Page 1

USER MANUAL FOR BEAMEX MC6 WORKSTATION,

ADVANCED PANEL MOUNTED CALIBRATOR AND COMMUNICATOR

Applies to firmware version 3.10

Dear user,

We have made every effort to ensure the accuracy of the contents of this man-

ual. Should any errors be detected, we would greatly appreciate to receive suggestions to improve the quality of the contents of this manual.

For more detailed technical data about Beamex MC6 Workstation, please contact the manufacturer.

8860500 / MC6WSuEng / Version 3.1

© Beamex 2015 - 2018

BEAMEX OY AB

Ristisuonraitti 10

FIN-68600 Pietarsaari

FINLAND

Tel +358 - 10 – 5505000

Fax +358 - 10 – 5505404

E-mail: sales@beamex.com

service@beamex.com

Internet: https://www.beamex.com

Page 2

Page 3

MC6 Workstation, User Manual - Contents i

CONTENTS

Part 1, Introduction

General 2

About This Manual .................................................................. 2

Where Am I? .................................................................... 2

Typographical Conventions ............................................. 3

Unpacking and Inspection ...................................................... 3

About MC6 Workstation 4

Starting MC6 Workstation ....................................................... 4

Firmware ................................................................................ 5

Hardware ................................................................................ 7

General ............................................................................ 7

Pressure Modules ............................................................ 8

Front Panel Connection Details ....................................... 9

Connectors at the Back of MC6 Workstation .................... 9

Memory ......................................................................... 10

Display ........................................................................... 10

Batteries ........................................................................ 11

PC Communication / Calibration Software ............................ 12

USB Communication Driver ........................................... 12

MC6 Workstation Related Tools Available for PC .......... 12

Options 13

Software Options .................................................................. 13

Hardware Modules/Options and Accessories ....................... 14

Related Products .................................................................. 14

Part 2, Active Terminals and Connections

General 16

Measurements 17

Pressure Measurement ........................................................ 17

Connecting and Disconnecting External Pressure

Modules ........................................................................ 17

Zeroing a Pressure Module ........................................... 17

Current Measurement .......................................................... 18

Voltage Measurement .......................................................... 18

Temperature Measurement (Thermocouple) ........................ 19

Temperature Measurement (RTD) ....................................... 19

Resistance Measurement .................................................... 20

Frequency Measurement ..................................................... 20

Pulse Counting..................................................................... 21

Switch Sensing .................................................................... 21

Generations/Simulations 22

Changing the Generated/Simulated Value ........................... 22

Using the Soft Numeric Keypad .................................... 22

Spinning ........................................................................ 23

Current Generation (Source or Sink) .................................... 24

Voltage Generation .............................................................. 24

Thermocouple Simulation .................................................... 25

RTD Sensor Simulation ........................................................ 25

Resistance Simulation .......................................................... 26

Frequency Generation ......................................................... 26

Pulse Generation ................................................................. 27

Thermocouple Connections 28

Part 3, Meter

About Meter 30

Page 4

ii MC6 Workstation, User Manual - Contents

Part 4, Calibrator

About Calibrator 32

Tools 33

General ................................................................................ 33

Part 5, Documenting Calibrator

General 36

Calibration Software ............................................................. 36

Calibrating Instruments 37

Generating/Simulating the Input Value .......................... 37

Instrument List ..................................................................... 38

Instruments ................................................................... 38

Plant Structure Levels ................................................... 39

Instrument List Window Menu ....................................... 39

Instrument Overview Window ............................................... 40

Calibrating an Instrument Using MC6 Workstation ............... 40

Changing the Pressure Module During Calibration ........ 42

About Fieldbus and HART Device Specifics .................. 43

Group Calibration 44

Collecting Instruments/Functions for Group Calibration ........ 44

Editing a Group ............................................................. 45

Calibrating a Group .............................................................. 45

Group Settings .............................................................. 46

Performing the Calibration ............................................. 46

Calibration Results 47

Deleting Calibration Results ................................................. 47

Digital Communication and MC6 Workstation 48

Getting and Editing Mapped Data ........................................ 48

Preparations .................................................................. 48

Getting Default Mappings .............................................. 49

Customizing the Mappings ............................................ 49

Part 6, Data Logger

General 52

Doing a Data Log 53

Configuring ........................................................................... 53

Saving and Opening Configurations .............................. 53

Starting the Data Log ............................................................ 54

Viewing and Saving or Deleting the Results ......................... 55

Viewing Saved Data Log Results .......................................... 55

Transferring Data Log Results to a Personal

Computer ............................................................................. 56

Part 7, Communicator

General 58

Warnings .............................................................................. 59

Connections 60

Selecting the Instrument 61

List of Found Devices ........................................................... 61

About Instrument Parameters 62

Instrument Parameters in General ........................................ 62

Calibrating or Data Logging HART instruments .................... 63

Calibrating or Data Logging Fieldbus Instruments ................ 63

Editing Parameters ............................................................... 64

Trimming a Fieldbus instrument ............................................ 65

Trimming a HART instrument ............................................... 66

HART Device Description Specifics 67

General ................................................................................ 67

Basic View ..................................................................... 68

Page 5

MC6 Workstation, User Manual - Contents iii

Managing Smart Transmitter Configurations 69

General ................................................................................ 69

Tools in MC6 workstation ..................................................... 69

Saving Configurations .................................................... 69

Viewing/Managing Configurations .................................. 70

Beamex MC6 Workstation Fieldbus Configuration

Viewer .................................................................................. 70

Uploading Configurations............................................... 70

Linking Configurations to CMX....................................... 70

Part 8, Settings

Settings 72

Optional Security Tool 73

General ................................................................................ 73

Applied Restrictrions ...................................................... 73

Supervisor Window ........................................................ 74

Part 9, Additional Information

Additional Information 76

User Defined Pressure Units ................................................ 77

User Defined PRT / RTD Sensors ........................................ 78

General .......................................................................... 78

Callendar van Dusen Formula for PRTs ........................ 79

ITS-90 PRT Sensor ....................................................... 79

Factor ............................................................................ 81

Check Sensor Conversion ............................................. 81

User Defined Transfer Functions .......................................... 82

User Defined Steps / Calibration Points ................................ 83

Controller Communication .................................................... 84

What Can be Done With Controller

Communication .............................................................. 84

Configuring Controller Communication .......................... 85

Changing Controller During Calibration .......................... 85

Appendix

Safety 88

Approvals ............................................................................. 88

Symbols Used ...................................................................... 88

Safety Precautions and Warnings ........................................ 89

Operating Conditions .................................................... 89

General Warnings ......................................................... 89

Warnings Concerning the Lithium Polymer

Battery Pack .................................................................. 90

Warnings Concerning Electrical Measurement

and Generation ............................................................. 92

General Warnings Concerning Pressure

Measurement ................................................................ 92

Warnings Concerning High Pressure ............................ 93

Disposal of Waste Electrical and Electronic Equipment 94

Beamex and WEEE ............................................................. 94

Disposal of Battery Pack ............................................... 94

Service 95

Cleaning MC6 Workstation................................................... 95

The Battery Charger ............................................................ 95

Sending MC6 Workstation for Service .................................. 95

Firmware Update ................................................................. 96

Resetting MC6 Workstation.................................................. 96

Recalibrating MC6 Workstation ............................................ 97

Uninstalling/installing Modules to/from MCS200 ................... 97

MC6 Workstation's Battery Pack and Charger ..................... 98

Statements 99

Disclaimer ............................................................................ 99

CE ........................................................................................ 99

Intellectual Property Rights ................................................ 100

Copyright..................................................................... 100

Trademarks ................................................................. 100

Index 101

Page 6

iv MC6 Workstation, User Manual - Contents

Page 7

MC6 Workstation User Manual - Feedback v

FEEDBACK

We want to improve our products and services constantly. Therefore we’d like

to know Your opinion of the product You use. Please spend a moment of Your

valuable time in filling this form. All respondents will receive a surprise gift in

return.

Certain questions can be answered immediately after receiving the product.

Others require some use of the product before You are able to answer them.

The best way to fill the form is to answer the items as it applies, and send the

form to us when all items are answered. There are however no definite restrictions; fill in the form when you feel like it (all items need not be answered).

Then send it to Beamex using one of the possibilities listed to the right.

Mail: Beamex Oy Ab

Quality Feedback

Ristisuonraitti 10

FIN-68600 Pietarsaari

FINLAND

Fax: +358 - 10 - 5505404

Only the next page needs to be

faxed to us.

Internet: https://www.beamex.com

A similar form is available as a web page

E-mail: support@beamex.com

Refer to the numbered items on the next

page in Your e-mail message.

Page 8

vi MC6 Workstation User Manual - Feedback

1. Name of the product you give feedback of:

_____________

2. Serial number and software version number

_____________ / _____________ (if applicable)

3. Any comments when receiving the product. Did the package contain all required items and was it as expected?

____________________________________________

____________________________________________

____________________________________________

4. For how long have you been using the product?

_____________

5. How helpful was the manual in using the product?

(Tick a box in the percentage scale below)

6. How well did the product suit your needs?

7. How satisfied are you with the product?

8. Did anything in the product exceed your expectations? In that

case, what was it?

____________________________________________

____________________________________________

____________________________________________

9. Did anything in the product disappoint you? In that case, please

specify.

____________________________________________

____________________________________________

____________________________________________

10. Any ideas You want to propose to Beamex so that we can improve our products, operations and/or services.

____________________________________________

____________________________________________

____________________________________________

Title & Name: ______________________________________

Address: ______________________________________

_________________________________________________

_________________________________________________

Please contact me concerning the Feedback I have given.

I want to receive more information on Beamex products.

Page 9

Things discussed in this part:

About this manual

Briefly about MC6 Workstation's hardware and firm-

ware

Available software and hardware options

Part 1

INTRODUCTION

Page 10

2 MC6 Workstation, User Manual – Part 1, Introduction

GENERAL

Thank you for buying Beamex MC6 Workstation. Because of its versatile features, it really is "more than a calibrator".

MC6 Workstation is one device with five different operational modes: Meter,

Calibrator, Documenting Calibrator, Data Logger and Fieldbus Communicator.

Attention!

Before taking MC6 Workstation into use, please read the

warnings available in Appendix.

ABOUT THIS MANUAL

MC6 Workstation's User Manual is divided into several parts as follows:

Part 1, Introduction discusses general matters.

Part 2, Active Terminals and Connections. Whatever you measure,

generate or simulate, here's how to make the necessary connections.

Part 3, Meter introduces the metering tool, which is handy for making

quick measurements. One measurement at a time.

Part 4, Calibrator. A more versatile tool which allows you to meas-

ure/generate/simulate two things simultaneously etc.

Part 5, Documenting Calibrator concentrates on instrument calibration

using the full featured documenting calibrator.

Part 6, Data Logger. Collecting and reviewing

data and transferring logged data to a PC.

Part 7, Communicator. Invoking digital com-

munication with modern instruments.

Part 8, Settings. How to customize MC6

Workstation and what the About window contains.

Part 9, Additional Information. About ad-

vanced tools for, e.g. adding custom pressure

units, connecting external devices etc.

WHERE AM I?

The header of each spread in MC6 Workstation's User Manual informs you of

where you are: The even page shows the part you are in and the odd page

shows the main topic you are currently viewing.

Example of even page header:

2 MC6 Workstation User Manual – Part 1…

Example of odd page header:

General - About This Manual 3

Page 11

General - Unpacking and Inspection 3

TYPOGRAPHICAL CONVENTIONS

The following typographical conventions apply to MC6 Workstation's User Manual:

Bold text is used in following situations:

References to User Manual topics and parts,

MC6 Workstation keywords, i.e. terms shown in the User Interface and

other keywords, e.g. the names of fieldbus parameters.

Notes are shown in Narrow text with a border above and to the

left of the note text. Notes typically inform you of something

useful concerning the current topic.

Warnings are shown in Narrow and Bold. They also have a

shaded background and are surrounded by a border line.

Whenever you see a warning, read it carefully and take it

seriously. By not observing warnings, you may - at worst damage the calibrator and/or even risk your life.

UNPACKING AND INSPECTION

At the factory each new MC6 Workstation passes a careful inspection. It should

be free of scrapes and scratches and in proper operation order upon receipt.

The receiver should, however, inspect the unit for any damage that may have

occurred during transit. If there are signs of obvious mechanical damage, package contents are incomplete, or MC6 Workstation does not operate according

to specifications, contact the purchasing sales office as soon as possible.

If you have to return the instrument to the factory for any reason, use the original packing whenever possible. Include a detailed description of the reason for

the return. Read also chapter Sending MC6 Workstation for Service in Ap-

pendix.

For a description of available options, see Options on page 13.

Standard accessories:

Accredited calibration certificate,

this User Manual,

Warranty Card,

a CD-ROM with product information, USB

Driver, other MC6 Workstation related software tools etc.,

pre-installed internal rechargeable Lithium

Polymer (LiPo) batteries,

battery charger/eliminator,

test leads and clips,

If certain internal pressure modules have been

purchased, a pressure T-hose and

USB cable.

Page 12

4 MC6 Workstation, User Manual – Part 1, Introduction

ABOUT MC6 WORKSTATION

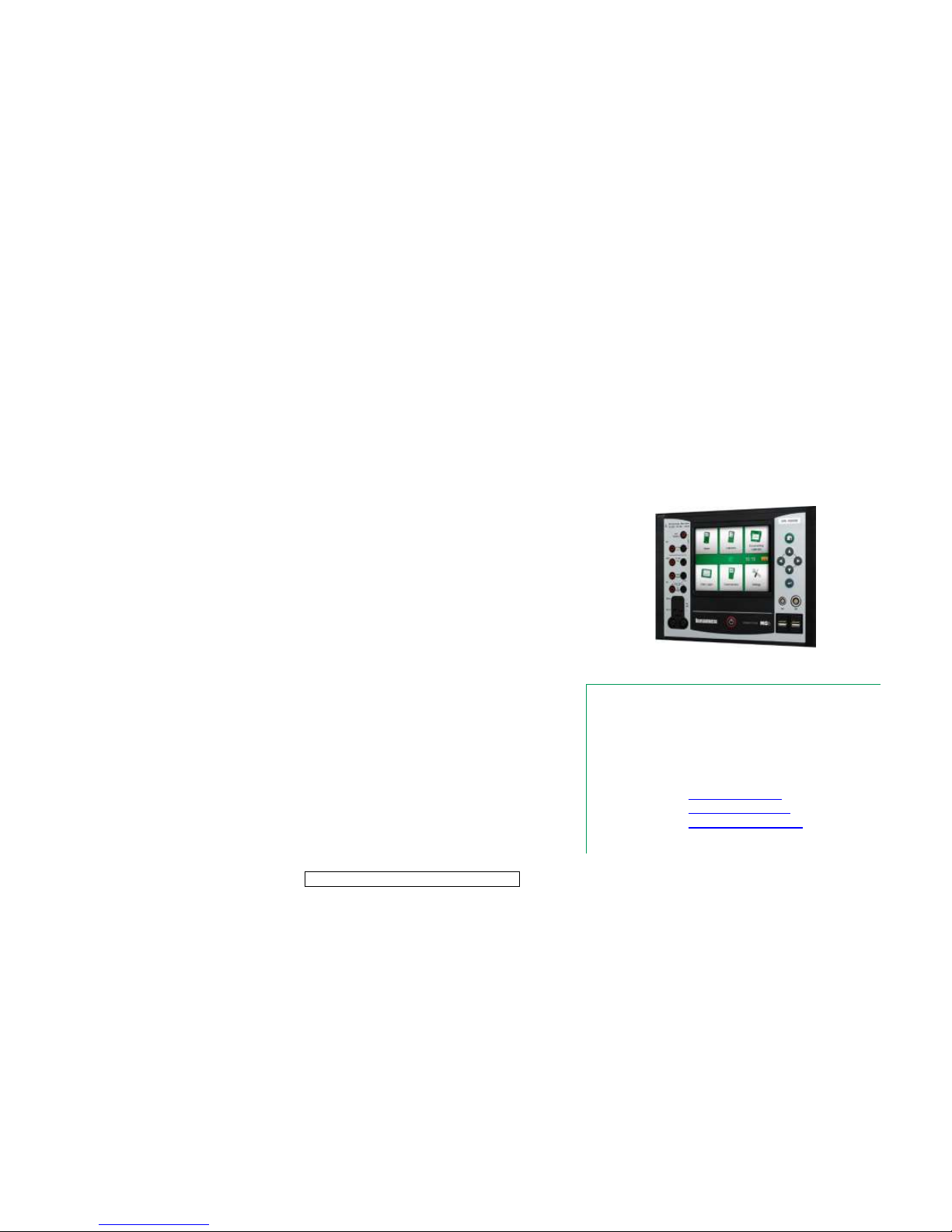

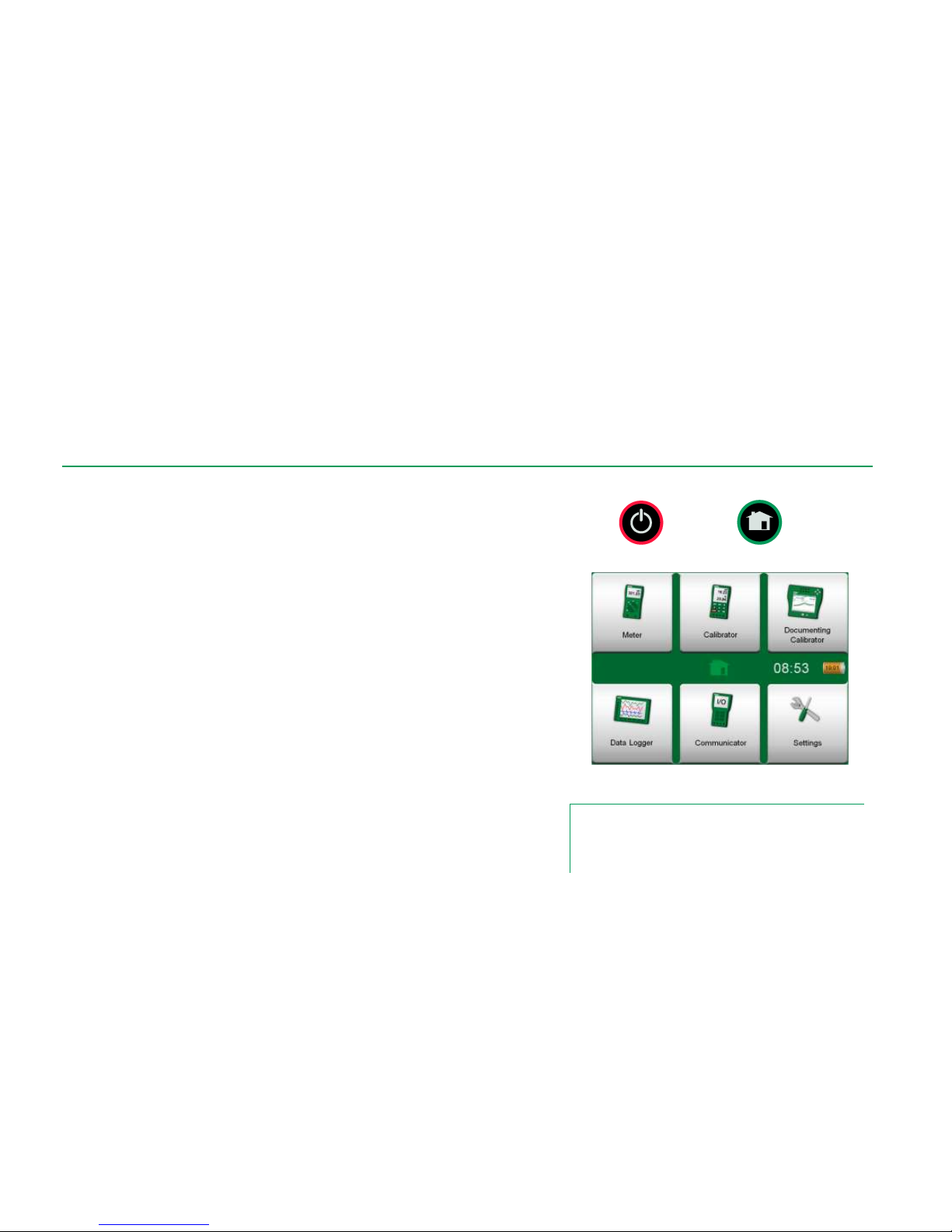

STARTING MC6 WORKSTATION

To start MC6 Workstation, switch the MCS200 Module Rack on and then press

MC6 Workstation's Power button for a few seconds. The startup procedure

ends in Home View (see picture on the right). From MC6 Workstation's Home

View you may advance to any of the available main functions. This manual contains detailed information of main functions as follows:

Meter in Part 3,

Calibrator in Part 4,

Documenting Calibrator in Part 5,

Data Logger in Part 6,

Communicator in Part 7 and

Settings in Part 8.

With the Home button (see picture on the right) you can always return to Home

View from wherever you are.

When MC6 Workstation is already running, pressing the Power button briefly

opens a dialog with the following options:

Power Off to shut down MC6 in Backup Mode, i.e. minimum power

consumption and full startup procedure.

Standby to set MC6 Workstation in Standby Mode allowing faster

startup when the Power button is pressed again.

Backlight Off to temporarily set the backlight off.

The button on the right side of the dialog:

Power Management to define Backlight Brightness and other power

management related settings. More in Part 8, Settings.

Power button (left) and Home button (right).

Home View

Note.

Certain main functions are options. They may not be available

in your MC6 Workstation. More of this in chapter Options on

page 13.

Page 13

About MC6 Workstation - Firmware 5

FIRMWARE

You can interact with MC6 Workstation by tapping on available buttons/controls

displayed on the touch screen. Optionally: use the hardware arrow keys to

move between the available buttons/controls. The first time you push a hardware arrow key the Hardware Focus Indicator is displayed (a blue border

around the active button/control). When using the hardware arrow keys, use the

hardware Enter key to select ("tap") a button/control.

Buttons often open a pop-up window for entering data, e.g. a unit button with

the text "mmH2O" opens a pop-up window of available units. Certain buttons do

have special functionality, like "Accept" and "Close" buttons. They close a popup window and either accept or reject the changes. There are other buttons,

e.g. for going to the next/previous page pages, scrolling through a wide table of

data, removing a number in a numeric field (backspace), clearing a numeric

field, etc. Most of them are familiar since they look similar as in personal computer software.

One important button is the Menu button which is available in the upper left

corner of almost any window. Tap on it to open a context-sensitive menu with,

among other things, a software version of the Home button presented on previous page.

Check Boxes are special buttons that are either "checked" or "unchecked".

See picture below. Again, the functionality is familiar from personal computers.

Check Boxes, both a checked

and an unchecked one.

Button without and with a Hardware Focus Indicator.

Accept button. Close button.

Menu button to the left.

Example of an opened menu.

Page 14

6 MC6 Workstation, User Manual – Part 1, Introduction

MC6 Workstation also has some "flat" buttons. They are used in, e.g lists. The

color of the flat buttons may vary depending on the context.

The following editable fields are available:

Text Fields,

Numeric Fields, in certain cases including Spinning and

Date/Time Fields.

The letters/numbers on all editable fields are blue to indicate that they are editable. Black texts are descriptive user interface texts that are not editable. An

example of a Text Field and the Text Edit Window is at the bottom right of this

page.

Use of Numeric Fields and Spinning is described in Part 2, Active Terminals

and Connections and Part 5, Documenting Calibrator.

Date Fields are actually special cases of Numeric Fields. Entering the date is

just like entering any numeric value.

Setting MC6 Workstation's time is a special case of the Spinning functionality.

See picture below. The "Left" and "Right" arrow buttons move the highlight to

another digit. The "Up" and "Down" arrow buttons change the value of the highlighted digit.

Time Setting window

Example of a list with flat buttons.

Text Field

Text Edit window

Page 15

About MC6 Workstation - Hardware 7

HARDWARE

GENERAL

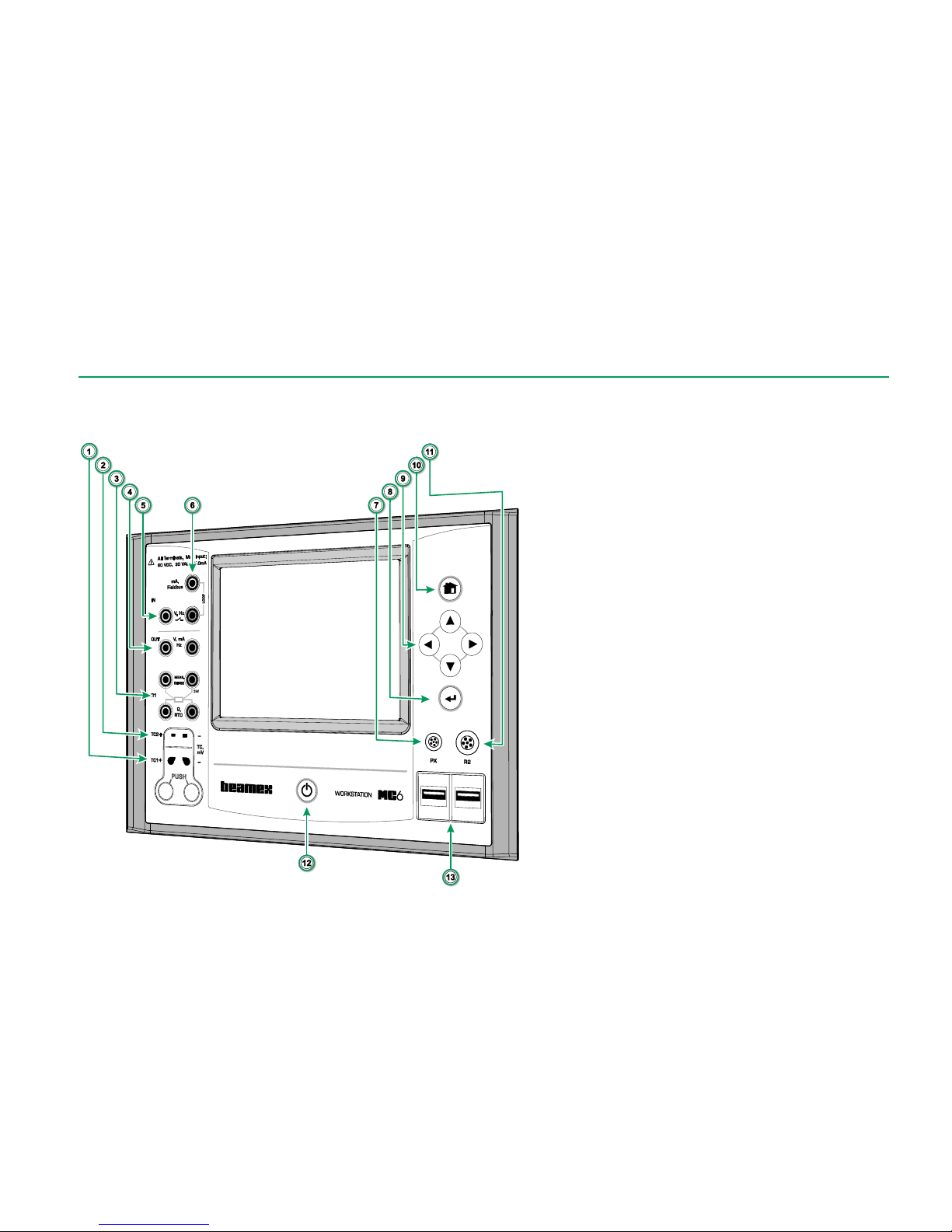

MC6 Workstation, front view.

Legend:

1. Thermocouple connector (TC1) with release but-

tons. For cables and standard TC plugs.

2. Thermocouple connector (TC2). For TC plugs with

flat contacts.

3. RTD and Resistor connector (R1). An R2 connector

is on the top of MC6 Workstation. More of R2 con-

nector on page 9.

4. Voltage, Current and Frequency output (OUT).

5. Voltage, Frequency and Switch input (IN ).

6. Current Measurement, Loop Supply, HART® and

Fieldbus connection (IN).

7. Connector for External Pressure Modules (PX).

8. Enter button for selecting the item surrounded with

the Hardware Focus Indicator.

9. Arrow buttons. First press displays the Hardware

Focus Indicator. Further presses move the indicator

on the touch screen.

10. Home button. Press this button to return to Home

View.

11. R2 connector. A possibility to connect an external

RTD sensor to MC6 Workstation. See also Hard-

ware Modules/Options and Accessories on page

14.

12. Power button. More in chapter Starting MC6 on

page 4.

13. Two USB-A connectors for connecting USB devices

to MC6 Workstation. See also chapter Firmware

Update in the Appendix.

Page 16

8 MC6 Workstation, User Manual – Part 1, Introduction

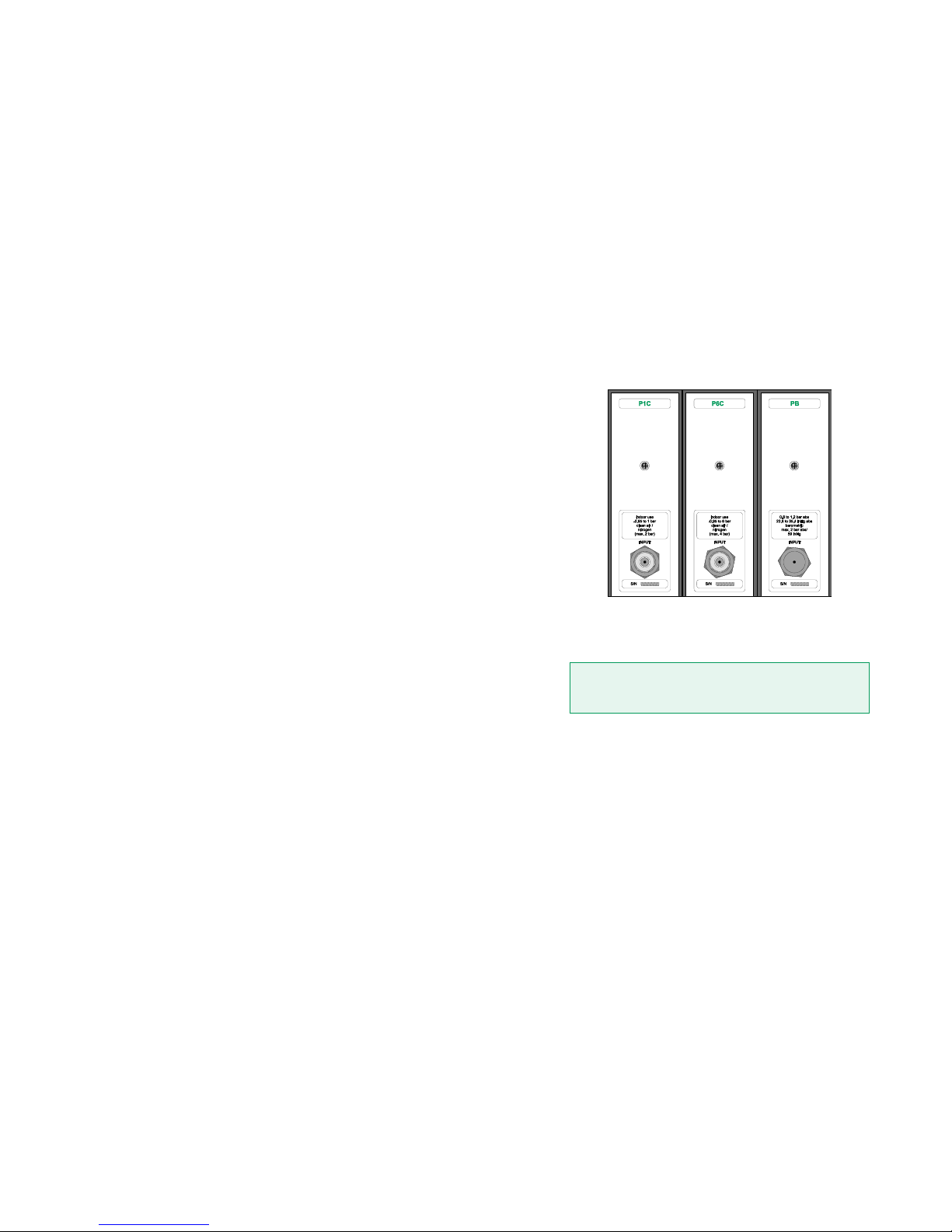

PRESSURE MODULES

MC6 Workstation supports up to nine pressure modules plus a barometric

module connected to it via a daisy chain communication cable inside MCS200.

The amount of modules varies depending on the system at hand. MC6 Workstation's User Interface refers to Pressure Modules as PX: P1C.

Where:

X is the ID address of a pressure module (0 to 9)

P1C etc. are the pressure module types.

The recommended pressure medium for pressure modules is clean air. Clean

non-corrosive liquids may optionally be used in modules with a measuring

range of 20 bar/300 psi or more. Avoid spilling liquid on MC6 Workstation when

connecting/disconnecting pressure hoses to/from pressure modules.

To avoid damaging the module, use hand tightening only when connecting the

pressure measurement hoses (max. torque 5 Nm, approx. 3.6 lbf ft). If the use

of tools is required to secure the connection (typically pressure modules with a

pressure range higher than 20 bar), apply the counterforce by placing a 14 mm

(approx. 9/16”) A/F spanner on the flats found in the module’s connector. The

overpressure protection of the internal pressure modules vents to the inside of

the module rack.

Barometric Module

Barometric Modules are shown as PB: PB in the MC6 Workstation's User Interface. The connection in front of a Barometric Module is meant for calibration

use. The thread is M5. To ensure valid barometric pressure measurements, do

not use the connection unless calibrating the module.

See Appendix for information on installing and uninstalling Pressure Modules.

Example of a set of Pressure Modules

in MCS200.

Remember to be cautious when working with pressure and

pressure modules. See also Appendix, chapters Safety

and Safety Precautions and Warnings.

Page 17

About MC6 Workstation - Hardware 9

FRONT PANEL CONNECTION DETAILS

If you use other pressure hoses than the one delivered by

Beamex, remove the connector meant for Beamex's pressure hoses and replace them with your own connectors.

The thread available in a Pressure Module's body is 1/8"

BSP.

R2 connector's pin order:

Outside view of the female

connector in MC6 Workstation.

1 Excitation current +

2 Sense +

4 Sense 5 Excitation current -

Note.

Leave pins 3, 6 and 7 unconnected in the male connector

meant for MC6 Workstation's R2 connector.

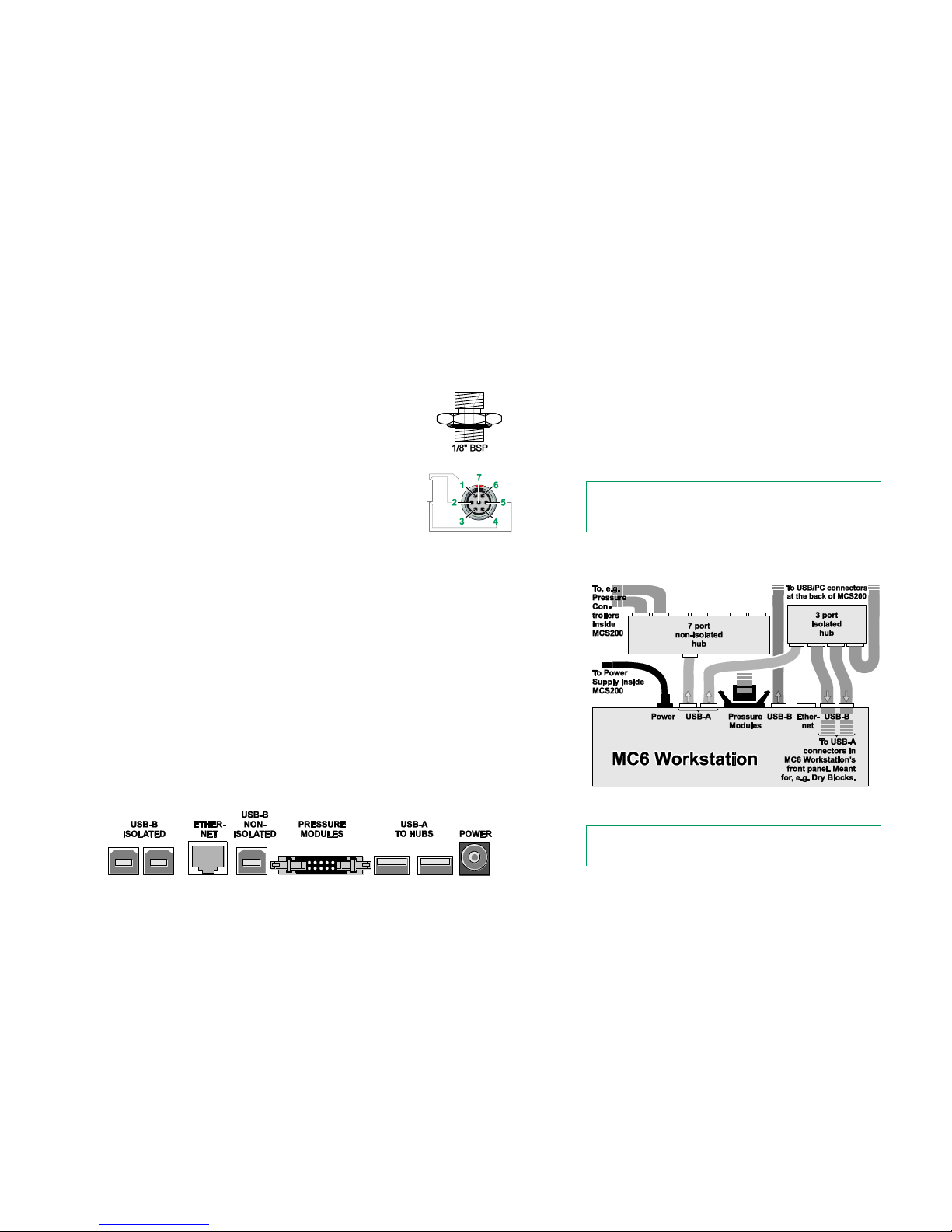

CONNECTORS AT THE BACK OF MC6 WORKSTATION

The rear end of MC6 Workstation (inside MCS200) includes the same connectors as in a portable MC6. There's also a Pressure Module connector for connecting Pressure modules in MCS200. See picture below.

USB Ports

The need for USB connectors in MC6 Workstation may be more than is available in a portable MC6. There may be several pressure controllers etc. in

MCS200 that requires communication with MC6 Workstation. That is why there

are two hubs included with MC6 Workstation inside MCS200. Two of the isolated hub's ports are connected to the USB-A ports in MC6 Workstation's front

panel allowing communication with, e.g. Dry Blocks.

A USB-B connector in MC6 Workstation is connected to the rear of MCS200. It

is meant for PC communication. Another USB-A connector is available via the

isolated hub. See rightmost picture.

Rear view of MC6 Workstation (inside MCS200).

Default connections inside MCS200.

Top view of MC6 Workstation.

Note.

All USB connectors are USB 2.0 Full Speed ports

Page 18

10 MC6 Workstation, User Manual – Part 1, Introduction

MEMORY

MC6 Workstation maintains data very much like personal computers. Data is

saved on a solid state memory that does not need any power to maintain its

state. Solid state memory is shock-proof so the data is not lost when the calibrator is transported. Also, you can safely save a large amount of instruments,

calibration results and data log results.

Available memory can be used for anything that requires it (e.g. instrument data, calibration results etc.).

DISPLAY

MC6 Workstation has a backlit 640 × 480 pixel 5.7" TFT touch screen display.

Use the touch screen with your fingers, gloves on or off. Optionally, use a stylus

meant for touch screen use.

See also brightness settings in Part 8, Settings.

Warning!

Using sharp tools such as a screwdriver on the touch

screen may damage it. More warnings in Appendix.

Page 19

About MC6 Workstation - Hardware 11

BATTERIES

MC6 Workstation has internal rechargeable Lithium Polymer (LiPo) batteries for

powering the internal clock when MCS200 is shut off. The charger is connected

to MCS200's power supply so the battery is automatically charged when

MCS200 is on. LiPo batteries do not suffer from the memory effect, so they may

be charged at any time. However, there are some serious safety issues concerning them, so read Warnings Concerning the Lithium Polymer Battery

Pack in Appendix.

A picture of a battery (or a plug, when charging or running on AC power) is

shown on many of MC6 Workstation's views. The "content" of the battery corresponds to the approximated charge level of MC6 Workstation's rechargeable

batteries. The maximum operating time of the batteries without recharging varies depending on the usage of the display back light. The usage of the 24 V

transmitter supply also affects the maximum operating time. Even with constant

maximum load, the standard rechargeable batteries should last for 10 hours. A

good average operating time is 16 hours.

The capacity of all batteries deteriorate with time. If MC6 Workstation's internal

clock is reset, it is time to replace the battery pack with a new one. See Appen-

dix for information on how to replace the Battery Pack.

Full battery Empty Battery

Notes.

A time approximate (hh:mm) is shown on the battery symbol.

During charging it is the charging time left, otherwise it is remaining usage time.

MC6 Workstation's internal clock/calendar uses a small

amount of power even when MCS200/MC6 Workstation is

switched off. Remember to check the capacity of the batteries

from time to time when MC6 Workstation is not in use. Recharge if needed.

Tap the battery icon to open a window displaying detailed battery/charging information.

Page 20

12 MC6 Workstation, User Manual – Part 1, Introduction

PC COMMUNICATION / CALIBRATION SOFTWARE

Beamex CMX Calibration Software supports MC6 Workstation from version

V2, revision 2.8 and onwards and also in Beamex LOGiCAL, a cloud based

tool for handling calibration results.

USB COMMUNICATION DRIVER

MC6 uses Windows' generic USB driver (WinUSB) provided by Microsoft. Supported operating systems: Windows® 7 … Windows® 10. Starting from Windows

8, the driver installation is self-contained, older versions may require Windows

Update connection.

MC6 WORKSTATION RELATED TOOLS AVAILABLE FOR PC

The following tools are available for download at Beamex's web site:

https://www.beamex.com. Look for Download Center and Software tools

for MC6 family.

Beamex MC6 Data Log Viewer, for transferring Data Log results to a

PC and viewing them on the PC.

Beamex MC6 Device Description Installer, for installing new Device

Descriptions of smart transmitters from a PC to MC6.

Beamex MC6 Fieldbus Configuration Viewer, for downloading smart

transmitter configurations read into MC6 to a PC.

Beamex MC6 Remote Controller, for controlling MC6 Workstation via

a PC.

Page 21

Options - Software Options 13

OPTIONS

SOFTWARE OPTIONS

The following software options are available:

Documenting Calibrator including computer communication with sup-

ported calibration software presented in chapter PC Communication /

Calibration Software on page 12,

Mobile Security Plus. This option requires that you have the Docu-

menting Calibrator option in MC6 and CMX Calibration Software ver-

sion V2, revision 2.11 or later.

Multi channel Data Logger,

Communicator, HART®,

*)Communicator, FOUNDATION Fieldbustm,

*)Communicator, PROFIBUS PAtm,

+)Drivers for External Controllers (Pressure and Temperature) and

Special Temperature Sensors.

*) Requires that communicating hardware is installed into MC6. Please con-

tact Beamex.

+)

When necessary, a connection cable is shipped when the software option

is bought.

Notes.

The software options available in the MC6 at hand can be

found in MC6's Settings main function. Select About option

and browse to page 3.

Whether the communication hardware needed for fieldbus

communication is installed or not, can be found in MC6's Set-

tings main function. Select About option and see page 1.

Page 22

14 MC6 Workstation, User Manual – Part 1, Introduction

HARDWARE MODULES/OPTIONS AND ACCESSORIES

Pressure Modules. Up to nine gauge and/or differential pressure mod-

ules may be installed in MCS200's Module Rack and additionally a barometric module.

Communicating hardware for MC6's Communicator software options.

See also Software Options on page 13.

Adapter cables for R2 connector. The R2 connector supports Beamex

Smart Reference Probe.

Cable for Pressure and Temperature Controllers.

Spare Battery Pack.

Pressure Hose Sets to be used together with internal and external

Pressure Modules.

Note.

The Pressure Modules internally connected to the MC6 Workstation at hand can be found in MC6's Settings main function.

Select About option and browse to page 2.

RELATED PRODUCTS

There are an increasing number of devices that can be used together with MC6

Workstation. The following list includes devices that are already available (valid

when this manual was printed):

External Pressure Modules (EXT),

Calibration hand pumps:

- PGV vacuum pump,

- PGL low pressure calibration pump,

- PGC pressure/vacuum pump,

- PGM high pressure pump,

- PGPH high pressure pneumatic pump and

- PGXH extra high pressure pump.

Beamex POC8 Automatic Pressure Controller,

Beamex Field Temperature Block (FB Series),

Beamex Metrology Temperature Block (MB

Series),

Beamex CMX Calibration Software and

Beamex LOGiCAL, a cloud based tool for

handling calibration results.

Page 23

Things discussed in this part:

A presentation of measurements MC6 Workstation is

capable of performing. For all measurements, the active terminals together with useful additional information for that particular measurement are presented.

Similarly, a presentation of generations and simula-

tions MC6 Workstation is capable of performing.

For generations/simulations, there is also information

on how to change the generated/simulated value.

Part 2

ACTIVE TERMINALS AND CONNECTIONS

Page 24

16 MC6 Workstation, User Manual – Part 2, Active Terminals and Connections

GENERAL

This section of MC6 Workstation's User Manual presents all measurements and

generations/simulations that MC6 Workstation is capable of performing. No

matter which of the available main functions you use in MC6 Workstation, the

connections presented here apply.

Settings in Meter and Calibrator are saved, so the next time you measure,

generate or simulate something, the previous settings are available as defaults.(*

In Calibrator also the additional information row settings for all measurements/generations/simulations are saved for future needs. However damping,

resolution and alarms are active for the current session only.

*) When you use Documenting Calibrator and select an instrument for cali-

bration, the instrument's settings (Quantity, Port etc.) are inherited to the

Calibrator.

Respectively, when creating a new instrument in Documenting Calibrator,

the settings in Calibrator's sub-windows are used as default settings for the

new instrument's input and output.

Notes.

For HART and Fieldbus instrument specifics, see Part 7,

Communicator.

For information on External Devices (Pressure and Temperature Controllers) used together with Calibrator and Documenting Calibrator, see Part 9, Additional Information.

Note.

In this manual, when presenting each measurement/generation/simulation there is a picture with highlighted active terminals. The highlight for possible optional connections is lighter.

Connections to instruments are included if it requires special

attention. See, e.g. Current Generation (Source or Sink) on

page 24.

Next…

Measurements on page 17

Generations/Simulations on page 22

Meter in part 3

Calibrator in part 4

Documenting Calibrator in part 5

Data Logger in part 6

Communicator in part 7

Additional Information in part 9

Page 25

Measurements - Pressure Measurement 17

MEASUREMENTS

PRESSURE MEASUREMENT

MC6 Workstation supports the use of both pressure modules in MCS200, if

installed, and the use of supported external pressure modules, when they are

connected to MC6 Workstation.

Note that pressure measurement requires knowledge of pressure types (absolute pressure, gauge pressure and differential pressure). Measuring pressure

with inadequate knowledge of pressure types and the dangers of pressure devices may result in false measurement results and/or serious accidents. Please

read the warnings in Appendix.

CONNECTING AND DISCONNECTING EXTERNAL PRESSURE MODULES

When an external pressure measurement module is connected and when applicable, MC6 Workstation opens a dialog. Among other information, the dialog

includes a possibility to choose where to use the connected external pressure

module.

An external pressure module may be disconnected at any time. MC6 Workstation indicates that an external pressure module was removed. If the module

was used for a measurement, the measurement stops.

ZEROING A PRESSURE MODULE

If the selected pressure module does not display zero gauge pressure when the

applied pressure is zero, the module has to be zeroed. To do it, apply zero

gauge pressure and tap the zero button:

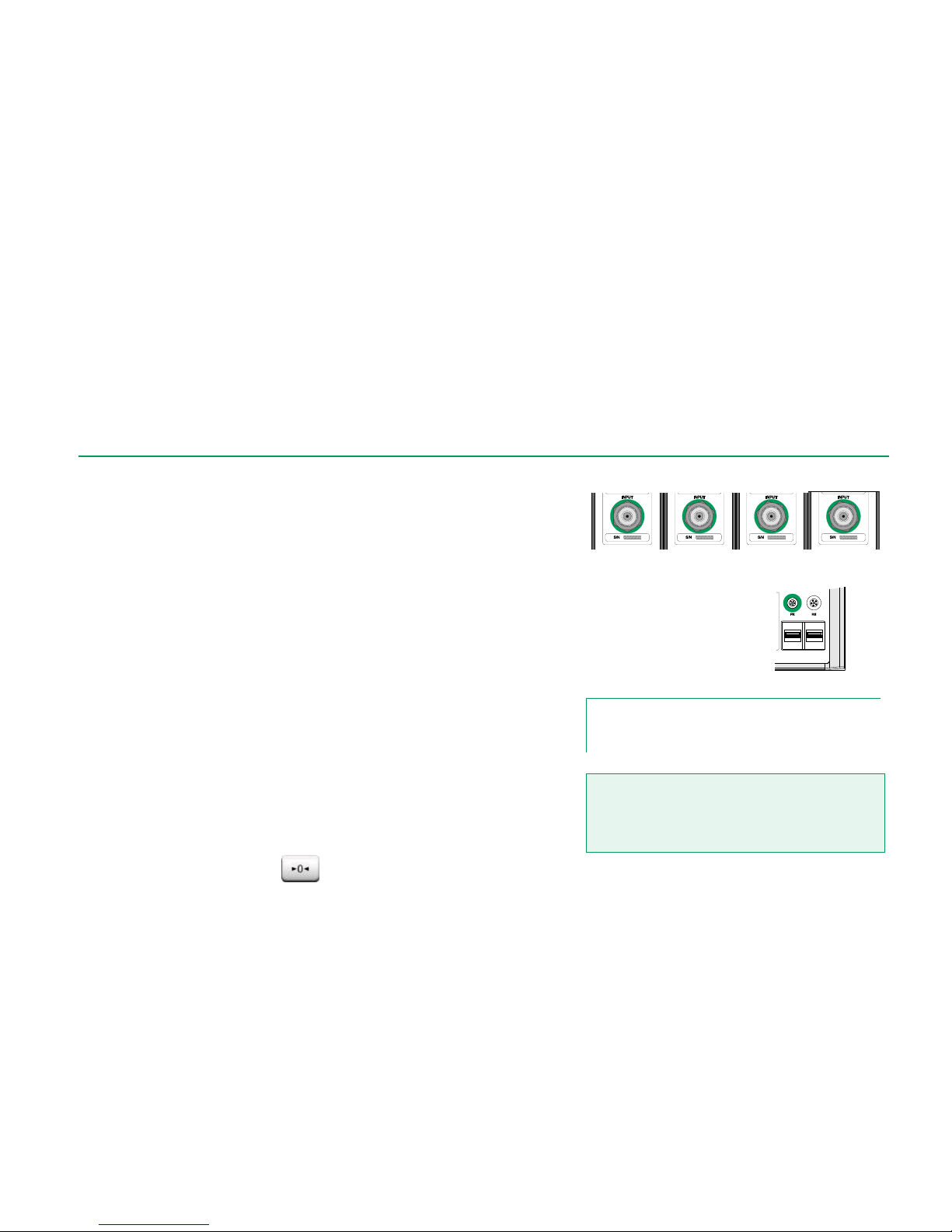

Example of pressure module connectors in MCS200.

PX, Connector

for external pressure measurement

modules in MC6

Workstation (right).

Note.

The amount of pressure modules in MCS200 on your particular

MC6 Workstation may differ from the picture presented above.

Warning!

Select a pressure module that has a suitable measurement

range for your pressure signal. Too low/high measurement

range on the pressure module results in faulty modules,

imprecise readings or even accidents.

Page 26

18 MC6 Workstation, User Manual – Part 2, Active Terminals and Connections

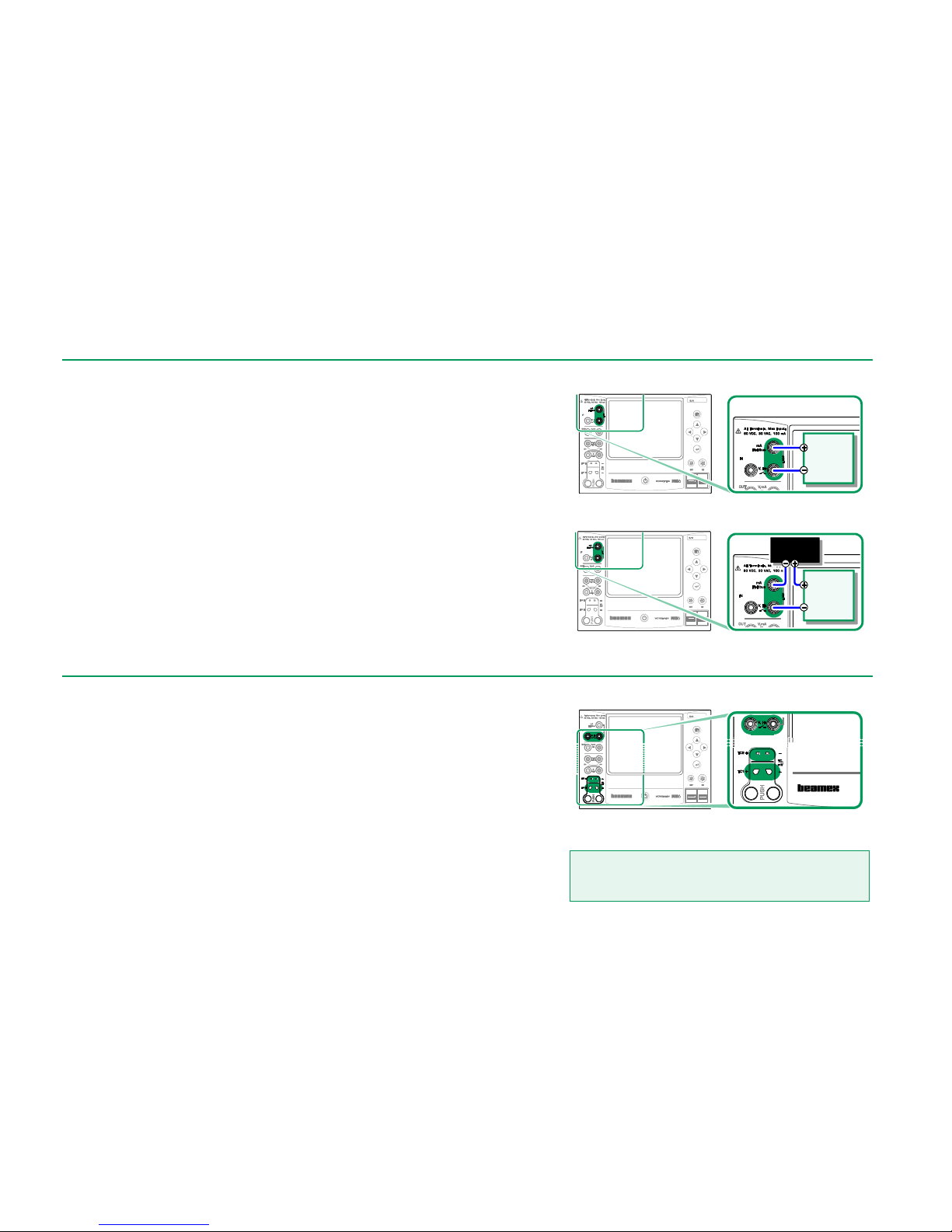

CURRENT MEASUREMENT

When measuring electric current, an important thing is selecting whether MC6

Workstation provides the 24 volt loop supply voltage or not. If not, an external

device should provide the loop supply voltage.

Connection depends on the loop supply setting. See pictures to the right.

See also: Current Generation (Source or Sink) on page 24.

Current measurement terminals. Internal supply

Range -101 … +101 mA

Current measurement terminals. External supply.

VOLTAGE MEASUREMENT

MC6 Workstation's voltage measurement terminals are listed below (top to bottom) as they are shown in the adjacent picture (left to right):

TC1, measurement range: -1.01 to +1.01 VDC.

TC2, measurement range: -1.01 to +1.01 VDC.

IN, measurement range: -1.01 to +60.6 VDC.

Note that you may measure non-supported thermocouple signals using either

TC1 or TC2 port. The reading is in (milli)volts, so you need a data table to convert the signal to temperatures. Calibrator‘s and Documenting Calibrator's

Scaling utility may be used for converting millivolts to temperatures.

See also: Voltage Generation on page 24 and

Temperature Measurement (Thermocouple) on page 19.

Voltage measurement terminals.

For ranges, see chapter to the left.

Warning!

Do not apply hazardous voltages to MC6 Workstation's

terminals.

Instrument

controlling

current

signal

External

Power Supply

Instrument

controlling

current

signal

Page 27

Measurements - Temperature Measurement (Thermocouple) 19

TEMPERATURE MEASUREMENT (THERMOCOUPLE)

MC6 Workstation has two thermocouple connectors. TC1 is for cables and

standard TC plugs. TC2 is for TC plugs with flat contacts.

Check the Sensor Type. Your measurement results are unreliable unless you

select the same sensor type as is connected to MC6 Workstation. Select also a

suitable Reference Junction compensation method. Wrong settings yield useless measurement results.

See also: Thermocouple Simulation on page 25 and

Voltage Measurement on page 18.

Warning!

When using another thermocouple or an RTD sensor connected to MC6 Workstation to

measure the external reference junction temperature: Keep in mind that there is no isolation between the thermocouple to be calibrated and the sensor measuring the reference temperature.

Thermocouple measurement terminals.

Range depends on sensor type

Note.

Thermocouple measurements are error prone. There may be

faulty connections, wrong (extension) cables and settings in

MC6 Workstation. If unsure, see chapter Thermocouple Con-

nections on page 28 and study thermocouple literature.

TEMPERATURE MEASUREMENT (RTD)

Check the sensor type. Make sure you select the same sensor type as is connected to MC6 Workstation. Otherwise your measurement results are unreliable.

For R1 terminals:

The two leftmost terminals are used in 2-wire systems. MC6 Workstation automatically checks the connection and displays the found wiring system.

For R2 terminal:

Beamex offers, as an option, an adapter for the R2 terminal. Please contact

Beamex for details. R2 terminal always uses 4-wire measurement.

See also: RTD Sensor Simulation on page 25,

Resistance Measurement on page 20 and

Resistance Simulation on page 26.

RTD measurement terminals.

Range depends on sensor type

Note.

If you get "+OVER" or “-OVER” error messages, check the

connections. If necessary, use 2-wire ohm measurement to

check the wiring.

Page 28

20 MC6 Workstation, User Manual – Part 2, Active Terminals and Connections

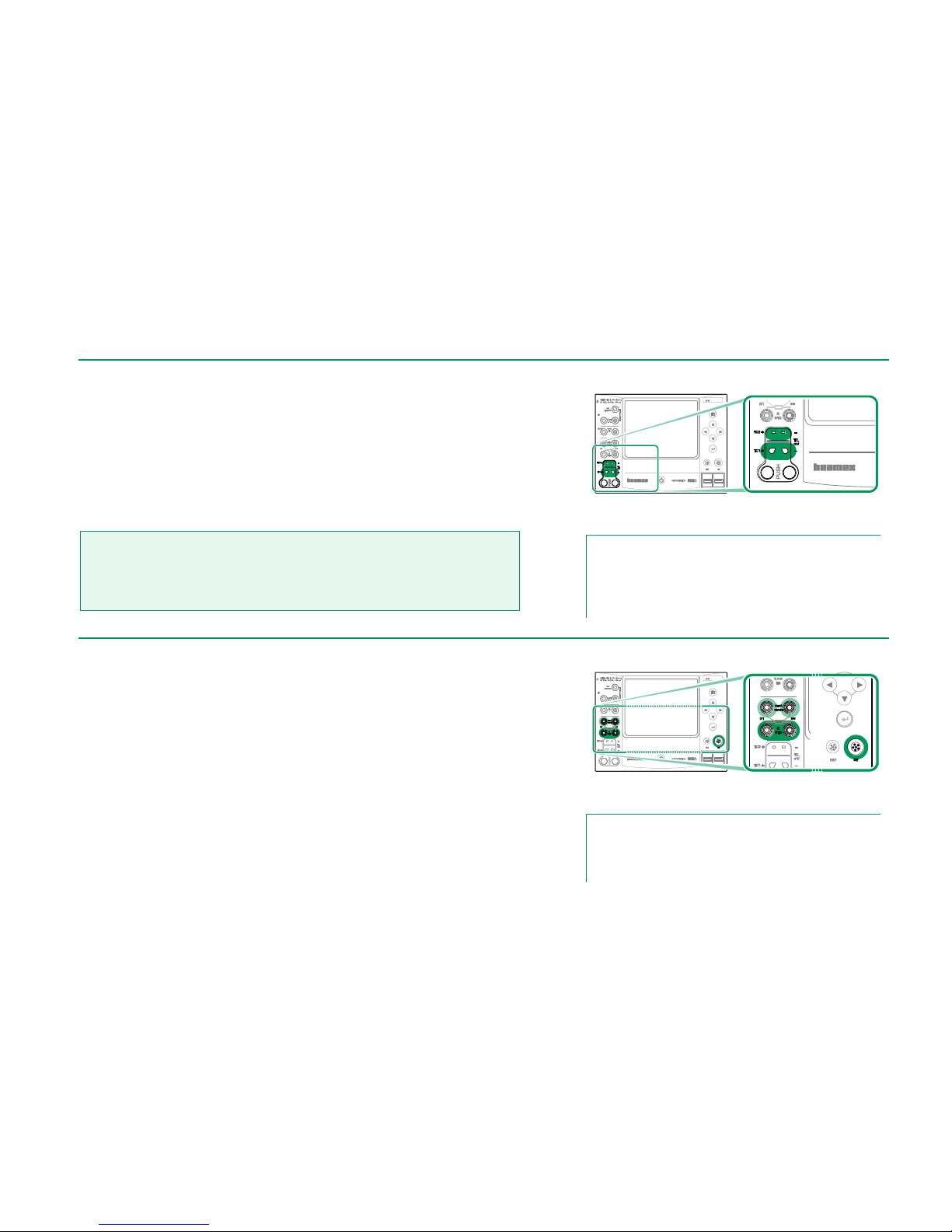

RESISTANCE MEASUREMENT

For R1 terminals:

The two leftmost terminals are used in 2-wire systems. MC6 Workstation automatically checks the connection and displays the found wiring system (2-wire,

3-wire or 4-wire).

For R2 terminal:

Beamex offers, as an option, an adapter for the R2 terminal. Please contact

Beamex for details. R2 terminal always uses 4-wire measurement.

See also: Resistance Simulation on page 26 and

Temperature Measurement (RTD) on page 19.

Resistance measurement terminals.

Range -1 … 4040 ohm

Note.

If you get "+OVER" or “-OVER” error messages, check the

connections. If necessary, use 2-wire ohm measurement to

check the wiring.

FREQUENCY MEASUREMENT

In frequency measurement, be sure you select a suitable trigger level setting.

To do it, tap on the button with the arrow pointing on a rising ramp and the current trigger level voltage. From the opened pop-up window: Select a suitable

trigger level.

See also: Frequency Generation on page 26,

Pulse Counting on page 21 and

Switch Sensing on page 21

Frequency measurement terminals.

Range 0.0027 … 51000 Hz

Note.

There is a trigger level choice for (dry) contacts with no external potential. 24V supply may also be used. Connect as light

blue line shows in picture above.

Page 29

Measurements - Pulse Counting 21

PULSE COUNTING

Pulse counting has three settings that should be checked before (re)starting a

pulse count:

Trigger level. Select a level that suits your signal.

Trigger edge. Select either rising or falling edge.

Zeroing. A possibility to zero the pulse count.

See also: Pulse Generation on page 27,

Frequency Generation on page 26 and

Frequency Measurement on page 20.

Pulse counting terminals.

Range 0 … 9 999 999 pulses

Note.

There is a trigger level choice for (dry) contacts with no external potential. 24V supply may also be used. Connect as light

blue line shows in picture above.

SWITCH SENSING

Switch Sensing has three settings:

A possibility to invert switch's open/close state indication.

Trigger level. Select a level that suits your switch. See note to the right.

Sound setting. Define whether MC6 Workstation emits a sound when

the switch's state change and if yes, when it is emitted.

See also: Pulse Counting on page 21 and

Pulse Generation on page 27,

You can also use Switch Sensing for binary signal detection. For normal switch

state detection: an open switch equals 1 / True and a closed switch 0 / False.

Switch sensing terminals.

Note.

There is a trigger level choice for (dry) contacts with no external potential. 24V supply may also be used. Connect as light

blue line shows in picture above.

Page 30

22 MC6 Workstation, User Manual – Part 2, Active Terminals and Connections

GENERATIONS/SIMULATIONS

Generations and simulations are supported in Calibrator, Documenting Calibrator and Data Logger.

Note.

The Meter is not capable of performing generations and simulations.

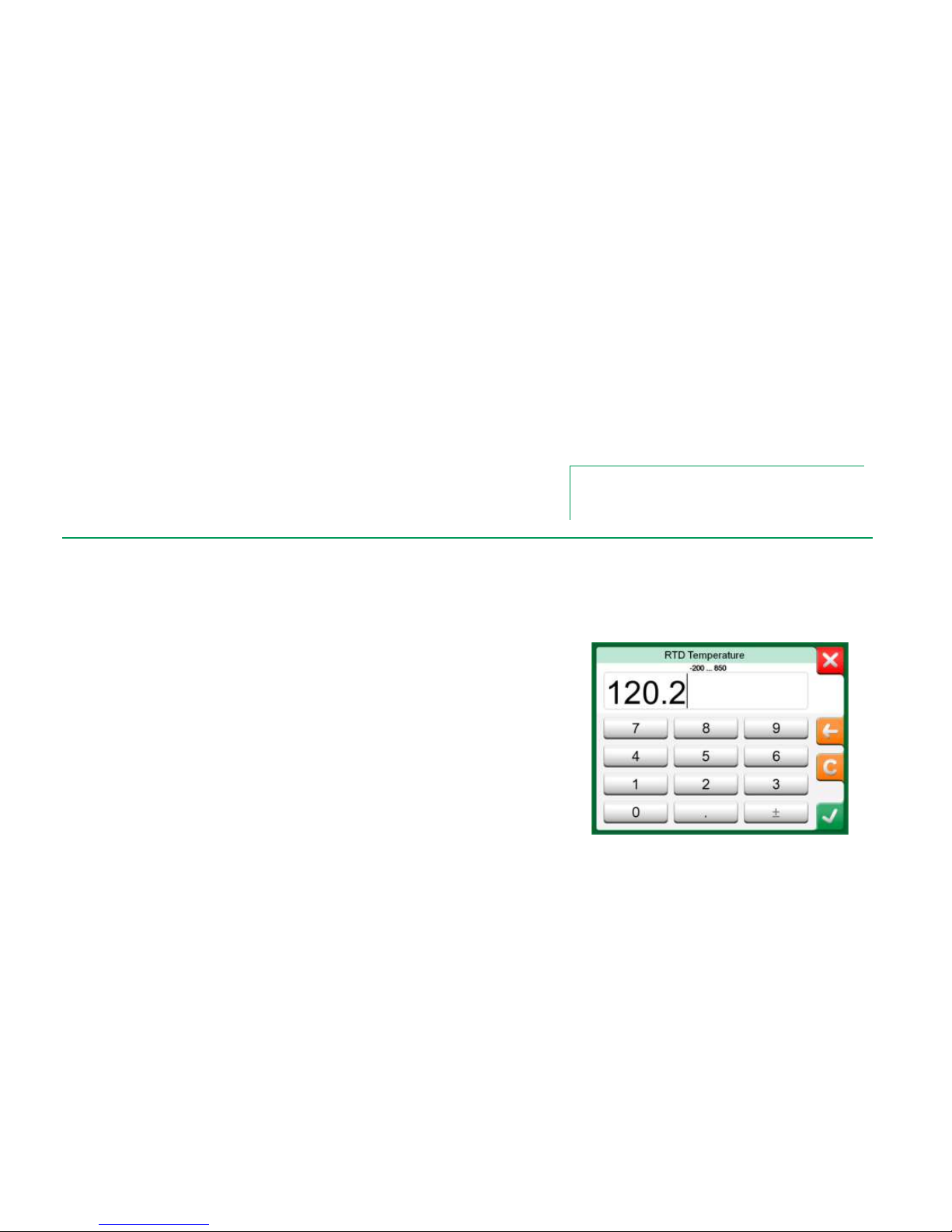

CHANGING THE GENERATED/SIMULATED VALUE

There are several ways of changing the generated/simulated value. The following subchapters present the available utilities.

USING THE SOFT NUMERIC KEYPAD

This utility is useful when a generated/simulated value (or any numeric field in

MC6 Workstation) is either empty (displaying dashes) or when a new and different value is needed. The soft numeric keypad opens when you tap on the

generated/simulated value (see picture to the right).Tap on numbers to enter a

value. Additional functions:

Use the "C" key on the right to clear the entered value.

Use the "Left Arrow" key to delete the number to the left of the cursor.

The entered value is taken into use when you close the window using the "Accept" button. Note that MC6 Workstation may use the entered value as a

source for the value's resolution. Enter trailing zeros to ensure useful resolution.

When applicable, the minimum and maximum limit of the entered value is shown

above the entered number. If you enter a value above/below the limits, and try to

accept it, MC6 Workstation stays in the soft numeric keypad window and replaces

the entered value with appropriate limit value and highlights the replaced value.

Soft Numeric Keypad.

Page 31

Generations/Simulations - Changing the Generated/Simulated Value 23

SPINNING

Spinning is a tool that is available in Calibrator and Documenting Calibrator.

It is useful when making small changes to an existing numeric value, one digit

at a time.

Non-empty numeric fields in Calibrator's generation/simulation windows have a

button with both "Up" and "Down" arrows to the left of the actual numeric value.

That is the Spinner button. Tap the Spinner button to activate spinning.

When spinning is active, one of the digits is highlighted. Change its value by

tapping the "Up" and "Down" arrows in the active spinner. To move the highlight to another digit, use the "Left" and "Right" arrows.

To stop spinning, tap the Spinner button again.

Inactive spinner

Active spinner

Notes.

Any changes in the numeric field are immediately reflected in

the generated/simulated signal.

You cannot exceed the minimum/maximum limits of a Function

when spinning.

The spinned value follows the resolution properties of the generated/simulated Function.

If a numeric field is empty (displaying dashes), first use the soft

numeric keypad to enter a value. Then you are able to utilize

the spinning tool.

Page 32

24 MC6 Workstation, User Manual – Part 2, Active Terminals and Connections

CURRENT GENERATION (SOURCE OR SINK)

MC6 Workstation's current generation can be done using one of two available

methods:

MC6 Workstation provides a 24 volt loop supply voltage (source mode).

Setting: Supply: On.

An external device provides the loop supply voltage (sink mode)

Setting: Supply: Off.

Connection depends on the loop supply setting. See pictures to the right.

See also: Current Measurement on page 18.

Note.

If the connected instrument utilizes digital communication and MC6 Workstation's 24 volt supply voltage is in use, the following battery symbol is shown in the user interface of Document-

ing Calibrator and Data Logger:

Current generation terminals. Internal supply.

Range 0 … 55 mA

Current generation terminals. External supply

VOLTAGE GENERATION

MC6 Workstation has two voltage generation terminals. They are listed below

(top to bottom) as they are shown in the adjacent picture (left to right):

TC1, generation range: -1 to +1 VDC.

OUT, generation range: -3 to +24 VDC.

Note that you may simulate non-supported thermocouple signals using TC1

port. Since you actually generate (milli)volts, you need a data table to convert

desired temperatures to millivolts.

See also: Voltage Measurement on page 18 and

Thermocouple Simulation on page 25.

Note.

It is advisable to enter 0 V output before connecting the circuit.

Voltage generation terminals.

For ranges, see chapter to the left.

Warning!

Short circuiting the voltage output may result in damage to

MC6 Workstation and/or the connected instrument.

Instrument

receiving

current

signal

External

Power Supply

Instrument

receiving

current

signal

Page 33

Generations/Simulations - Thermocouple Simulation 25

THERMOCOUPLE SIMULATION

Thermocouple simulation is available from TC1 terminals only.

Check the Sensor Type. Your simulations are unreliable unless you select the

same sensor type as is connected to MC6 Workstation. Also select a suitable

Reference Junction compensation method. Wrong Reference Junction setting

yields useless results. See chapter Thermocouple Connections on page 28.

See also: Temperature Measurement (Thermocouple) on page 19.

Warning!

When using a thermocouple or an RTD sensor connected to MC6 Workstation to measure the external reference junction temperature: Keep in mind that there is no isolation

between the instrument to be calibrated and the sensor measuring the reference temperature.

Thermocouple simulation terminals.

Range depends on selected sensor type

Note.

Thermocouple measurements are error prone. There may be

faulty connections, wrong (extension) cables and settings in

MC6 Workstation. If unsure, see chapter Thermocouple Con-

nections on page 28 and study thermocouple literature.

RTD SENSOR SIMULATION

RTD simulation is available from R1 terminals only.

Use of 2-, 3- or 4-wire connection is up to the receiving instrument. Connect the possible third and fourth wire according to the requirements of

the connected instrument, but use only the two leftmost R1 terminals

in MC6 Workstation. See adjacent picture.

Check the Sensor Type. Make sure you select the same sensor as the

instrument receiving the simulated signal requires. Otherwise your simulations are unreliable. See also note in next chapter.

See also: Temperature Measurement (RTD) on page 19 and

Resistance Simulation on page 26.

RTD simulation terminals.

Range depends on selected sensor type

Notes.

AC measurement current from the instrument under test is not

supported. With pulsed measurement current, set a wait time

of few milliseconds before the resistance is measured.

Instrument

receiving

simulation

signal

Page 34

26 MC6 Workstation, User Manual – Part 2, Active Terminals and Connections

RESISTANCE SIMULATION

Use of 2-, 3- or 4-wire connection is up to the receiving instrument. Connect the

possible third and fourth wire according to the requirements of the connected

instrument, but use only the two leftmost RTD1 terminals in MC6 Work-

station. See adjacent picture.

MC6 Workstation monitors the resistance measurement current. If the current is

too high, MC6 Workstation cannot simulate the right resistance value and displays an error message.

See also: Resistance Measurement on page 20 and

RTD Sensor Simulation on page 25.

Note.

When simulating resistance or an RTD sensor, using R1 port, MC6 Workstation does not support measuring the simulated signal using R2 port.

Resistance simulation terminals.

Range 0 … 4000 ohm

Notes.

AC measurement current from the instrument under test is not

supported. With pulsed measurement current, set a wait time

of few milliseconds before the resistance is measured.

FREQUENCY GENERATION

Before generating frequencies, the following settings should be checked:

Amplitude. Defined from the button with the "V" value.

Waveform and Duty Cycle. Set together from the rightmost button.

Duty Cycle is the ratio of the output high time to the total cycle time. Due to

technical reasons, the entered Duty Cycle is not always realized with relatively

high frequencies. When the realized Duty Cycle differs from the desired Duty

Cycle, the realized Duty Cycle is shown with an asterisk (*) in front of it, e.g.:

*8 %

See also: Frequency Measurement on page 20 and

Pulse Generation on page 27.

Frequency generation terminals.

Range 0.0005 … 50000 Hz

Instrument

receiving

simulation

signal

Page 35

Generations/Simulations - Pulse Generation 27

PULSE GENERATION

Before generating pulses, the following settings should be checked:

Frequency. To set the frequency, tap on the button with the "Hz" value.

Amplitude. Defined from the button with the "V" value.

Waveform and Duty Cycle. Set together from the rightmost button.

Duty Cycle is the ratio of the output high time to the total cycle time. Due to

technical reasons, the entered Duty Cycle is not always realized with relatively

high frequencies. When the realized Duty Cycle differs from the desired Duty

Cycle, the realized Duty Cycle is shown with an asterisk (*) in front of it, e.g.:

*8 %

See also: Pulse Counting on page 21 and

Frequency Generation on page 26.

Pulse generation terminals.

Range 0 … 9 999 999 pulses

Page 36

28 MC6 Workstation, User Manual – Part 2, Active Terminals and Connections

THERMOCOUPLE CONNECTIONS

With thermocouples, connections and reference junction settings are crucial for

getting accurate results. Reference Junction Modes available:

Internal is the simplest. Use suitable thermocouple, extension or compensation

wires to connect to MC6 Workstation. MC6 Workstation takes care of the Reference Junction compensation. The upper picture to the right presents the connection to TC1 terminals. You may optionally also use the TC2 terminals.

External R1 and External R2 use an external RTD sensor measuring the Reference Junction temperature, connected to selected terminal. The lower picture

to the right presents the connections to TC1 and R1 terminals.

Fixed (0°C) and Manual are used when a compensation box, a temperature

controller or similar method is utilized for fixing the Reference Junction temperature. Manual allows you to enter any temperature. Fixed (0°C) is a quick way of

"entering" zero degrees centigrade. Connection picture to TC1 below.

Fixed/Manual Reference Junction temperature.

Before measuring, ensure that MC6 Workstation's temperature has stabilized. Temperature differences between

MC6 Workstation and the environment affect the accuracy

of TC measurements.

Internal Reference Junction.

An RTD connected to R1 terminals measures

the Reference Junction temperature.

Copper

Fixed

Reference

Junction

Temperature

TC sensor

or a

TC signal receiver

TC materials

(TC, extension or

compensation wires)

TC sensor

or a

TC signal receiver

TC materials

(TC, extension or

compensation wires)

Reference temperature

TC sensor

or a

TC signal receiver

TC materials

(TC, extension or

compensation wires)

RTD

Copper

Page 37

Things discussed in this part:

Presenting the Meter and

how to take it into use.

Part 3

METER

Page 38

30 MC6 Workstation, User Manual – Part 3, Meter

ABOUT METER

The Meter can be used for quickly checking any device producing a signal that

is measurable with MC6 Workstation. For calibration needs, use one the calibration related main functions available in MC6 Workstation.

Start the Meter by tapping the Meter icon in MC6 Workstation's Home View

(see adjacent picture). A window like the one on the lower right corner of this

page opens. To measure a signal, do as follows:

Select the Quantity of the signal by tapping one of the nine buttons on

the lower part of the Meter window.

Other, Quantity dependent settings appear on top of the Meter window.

For information on connections and essential settings, see Part 2, Active Ter-

minals and Connections.

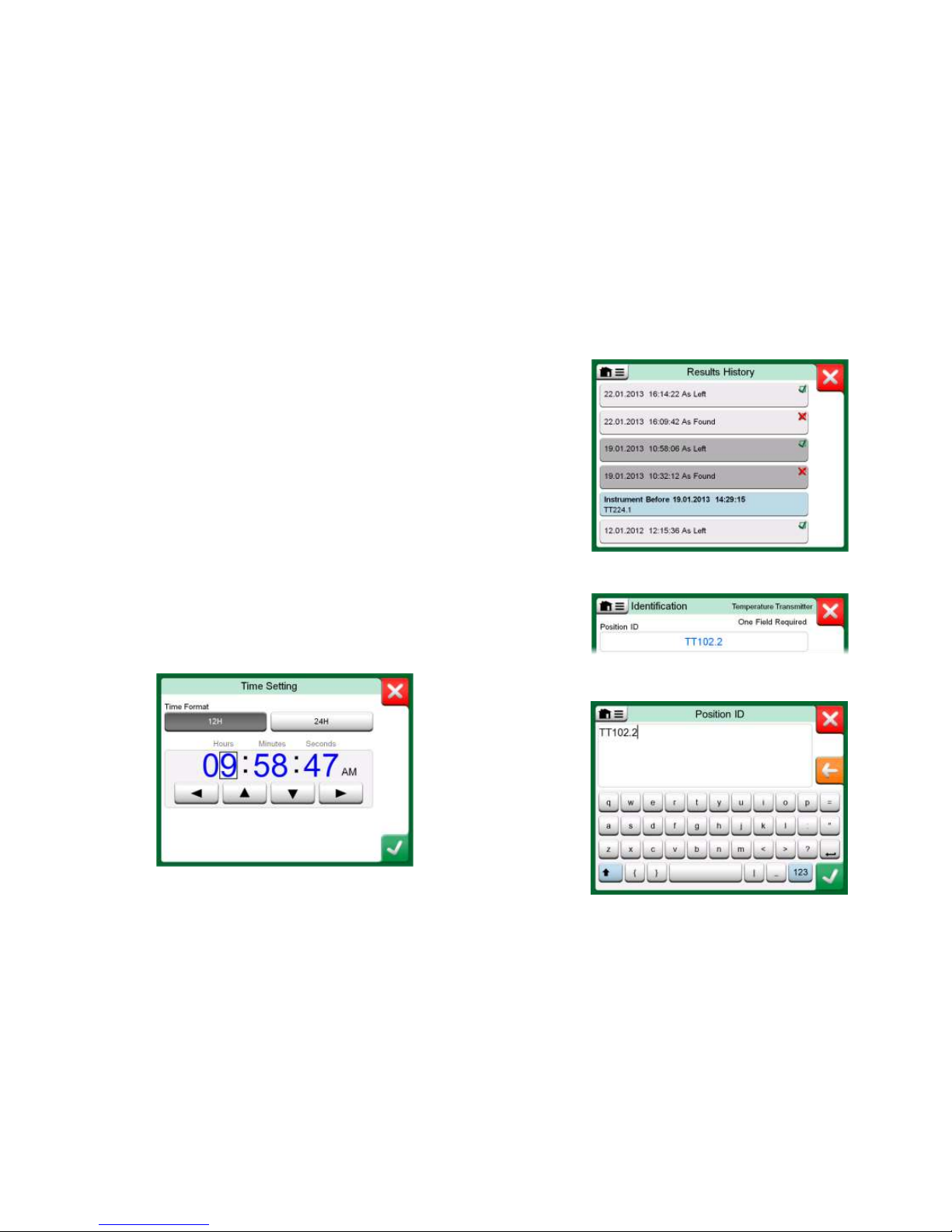

Home View with Meter selected

Current Measurement using Meter

Page 39

Things discussed in this part:

How to use the Calibrator

Presenting the available additional

Tools in Calibrator

Part 4

CALIBRATOR

Page 40

32 MC6 Workstation, User Manual – Part 4, Calibrator

ABOUT CALIBRATOR

The Calibrator can be used for calibrating instruments. It consists of two subwindows which can be independently(* configured to measure, generate or simulate a signal. One sub-window for the instrument's input and another for the

instrument's output.

Start the Calibrator by tapping on the Calibrator icon in MC6 Workstation's

Home View (see adjacent picture). A window like the one on the lower right

corner of this page opens. To configure a sub-window do as follows:

Select the Quantity of the signal by tapping the button in the upper left

corner of the sub-window. Hint: Quantity button has bold font.

Other, Quantity dependent settings appear to the right of Quantity but-

ton. The button closest to the Quantity button defines whether you

measure, generate or simulate a signal and which terminals are active.

For information on connections and essential settings, see Part 2, Active Ter-

minals and Connections.

Note.

If you want to document your calibration results, use MC6 Workstation's optional Document-

ing Calibrator feature or manually document the calibration data displayed in Calibrator.

For information on External Devices (Pressure and Temperature Controllers) used together

with Calibrator, see Part 9, Additional Information.

*) A measurement, generation or simulation in one sub-window reserve terminals in

MC6 Workstation. This may affect the availability of measurements, generations and

simulations in the other sub-window. To free terminals, tap on the quantity button

and in the opened window, tap on the "Stop" button.

Home View with Calibrator selected

Calibrator in use

Page 41

Tools - General 33

TOOLS

GENERAL

Calibrator window has Tools buttons in the lower left corner of each subwindow. See the picture to the right. The following list presents available tools.

Certain tools are available for measurements only and others for generations/simulations only.

Tool Description

Tools button. See also note below.

Scaling

Any signal may be scaled provided the conversion is

known. When scaling is active, it is indicated with a triangle in the unit button. The true measurement value is

shown in the additional info row at the bottom of the

sub-window.

Tools available for measurements.

Note.

For practical reasons, the available Tools are limited for

Switches.

Alarm

Main measurements may be assigned with four alarm

limits: high, low, high and low change rate. Active

alarms are shown above the main measurement.

When an alarm limit is exceeded, a warning signal is

heard. A button for acknowledging an alarm appears

when needed.

Leak / Stability Test

A leak/stability test may be assigned to main measurements. It tests the leak or stability of, e.g. a pressure

measurement system.

In the Leak / Stability Test configuration window: Enter

Test time and start recording. Use the "+30 sec" button

to increase the test time, when needed.

Continues on next page…

Page 42

34 MC6 Workstation, User Manual – Part 4, Calibrator

Tool Description

Tools available for generations and simulations.

Quick Access Buttons in use

Notes.

Several Tools have a "Stop" button in the pop-up window the

Tool is configured in. To stop, e.g. Damping, open the Damping configuration window and tap the "Stop" button. Then MC6

Workstation reverts to default damping settings.

Changing the Quantity of a sub-window revert all Tools, except

Additional Info settings, to their default settings for that particular Quantity.

In Calibrator window: the additional info fields with black text

may be zeroed "on the fly". Zeroing options are available in

Additional Info window's menu.

Some of the tools presented here are also available in Docu-

menting Calibrator and Data Logger.

Damping

Use damping when a measurement signal contains unwanted noise. Select one of the available options.

When Damping is used, a funnel appears to the left of the

main measurement. When damping is active, the following symbol is shown above the unit button:

.

Resolution

Any signal's resolution may be increased or decreased.

Altered resolution is indicated in sub-window, e.g. ".-2"

equals two less decimals.

Additional Info

Including additional information fields at the bottom of a

sub-window is always available. The available fields,

however, depend on the quantity/settings. Up to four

fields may be added to both sub-windows. The additional

information row settings are saved for future needs. See

also notes to the right.

Function Info

Always available. Opens a pop-up window with information of current function (measurement range, uncertainties etc.).

Step

Available for generations/simulations: Opens a window

for defining a step function for the generated/simulated

signal.

Ramp

Available for generations/simulations: Opens a window

for defining a ramp function for the generated/simulated

signal.

Quick Access

Available for generations/simulations: Opens a window

for defining five shortcuts to user configurable generation/simulation values. Quick Access buttons appear at

the bottom of the sub-window, taking over the space of

possible additional info data.

Page 43

Things discussed in this part:

An introduction to calibration

How to calibrate instruments using

MC6 Workstation's Documenting Calibrator

How to do a Group Calibration

How to view calibration results

How to read instrument data from devices

using digital communication

Part 5

DOCUMENTING CALIBRATOR

Page 44

36 MC6 Workstation, User Manual – Part 5, Documenting Calibrator

GENERAL

MC6 Workstation's Documenting Calibrator is an optional, more advanced

tool than the "plain" Calibrator that is also available in MC6 Workstation. If your

MC6 Workstation does not have this option installed, the Documenting Cali-

brator icon is disabled.

Documenting Calibrator saves instrument data and presents them in a list.

Instrument data consists of input and output quantities and ranges as well as

other data that defines the instrument. Starting to calibrate an instrument is fast,

since all the required data are immediately taken into use.

Instruments to be calibrated may be received from calibration software communicating with MC6 Workstation. Alternatively, instruments may be created in

MC6 Workstation itself.

Calibration results are saved and they can be viewed in MC6 Workstation and

also sent to calibration software for further analysis.

Open Documenting Calibrator by tapping on the Documenting Calibrator

icon in MC6 Workstation's Home View (see adjacent picture).

Home View with Documenting Calibrator

selected.

CALIBRATION SOFTWARE

When this manual was printed, the following calibration software supported

communication with MC6 Workstation:

Beamex CMX Calibration Software, version 2, revision 2.9. Light, Pro-

fessional and Enterprise editions.

Beamex LOGiCAL, a cloud based tool for handling calibration results.

Note.

Older Beamex calibration software do not support MC6 Workstation.

Page 45

Calibrating Instruments - Calibration Software 37

CALIBRATING INSTRUMENTS

Instruments are typically calibrated following the procedure shown in the adjacent picture.

In MC6 Workstation, you first select (or create) the instrument to be calibrated.

Then perform the As Found calibration – as many repeats as is required - and

decide whether or not adjustment is needed. Often you then do the required

amount of As Left repeats to document the instrument's state after the possible

adjustment.

A calibration procedure using MC6 Workstation is presented in the following

pages.

GENERATING/SIMULATING THE INPUT VALUE

How you change the generated/simulated value is explained in Part 2, Active

Terminals and Connections, chapter Changing The Generated/Simulated

Value.

Typical calibration procedure

Note.

Although MC6 Workstation assists you in doing the calibration,

you need to know how instruments are calibrated; be, e.g. a

calibration technician. MC6 Workstation is a tool for calibra-

tion professionals.

Page 46

38 MC6 Workstation, User Manual – Part 5, Documenting Calibrator

INSTRUMENT LIST

When you start the Documenting Calibrator, you arrive in Instrument List window. See adjacent picture for an example of an Instrument List.

MC6 Workstation allows you to hierarchically organize your instruments into a

Plant Structure. The Instrument List window may contain both instruments (gray

items) and Plant Structure Levels (yellow items). The following sub chapters

present features available in Instrument List window and its menu.

INSTRUMENTS

Instruments have a gray background in the Instrument List window. The instrument's upper text row displays the contents of one of the following fields: Posi-

tion ID, Name, Device ID or Device Serial Number. The first non-empty of the

aforementioned fields, in presented order, is displayed. The second row displays (possible) Function Name and Calibration Due Date data.

If the instrument has been calibrated, the rightmost end displays an icon. The

displayed icon depends on whether the instrument's latest calibration

"Passed", i.e. the found maximum errors were smaller than the instrument's

"Reject If" error limit, or did it "Fail". See pictures to the right.

To select an instrument for calibration, tap on it. Then the Instrument Over-

view Window, presented on page 40, opens.

To create a new instrument, tap the "Create New Instrument" button. See picture to the right. Then several pages of instrument configuration data opens.

Note that by default only basic pages are shown. View all pages by selecting

Show, All Pages from the menu available when creating/editing an instrument.

To delete an instrument, select it and use the delete command available in the

menu of opened Instrument Overview Window, presented on page 40.

Example of an Instrument List.

Note.

The Instrument List may be several pages long. Remember to

use the page browse buttons available on the right side of the

window.

Instrument's latest calibration "Passed"

Instrument's latest calibration "Failed"

"Create New Instrument" button

Page 47

Calibrating Instruments - Instrument List 39

PLANT STRUCTURE LEVELS

The name of the current Plant Structure Level is shown on the status bar. Tap

on the bar to see the full Plant Structure path. Plant Structure Sub Levels have

yellow background and the upper right corner is folded. The Level's name is

displayed and on the lower right corner, the amount of further Sub Levels + the

amount of instruments found on the next Sub Level.

To select a Plant Structure Level, tap on it. Then the contents of that level are

displayed. To return to the previous level, tap on the "Back" button found on

the right side of the Instrument List window.

Creating and managing Plant Structure Levels is presented in chapter In-

strument List Window Menu below.

INSTRUMENT LIST WINDOW MENU

The Instrument List window's menu contains a lot of useful tools:

Create New for creating a new Instrument etc. (See adjacent picture.)

Sort for sorting the list contents alphabetically etc.

Sorting icons shown in status bar (ascending / descending):

/ / /

Identification Due Date Creation

Show to display all or filter to a selected group of items in the list. The

group can be, e.g. all calibrated instruments. When filtering is active, the

following icon is shown in the status bar:

Plant Structure for defining how the Plant Structure is shown.

Browse to jump to start/end of list or finding instruments. When find is in

use, the following icon is shown in the status bar:

Management for deleting all Instruments/Results/Plant Structure levels

and also for moving/renaming Plant Structure levels.

Current Plant Structure Level is called "Pulp".

A total of 22 instruments are located on this

Level and all its Sub Levels. Sub Level

"Evaporation" has two Sub Levels and

18 instruments.

"Back" button

Notes.

Deleting a branch level also deletes all instruments and calibrations found on that level and all its sub levels.

You cannot delete the structure root level.

Warning!

Once an item is deleted, there is no way to retrieve it.

Instrument List Window's menu

Page 48

40 MC6 Workstation, User Manual – Part 5, Documenting Calibrator

INSTRUMENT OVERVIEW WINDOW

When an instrument is selected, the Instrument Overview window opens and

general data of the selected instrument is presented. See adjacent picture.

With the help of the buttons on the right side of the window, you may

edit/check the instrument data,

view calibration results for this instrument (if applicable) or

start calibrating the selected instrument and open the calibration window

(from the check mark on green background).

The bulleted list above is presented in the same order as the icons are in In-

strument Overview window.

Note that the menu contains some useful instrument related tools.

Instrument Overview Window

CALIBRATING AN INSTRUMENT USING MC6 WORKSTATION

When you start calibrating an instrument, the Calibration window opens. See

adjacent picture. Note that a possible Before Calibration Note window may

open before the Calibration window is shown.

Before you tap the Start button, ensure that the signals are "live", i.e. measurements and the required connections are as they should. If unsure, use the

connection diagrams found in the Instrument Overview Window. It opens from

the Info button.

If gauge pressure modules are used in the calibration, remember to zero them

before starting the calibration.

Tap the Start button to begin calibration. The rest depends on the instrument

setting: Automatic Acceptance.

Button for zeroing a pressure module in the

lower right corner.

Page 49

Calibrating Instruments - Calibrating an Instrument Using MC6 Workstation 41

When Automatic Acceptance is in use (checked), MC6 Workstation accepts

calibration point automatically as follows:

1. MC6 Workstation uses the Max. Point Deviation value to see if the input signal is close enough to the next calibration point.

2. When close enough, MC6 Workstation checks the signal stability to decide whether the readings can be saved or not.

3. When signal stability is reached, a timer counts down as set in Point

Delay and then the readings are saved only if the signal stability is still

valid. See hourglass in adjacent picture. If a signal becomes unstable,

MC6 Workstation returns to phase 2.

Use the Force Accept button to manually accept points when, e.g. the calibration does not advance because of an unstable input and/or output signal.

When Automatic Acceptance is not in use, every calibration point is manually

accepted. Then tap the Accept Point button seen in the Calibration window.

See lowermost picture to the right.

As the calibration advances, the graph is drawn from point to point. A grey column indicates where next target point is. The width of the grey column is based

on Max. Point Deviation setting. Numeric values for the next target point can

be seen in the lower right corner. If any of the points exceed the error limits

(blue dotted lines), the graph is colored red.

The Pause (||) button allows you to reject a calibration or undo a point. The

button with the "speech bubble" allows you to add notes to each calibration

point. For further options, open the menu.

If you need to change the Pressure Module during the calibration, see chapter

Changing the Pressure Module During Calibration on page 42.

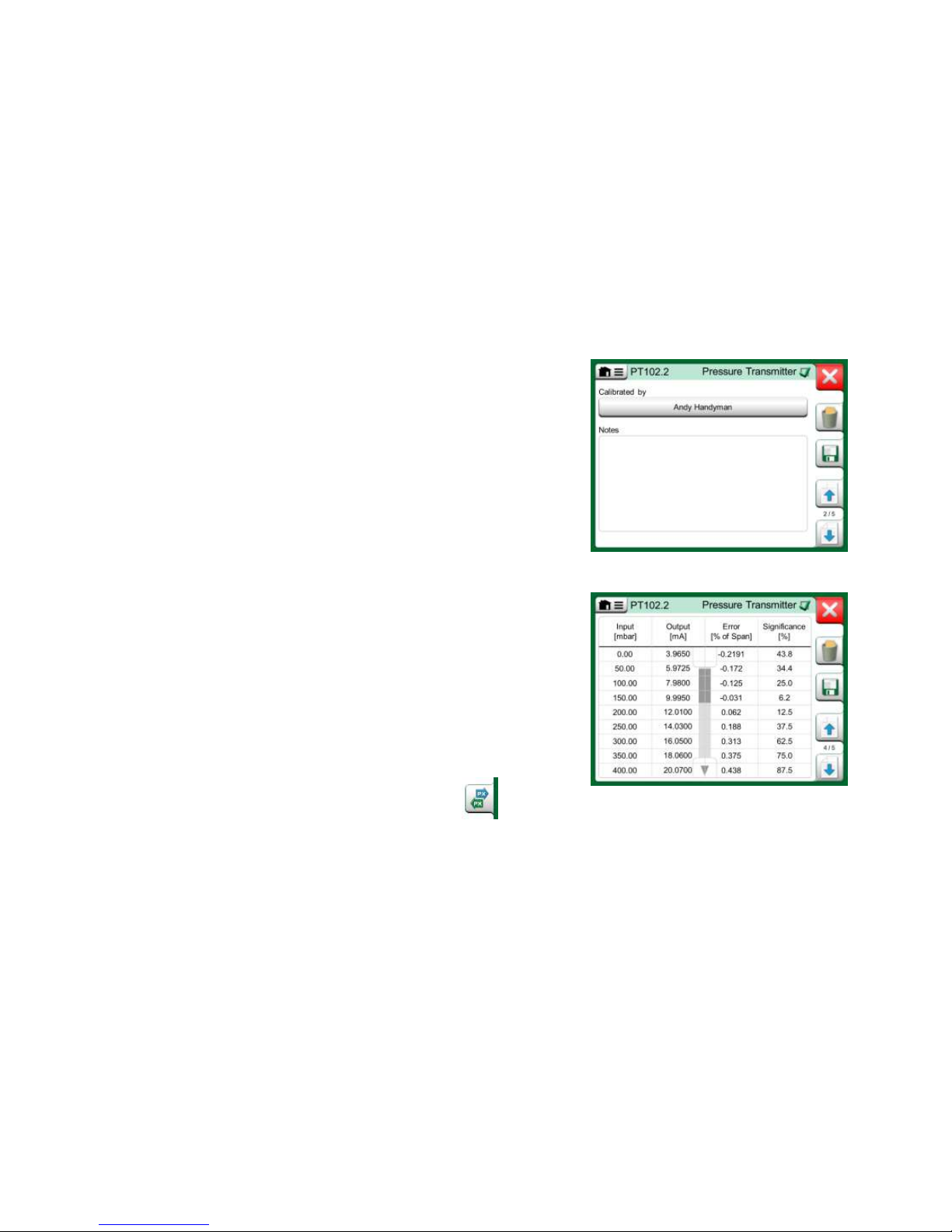

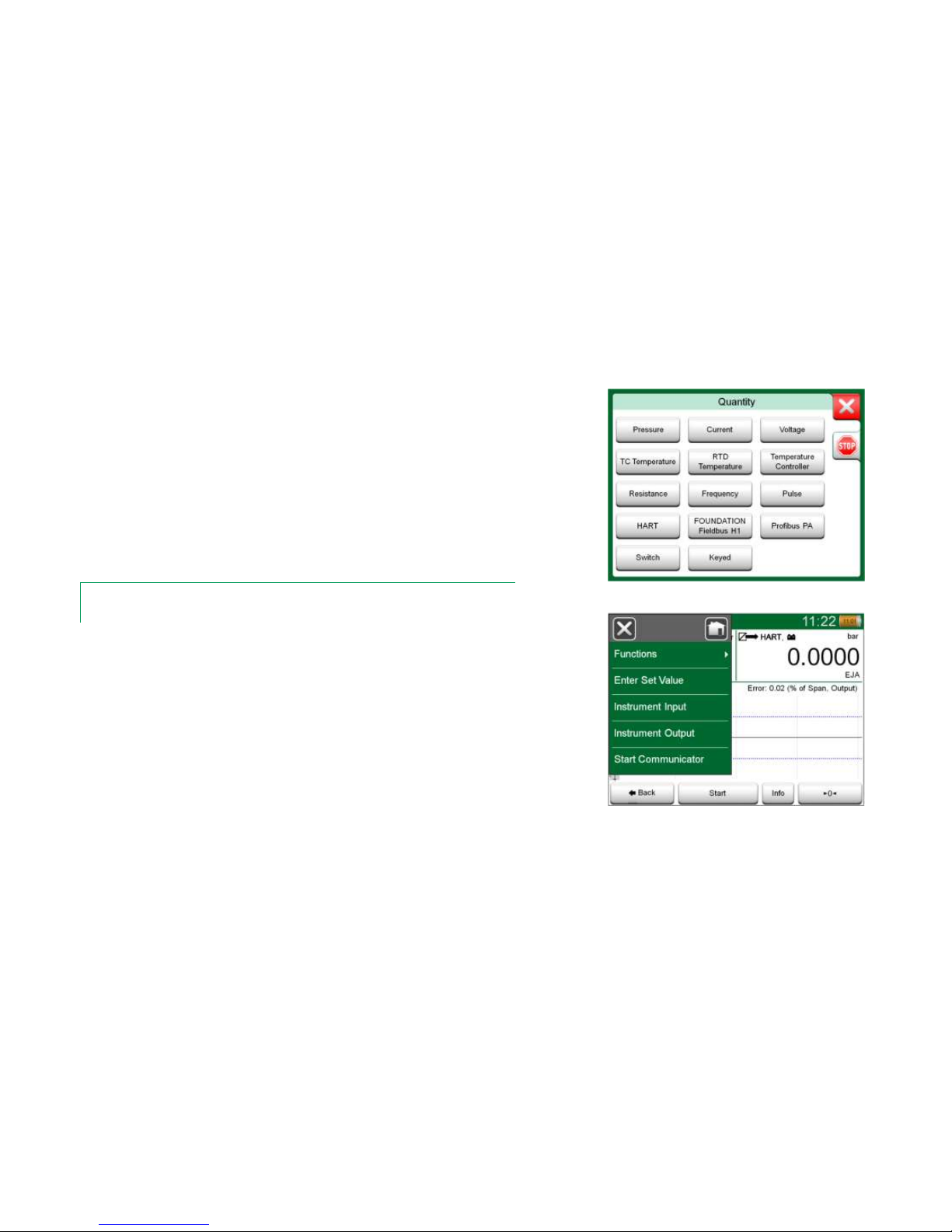

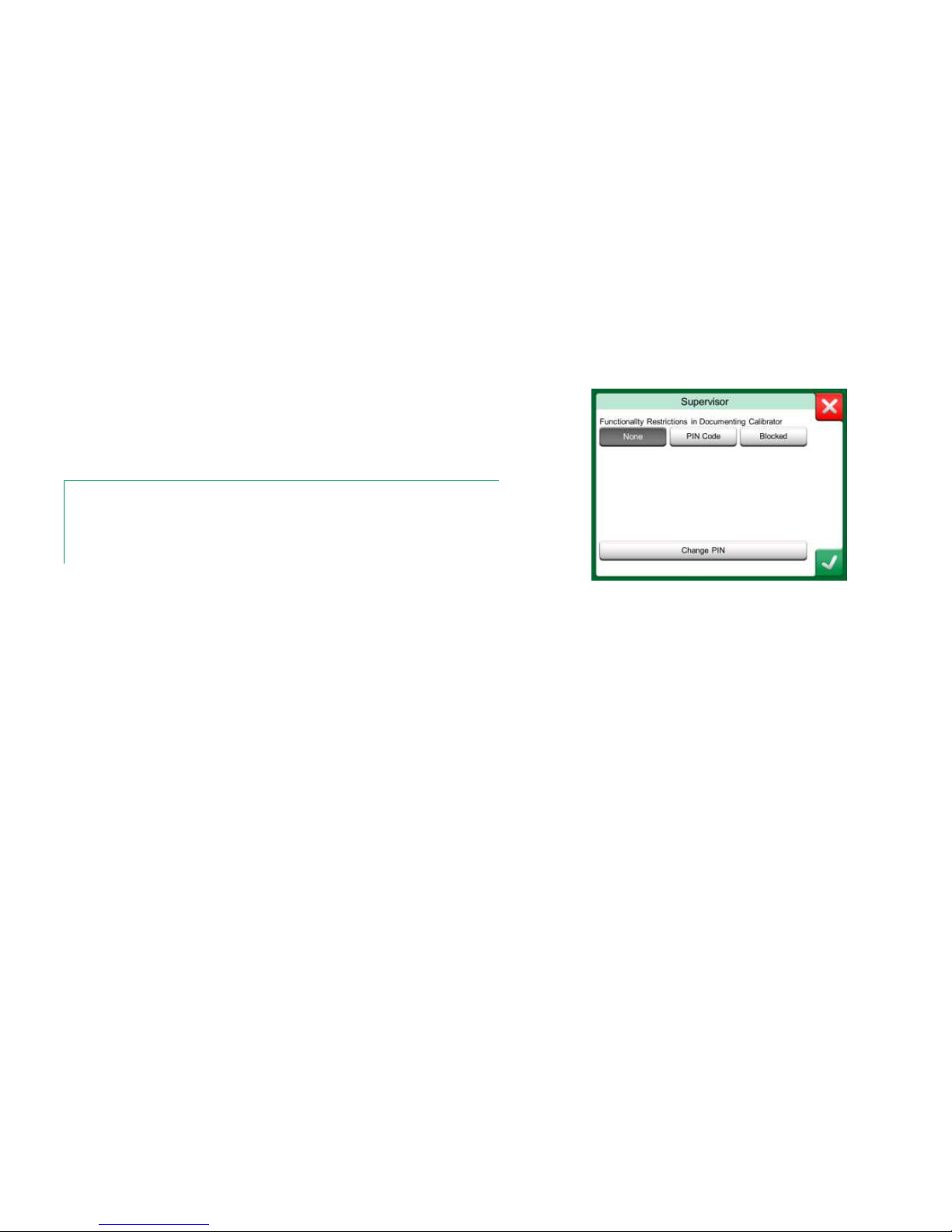

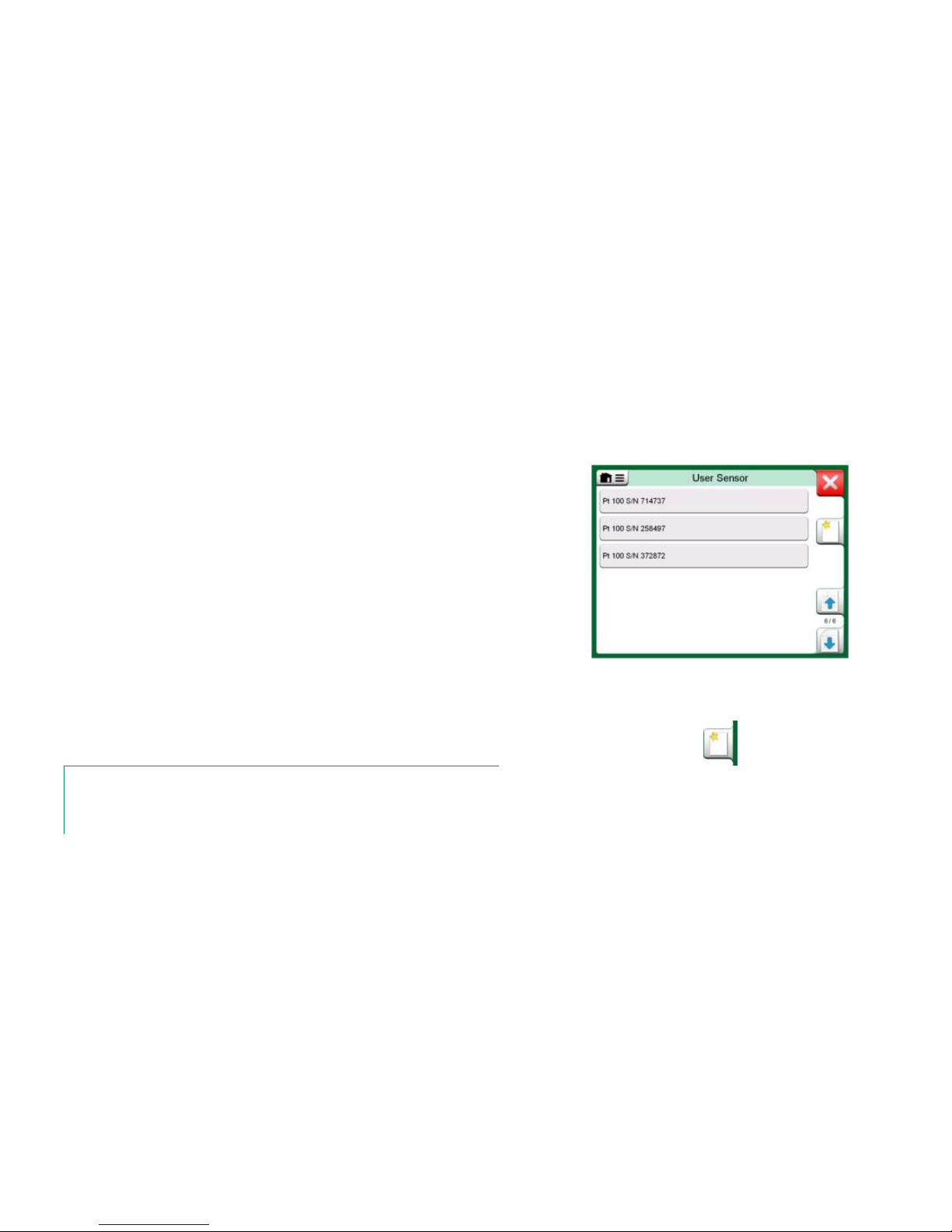

Note.