Specifications are subjec t to changes without prior notice.

Measured in specific conditions

Please kee p for further u se

Designed f or color print ing

Other use o f the device i s outside the permit ted purpose and can not be

guarantee d by the manufac turer.

The manufacturer cannot be held responsible for incorrect installations or

inappropriate adjustments of the sensor.

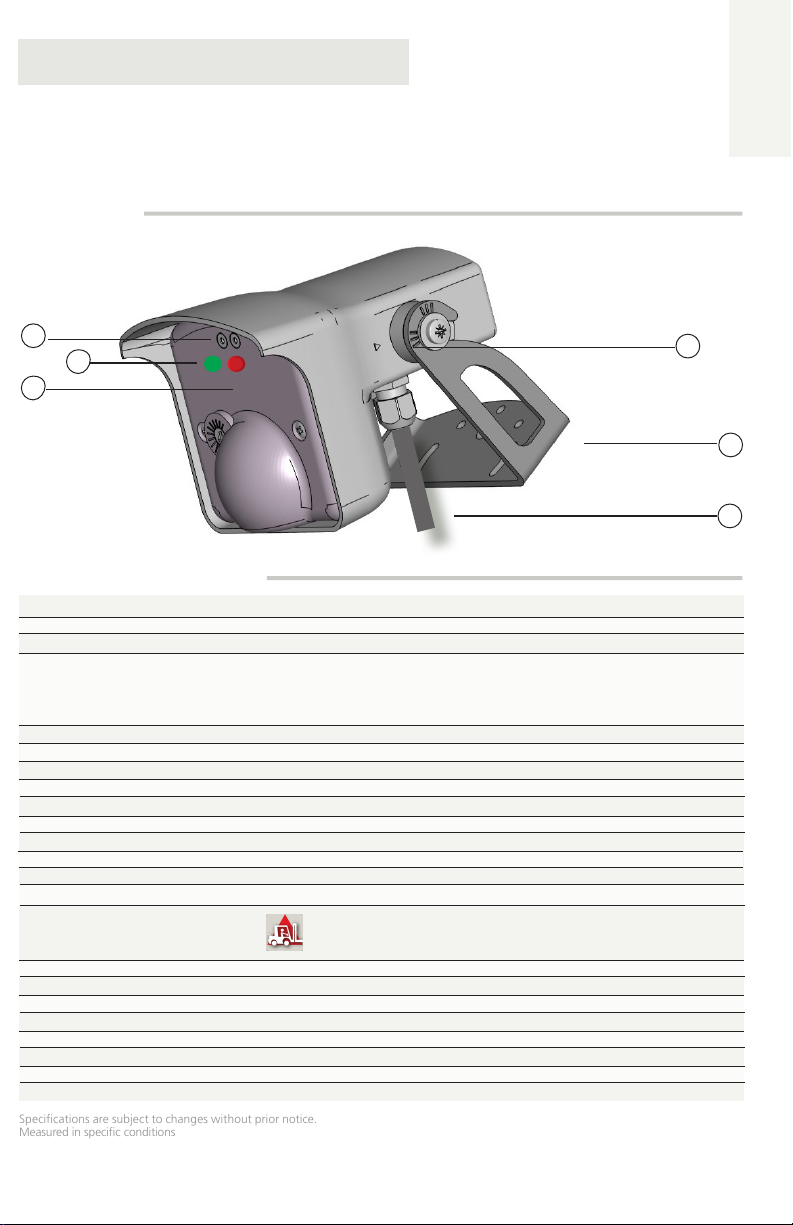

DESCRIPTION

1

2

3

TECHNICAL SPECIFICATIONS

Supply voltage:

Power consumption:

Mains frequency:

Output:

Max. contact voltage:

Max. contact current:

Max. switching power:

Output holdtime:

Mounting height:

Temperature range:

Humidity:

Degree of protection:

Dimensions:

Materials:

Weight:

Cable length:

Norm conformity:

12V to 24V AC ±10%; 12V to 24V DC +10% / -3%

< 3.5 W

50 to 60 Hz

2 relays (free of potential change-over contact)

42 V AC/DC

1 A (resistive)

30 W (DC) / 48 VA (AC)

0.5 s

8 ft - 16 ft

from -22 °F to + 140 °F

0 - 95% non condensing

IP65 / NEMA 4

5 in (L) x 4 in (H) x 3.8 in ( W)

ABS and polycarbonate

14 oz

32 ft / 105 m

Electromagnetic Compatibility (EMC) 2004/108/ EC, R&TTE: 1999/5/EC

IS40-P

ENGLISH

Presence sensor

for automatic industrial doors

1. push buttons

2. LED’s

3. infrared emitter

4. sensor angle indicator

5. bracket

6. cable

4

5

6

Technology:

Transmitter frequency/wavelength:

Transmitter power density:

Detection mode:

Detection field:

Min. detection speed:

Reaction time:

Tilt angle:

75.5696.07 IS4 0P 20170313 Page 1 of 8

active infrared (AIR)

875 nm

< 250 mW/m²

motion & presence

10 ft x 10 ft at max. mounting height of 16ft (emitting spots**)

0 in/s to activate detection

250 ms

15° - 45°

** zone detected by spotfinder, i.e. slightly larger than actual detection field

PRECAUTIONS

• This device IS NOT intended for use as a safety sensor.

• Not recommended for dynamic envioronments. (snow, rain, fog, etc.)

• Shut off all power before attempting any wiring procedures.

• Maintain a clean & safe environment.

• Constantly be aware of pedestrian/vehicle traffic around the area.

• Always stop pedestrian/vehicle traffic through the doorway when performing tests that may result in unexpected reactions

by the door.

• ESD electrostatic discharge: Circuit boards are vulnerable to damage by electrostatic discharge. Before handling any board

ensure you dissipate your body’s charge.

• Always check placement of all wiring before powering up to insure that moving parts will not catch any wires and cause

damage to equipment.

• Ensure compliance with all applicable safety standards upon completion of installation.

• DO NOT attempt any internal repair of the sensor. All repairs and/or component replacements must be performed by BEA Inc.

Unauthorized disassembly or repair:

1. May jeopardize personal safety and may expose one to the risk of electrical shock.

2. May adversely affect the safe and reliable performance of the product and will result in a voided product warranty.

LED- SIGNAL

Activation/Pulse detection

LED flashes quickly

Presence detection

Setup

LED flashes

Parameter indication for manual setup

LED flashes

Value indication for manual setup

DIMENSIONS ( inches )

Wall mounting

Ceiling mounting

Bracket dimensions

SAFETY INSTRUCTIONS

Only trained and

qualified personnel

may install and setup

After installation,

save an access code

to lock the sensor.

Test the sensor for proper

performance before

leaving the premises.

the sensor.

The installer of the door system is responsible for carrying out a risk assessment and installing the sensor and the

door system in compliance with applicable national and international regulations and standards on door safety.

The warranty is void if

unauthorized repairs

are made or attempted

by unauthorized

personnel.

MOUNTING TIPS

Do not cover the

sensor.

Avoid extreme

vibrations.

Avoid proximity to neon

lamps or moving objects.

Avoid exposing the

sensor to sudden

temperature changes.

Page 2 of 8 75.5696.07 IS40P 20170313

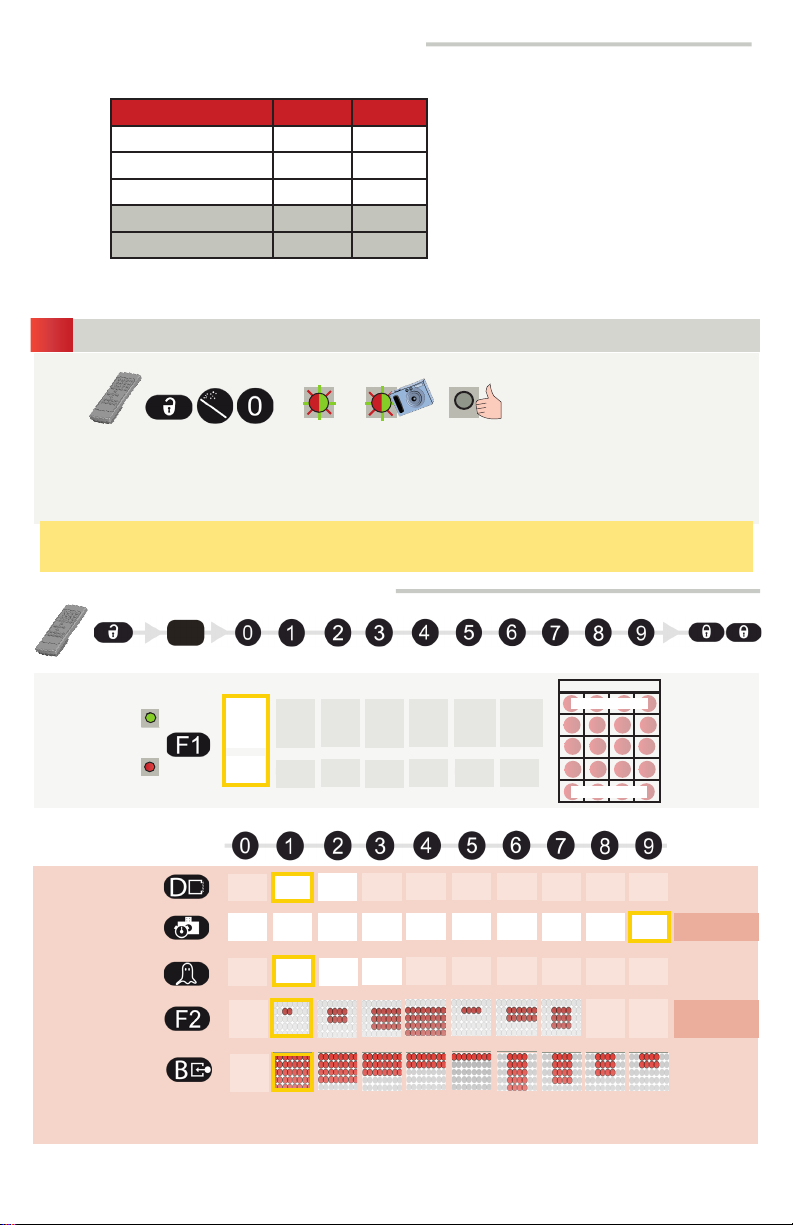

HOW TO USE THE REMOTE CONTROL

After unlocking, the red LED

flashes and the sensor can be

adjusted by remote control.

ADJUSTING ONE OR MORE PARAMETERS

CHECKING A VALUE

RESTORING TO FACTORY VALUES

SAVING AN ACCESS CODE

The access code is recommended for sensors installed close to each other.

If the red LED flashes quickly after unlocking, enter an

access code from 1 to 4 digits.

If you do not know the access code, cut and restore

the power supply and within the first minute, you

can access the sensor without introducing any access

code.

x

The number of flashes

indicates the value of the

chosen parameter.

DELET ING AN ACCESS CODE

If you do not know the access code, cut and restore the power supply and, within the first minute, you can access

the sensor without introducing any access code. Additionally, within this minute an unknown access code may be

deleted via the remote following the steps outlined below. Press unlock, lock, 0, 0, 0, 0.

DELET ING AN UNKNOWN ACCESS CODE

75.5696.07 IS4 0P 20170313 Page 3 of 8

4

8

12

16

20

ft

ft

6

3 0

3

6

DOOR

MOUNTING

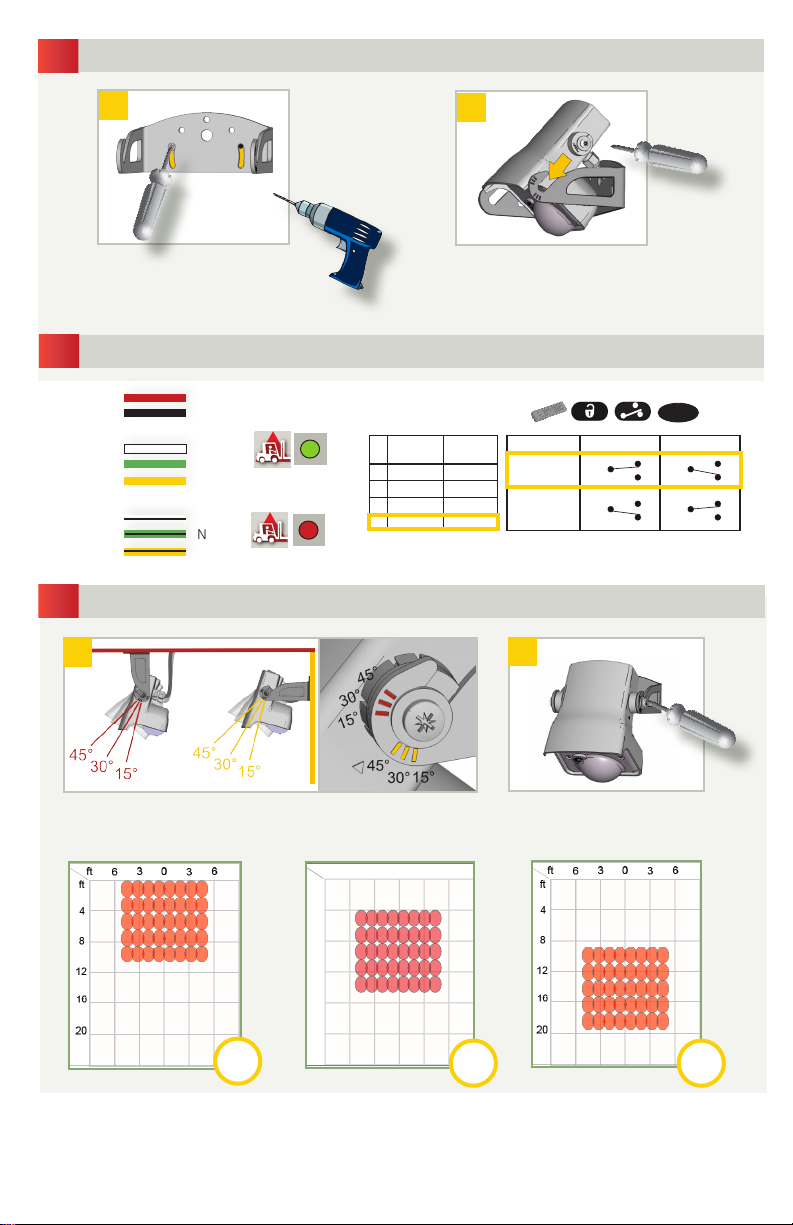

1

1

Remove the bracket from the sensor.

Drill 2 holes accordingly. Mount the

bracket firmly. If necessary, drill an

additional hole to facilitate wire routing

WIRING

2

RED

BLACK

WHITE

GREEN

YELLOW

WHITE/BLACK

GREEN/BLACK

YELLOW/BLACK

SENSOR ANGLE

3

12-24 V

AC-DC

COM

NO

NC

COM

NO

NC

1

POWER SUPPLY

AIR OUTPUT 1

Presence or pulse signal

AIR OUTPUT 2

Presence signal

CEILING

2

Position the sensor on the

bracket and tighten the screws.

RELAY CONFIGURATION

Motion

Presence

Relay

1 Active Passive

2 Passive Active

3 Passive Passive

4 Active Active

Relay

1-4

Description Detection No Detection

Active

Relay

Passive

Relay

NO

COM COM

NC

NO

COM COM

NC

2

NO

NC

NO

NC

WALL

Adjust the angle of the sensor to position the detection fields.

DOOR

• The graphics above are not to scale and for illustration purposes and represent an approximate AIR detection field when mounted at

• It’s important to adjust the sensor angle to position the AIR field correctly for your application. Utilizing a mounting bracket, sensor

Page 4 of 8 75.5696.07 IS40P 20170313

15°

16 ft.Infrared field = emitting spots detectable by using the Spotfinder. The actual detection field is slightly smaller and influenced by

external factors.

location and reveal will dictate the sensor angle for your application.

DOOR

Tighten the screws firmly.

DOOR

30° 45°

AIR PATTERN SIZE AT 15O SENSOR ANGLE

Approximate default AIR pattern size using a 15º sensor tilt angle. The higher the mounting height the larger the AIR

pattern.

Width *

5 ft

7 ft

7. 5 f t

8.5 ft

10 f t

15-20 s 3 s

Depth *

5 ft

7 ft

7. 5 f t

8.5 ft

10 f t

* Dimensions are approximate.

4

Mounting Height

11. 5 f t

16 ft

SETUP

8 ft

10 f t

13 f t

(max)

Launch a setup to make a reference picture.

Step out of the detection field and do not leave any tools inside the detection field.

Upon power-up, the sensor launches a short setup.

IMPORTANT: Perform a functional test for proper operation before leaving the site.

POSSIBLE REMOTE CONTROL SETTINGS

DOOR EXAMPLE

First Line

OUTPUT

REDIRECTION

RELAY 1

RELAY 2

motion

presence

signal

air entry

pulse

air exit

pulse

first or

last line

air entry

pulse

presencepresencepresence

presencepresencepresencepresence

first or

last line

air exit

pulse

presence

presence presence

presencepresence

presence

presence presence

Last Line

A

FREQUENCY

MAX. PRESENCE

DETECTION TIME

IR-CURTAIN

IMMUNITY

TARGET

SIZE

B

1 min 2 min30 s 10 min 20 min5 min 1 h 2 h1 h 30

low normal

high

*no

learn

* not

guaranteed

The position of the

target in the field is

random.

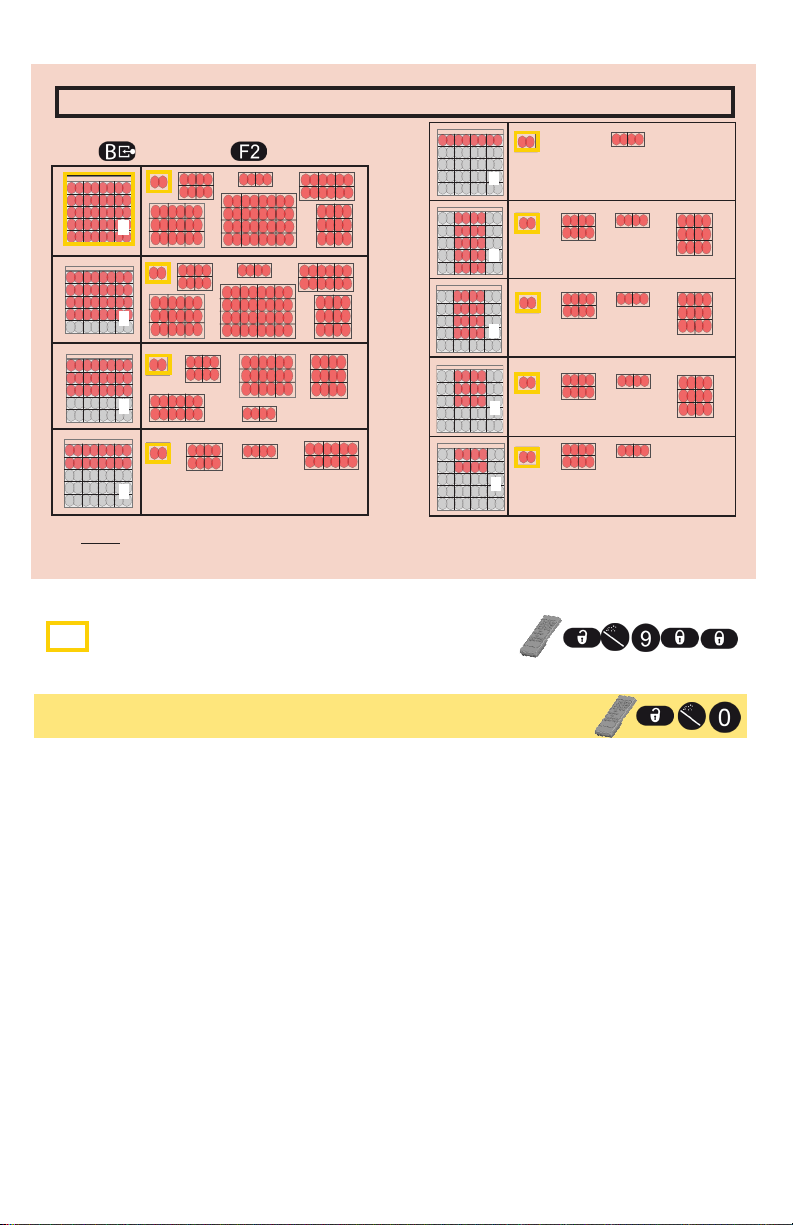

AIR-DETECTION

FIELD*

*AIR-DETECTION FIELD / TARGET SIZE CONTINUED ON NEXT PAGE

75.5696.07 IS4 0P 20170313 Page 5 of 8

DOOR

DOOR

DOOR

DOOR

2

3

7

5

6

2

5

6

1

1

2

3

4

7

5

6

1

2

3

4

7

5

6

1

DOOR

DOOR

DOOR

DOOR

DOOR

5

2

1

7

5

1

2

1

7

5

2

1

7

5

2

1

5

THE TARGET POSITION WITHIN THE "AIR" FIELD IS RANDOM

AIR PATTERN

SIZE

1

AVAILABLE TARGET SIZE

5

6

2

3

4

7

8

9

NOTE: TARGET SIZE MUST BE CAPABLE TO FIT INSIDE THE CHOSEN AIR PATTERN SIZE

FACTORY VALUES

IMPORTANT: Always finish an adjustment session by launching a setup

RESET TING TO FACTORY VALUES:

(see step 4)

and test the proper operation of the installation before leaving the premises.

Page 6 of 8 75.5696.07 IS40P 20170313

TROUBLESHOOTING

The door never closes

and the LED is ON.

The door remains

closed and the LED

is OFF.

The infrared sensor

does not react.

Object in the AIR detection

area.

The sensor power is off.

The infrared power emission

is too low according to the

mounting height.

Improper Target Size.

Move objects or reduce automatic learn time.

1

Wait for learn time to expire and/or Launch a

2

setup or cycle power

1

Check the wiring and the power supply.

1

Launch a new setup.

Step out of the detection field!

Ensure the target size is not to large

1

or larger than the pattern size.

The door opens

and closes

constantly.

Sporadic presence

detections for no

reason.

The red LED is

permanently ON

after a setup.

The setup lasts more

than 30 seconds.

The sensor does not

unlock and the red

LED flashes quickly.

The sensor does

not respond to the

remote control.

The sensor is disturbed

by the door motion or

vibrations caused by the

door motion.

The presence detection is

disturbed by rain or lamps.

The sensor is not installed

properly.

The sensor has failed the

AIR-setup.

The setup is disturbed.

Another sensor causes

interference.

The sensor needs an access

code to unlock.

The remote control

batteries are weak or

improperly installed.

The remote control is

poorly aimed.

The sensor is not powered.

Make sure the sensor is anchored properly.

1

Increase the sensor angle.

2

Reduce the AIR detection zone.

3

Set the AIR-curtain immunity to value 3.

1

Fasten the sensor firmly.

1

Launch a new setup and step out of the

1

detection field.

Make sure the detection field is clear and

1

launch a new setup.

Select a different frequency for each sensor.

1

Enter the right access code.

1

If you do not know the access code, refer to

2

page 3 and delete an unknown code.

Check the batteries and change them

1

if necessary.

Point the remote control towards the sensor.

1

Check the power supply of the sensor.

1

75.5696.07 IS4 0P 20170313 Page 7 of 8

©BEA | Original instructions | 75.5696

ACCESSORIES

10INDBRACKET

10BR3

10REMOTE

SINGLE LED

TRAFFIC LIGHT

10SPOTFINDER

DUAL LED

TRAFFFIC LIGHT

1024VAC

10MINIDBRACKET

COLUMN LIGHT

MODULAR

COLUMN LIGHT

Upon completion of the installation or service work, at a minimum, perform a safety inspection

for the type of Door/Gate per the manufacturer recommendations and/or per ANSI/DASMA guidelines

for best industry practices. Some examples but not limited to are ANSI/DASMA 102, ANSI/DASMA

107, UL 325. Make certain all appropriate industry warning labels are applied. It is the responsibility

of the installer/service personell to be familiar with national and local codes, standards, and regulatory

requirements. BEA Inc. recommends for installers and service personnel to be factory trained for the

type of door/gate system prior to performing installation or service.

BEA hereby declares that the MILAN is in conformity with the basic requirements and the

other relevant provisions of the directive 2004/108/EC.

Angleur, April 2011 Jean-Pierre Valkenberg, authorized representative

The complete declaration of conformity is available on our website: www.bea-industrial.be

Only for EC countries: According the European Guideline 2002/96/EC for Waste Electrical and Electronic Equipment (WEEE)

Tech Support: 1-800-407-4545 | Customer Service: 1-800-523-2462 | General Tech Questions: Tech_Services@beainc.com | Tech Docs: www.beasensors.com

Page 8 of 8 75.5696.07 IS40P 20170313

Loading...

Loading...