Page 1

FBXXX___tgeng0000

Field Temperature Block series

Beamex® FB150, FB350, FB660

User Guide

Page 2

FBXXX Field Temperature Block

ii

Page 3

iii

Table of Contents

1 Before You Start .......................................................................1

1.1 Introduction ............................................................................................... 1

1.2 Unpacking ................................................................................................ 2

1.3 Symbols Used ........................................................................................... 3

1.4 Safety Information ..................................................................................... 4

1.4.1 Warnings .........................................................................................................4

1.4.2 Cautions ..........................................................................................................6

1.5 CE Comments ........................................................................................... 7

1.5.1 EMC Directive .................................................................................................7

1.5.2 Immunity Testing .............................................................................................8

1.5.3 Emission Testing ..............................................................................................8

1.5.4 Low Voltage Directive (Safety) ........................................................................8

1.6 Authorized Service Centers ...................................................................... 9

2 Specications and Environmental Conditions .................... 11

2.1 Specifications ......................................................................................... 11

2.2 Environmental Conditions ....................................................................... 12

3 Quick Start .............................................................................. 13

3.1 Setup ....................................................................................................... 13

3.2 Parts and Controls .................................................................................. 14

3.2.1 Display Panel ................................................................................................15

3.2.2 Display ..........................................................................................................16

3.2.3 Power Panel ..................................................................................................17

3.2.4 -R Option Panel (-R models only) ..................................................................20

3.3 Languages .............................................................................................. 21

3.3.1 Language Selection ......................................................................................22

3.3.2 Reset to English Language ...........................................................................22

4 Menu Structure .......................................................................23

4.1 Temp Setup Menu ................................................................................... 23

4.2 Prog Menu .............................................................................................. 24

4.3 System Menu .......................................................................................... 25

4.4 Input Setup (-R only) ............................................................................... 26

5 Controller operation...............................................................27

Page 4

FBXXX Field Temperature Block

iv

5.1 Main Screen ............................................................................................ 27

5.2 Main Menu .............................................................................................. 28

5.2.1 Temp Setup ................................................................................................... 28

5.2.2 Prog Menu .....................................................................................................30

5.2.3 System Menu .................................................................................................32

5.2.4 INPUT SETUP (-R model only) ......................................................................38

6 Digital communication interface...........................................43

6.1 Wiring ...................................................................................................... 43

6.1.1 Setup .............................................................................................................43

6.1.2 Serial Operation ............................................................................................43

6.2 Command Syntax ................................................................................... 44

6.3 Commands by Function or Group .......................................................... 45

6.4 Serial Commands - Alphabetic Listing ................................................... 48

6.5 Non-SCPI Process Commands ............................................................... 66

6.6 Non-SCPI Commands by Function or Group ......................................... 66

7 Troubleshooting .....................................................................69

8 Maintenance ...........................................................................71

8.1 Field Temperature Block Performance Analysis ..................................... 71

Page 5

v

Tables

Table 1 Symbols used ........................................................................................ 3

Table 2 Base Unit Specifications ..................................................................... 11

Table 3 -R Option Specifications .................................................................... 12

Table 4 Matching Certificate Values to ITS-90 Coefficients ............................. 39

Table 5 Setting Coefficients Rtpw, a8, b8, and b4 ........................................... 39

Table 6 Commands by Function or Group ....................................................... 45

Table 7 PROG:SEQ:PAR parameters ............................................................... 55

Table 8 Troubleshooting, problems, causes and solutions .............................. 69

Page 6

FBXXX Field Temperature Block

vi

Figures

Figure 1 Clamp-on ferrite installation ................................................................ 8

Figure 2 FBXXX Field Temperature Block ........................................................ 14

Figure 3 Display panel and keys ..................................................................... 16

Figure 4 FBXXX display ................................................................................... 17

Figure 5 FB150 power panel ........................................................................... 19

Figure 6 FB350 and FB660 power panel ......................................................... 19

Figure 7 -R option panel ................................................................................. 20

Figure 8 Probe connector wiring ..................................................................... 21

Figure 9 Steps to language selection .............................................................. 22

Figure 10 Main Menu - Temp SetUp ................................................................ 23

Figure 11 Main Menu - Prog Menu .................................................................. 24

Figure 12 Main Menu - System Menu .............................................................. 25

Figure 13 Main Menu - Input Setup ................................................................ 26

Figure 14 RS-232 wiring .................................................................................. 44

Page 7

1

Before You Start

Introduction

1 Before You Start

1.1 Introduction

Field Temperature Blocks (FB150, FB350, and FB660) are designed to be reliable,

stable heat sources that can be used in the eld or laboratory. They offer accuracy,

portability, and speed for nearly every eld calibration application. The instruments

have been designed with the eld user in mind and are easy to use while maintaining

stability, uniformity, and accuracy comparable to some laboratory instruments.

Special built-in features make Field Temperature Blocks extremely adaptable. The

exclusive Voltage Compensation allows the technician to plug into mains power with

voltage from 90 V ac to 250 V ac without degradation to the instrument. The Ambient

Temperature Compensation provides the largest operating range in the industry (0°C

to 50°C) with the largest guaranteed temperature range (13°C to 33°C). The Gradient Temperature Compensation keeps the axial gradient within specication over the

entire temperature range of the instrument and over the specied guaranteed operating temperature range. These combined features along with the rugged design, light

weight, and small size make this line of instruments ideal for eld applications.

Unique Patent Pending safety features make these the safest eld heat sources available. The unique Air Flow Design keeps the probe handle cool protecting delicate

instruments and the user. The Block Temperature Indicator shows the user when the

well temperature is above 50°C letting the user know when it is safe to remove the

insert or move the instrument. The indicator light illuminates when the instrument is

energized and the well is above 50°C. If the instrument is removed from mains power,

the indicator light ashes until the well has cooled to less than 50°C.

The optional “-R” version (“FBXXX-R”) combines the heat source with a built-in

reference.

The Field Temperature Blocks’ controller uses a PRT sensor and thermoelectric modules or heaters to achieve stable, uniform temperatures throughout the block.

The LCD display continuously shows many useful operating parameters including the

block temperature, the current set-point, block stability, and heating and cooling status.

For the -R version, the reference temperature readings are displayed. The display can

be set to show the information in one of eight different languages; English, Japanese,

Chinese, German, Spanish, French, Russian, and Italian.

The instrument’s rugged design and special features make them ideal for the eld or

the laboratory. With proper use, the instrument provides continued accurate calibration

of temperature sensors and devices. Before use, the user should be familiar with the

warnings, cautions, and operating procedures of the block as described in the User’s

Guide.

Page 8

FBXXX Field Temperature Blocks

Unpacking

2

1.2 Unpacking

Unpack the instrument carefully and inspect it for any damage that may have occurred

during shipment. If there is shipping damage, notify the carrier immediately.

Verify that the following components are present:

FB150

FB150 Field Temperature Block

Insert: FB150-MH2, FB150-MH1, or FB150-B

Power Cord

RS-232 Cable

User Guide

Calibration Certicate and calibration label

LEMO Connector (-R model only)

Well Insulator

Clamp-on ferrites (3) [-R model only]

Tongs (insert removal tool)

FB350

FB350 Field Temperature Block

Insert: FB350-MH2, FB350-MH1, or FB350-B

Power Cord

RS-232 Cable

User Guide

Calibration Certicate and calibration label

LEMO Connector (-R model only)

Clamp-on ferrites (3) (-R model only)

Tongs (insert removal tool)

FB660

FB660 Field Temperature Block

Insert: FB660-MH2, FB660-MH1, or FB660-B

Power Cord

RS-232 Cable

User Guide

Calibration Certicate and calibration label

LEMO Connector (-R model only)

Clamp-on ferrites (3) [-R model only]

Tongs (insert removal tool)

Page 9

3

Before You Start

Symbols Used

If all items are not present, contact an Authorized Service Center (see Section 1.6Authorized Service Centers on page 9).

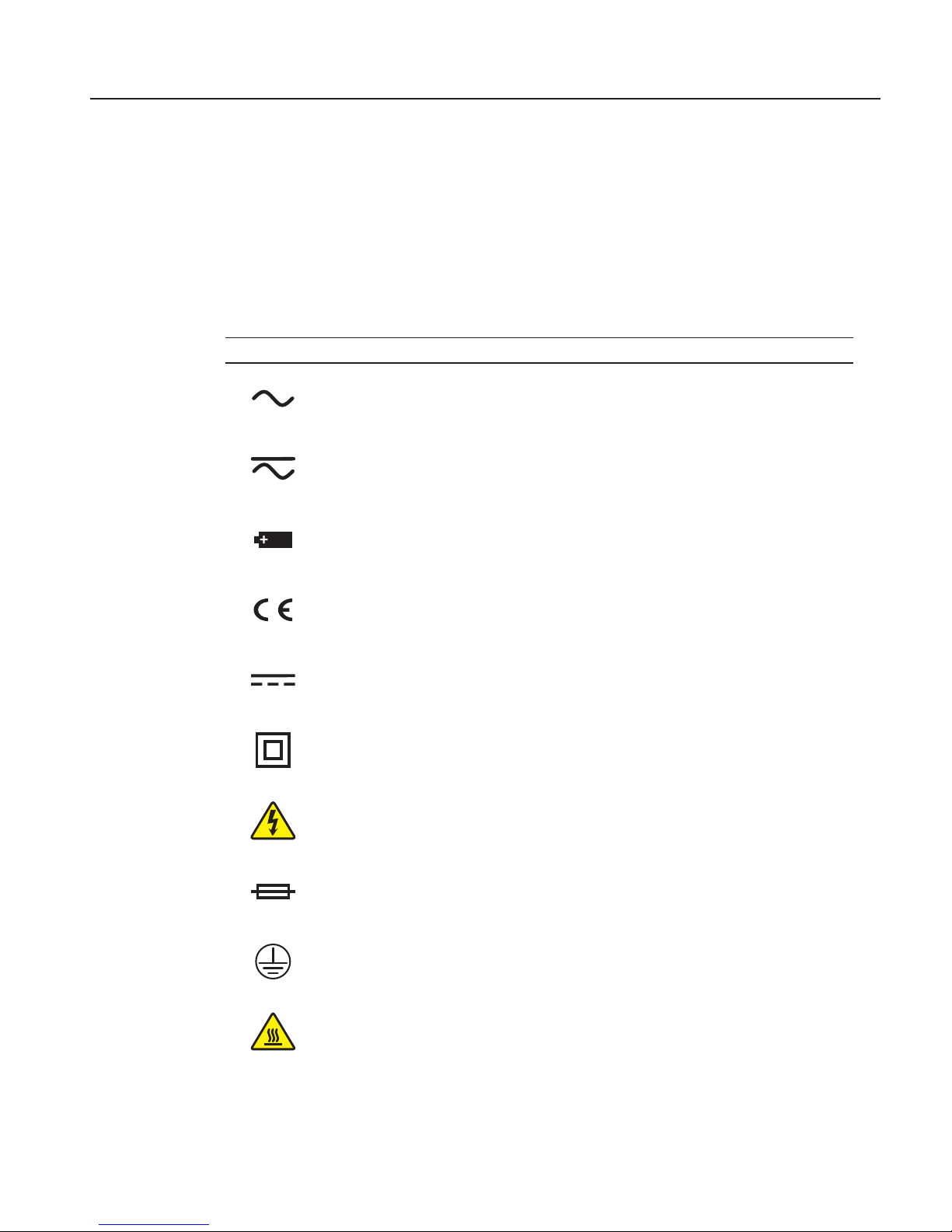

1.3 Symbols Used

Table 1 lists the International Electrical Symbols. Some or all of these symbols may be

used on the instrument or in this guide.

Table 1 Symbols used

Symbol Description

AC (Alternating Current)

AC-DC

Battery

Complies with European Union directives

DC

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface (Burn Hazard)

Page 10

FBXXX Field Temperature Blocks

Safety Information

4

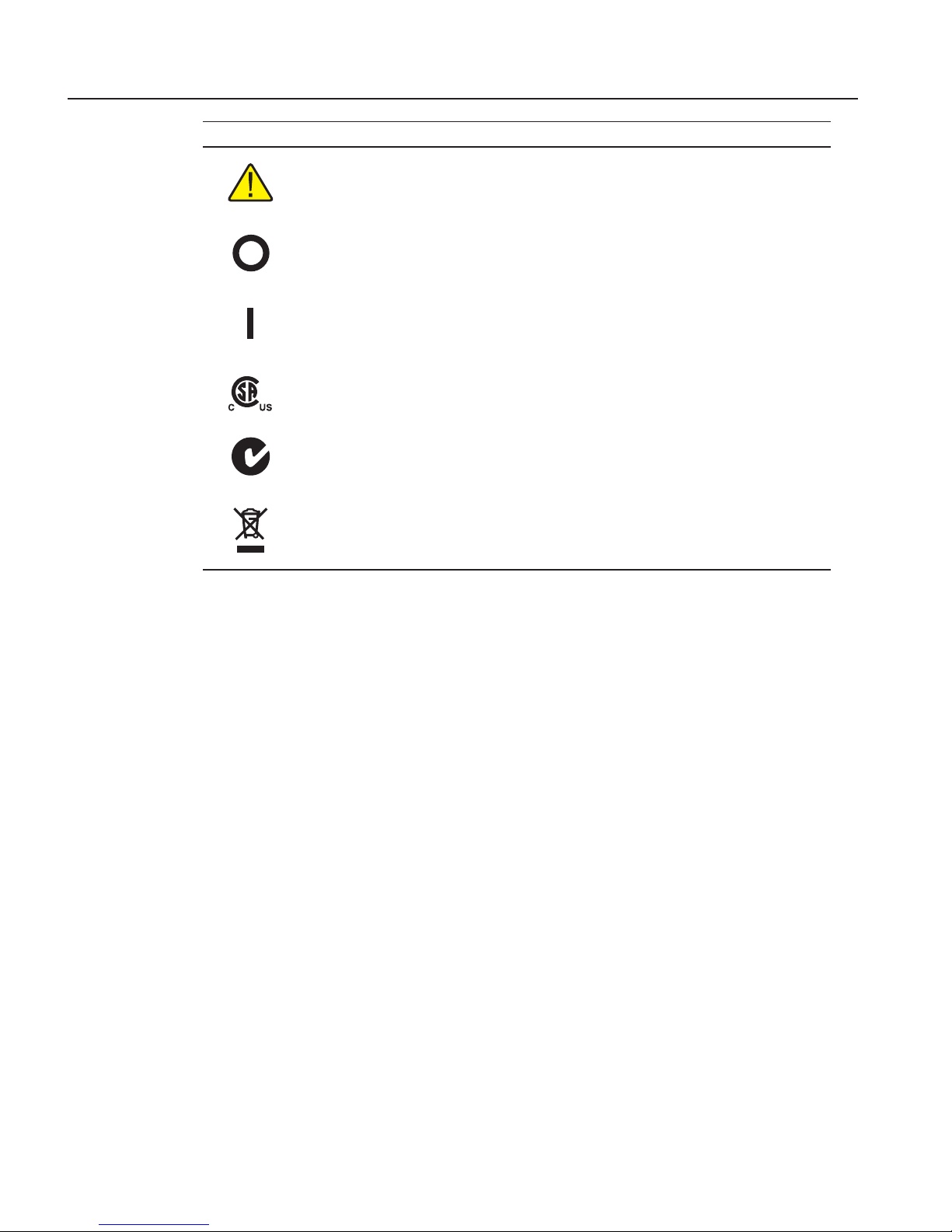

Symbol Description

Read the User’s Guide (Important Information)

Off

On

Canadian Standards Association

C-TICK Australian EMC mark

The European Waste Electrical and Electronic Equipment (WEEE) Directive (2002/96/

EC) mark.

1.4 Safety Information

Field Temperature Blocks are designed in accordance with IEC 61010-1, IEC 610102-010 and CAN/CSA 22.2 No 61010.1-04. Use this instrument only as specied in this

manual. Otherwise, the protection provided by the instrument may be impaired. Refer

to the safety information in the Warnings and Cautions sections below.

The following denitions apply to the terms “Warning” and “Caution”.

“Warning” identies conditions and actions that may pose hazards to the user.

“Caution” identies conditions and actions that may damage the instrument

being used.

1.4.1 Warnings

To avoid personal injury, follow these guidelines.

GENERAL

DO NOT use this instrument in environments other than those listed in the User’s

Guide.

Inspect the instrument for damage before each use. Inspect the case. Look for cracks

or missing plastic. DO NOT use the instrument if it appears damaged or operates

abnormally.

Page 11

5

Before You Start

Safety Information

Follow all safety guidelines listed in the User’s Guide.

Calibration equipment should only be used by trained personnel.

If this equipment is used in a manner not specied by the manufacturer, the protection

provided by the equipment may be impaired.

Before initial use, or after transport, or after storage in humid or semi-humid environments, or anytime the instrument has not been energized for more than 10 days, the

instrument needs to be energized for a “dry-out” period of 2 hours before it can be

assumed to meet all of the safety requirements of the IEC 1010-2. If the product is wet

or has been in a wet environment, take necessary measures to remove moisture prior

to applying power such as storage in a low humidity temperature chamber operating at

50°C for 4 hours or more.

DO NOT use this instrument for any application other than calibration work. The

instrument was designed for temperature calibration. Any other use of the instrument

may cause unknown hazards to the user.

DO NOT place the instrument under a cabinet or other structure. Overhead clearance

is required. Always leave enough clearance to allow for safe and easy insertion and

removal of probes.

Use of this instrument at HIGH TEMPERATURES for extended periods of time

requires caution.

Completely unattended high temperature operation is not recommended due to safety

hazards that can arise.

This instrument is intended for indoor use only.

Follow all safety procedures for the test and calibration equipment you use.

Do not use the instrument if it operates abnormally. Protection may be impaired. When

in doubt, have the instrument serviced.

DO NOT operate the Field Temperature Block around explosive gas, vapor, or dust.

DO NOT operate instrument at orientations other than upright. Tilting the instrument

or laying it down on its side during use could create a re hazard.

BURN HAZARD

The instrument is equipped with a Block Temperature Indicator (front panel LED

HOT indicator) even when the instrument is unplugged. When the indicator is ashing, the instrument is disconnected from mains power and the temperature of the block

is above 50°C. When the indicator is illuminated, always on, the instrument is powered and the block temperature is above 50°C.

DO NOT turn the instrument upside down with the inserts in place; the inserts will

fall out.

DO NOT operate near ammable materials.

Page 12

FBXXX Field Temperature Blocks

Safety Information

6

Use of this instrument at HIGH TEMPERATURES for extended periods of time

requires caution.

DO NOT touch the well access surface of the instrument.

The block vent may be very hot due to the fan blowing across the heater block of the

instrument.

The temperature of the well access is the same as the actual display temperature, e.g. if

the instrument is set to 600°C and the display reads 600°C, the well is at 600°C.

Probes and inserts may be hot and should only be inserted and removed from the

instrument when the instrument indicates temperatures less than 50°C.

DO NOT turn off the instrument at temperatures higher than 100°C. This could create

a hazardous situation. Select a set-point less than 100°C and allow the instrument to

cool before turning it off.

The high temperatures present in Field Temperature Blocks designed for operation

at 300°C and higher may result in res and severe burns if safety precautions are not

observed.

ELECTRICAL HAZARD

These guidelines must be followed to ensure that the safety mechanisms in this instrument operate properly. This instrument must be plugged into an AC only electric outlet

according to Table 2, Specications . The power cord of the instrument is equipped

with a grounding plug for your protection against electrical shock hazards. It must be

plugged directly into a properly grounded receptacle. The receptacle must be installed

in accordance with local codes and ordinances. Consult a qualied electrician. DO

NOT use an extension cord or adapter plug.

If supplied with user accessible fuses, always replace the fuse with one of the same

rating, voltage, and type.

Always replace the power cord with an approved cord of the correct rating and type.

HIGH VOLTAGE is used in the operation of this equipment. SEVERE INJURY or

DEATH may result if personnel fail to observe safety precautions. Before working

inside the equipment, turn power off and disconnect power cord.

1.4.2 Cautions

To avoid possible damage to the instrument, follow these guidelines:

DO NOT leave the inserts in the instrument for prolonged periods. Due to the high

operating temperatures of the instrument, the inserts should be removed after each use

and buffed with a Scotch-Brite® pad or emery cloth (see Section 8Maintenance on

page 71).

Always operate this instrument at room temperature between 5°C and 50°C (41°F to

122°F). Allow sufcient air circulation by leaving at least 15 cm (6 in) of clearance

Page 13

7

Before You Start

CE Comments

around the instrument. Overhead clearance of 1 meter (3 ft) is required. DO NOT

place instrument under any structure.

Component lifetime can be shortened by continuous high temperature operation.

DO NOT use uids to clean out the well. Fluids could leak into electronics and damage the instrument.

Never introduce any foreign material into the probe hole of the insert. Fluids, etc. can

leak into the instrument causing damage.

Unless recalibrating the instrument DO NOT change the values of the calibration constants from the factory set values. The correct setting of these parameters is important

to the safety and proper operation of the block.

DO NOT allow the probe sheath or inserts to drop into the well. This type of action

can cause a shock to the sensor and affect the calibration.

The instrument and any thermometer probes used with it are sensitive instruments that

can be easily damaged. Always handle these devices with care. DO NOT allow them

to be dropped, struck, stressed, or overheated.

DO NOT operate this instrument in an excessively wet, oily, dusty, or dirty environment. Always keep the well and inserts clean and clear of foreign material.

The Field Temperature Block is a precision instrument. Although it has been designed

for optimum durability and trouble free operation, it must be handled with care. Al-

ways carry the instrument in an upright position to prevent the inserts from dropping

out. The convenient handle allows for hand carrying the instrument.

If a mains supply power uctuation occurs, immediately turn off the instrument.

Power bumps from brown-outs could damage the instrument. Wait until the power has

stabilized before re-energizing the instrument.

The probe and the block may expand at different rates. Allow for probe expansion

inside the well as the block heats. Otherwise, the probe may become stuck in the well.

Most probes have handle temperature limits. If the probe handle limits are exceeded,

the probe may be permanently damaged. Due to a unique Air Flow Design, Field Tem-

perature Blocks protect the probe handle temperature and provide a safer temperature

handle for the user.

1.5 CE Comments

1.5.1 EMC Directive

Beamex equipment has been tested to meet the European Electromagnetic Compatibility Directive (EMC Directive, 89/336/EEC). The Declaration of Conformity for your

instrument lists the specic standards to which the instrument was tested.

Page 14

FBXXX Field Temperature Blocks

CE Comments

8

The instrument was designed specically as a test and measuring device. Compliance

to the EMC directive is through IEC 61326-1 Electrical equipment for measurement,

control and laboratory use.

As noted in the IEC 61326-1, the instrument can have varying congurations. The

instrument was tested in a typical conguration with shielded RS-232 cables.

1.5.2 Immunity Testing

Using Clamp-On Ferrites

For the –R model only, clamp-on ferrites are provided for use in improving its electromagnetic (EM) immunity in environments of excessive EM interference. During EMC

testing we found that ferrites clamped around probe cables for the Reference PRT input reduced the risk the EM interference affects measurements. Therefore, we recommend that the clamp-on ferrites provided be used on the cables of probes attached to

the readout, especially if the product is used near sources of EM interference such as

heavy industrial equipment.

To attach a ferrite to a probe cable, make a loop in the cable near the connector and

clamp the ferrite around half of the loop as shown in the diagram. The ferrite can be

easily snapped open and moved to a new probe when needed.

Figure 1

clamp-on ferrite

connector

probe

Clamp-on ferrite installation

1.5.3 Emission Testing

The instrument fullls the limit requirements for Class A equipment. The instrument

was not designed to be used in domestic establishments.

1.5.4 Low Voltage Directive (Safety)

In order to comply with the European Low Voltage Directive (2006/95/EC), Beamex equipment has been designed to meet the EN 61010-1 and the EN 61010-2-010

standards.

Page 15

9

Before You Start

Authorized Service Centers

1.6 Authorized Service Centers

Please contact the following Authorized Service Center to coordinate service on your

Beamex product:

Beamex Oy Ab

Ristisuonraitti 10

FI-68600 Pietarsaari

Finland

When contacting a Service Centers for support, please have the following information

available:

Model Number

Serial Number

Voltage

Complete description of the problem

Page 16

Page 17

11

Specications and Environmental Conditions

Specications

2 Specications and Environmental Conditions

2.1 Specications

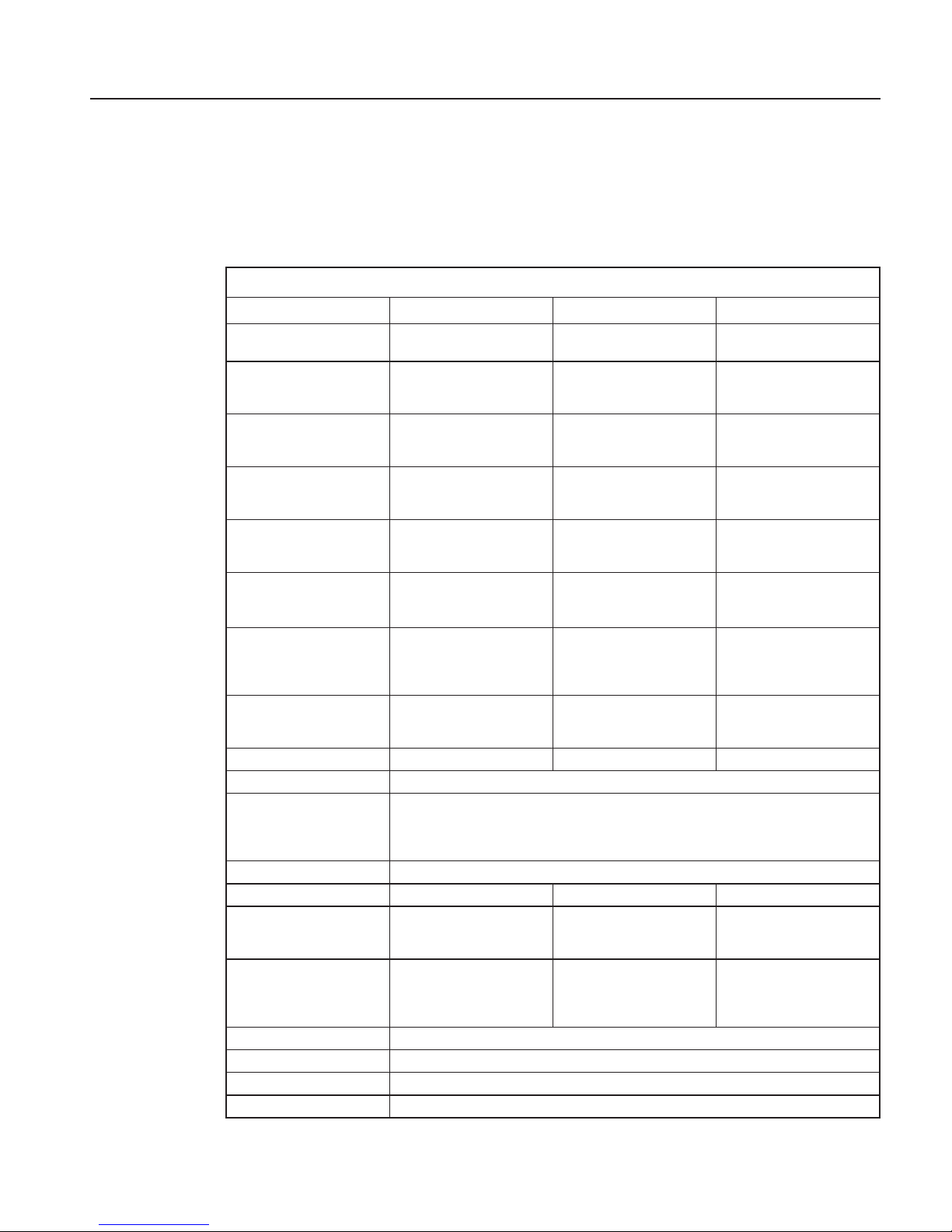

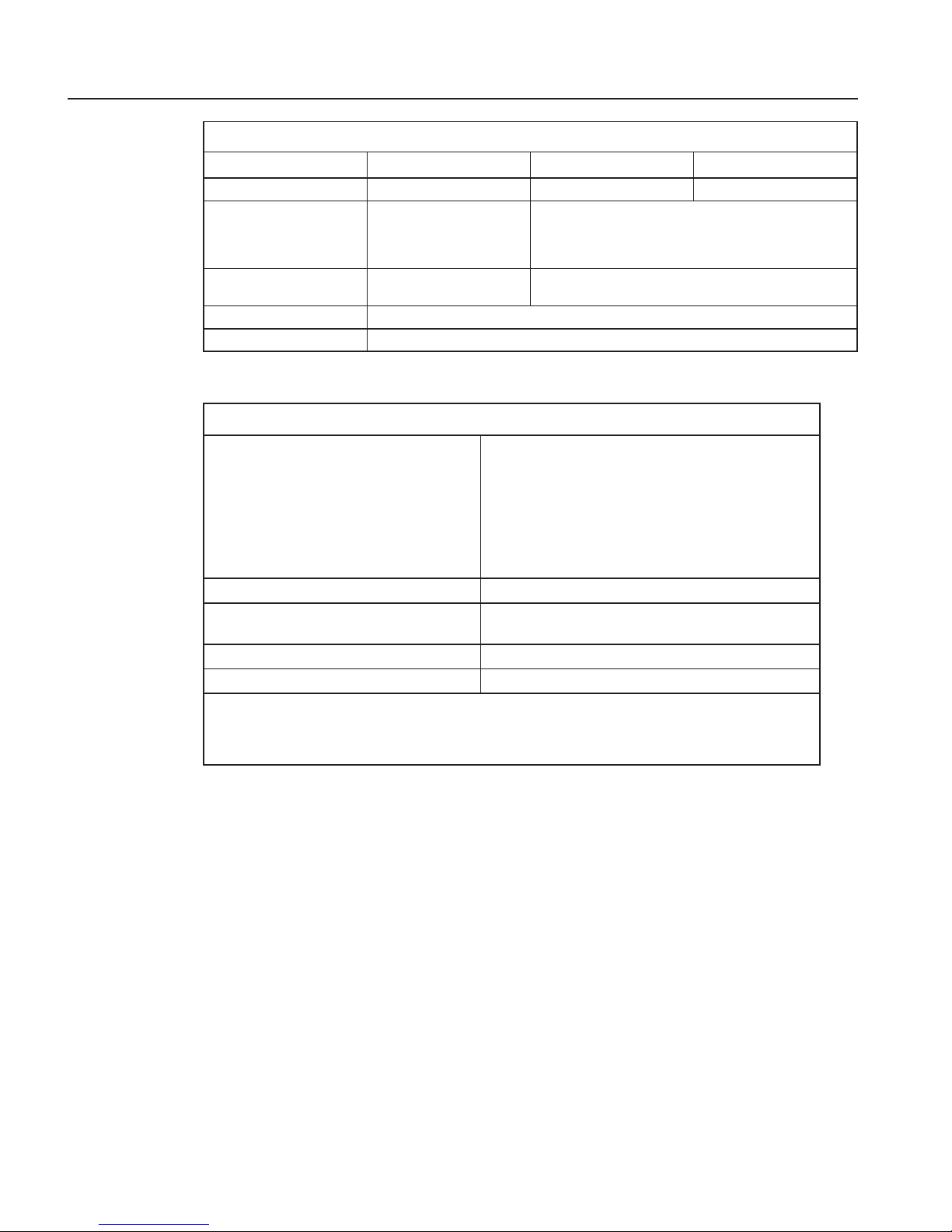

Table 2 Base Unit Specifications

Base Unit Specifications

FB150 FB350 FB660

Temperature Range at

23°C

–25°C to 150°C

(-13°F to 302°F)

33°C to 350°C

(91°F to 662°F)

50°C to 660°C

(122°F to 1220°F)

Display Accuracy ±0.2°C Full Range ±0.2°C Full Range ±0.35°C at 50°C

±0.35°C at 420°C

±0.5°C at 660°C

Stability ±0.01°C Full Range ±0.02 °C at 33°C

±0.02 °C at 200°C

±0.03°C at 350°C

±0.03°C at 50°C

±0.05°C at 420°C

±0.05°C at 660°C

Axial Uniformity at 40

mm (1.6 in)

±0.05°C Full Range ±0.04°C at 33°C

±0.1°C at 200°C

±0.2°C at 350°C

±0.05°C at 50°C

±0.35°C at 420°C

±0.5°C at 660°C

Axial Uniformity at 60

mm (2.4 in)

±0.07°C Full Range ±0.04°C at 33°C

±0.2°C at 200°C

±0.25°C at 350°C

±0.1°C at 50°C

±0.6°C at 420°C

±0.8°C at 660°C

Radial Uniformity ±0.01°C Full Range ±0.01°C at 33°C

±0.015°C at 200°C

±0.02°C at 350°C

±0.02°C at 50°C

±0.05°C at 420°C

±0.1°C at 660°C

Loading Effect (with

a 6.35 mm reference

probe and three 6.35

mm probes)

±0.006°C Full Range ±0.015°C Full Range ±0.015°C at 50°C

±0.025°C at 420°C

±0.035°C at 660°C

Loading Effect (versus

display with 6.35 mm

probes)

±0.08°C Full Range ±0.2°C Full Range ±0.1°C at 50°C

±0.2°C at 420°C

±0.2°C at 660°C

Hysteresis 0.025°C 0.06°C 0.2°C

Operating Conditions 0°C to 50°C, 0% to 90% RH (non-condensing)

Environmental

conditions for all

specications except

temperature range

13°C to 33°C

Immersion (Well) Depth 150 mm (5.9 in)

Insert OD 30 mm (1.18 in) 25.3 mm (1.00 in) 24.4 mm (0.96 in)

Heating Time 16 min: 23°C to 140°C

23 min: 23°C to 150°C

25 min: –25°C to 150°C

5 min: 33°C to 350°C 15 min: 50°C to 660°C

Cooling Time 15 min: 23°C to –25°C

25 min: 150°C to –23°C

32 min: 350°C to 33°C

14 min: 350°C to 100°C

35 min: 660°C to 50°C

25 min: 660°C to 100°C

Resolution 0.01°

Display LCD,°C or°F user-selectable

Key Pad Arrows, Menu, Enter, Exit, 4 soft keys

Size (H x W x D) 290 mm x 185 mm x 295 mm (11.4 x 7.3 x 11.6 in)

Page 18

FBXXX Field Temperature Block

Environmental Conditions

12

Base Unit Specifications

FB150 FB350 FB660

Weight 8.16 kg (18 lbs) 7.3 kg (16 lbs) 7.7 kg (17 lbs)

Power Requirements 100 V to 115 V (±10%)

50/60 Hz, 575 W

230 V (±10%) 50/60 Hz,

575 W

100 V to 115 V (±10%), 50/60 Hz, 1400 W

230 V (±10%), 50/60 Hz, 1800 W

System Fuse Ratings 115 V: 6.3 A T 250 V

230 V: 3.15 A T 250 V

15 A, 250 V Thermal Circuit Breakers

Computer Interface RS-232

Safety EN 61010-1:2001, CAN/CSA C22.2 No. 61010.1-04

Table 3 -R Option Specifications

-R Specifications

Built-in Reference Thermometer Readout

Accuracy

(4-Wire Reference Probe)

†

± 0.013 °C at -25 °C

± 0.015 °C at 0 °C

± 0.020 °C at 50 °C

± 0.025 °C at 150 °C

± 0.030 °C at 200 °C

± 0.040 °C at 350 °C

± 0.050 °C at 420 °C

± 0.070 °C at 660 °C

Reference Resistance Range 0 ohms to 400 ohms

Reference Resistance Accuracy‡ 0 ohms to 42 ohms: ±0.0025 ohms

42 ohms to 400 ohms: ±60 ppm of reading

Reference Characterizations ITS-90, CVD, IEC-60751, Resistance

Reference Measurement Capability 4-wire

†

The temperature range may be limited by the reference probe connected to the readout. The BuiltIn Reference Accuracy does not include the sensor probe accuracy. It does not include the probe

uncertainty or probe characterization errors.

‡

Measurement accuracy specications apply within the operating range and assume 4-wires for PRTs.

2.2 Environmental Conditions

Although the instrument has been designed for optimum durability and trouble-free

operation, it must be handled with care. The instrument should not be operated in an

excessively dusty or dirty environment. Maintenance and cleaning recommendations

can be found in the Maintenance section. The instrument operates safely under the following environmental conditions:

ambient temperature range: 0-50°C (32-122°F)

ambient relative humidity: 0 % to 90 % (non-condensing)

mains voltage: within ±10% of nominal

vibrations in the calibration environment should be minimized

altitude: less than 2,000 meters

indoor use only

Page 19

13

Quick Start

Setup

3 Quick Start

3.1 Setup

Note: The instrument will not heat, cool, or control until the “SET PT.”

parameter is “Enabled”.

Place the block on a at surface with at least 15 cm (6 in) of free space around the instrument. Overhead clearance is required. DO NOT place under a cabinet or structure.

Plug the instrument power cord into a mains outlet of the proper voltage, frequency,

and current capability (see Section 2.1, Specications, on page 11 for power details).

Observe that the nominal voltage corresponds to that indicated on the front of the

block.

Carefully place the insert into the well. Inserts should be of the smallest hole diameter possible still allowing the probe to slide in and out easily. Various insert sizes

are available. Contact an Authorized Service Center for assistance (see Section 1.6,

Authorized Service Centers, on page 9). The well must be clear of any foreign objects,

dirt and grit before an insert is installed. The insert is installed with the two small tong

holes positioned upward.

Turn on the power to the block by toggling the switch on the power entry module.

After a brief self-test, the controller should begin normal operation. The main screen

appears within 30 seconds. If the instrument fails to operate, please check the power

connection. The display shows the well temperature, and waits for user input before

further operation.

Press “SET PT.” and use the arrow keys to set the desired set-point temperature. Press

“ENTER” to save the desired set-point and enable the instrument. After ve (5) seconds, the instrument should start to operate normally and heat or cool to the designated

set-point.

Page 20

FBXXX Field Temperature Block

Parts and Controls

14

Figure 2 FBXXX Field Temperature Block

3.2 Parts and Controls

This section describes the exterior features of the Field Temperature Block. All interface and power connections are found on the front of the instrument (see Figure 2).

Page 21

15

Quick Start

Parts and Controls

3.2.1 Display Panel

Figure 3 on next page shows the layout of the display panel.

Display (1)

The display is a 240 x 160 pixel monochrome graphics LCD device with a bright LED

backlight. The display is used to show current control temperature, measurements,

status information, operating parameters, and soft key functions.

udlr Arrow Keys (2)

The Arrow Keys allow you to move the cursor on the display, change the display layout, and adjust the contrast of the display. The contrast can only be adjusted using the

u and d arrow keys while viewing the main display window.

Enter Key (3)

The Enter Key allows you to select menus and accept new values.

SET PT. (4)

The Set Pt. Key allows you to enable the instrument to heat or cool to a desired setpoint. Until this key is enabled, the instrument will not heat or cool. It is in a “sleep”

state for safety of the operator and instrument.

°C/°F Key (5)

The °C/°F Key allows you to change the displayed temperature units from °C to °F

and vice versa.

Menu Key (6)

The Menu Key allows the user to access all parameter and settings menus. From the

main menu, the user can use the soft keys to access submenus and functions.

Exit Key (7)

The Exit Key allows you to exit menus and cancel newly entered values.

Soft Keys (8)

The Soft Keys are the four buttons immediately below the display (labeled F1 to F4).

The functions of the soft keys are indicated on the display above the buttons. The

function of the keys may change depending on the menu or function that is selected.

Page 22

FBXXX Field Temperature Block

Parts and Controls

16

Block Temperature Indicator (9)

The Block Temperature Indicator lamp allows users to know when the block temperature is safe (50°C to 60°C) to remove inserts or move the Field Temperature Block.

The indicator light is lit continuously once the block has exceeded approximately

50°C (varies 50°C to 60°C). The indicator light stays lit until the block cools to less

than approximately 50°C. If the instrument is disconnected from mains power, the

indicator light ashes until the block temperature is less than approximately 50°C.

Figure 3 Display panel and keys

3.2.2 Display

The front panel display is shown in detail in Figure 4 on opposite page.

Heat Source Temperature (1)

The most recent block temperature measurement is shown in large digits in the box at

the top of the screen.

Set-point Temperature (2)

The current set-point temperature is displayed just below the Process Temperature.

Reference Thermometer Temperature (3) [-R models only]

When installed, the most recent reference thermometer measurement is shown on the

screen.

Page 23

17

Quick Start

Parts and Controls

Stability Status (4)

On the right hand side of the screen, you will nd a graph displaying the current status

of the stability of the Field Temperature Block.

Heating/Cooling Status (5)

Just below the stability graph there is a bar graph that will indicate HEATING, COOLING, or CUTOUT. This status graph indicates the current level of heating or cooling if

the instrument is not in cutout mode.

Soft Key Functions (6)

The four texts at the bottom of the display (not shown) indicate the functions of the

soft keys (F1–F4). These functions change with each menu.

Editing Windows

While setting up and operating the instrument, you are often required to enter or select

parameters. Editing windows appear on the screen when necessary to show the values

of parameters and allow edits.

Figure 4 FBXXX display

3.2.3 Power Panel

The following are found on the lower front panel of the instrument (see Figures 5 and

Figure 6 on page 19).

Page 24

FBXXX Field Temperature Block

Parts and Controls

18

Power Cord Plug (1)

The power supply cord attaches to the lower front power panel. Plug the cord into an

AC mains supply appropriate for the voltage range as specied in the specications

tables.

Power Switch (2)

For the FB150, the power switch is located on the power entry module of the unit at

the lower center of the power panel.

For the FB350 and FB660, the power switch is located between the RS-232 and the

circuit breakers.

Serial Connector (3)

On the FB150, the serial connector is a 9-pin subminiature D type located on the

power panel above the power entry module. On the FB350 and FB660, the serial

connector is a 9-pin subminiature D type located on the power panel to the left of the

power switch. The serial (RS-232) interface can be used to transmit measurements and

control the operation of the instrument.

Fuses

For the FB150, the fuses are located inside the power entry module of the unit (Figure

5 on opposite page).

If necessary, fuses must be replaced according to Specications (see Section 2.1,

Specications, on page 11.

Thermal Circuit Breakers (5)

For the FB350 and FB660, the thermal circuit breakers are separate from the power

connector (Figure 6 on opposite page). Circuit breakers can be reset by pressing the

button in the center of each circuit breaker.

Page 25

19

Quick Start

Parts and Controls

Figure 5 FB150 power panel

Figure 6 FB350 and FB660 power panel

Page 26

FBXXX Field Temperature Block

Parts and Controls

20

3.2.4 -R Option Panel (-R models only)

The -R (reference sensor) panel is the readout portion of the instrument and is only

available with -R models.

Figure 7 -R option panel

Reference Thermometer Connection (1)

The 6-pin Lemo smart connector on the front panel allows a reference probe to be attached to the instrument for use with the reference thermometer function of the instrument. The smart connector stores probe calibration coefcients. Using an adapter, the

6-pin Lemo will accept traditional connectors and the probe coefcients can be entered

into the readout or an appropriate characterization curve can be selected through the

user interface (see Section 1.5.2, Immunity Testing, on page 8 for information on using clamp-on ferrites).

A PRT is the only type of probe that is supported by the reference thermometer input.

The PRT (RTD or SPRT) probe connects to the reference thermometer input using a

6-pin Lemo connector. Figure 8 shows how a four-wire probe is wired to the 6-pin

Lemo connector. One pair of wires attaches to pins 1 and 2 and the other pair attaches

to pins 4 and 5 (pins 1 and 5 source current and pins 2 and 4 sense the potential). If

a shield wire is present, it should be connected to pin 3, which is also used for the

memory circuit. Pin 6 is only used for the memory circuit.

Page 27

21

Quick Start

Languages

Figure 8

5 4

2

1

Memory

3

6

Pin 1

Excitation

Current –

Pin 2

Sense –

Pin 3

Memory –

(GND)

Pin 4

Sense +

Pin 5

Current +

Pin 6

Memory +

Pre-assembled

inside connector

PRT

Probe connector wiring

A two-wire probe can also be used with the reference thermometer. It is connected

by attaching one wire to both pins 1 and 2 of the plug and the other wire to both pins

4 and 5. If a shield wire is present, it should be connected to pin 3. Accuracy may be

signicantly degraded using a two-wire connection because of lead resistance.

3.3 Languages

The display on Field Temperature Blocks can be set to different languages depending

on the conguration.

Page 28

FBXXX Field Temperature Block

Languages

22

European: English, French, Spanish, Italian, German

Russian: Russian, English

Asian: English, Chinese, Japanese

3.3.1 Language Selection

Select the language to be displayed by following the steps shown in Figure 9 on this

page.

Figure 9 Steps to language selection

3.3.2 Reset to English Language

If you are in a language and need a short cut exit, press F1 and F4 simultaneously to

reset the display to English.

To reset to your originally selected language after resetting to English, follow the steps

in Figure 9 on this page.

Note: The F1 and F4 English shortcut override is temporary. If you toggle the

power off, the instrument will return to the language selected in the DISPLAY

SETUP menu rather than coming up in English.

Page 29

23

Menu Structure

Temp Setup Menu

4 Menu Structure

4.1 Temp Setup Menu

Figure 10

FB150/ FB350/ FB660 MAIN MENU

F1 F2 F3 F4

TEMP SETUP PROG MENU SYSTEM MENU INPUT SETUP (-R ONLY)

F1 Setup

Scan Rate: <edit> Degrees per minute at which the Block increases or decreases temperature

Stability Limit: <edit> The defined minimum stability over a 2 minute period before alarm is activated

Stability Alarm: (ON/OFF) <select> Audible alarm indicating Block is stable

F2 View Cutout

Soft Cutout: <edit> User adjustable safety cutout

Hard Cutout: <View Only> Factory set safety cutout

Hot Keys (while viewing main screen)

SETPoinT- Set Point Key

Setpoint: <Edit> Set point temperature

ENTER – <Enable control of the unit>

F1 – SELECT PRESET <1-8> <select>

F1 – EDIT PRESETS <1-8> <edit>

F4 – SAVE/DISABLE System <disables control of instrument>

ºC / ºF Key - Units: <°C, °F> Changes temperature units

Up/ Down Arrow Keys <toggle> <adjust contrast>

Up Key: Darker

Down Key: Lighter

F1 & F4 Keys (Same Time)

< Reset to English Language >

F1 & F3 Keys (Same Time)

< Turn off key press beep >

Code Update Mode Keys

ENTER & EXIT Keys (hold during power up) <initiate code update mode> Allows instrument software to be updated

Main Menu - Temp SetUp

Page 30

FBXXX Field Temperature Block

Prog Menu

24

4.2 Prog Menu

Figure 11

FB150/ FB350/ FB660 MAIN MENU

F1 F2 F3 F4

TEMP SETUP PROG MENU SYSTEM MENU INPUT SETUP (-R ONLY)

F1 RUN PROGram

TEST STATUS: < OFF, RUN><select> Changes status of current test

RUN TEST: < RAMP/SOAK > Runs selected test

RECORD DATA: <YES/NO> <select> (-R Only) Records data for ramp/soak

TEST ID: (Text, 16 char, English ASCII only > (-R Only) Alpha-numeric identification for test

F2 Ramp & Soak

No. of SETPOINTS:<1-8><select>

SOAK TIME: <Minutes><edit> Length of time in minutes at which the Block remains at the set point temperature

Number of CYCLES: <1 – 99> <edit> Number of times the Block repeats the ramp/soak program

DIRECTION: < → ,( Down arrow)> <select>

PASS TOLERANCE: <edit> (-R only) Pass/Fail criteria for the ramp/soak program

F1 SET POINTS

SETPOINT 1: <edit> °C

SETPOINT 2: <edit> °C

SETPOINT 3: <edit> °C

SETPOINT 4: <edit> °C

SETPOINT 5: <edit> °C

SETPOINT 6: <edit> °C

SETPOINT 7: <edit> °C

SETPOINT 8: <edit> °C

F3 TEST RESULT (-R Only)

F1 VIEW TESTS

DISPLAY TEST: <1 - 16><Select> Displays test results

DATE: <view only>

TIME: <view only>

F2 PRINT TESTS

PRINT TEST: <NO, YES><select> Print all test data to to RS-232 port

F3 ERASE TESTS

Erase Tests: <No, Yes><select>, Erases all tests

Main Menu - Prog Menu

Page 31

25

Menu Structure

System Menu

4.3 System Menu

Figure 12

FB150/ FB350/ FB660 MAIN MENU

F1 F2 F3 F4

TEMP SETUP PROG MENU SYSTEM MENU INPUT SETUP (-R ONLY)

F1 System Setup

F1 DISPLAY SETUP

LANGUAGE: <English, Japanese, Chinese, German, Spanish, French, Russian, Italian> <Select>

DECIMAL: <PERIOD, COMMA><Select>

KEY AUDIO: <ON, OFF> <select>

F2 COMMunication SETUP

BAUD RATE: <1200, 2400, 4800, 9600, 19200, 38000>

LINEFEED: <ON, OFF> <Select>

F3 DATE TIME (-R Only)

TIME: <edit> (Military Time Only)

DATE (Adjust): <edit>

REPORT DATE: <(mm/dd/yyyy), (dd,mm,yyyy)><Select>

F2 PASSWORD

USER PASSWORD: <edit>

PROTECTION : <LOW, HIGH><select>

F3 CALIBration

F1 CALPOINTS

TEMPerature 1: <edit>

TEMPerature 2:

<edit>

TEMPerature 3:

<edit>

GRADient 1: <edit>

GRADient 2: <edit>

GRADient 3: <edit>

GRADient 4: <edit> (FB660 only)

GRADient 5: <edit> (FB660 only)

F2 CONTRoller

TEMPerature Proportional Band: <edit>

TEMPerature INTegration:

<edit>

TEMPerature DERivative:

<edit>

F3 CALibration REFerance

(-R only)

REF C0: <edit>

REF C100:

<edit>

IINPUT CALibration DATE:

<edit>

F4 SYSTEM INFO <View only>

MODEL: <View only>

SERIAL number: <View only>

Firm Ware VERsion: <View only>

CALibration DATE: <View only>

INPUT CALibration DATE: <View only> (-R only)

Main Menu - System Menu

Page 32

FBXXX Field Temperature Block

Input Setup (-R only)

26

4.4 Input Setup (-R only)

Figure 13

FB150/ FB350/ FB660 MAIN MENU 10

F1 F2 F3 F4

TEMP SETUP PROG MENU SYSTEM MENU INPUT SETUP (-R ONLY)

F1 REFerence INPUT

F1 PROGram PROBE

SERIAL number: <edit> <alpha-numeric>

INPUT CALibration DATE: <edit>

PROBE TYPE:

<ITS-90,CVD,IEC 60751,Resistance><select>

List:

ITS-90 CVD IEC 60751 Resistance

RTPW R0

A Alpha

B Beta

C Delta

A4

B4

PROGRAM probe <YES, NO> <password required to program probe>

F2 TEST reference CALibration

RESISTANCE: <edit> Ω

TEMPERATURE:

<Calculated value displayed> <view only> °C

Main Menu - Input Setup

Page 33

27

Controller operation

Main Screen

5 Controller operation

This chapter discusses in detail how to operate the Field Temperature Block temperature controller and/or thermometer readout using the front control panel. Using

the front panel keys and liquid crystal display (LCD) the user may monitor the well

temperature, set the temperature set-point in °C or °F, monitor the heater output

power, monitor the stability, set the cutout set-point, set the operating parameters, and

congure the communication interface. For the -R model, the user has full control of

thermometer readout functions of the instrument using the front panel keys and the

LCD. A diagram of the full menu structure can be found in Section 4, Menu Structure,

on page 23. When active, menu keys are selected using the soft keys (F1-F4).

5.1 Main Screen

The LCD on the front panel allows direct viewing of the control temperature (actual

well temperature), reference thermometer temperature (-R model only), heating or

cooling power, stability state, current set-point information, and current program information. The temperature displayed is either in °C or °F. The displayed temperature

units can easily be changed by pressing the C/F key on the front panel.

HEAT SOURCE TEMPERATURE

This is the temperature of the block as measured by the control sensor. The controller

heats or cools the block to force the control temperature equal to the set-point.

SET-POINT (SETPT)

This is the current set-point.

REFERENCE TEMPERATURE (REF) (-R model only)

This is the temperature measured by an external reference thermometer attached to the

Reference Thermometer 6-pin Smart Lemo input.

CONTROL - STAB (Stability)

This shows the stability of the block. When the stability is within the set limit this line

is at.

CONTROL - HEAT/COOL

This shows the relative heating or cooling power (duty cycle) in percent.

HEATING, COOLING, CUTOUT

This shows the status of heating or cooling or the cutout when activated. The bar graph

indicates the relative heating or cooling power.

Page 34

FBXXX Field Temperature Blocks

Main Menu

28

5.2 Main Menu

The MAIN MENU is accessed through the MENU button and allows access to all

main submenus. The submenus allow the user to setup the instrument as desired and to

change system parameters as needed.

5.2.1 Temp Setup

The TEMP SETUP menu contains Field Temperature Block functions related to temperature setup.

5.2.1.1 Setup

5.2.1.1.1 SCAN RATE

The SCAN RATE parameter can be set such that when the set-point is changed, the

Field Temperature Block heats or cools at a specied rate, degrees per minute, (°C/min

or °F/min) until it reaches the new set-point.

The Scan Rate can be set from 0.1 to 500 °C/min (0.2 to 900 °F/min). However, the

maximum scan rate is limited by the natural heating or cooling rate of the instrument,

which will be less than the maximum setting, especially when cooling.

The Scan Rate can be adjusted using the arrow keys. Once the scan rate has been set,

press “ENTER” to set the new scan rate.

5.2.1.1.2 STABLE LIMIT

NOTE: The Field Temperature Block should not be expected to operate better

than the stability specification set forth in the Specifications section of this

guide. Therefore, the minimum setting of the stability limit should not be less

than the stability specification.

The STABLE LIMIT parameter allows the instrument to notify the user when it has

achieved the stability limit set in this parameter. There are two notications: visual

and audible. The visual notication is always active. When the instrument is operating

within the stability limit, the stability graph on the main screen remains at once the

instrument is within the given specication, otherwise the graph indicates the instrument is not yet stable. The audible, if enabled, alerts the user once per set-point when

the instrument achieves the set stability limit. Use the arrow keys to set the desired

stability limit and press “ENTER” to accept the new stability limit.

Example:

A specic calibration process requires the instrument to operate within ±0.1°C. “0.1”

would be entered into the stability limit parameter. When the instrument’s stability is

within ±0.1°C, the graph is at and the audible alarm (if enabled) noties the user that

the instrument is operating within ±0.1°C. Use the arrow keys to set the desired stability limit and press “ENTER” to accept the new stability limit.

Page 35

29

Controller operation

Main Menu

5.2.1.1.3 STABLE ALARM

The audible alarm described in STABLE LIMIT is turned on or off using the STABLE

ALARM parameter. Select the either “Enable” or “Disable” using the left or right arrow keys and press “ENTER” to accept the selection.

5.2.1.2 CUTOUT

The view CUTOUT contains the Cutout functions of the instrument.

5.2.1.2.1 SOFT CUTOUT

The SOFT CUTOUT is user settable. As a protection against software or hardware

fault or user error, the block is equipped with the adjustable cutout device that shuts

off power to the heat source if the well temperature exceeds a set value. It is factory

set as a default ten degrees above the high limit of the instrument. The user should

set the Soft Cutout according to the temperature limits of the probes being calibrated.

The Soft Cutout can act as a safety barrier to protect probes from being over heated

to temperatures beyond their specied temperature limits if the Soft Cutout is set appropriately for probes under test. This feature protects the instrument and probes from

excessive temperatures.

If the cutout is activated because of excessive well temperature, power to the heat

source shuts off and the instrument cools. The heat source remains in cutout mode

and active heating and cooling is disabled until the user manually resets the cutout. If

the over-temperature cutout has been triggered, the instrument displays “CUTOUT”

above the duty cycle bar graph, which indicates a cutout condition. The instrument

remains in cutout mode until the temperature is reduced and the cutout is reset. The

well temperature must drop a few degrees below the cutout set-point before the cutout

can be reset.

For safety reasons, the cutout only has one mode — manual reset. Manual reset mode

means the cutout must be reset by the operator after the temperature falls below the

set-point.

The SOFT CUTOUT parameter can be set to any temperature over the range of the

instrument. The cutout should be set within 5-10° of the safety limit of the equipment

being calibrated or used with the Field Temperature Block.

NOTE: CUTOUT RESET: If the Field Temperature Block exceeds the

temperature set in the soft cutout menu or if it exceeds the maximum operating

temperature of the instrument, a cutout condition occurs. If this happens, the

instrument enters cutout mode and will not actively heat or cool until the user

resets the instrument.

To reset the cutout, the instrument temperature must cool to lower than the cutout setpoint. Once the instrument has cooled the user may reset the instrument by pressing

“SET PT.” and pressing “ENTER” to engage instrument.

Page 36

FBXXX Field Temperature Blocks

Main Menu

30

5.2.1.2.2 HARD CUTOUT

The HARD CUTOUT parameter is a view only function and indicates the factory setting for the hard cutout. The Hard Cutout is not user settable.

5.2.2 Prog Menu

The PROG MENU (PROGRAM MENU) allows access to the automated and manual

program selections.

5.2.2.1 RUN PROG

The RUN PROG (RUN PROGRAM) allows the user to access program status

features.

5.2.2.1.1 TEST STATUS

The TEST STATUS option controls the state of the program. The user selects to Run

the program or to turn the program Off.

5.2.2.1.2 RECORD DATA

The RECORD DATA option allows the user to select to record the data from the test

(Yes) or not to record data (No).

5.2.2.1.3 TEST ID

The TEST ID (Identication) allows the user to enter a Test ID number for the current

test. The Test ID can be an alpha numeric entry up to 16 characters in length.

5.2.2.2 RAMP/SOAK

The RAMP/SOAK feature automatically cycles the Field Temperature Block between

temperatures while holding at each temperature for the length of time set by the user.

5.2.2.2.1 NO. SETPOINTS

The NO. SETPOINTS is the number of set-points dened for a given program. The

number of set-points for each program can be set from 1 to 8 and vary depending on

the needs of the user. Set the maximum number of set-points needed for the program

selected. Once the number of set-points is selected, press “ENTER” to accept the new

setting.

5.2.2.2.2 SOAK TIME

The SOAK TIME parameter is the number of minutes that each of the program setpoints is maintained. The time starts when the temperature settles to within the specied stability. The stability limit is set in the TEMP SETUP|SETUP|STABLE LIMIT

window.

Page 37

31

Controller operation

Main Menu

5.2.2.2.3 NO. CYCLES

The NO. CYCLES parameter is the number of times that the program is repeated.

5.2.2.2.4 DIRECTION

The DIRECTION parameter controls whether the set-points are sequenced in one

direction, 1-8, or both directions, 1-8 and 8-1, before the sequence is repeated. If the

both directions option is selected, the program sequences from the rst set-point to the

last and then reverses direction sequencing from the last to the rst.

5.2.2.2.5 PASS TOLERANCE

The PASS TOLERANCE is the allowable tolerance condition for the test and is used

to highlight test points that have large errors.

5.2.2.2.6 SETPOINTS

The SETPOINTS menu allows the user to set each of the set-points for the program.

Only the number of set-points dened by NO SETPOINTS will be displayed. Setpoints can be quickly selected using the Up/Down arrow keys to scroll through the setpoints. Press “Enter” to activate the set-point and make it editable. Once editable, use

the Up/Down arrow keys to enter the values and the Left/Right arrow keys to scroll

through the digits in the value. Press “Enter” to accept the value entered.

5.2.2.2.6.1 SETPOINT 1 – SETPOINT 8 (Depending on NO. SETPOINTS defined)

The SETPOINT n parameter is the designated temperatures for the set-points selected

for the program.

5.2.2.3 TEST RESULTS

The TEST RESULTS MENU allows the user access to the tests parameters.

5.2.2.3.1 VIEW TESTS

The VIEW TESTS menu allows the user to view the results of up to 16 tests.

5.2.2.3.1.1 TEST ID

The TEST ID (TEST IDENTIFICATION) parameter allows the user to select from 16

tests to view.

5.2.2.3.1.2 TYPE

The TYPE parameter allows the user to select between viewing Ramp & Soak results.

5.2.2.3.1.3 DATE (VIEW ONLY)

The DATE the selected test was performed.

Page 38

FBXXX Field Temperature Blocks

Main Menu

32

5.2.2.3.1.4 TIME (VIEW ONLY)

The TIME the selected test was performed.

5.2.2.3.1.5 RESULTS (press ENTER)

The RESULTS menu is the second part of the VIEW TESTS menu and allows the user

to view the results of the selected test.

5.2.2.3.1.5.1 RAMP & SOAK

5.2.2.3.1.5.1.1 TEST ID

The TEST ID (TEST IDENTIFICATION) parameter allows the user to select from 16

tests to view.

5.2.2.3.1.5.1.2 WELL

The WELL (WELL TEMPERATURE) result provides the temperature of the dry-well

as measured by the control sensor.

5.2.2.3.1.5.1.3 REF

The REF (REFERENCE) result provides the temperature of the reference probe.

5.2.2.3.2 PRINT TESTS

The PRINT TESTS parameter allows the user to the option to print the selected test

results. YES enables the print option. NO disables the print option.

5.2.2.3.3 ERASE TESTS

The ERASE TESTS option is unconditionally password protected. The user has the

choice, YES/NO, to erase all of the stored tests. A warning is presented to the user

stating that all tests will be erased.

5.2.3 System Menu

The System Menu allows the user to set up the display settings, communications protocol, date/time settings (-R model only), password settings, calibrations settings, and

view system information.

5.2.3.1 SYSTEM SETUP

The SYSTEM SETUP menu contains the Display Setup, Communications Setup, and

Date/Time Setup (-R model only).

Page 39

33

Controller operation

Main Menu

5.2.3.1.1 DISPLY SETUP

The DISPLY SETUP (DISPLAY SETUP) parameter contains the language selection,

decimal separator, and keypad sound parameters.

5.2.3.1.1.1 LANGUAGE

The LANGUAGE parameter is used to set the display language. Use the right or left

arrow key to select the preferred language and press “ENTER” to accept the selection.

The user needs to exit from the SYSTEM MENU window in order for the change in

language selection to take affect.

NOTE: If the wrong language is selected, return to the Main Screen by holding

EXIT for a few seconds. Once the Main Screen is displayed, simultaneously

press and hold F1 and F4 to set to English temporarily. Then return to the

DISPLAY SETUP screen and set the correct language.

5.2.3.1.1.2 DECIMAL

The DECIMAL parameter is used to determine the decimal separator, a comma or a

period. Select the desired decimal separator using the right or left arrow key and press

“ENTER” to accept the selection.

5.2.3.1.1.3 KEY AUDIO

The KEY AUDIO parameter (F1 and F3 Keys pressed simultaneously) enables or

disables the key press beep.

5.2.3.1.2 COMM SETUP

The COMM SETUP (COMMUNICATIONS SETUP) menu contains the serial interface parameters. The parameters in the menu are—BAUD RATE and LINEFEED.

5.2.3.1.2.1 BAUD RATE

The BAUD RATE parameter determines the serial communication transmission rate or

baud rate.

BAUD may be programmed to 1200, 2400, 4800, 9600, 19200, or 38400 baud.

5.2.3.1.2.2 LINEFEED

The LINEFEED enables (On) or disables (Off) transmission of a line feed character

(LF, ASCII 10) after transmission of any carriage-return. The LINEFEED default setting is on. The line feed parameter can be turned on or off as needed by the user.

Page 40

FBXXX Field Temperature Blocks

Main Menu

34

5.2.3.1.3 DATE TIME (-R model only)

The DATE TIME menu allows the user to set the format for the date and time. Additionally, the user sets the date and time for the date and time stamp function.

5.2.3.1.3.1 TIME

The TIME parameter allows the user to set the internal time for the instrument. The

time is tracked using a 24-hour clock. To set the time, press “Enter” and use the arrow

keys to set the time and press “Enter” to accept the selection.

5.2.3.1.3.2 DATE

The DATE parameter allows the user to enter the date for the date/time stamp function. Press “Enter” to access the parameter. Use the arrow keys to enter the date and

press “Enter” to accept the selection.

5.2.3.1.3.3 REPORT DATES

The REPORT DATES parameter allows the user to select the date format. Use the

left and right arrow keys to choose the date format, mm/dd/yyyy or dd/mm/yyyy, and

press “Enter” to accept the selection.

5.2.3.2 PASSWORD

The PASSWORD (PASSWORD SETUP) menu is used to set the system password or

set the level of protection that conditional engages or disengages protection of certain

groups of parameters.

5.2.3.2.1 USER PASSWORD

The USER PASSWORD parameter allows the users to enter and change the system

and conditional password used to access protected menus. The Password is a number

between one and four digits. Each digit of the password can be a number from 0 to

9. The default System Password is “1234”. If desired, the System Password can be

changed in this menu by using the numeric keys to enter the new password and pressing “ENTER”.

5.2.3.2.2 PROTECTION

The PROTECTION parameter is used to enable (HIGH) or disable (LOW) password

protection for the conditional parameters. The password is the same as the system

password. The user has to option to conditionally password protect the Soft Cutout,

Ramp & Soak, and Probe Prog. The user selects to “HIGH” or “LOW” the conditional password using the left and right arrow keys and presses “Enter” to accept the

selection.

Page 41

35

Controller operation

Main Menu

5.2.3.3 CALIB

CAUTION: Calibration parameters must be correct for the instrument to

function properly.

The CALIB (CALIBRATION) menu allows the user access to the calibration parameters for the instrument. Access to the heat source and readout calibration parameters

is protected by a password. Calibration parameters are programmed at the factory

when the instrument is calibrated. These parameters may be adjusted to improve the

accuracy of the instrument by qualied personnel.

CAUTION: DO NOT change the values of the control parameters from the

factory set values unless you are recalibrating the instrument. The correct

setting of these parameters is important to the safe and proper operation of the

block.

The parameters in the CALIB menu are set at the factory and must not be altered unless recalibrating the instrument. Recalibration of the instrument should be performed

by trained, knowledgeable personnel. The correct values are important to the accuracy

and proper and safe operation of the block. Access to these parameters is protected by

a password. In the event that the calibration parameters need to be reentered into the

instrument, these constants and their settings are listed in the Report of Calibration

shipped with the instrument.

5.2.3.3.1 CAL POINTS

The CAL POINTS (CALIBRATION POINTS SETUP) menu contains the heat source

calibration constants, TEMP CALPT 1, TEMP CALPT 2, and TEMP CALTPT 3. Use

the arrow keys to enter the set-point for each calibration point and press “Enter” to

accept the entry. The calibration points should be selected applicable to model with a

low, mid-range, and high set-point.

5.2.3.3.1.1 TEMP 1

The TEMP 1 parameter is the offset in °C for the heat source accuracy at the 1st calibration point.

5.2.3.3.1.2 TEMP 2

The TEMP 2 parameter is the offset in °C for the heat source accuracy at the 2nd

calibration point.

5.2.3.3.1.3 TEMP 3

The TEMP 3 parameter is the offset in °C for the heat source accuracy at the 3rd calibration point.

Page 42

FBXXX Field Temperature Blocks

Main Menu

36

5.2.3.3.1.4 GRAD 1

The GRAD 1 parameter is ratio for the top zone heater control for the axial gradient

calibration at the 1st calibration point.

5.2.3.3.1.5 GRAD 2

The GRAD 2 parameter is ratio for the top zone heater control for the axial gradient

calibration at the 2nd calibration point.

5.2.3.3.1.6 GRAD 3

The GRAD 3 parameter is ratio for the top zone heater control for the axial gradient

calibration at the 3rd calibration point.

5.2.3.3.1.7 GRAD 4 (FB660 only)

The GRAD 4 parameter is a ratio for the top zone heater control for the axial gradient

calibration at the fourth calibration point.

5.2.3.3.1.8 GRAD 5 (FB660 only)

The GRAD 5 parameter is a ratio for the top sone heater control for the axial gradient

calibration at the fth calibration point.

5.2.3.3.1.9 CALDATE

The CALDATE parameter is the calibration date for the heat source. Use the arrow

keys to enter the calibration date in the format selected in DATE FORMAT.

5.2.3.3.2 CONTRL

The CONTRL (CONTROL SETUP) menu is used to access the controller parameters.

5.2.3.3.3 TEMP PB

The TEMP PB parameter is the main zone proportional band and the gain in °C that

the instrument’s proportional-integral-derivative (PID) controller uses for main zone

control.

5.2.3.3.3.1 TEMP INT

The TEMP INT parameter is the main zone integral, which is the integration time in

seconds that the instrument’s PID controller uses for main zone control.

5.2.3.3.3.2 TEMP DER

The TEMP DER parameter is the main zone derivative, which is the derivative time in

seconds that the instrument’s PID controller uses for main zone control.

Page 43

37

Controller operation

Main Menu

5.2.3.3.4 CAL REF (-R model only)

The CAL REF (REFERENCE INPUT CALIBRATION) menu is used to access the

reference PRT calibration parameters. Use these parameters to adjust the measurement

at 0 and 100Ω.

5.2.3.3.4.1 REF1C0

The REF1C0 parameter is the rst calibration point for the reference resistance.

5.2.3.3.4.2 REF1C100

The REF1C100 parameter is the second calibration point for the reference resistance.

5.2.3.3.4.3 INPUT CAL DATE

The INPUT CAL DATE parameter is the calibration date for the readout. Use the arrow keys to enter the calibration date in the format selected in DATE FORMAT.

5.2.3.4 SYSTEM INFO (view only)

The SYSTEM INFO (SYSTEM INFORMATION) menu displays manufacturer information regarding the instrument.

5.2.3.4.1 MODEL

The MODEL parameter displays the model number of the instrument.

5.2.3.4.2 SERIAL

The SERIAL (SERIAL NUMBER) parameter displays the serial number of the

instrument.

5.2.3.4.3 FW VER

The FW VER (FIRMWARE VERSION0 parameter displays the rmware version

used in the instrument.

5.2.3.4.4 CAL DATE

The CAL DATE (CALIBRATION DATE) parameter displays the calibration date of

the heat source.

5.2.3.4.5 INPUT CAL DATE (-R model only)

The INPUT CAL DATE (-R CALIBRATION DATE) parameter displays the calibration date for the readout or the -R module.

Page 44

FBXXX Field Temperature Blocks

Main Menu

38

5.2.4 INPUT SETUP (-R model only)

The INPUT SETUP menu allows all the parameters related to the -R module or

readout function of the instrument to be accessed. The parameters found in this menu

affect the performance, accuracy and display type of the reference PRTs.

5.2.4.1 REF INPUT

The REF INPUT (REFERENCE INPUT) menu contains the parameters for the

reference input to the readout module of the instrument. The Reference Input is only

compatible with PRTs with ITS-90, Callendar Van-Dusen, or IEC-60751 coefcients.

Additionally, the Reference Input will read straight resistance.

The probe serial number and coefcients can be found on the calibration certicate

that was shipped with the probe. If the probe requires calibration, contact an Authorized Service Center to inquire about calibration services.

5.2.4.1.1 PROG PROBE

The PROG PROBE (REFERENCE PROBE SETUP) menu is used to setup the reference probe parameters.

5.2.4.1.1.1 SERIAL

The SERIAL (SERIAL NUMBER) parameter allows the user to enter ten digit alpha

numeric serial number for the reference probe. Character range = {0-9, A-Z, ‘-‘,

<Blank>}. Minimum required is 1 character.

When a blank space is entered, any characters after the blank are dropped. For example, change S/N 1234-5678 to S/N TEST1. Enter TEST1<Blank Space>678. The

serial number will drop the last three characters and enter the S/N TEST1.

5.2.4.1.1.2 CAL DATE

The CAL DATE parameter is used to enter the calibration date for the reference

probe. Use the arrow keys to enter the calibration date in the format selected in DATE

FORMAT.

5.2.4.1.1.3 PROBE TYPE

The PROBE TYPE parameter is used to choose which probe conversion type to be

setup. Use the left and right arrow keys to select the conversion type and press “Enter”

to accept selection.

5.2.4.1.1.3.1 TYPE (ITS-90)

The TYPE parameter can be ITS-90, Callendar Van-Dusen (CVD), IEC-60751, or

Resistance. The ITS-90 option is for PRTs calibrated and characterized using the International Temperature Scale of 1990 (ITS-90) equations. Subranges 4, and 7 through 11

are supported. The parameters that appear when ITS-90 is selected are “Serial” (Serial

Number), “Cal Date”, “RTPW”, “COEF A”, “COEF B”, “COEF C”, “COEF A4”,

Page 45

39

Controller operation

Main Menu

and “COEF B4”. These should be set with the corresponding values that appear on

the calibration certicate of the PRT. The parameter “RTPW” takes the triple point of

water resistance, often labeled “R0.01” or “R(273.16K)” on the certicate. Parameters

“COEF A”, “COEF B”, “COEF C” take the an, bn and cn coefcients where n is a

number from 7 to 11. Parameters “COEF A4” and “COEF B4” take the a4 and b4 coefcients on the certicate. Any ITS-90 parameter of the instrument that does not have a

corresponding coefcient on the PRT’s certicate must be set to 0.

The following table (Table ) shows which parameter to set for each of the coefcients

that may appear on the certicate. The example that follows demonstrates how to set

the ITS-90 parameters for certain cases.

Table 4 Matching Certificate Values to ITS-90 Coefficients

ITS-90 Coefficient Certicate Value

COEF A a7, a8, a9, a10, or a11

COEF B b7, b8, b9, or 0

COEF C c7 or 0

COEF A4 a4

COEF B4 b4

NOTE: If the certificate has two sets of coefficients, one set for “zero-power”

calibration and one set for 1 mA calibration, use the coefficients for the 1 mA

calibration.

Example 1:

A PRT was calibrated to ITS-90 and its calibration certicate states values for coefcients Rtpw, a4, b4, a8, and b8. Set the instrument’s parameters with values from the

certicate as follows.

Table 5 Setting Coefficients Rtpw, a8, b8, and b4

Coefficient Certicate Value

RTPW Rtpw

COEF A a8

COEF B b8

COEF C 0

COEF A4 a4

COEF B4 b4

5.2.4.1.1.3.1.1 PROG PROBE

The PROG PROBE parameter is used to tell the instrument to program a Smart Lemo

with the appropriate probe coefcients. Use the arrow keys to select “Yes” or “No”.

If “Yes” is selected, the Smart Lemo will be programmed with the appropriate coefcients for the selected conversion type. For ITS-90 and CVD, the coefcient values

need to entered before programming the Smart Lemo. For IEC-60751 and Resistance,

no values are required to program the Smart Lemo.

Page 46

FBXXX Field Temperature Blocks

Main Menu

40

5.2.4.1.1.3.2 TYPE (CVD)

The CVD (Callendar-Van Dusen) conversion is for RTD probes that use the CallendarVan Dusen equation:

The parameters that appear when CVD is selected are “Serial” (Serial Number),

“Cal Date”, “R0”, “ALPHA”, “DELTA” and “BETA”, which can be set by the user.

For IEC-751, DIN-43760 or ASTM E1137 sensors, the coefcients for R0, ALPHA,

DELTA, and BETA are 100.0, 0.00385055, 1.4998, and 0.1086 respectively.

Some probes may be provided with A, B, and C coefcients for the Callendar-Van

Dusen equation in the following form:

The A, B, and C coefcients can be converted to Alpha, Beta and Delta coefcients

using the following equation:

5.2.4.1.1.3.2.1 PROG PROBE

The PROG PROBE parameter is used to tell the instrument to program a Smart Lemo

with the appropriate probe coefcients. Use the arrow keys to select “Yes” or “No”.

If “Yes” is selected, the Smart Lemo will be programmed with the appropriate coefcients for the selected conversion type. For ITS-90 and CVD the coefcient values

need to entered before programming the Smart Lemo. For IEC-60751 and Resistance,

no values are required to program the Smart Lemo.

5.2.4.1.1.3.3 TYPE (IEC-60751)

The IEC-60751 conversion is for RTD probes that use the International Electrotechnical Commission (IEC) Standard Publication 751.

Page 47

41

Controller operation

Main Menu

5.2.4.1.1.3.3.1 PROG PROBE

The PROG PROBE parameter is used to tell the instrument to program a Smart Lemo

with the appropriate probe coefcients. Use the arrow keys to select “Yes” or “No”.

If “Yes” is selected, the Smart Lemo will be programmed with the appropriate coefcients for the selected conversion type. For ITS-90 and CVD the coefcient values

need to entered before programming the Smart Lemo. For IEC-60751 and Resistance,

no values are required to program the Smart Lemo.

5.2.4.1.1.3.4 TYPE (RESISTANCE)

The RESISTANCE option displays the resistance, in ohms, of the selected reference

probe. This temporarily overrides the temperatue conversion. The temperature conversion type can be restored without losing coefcients.

5.2.4.1.2 TEST CALC

The TEST CALC (TEST REFerance CALCULATION) allows the technician to test

the output of a specic conversion algorithm. Simply select the conversion type and

enter a value for the requested parameter. Press ENTER, the algorithm computes the

answer, and it is displayed immediately in the parentheses at the bottom of the screen,

TEMPERATURE: XX.XXX.

Page 48

Page 49

43

Digital communication interface

Wiring

6 Digital communication interface

The Field Temperature Block is capable of communicating with and being controlled

by other equipment through the RS-232 digital interface.

With a digital interface the instrument may be connected to a computer or other equipment. This allows the user to input the set-point temperature, monitor the temperature,

communicate with the readout to obtain measurement data, control operating conditions and access any of the other controller functions, all using remote communications equipment. The RS-232 serial interface allows serial digital communications

over fairly long distances. With the serial interface, the user may access any of the

functions, parameters and settings discussed in this section.

6.1 Wiring

The serial communications cable attaches to the instrument through the DB-9 connector at the front of the instrument. Figure 14 on next page, shows the pin-out of this

connector and suggested cable wiring. To eliminate noise, the serial cable should be

shielded with low resistance between the connector (DB9) and the shield.

6.1.1 Setup

Before operation the serial interface must rst be set up by programming the BAUD

rate and other conguration parameters. These parameters are programmed within

the communications menu. The serial interface parameters can be accessed from the

main menu by MENU|SYSTEM MENU|SYSTEM SETUP|COMM SETUP|. For more

information on the serial interface parameters, see Section 5.2.3.1.2COMM SETUP on

page 33.

6.1.2 Serial Operation

The serial communications uses 8 data bits, one stop bit, and no parity. The setpoint and other commands may be sent via the serial interface to set the temperature

set-point and view or program the various parameters. The interface commands are

discussed in the “Digital Interface” section.

Page 50

FBXXX Field Temperature Block

Command Syntax

44

Figure 14 RS-232 wiring

6.2 Command Syntax

Field Temperature Blocks accept commands for setting parameters, executing functions or responding with requested data. These commands are in the form of strings of

ASCII-encoded characters. As far as possible, the Field Temperature Block command

syntax conforms to SCPI-1994. One notable exception is that compound commands

are not allowed as explained below.

Commands consist of a command header and, if necessary, parameter data. All commands must be terminated with either a carriage return (ASCII 0D hex or 13 decimal)

or new line character (ASCII 0A hex or 10 decimal).