-button)

Safety switch

Drive

12 V DC

Mains

100–240V AC

50/60Hz

HC520

purple

blue

orange

black

grey

red

Connection:

Control

Connection:

Battery

A B

DC

• Risk of injury due to electric shock.

• Connection may only be performed by a qualified electri-

cian!

• The device only offers back-of-hand protection, not

touch protection.

• Always take into account the device switching current.

Connect the device as follows:

Wiring

7-en

Page 8

After connecting, check that the running direction of the

M

M

+ -

Smoke detector

purple

blue

M

M

+ -

Higher-level control unit

purple

blue

orange

drive is correct. It is irrelevant whether the safety switch is

set "up" or "down". The lettering ("A, B, C, D") in the connection diagram is not shown on the switch and is only used for

reasons of clarity in the figure.

If the shading solution rotates in the incorrect direction, the safety switch connections will need to be swapped around as follows:

• Connections "A" and "B" with incorrect implementation of the function

selected with DIP switch 5 in the event of power failure.

• Connections "C" and "D" with forced opening of the shading solution

when the safety switch is actuated.

Optional possible connection points (central input)

Smoke detector

Higher-level control unit, radio, etc.

8-en

Page 9

Explanation of functions

Automatic opening movement in the event of power

failure

In the event of power failure, the drive automatically raises the shading solution with a battery buffer (can be set using DIP switches). This function is

switched on upon delivery.

Safety switch

If the control unit is no longer functional due to a fire, the escape route can still

be opened in spite of this. When pressed, the safety switch bridges the control

unit, connects the battery directly to the motor and starts the shading solution’s opening movement.

9-en

Page 10

Setting and function of the DIP

ON ON ON ON ON ON

1 2 3 4 5 6

ONOFF

switches

Factory setting: All the DIP switches are set to

OFF.

Switch Position Function

DIP 1

DIP 2

DIP 3

DIP 4

DIP 5

ON Individual operation preferred over central input

OFF Central input preferred over individual operation

ON No alarm message (signal tone)

OFF Alarm message (signal tone) after 1,000 travel cycles

or two years

ON Travel mode until battery discharged in the event of

low battery voltage

OFF Only opening movement possible in the event of low

battery voltage

ON Venetian blind operation (touch mode possible)

OFF Roller shutter operation

ON No action in the event of power failure

OFF The shading solution’s opening movement takes

place in the event of power failure

10-en

Page 11

Switch Position Function

ON No blockage detection

DIP 6

OFF Blockage detection in the DOWN direction with re-

versal

Setting the limit positions without

connecting to the control unit

If the limit positions are to be set before the controller is installed, proceed as

follows:

Connect the tubular drive to the Y plug.

Attention

The tubular drive moves off immediately after connecting to

the battery. Stopping is only possible by disconnecting the

battery.

Connect the battery to the Y plug.

Extend or reduce the range of travel by turning the corresponding set screw

on the tubular drive.

The direction of rotation of the tubular drive can be changed

by swapping the wires at "+" and "-".

11-en

Page 12

Maintenance

We advise replacing the battery and having the system maintained by a specialist company according to the information contained in the handover report

at regular intervals, at the latest every 1,000travel cycles or every two years.

On delivery, the escape route control unit is set using the DIP

switch2 so that an alarm message (signal tone) sounds when

the battery has to be replaced.

Technical data

Type HC520-2600mAh HC520-3000mAh

Rated voltage 100-240 V AC 50/60 Hz

Switching current 5 A / 12 VDC 6.3 A / 12 VDC

Power consumption 1.1VA

Degree of protection IP 20

Class of protection

(dependent on correct assembly)

Permissible ambient temperature 0 to +60 °C

Type of mounting Flush mounted

For rechargeable battery 2600mAh 3000mAh

For tubular drive up to 10Nm 20Nm

0

12-en

Page 13

What to do if...?

Problem Remedy

Drive is not functioning. Check connection.

Check position of safety switch.

Drive is running in the wrong direction.

The control unit does not carry out

the automatic opening movement.

A signal tone sounds. Have battery replaced by a qualified

Drive does not reach the lower limit

position.

Drive only runs in UP direction. Check position of safety switch.

The drive does not carry out the drive

command correctly.

Drive does not stop after detecting a

blockage.

Replace stranded wires for and .

Check DIP switch setting.

Check connection.

Check battery voltage.

electrician.

Check system for an obstacle or

sluggish running.

Check battery voltage.

Check whether a switch has been

used for individual operation instead

of the stipulated push-button.

13-en

Page 14

Simplified EU declaration of

conformity

Becker-Antriebe GmbH hereby declares that this control unit complies with

Directives 2014/30/EU and 2014/35/EU.

The full text of the EU declaration of conformity is available at the following

web address:

www.becker-antriebe.com/ce

Subject to technical changes without notice.

14-en

Page 15

Handover report for the customer

ON ON ON ON ON ON

1 2 3 4 5 6

ON

OFF

The installing company hereby confirms that the following work and functions

have been carried out and checked.

• Connection of the escape route control unit according to these instruc-

tions.

• Two-pole changeover switch installed as a safety switch.

• Drive’s running direction for individual operation and, if necessary, op-

tionally connected devices checked.

• Drive’s battery mode checked in the event of power failure.

• Correct execution of the function selected with DIP switch 5 checked in

the event of power failure.

• Shading solution’s forced opening movement checked when the safety

switch is pressed.

• The system was installed in a proper and functional manner. All the func-

tions, particularly the safety opening movement, were performed by the

customer.

• By way of their signature, the user confirms that the system is working

correctly and was handed over properly.

• DIP switch settings upon handover. Please indicate the position of the

DIP switches with a tick:

Date, name, address and signature: Specialist company

15-en

Page 16

16-en

Page 17

Handover report for the installing

ON ON ON ON ON ON

1 2 3 4 5 6

ON

OFF

company

The installing company hereby confirms that the following work and functions

have been carried out and checked.

• Connection of the escape route control unit according to these instruc-

tions.

• Two-pole changeover switch installed as a safety switch.

• Drive’s running direction for individual operation and, if necessary, op-

tionally connected devices checked.

• Drive’s battery mode checked in the event of power failure.

• Correct execution of the function selected with DIP switch 5 checked in

the event of power failure.

• Shading solution’s forced opening movement checked when the safety

switch is pressed.

• The system was installed in a proper and functional manner. All the func-

tions, particularly the safety opening movement, were performed by the

customer.

• By way of their signature, the user confirms that the system is working

correctly and was handed over properly.

• DIP switch settings upon handover. Please indicate the position of the

DIP switches with a tick:

Date, name, address and signature: Customer

17-en

Page 18

18

Page 19

19

Page 20

Loading...

Loading...